1Turn off the power at the main switch and open the door of the control cabinet. The door can not

be opened unless the main switch is turned off.

2Turn on thepower in the cabinet by turning the white shaft of the main switch clockwise. There

will now be electric current in components of the cabinet, so avoid contact with any live

components.

3The Altivar 31 has four buttons and a screen. It should now be rdY thescreen. There is an up and a

down button on the left side and esc and ent touch button on the screen.

4Press (Ent) once and "Set" appears on the screen.

5Press (Ent) againand "ACC"(acceleration)will appear on the screen.

6Press (Ent) againand a value will be displayed on the screen. The ACC value is set to 3.0at the

factory. This value indicates the timein seconds for the main the drive to go from 0 to full speed. A

higher ACC value (longer time period to go from 0 to full speed) will make it easier to have fine

speed adjustments.

7 Use the up / down arrowsto adjust to the desired ACC setting. The Factorysetting @ 3.0,

corresponds to 2.4 Hz per press of the remote control.

Increasing to 6.0s reduces every remote button press to1.2Hz steps.

The Altivar 31 cango from 0 to full speed of 50 Hz

8Press (Ent) to save the new value.

9Press (Esc) to return to the"ACC"

10th Press down arrowto scroll to "dEC" (deccelerate)this time setting the timeto go from full

speed to stop.

11th Press enter and the value of dEC will appear on the screen.

12th Adjust to thedesired value. The value of ACC and dEC need not be equal. Ifdesired, one can

have fine adjustemt on the ACC to allow a slower rate of acceparation speed up while a coarse

adjustment on reducing speed.

13th Press (Ent) to save.

14th Press (Esc) button repeatedly until 'rdY "on screen

15th Test thenew setting and adjust if necessary (Section 4-14)

16th When theadjustment is complete the power is turned off by turning the white shaft of themain

switch counterclockwise.

17th The door of the cabinet is closed.

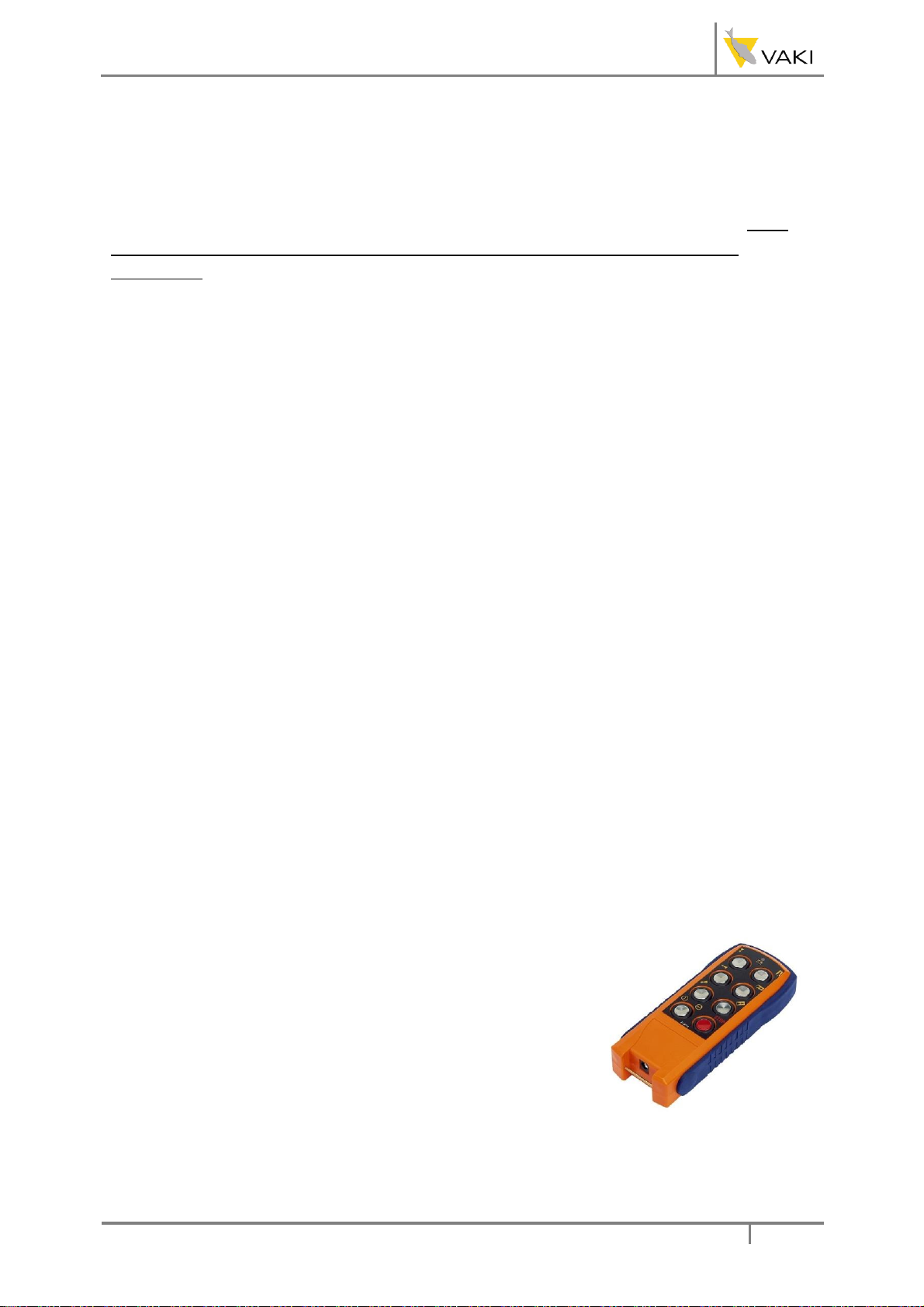

3.7 Remote Control

Wireless remotecontrol is optional and highly recommended. With

this you can start and stop the priming pump and the main pump,

and control the speed of the main pump. (see page10 of the

manual)

Inside the control cabinet there is an antennae for wireless

connection tothe handheld remote unit.

The remote must be rechargedwith thebatterycharger supplied.