8

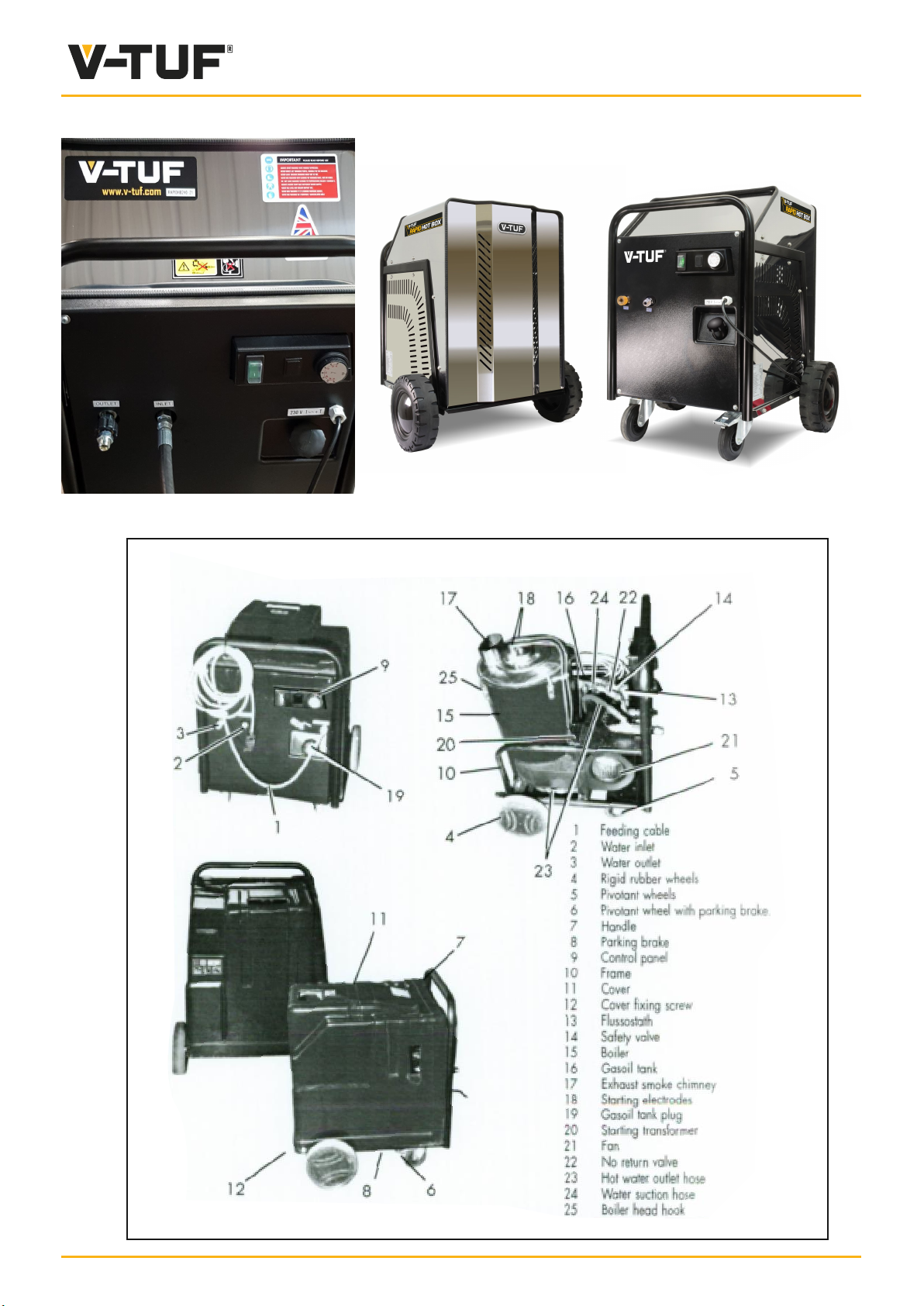

INSTALLATION

OPERATORS IN CHARGE

The machine installation will be carry out only by skilled technicians with the care and

responsibility of the user.

Connect the suction hose to the inlet coupling.

Connect the outlet hose to the outlet coupling.

Connect the other end of the suction hose to

the water tap.

Check that the electric plug has all the required

characteristics and the proper differential protection

than, connect if into the electrical socket.

NOTE: if is possible, do not use electrical extensions.

WARNING: the electrical feeding network must be equipped with an high sensibility

differential switch with an interference thresold id equal to 30 mA.

The machine must be earthed at a contact voltage resistant value not over 25 V.

The machine must be installed so that the pipings connot be damaged by people or things.

The machine should be placed out of passage ways and in order to avoid mechanical stress

and damages.

CHECKS BEFORE USE

Before the use, check that all the parts was fitted up

and that the installation was checked by skilled personnel.

Check that are gasoil in the apposite tank,

if not, fill up.

Turn on the water lap.

Check that the thermostat is in "O” °C position.

Start the machine acting on the apposite (ON/OFF) burner switch and wait for 30 sec. to

obtain the filling of the gasoil pump, act on the thermostat knob and put the temperature

selector at 90° C for almost 30 sec. than, select tha water working temperature acting on

the same knob.

When the request temperature is reached, the burner automatically stop and start again

every time the temperature reachees.

At the end of the work, put the thermostat knob at ("0") 0° C position and wait for the

water to be cold.

Act on the (ON/OFF) burner switch to stop the machine then, close the water tap.

H O outlet

2H O inlet

2

Burner ON/OFF switch

Thermostat knob

USE