Before you start building your new microphone please carefully read this

building instructions.

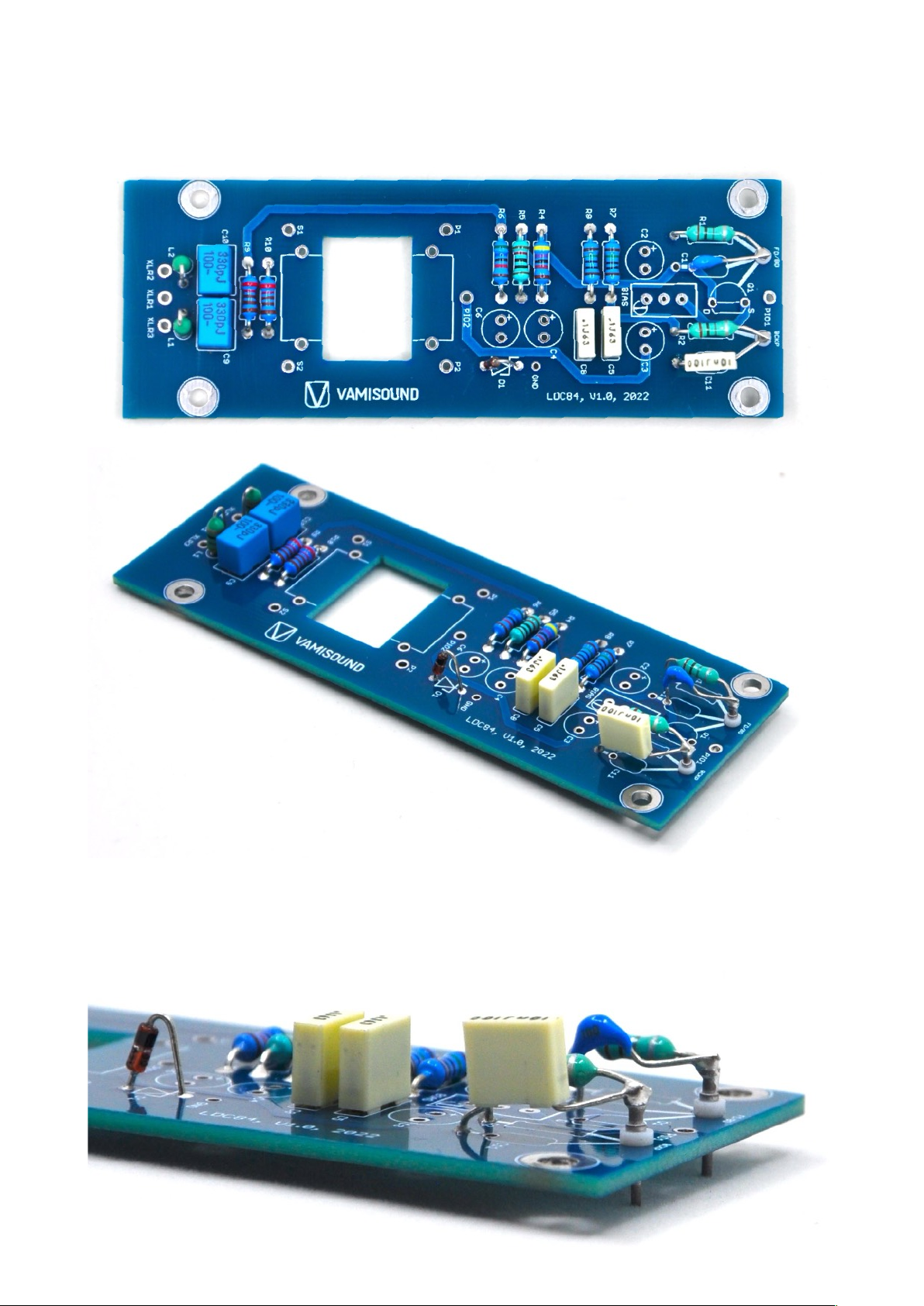

Attention: VAMISOUND LDC84 is a medium-heavy project. The circuit is made

up of only a few components. However, it should be borne in mind that certain

manual skills will be required or the successful completion of the mic

construction. Good soldering experience and soldering stations with fine

soldering tip are recommended. If you do not have this, please delegate the

construction to a more experienced technician with proper equipment. We

are not responsible for malfunctioning construction or injuries associated

with improper assembly of our kits.