Route the gas supply line to the appliance inlet

connectionpoint (seefigure

2).

Note: Pressure testing the line for leaks may need to

be performed before the line

is

connected to the

appliance

-

see section

12.

Gas

connectionto the appliance is 318"NPT.

Use only new black iron or steel pipes or copper

tubing

if

acceptable

-

check local codes.

Note that in

USA

copper tubing must be internally tinned for

protection against suRur compounds.

Unions ingas linesshould'be

of

groundjoint type.

The gas supply line must be sized and installed to

provide a supply of gas sufficient to meet the

maximum demand of the appliance without undue

loss of pressure.

Sealants used must be resistant to the action of all

gas constituents including LP gas. Sealants should

be applied lightly to male threads to ensure excess

sealant does notenter gas lines.

The supply line should include a manual shut-off

valve to allow the appliance to be disconnected for

servicing.

A

plugged 1/8mNPTtapping must be installed in the

line. The tapping must be accessible for test gauge

connectionand be immediately upstream of the gas

supplyconnectiontothe appliance.

9.1

Detach the pedestal front panel by removing two

screws.

9.2

Place the pedestal in position (see figure 10). The

bottomrear of the pedestalmust be at least

Ha

from

the back wall to allow room for the stove top

overhang.

9.3

Markthe floor with the floor fixing positionsthrough

the holesinthe pedestal(seefigure 10).

9.4

Remwe the pedestal. Drill the floor at the marked

positionsandfit plugs

if

necessary.

9.5

For easier fixing, fit the two woodscrews supplied

into the floor partially leaving a space between the

screw heads and the floor. The pedestal has two

'keyhole' openings in its battomchannels. Place the

pedestalback in positionby dropping it to locatethe

screws in the wide holes of the keyholes and then

sliding the pedestalbackto locate the screws in the

narrowslots of the keyholes.Tightenthe screws.

9.6

Fitthe inletelbowtothe supply pipe.

Note:

If

the optlone1clrculatlngfan klt Is Intended to

t#

Instolkd,

It

wlll

be

easlest to

fit

It

at

thls stage

9.7

Place the main appliance unit over the pedestal,

align the

4

fixing holes

(2

at each side) and secure

the unittothe pedestalwith

4

machine screws.

10.1

If

using any optional vent extension kits

#905VEK.

cut tothe requiredsizes

-

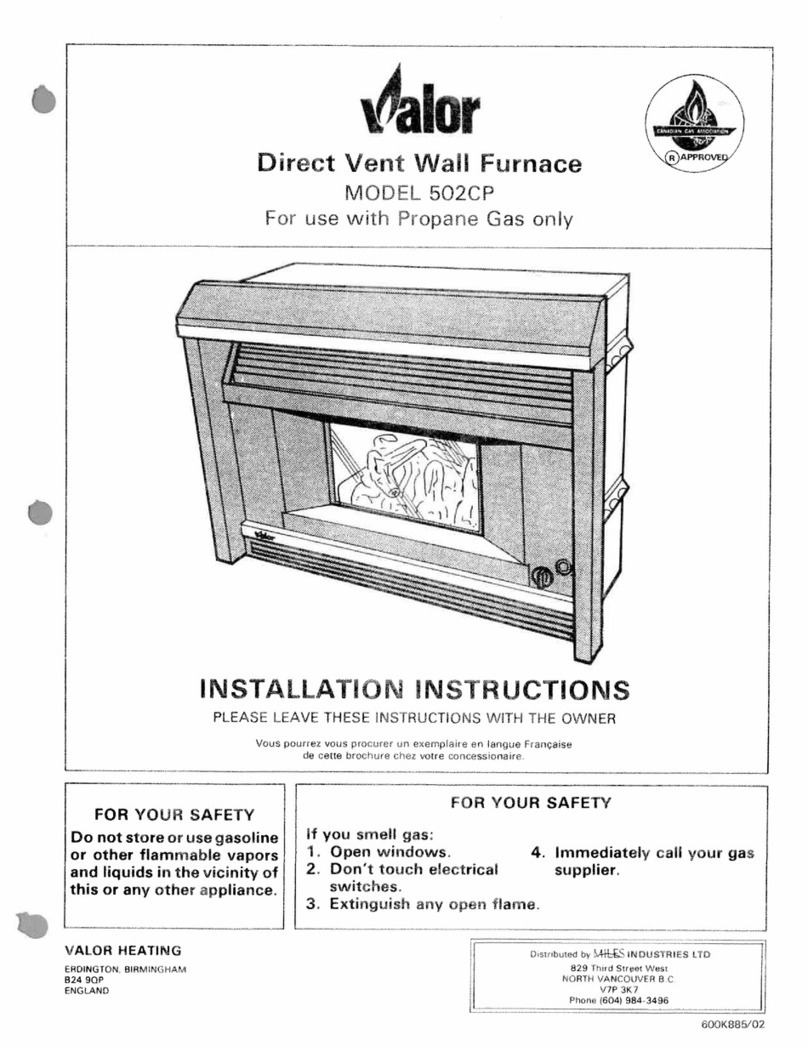

see venting graphfigure 1.

10.2

Identify the appliance top decorative collar. The

collars have identificationlabels. Remwe the label.

Placethe collarwer the vertical sectionof the elbow

or vertical extension. Locate the elbow unit or

vertical extensionfully overthe appliance vent ducts.

10.3

If

any vertical extensionunits are installed, locatethe

elbow unitfully werthe top

of

the extension.

10.4

Rotatethe elbow until

it

is in direct line with the wall

opening.

10.5

lf'ahorkontalextensionis required, loosely

fit

a joint

masking collar (supplied with the kit) over the

extension.

Fit

the extension fully to the end of the

elbow.

If

necessary, temporarilysupport

it.

10.6

Loosely

fit

the joint maskingcollar (suppliedwith the

appliance vent unit) wer the free end of the

horizontal length of the vent. Loosely fit the

decorative wall collar over the horizontal length of

the vent with the central dished area projecting into

the room.

10.7

Measure the distance from the elbow or horizontal

extension to the wall allowing for the amount of

overlap where the elbow or extension enters the

terminal unit (figure

11

dimension 'Am).

10.8

Calculate the total length of terminal required. This

length is:- Elbow or extension to wall (figure 11

dimension "A")

+

Wall thickness (figure 11

dimension

'B")

+

35/e"

(terminal length outside wall).

T~I.nqthmA+B+34L"

Flg.11

Vent termlnal

length