Vacon 100 Flow page2

Index

Index........................................................................................................................... 2

Preface ........................................................................................................................ 3

1 Safety ....................................................................................................................... 4

2 Wiring and display...................................................................................................... 6

2.1 Cable diameter and fuses..................................................................................................... 6

2.2 Shielded cables ................................................................................................................... 6

2.3 Control keys........................................................................................................................ 7

2.4 Operation of the display....................................................................................................... 8

2.4.1 Icons ........................................................................................................................... 8

3.1 Scrolling through parameters ............................................................................................... 9

3.2 Viewing and modifying a parameter ..................................................................................... 9

3.3 Monitoring Menu ............................................................................................................... 10

3.3.1 Change multimonitor menu ......................................................................................... 10

3.3.2 Trend Curve ............................................................................................................... 10

3.4 Vacon 100 Wizard. ............................................................................................................ 11

3.5 Startup Wizard. ................................................................................................................. 11

3.6 Quick setup parameter group............................................................................................. 12

3.7 Parameter group setting .................................................................................................... 13

3.8 The distribution of DI (digital inputs).................................................................................. 14

3.8.1 Functions for DI ......................................................................................................... 15

3.9 Favourites folder ............................................................................................................... 17

3.9.1 Saving parameters in the favourites folder ................................................................... 17

3.9.2 Removing parameters from the favourites folder .......................................................... 17

3.10 Cooling fan control .......................................................................................................... 17

3.11 Default page display ........................................................................................................ 18

3.12 Saving and loading parameter setting + factory setting ..................................................... 18

3.13 Parameter lock ................................................................................................................ 18

3.14 Faults and alarms ............................................................................................................ 19

3.14.1 Errors ...................................................................................................................... 19

3.15 Monitoring values ............................................................................................................ 20

4 Vacon Live................................................................................................................21

5 Commissioning the drive............................................................................................22

6 Applications ..............................................................................................................24

6.1 Application defaults ........................................................................................................... 24

6.2 Start Application via Wizard ............................................................................................... 24

6.2.1 Default Application (Wizard)........................................................................................ 25

6.2.1.1 Application example: 0 - 10 V tracking control (using Default Wizard 6.2.1) ............ 26

6.2.1.2 Application example: 4 to 20 mA tracking control (using Default Wizard 6.2.1)........ 27

6.2.1.3 Application example: Up-down control (using Default Wizard 6.2.1)........................ 28

6.2.2 PID-Control Application (Wizard) ................................................................................. 29

6.2.2.1 Application example: PID control (using PID control Wizard 6.2.2).......................... 30

6.2.2.2 Terminals ............................................................................................................ 32

7 Pressurised Water Systems ........................................................................................33

7.1 Pressurised water system wiring plan (PID) ........................................................................ 33

7.2 Setting up pressurised water systems ................................................................................. 34

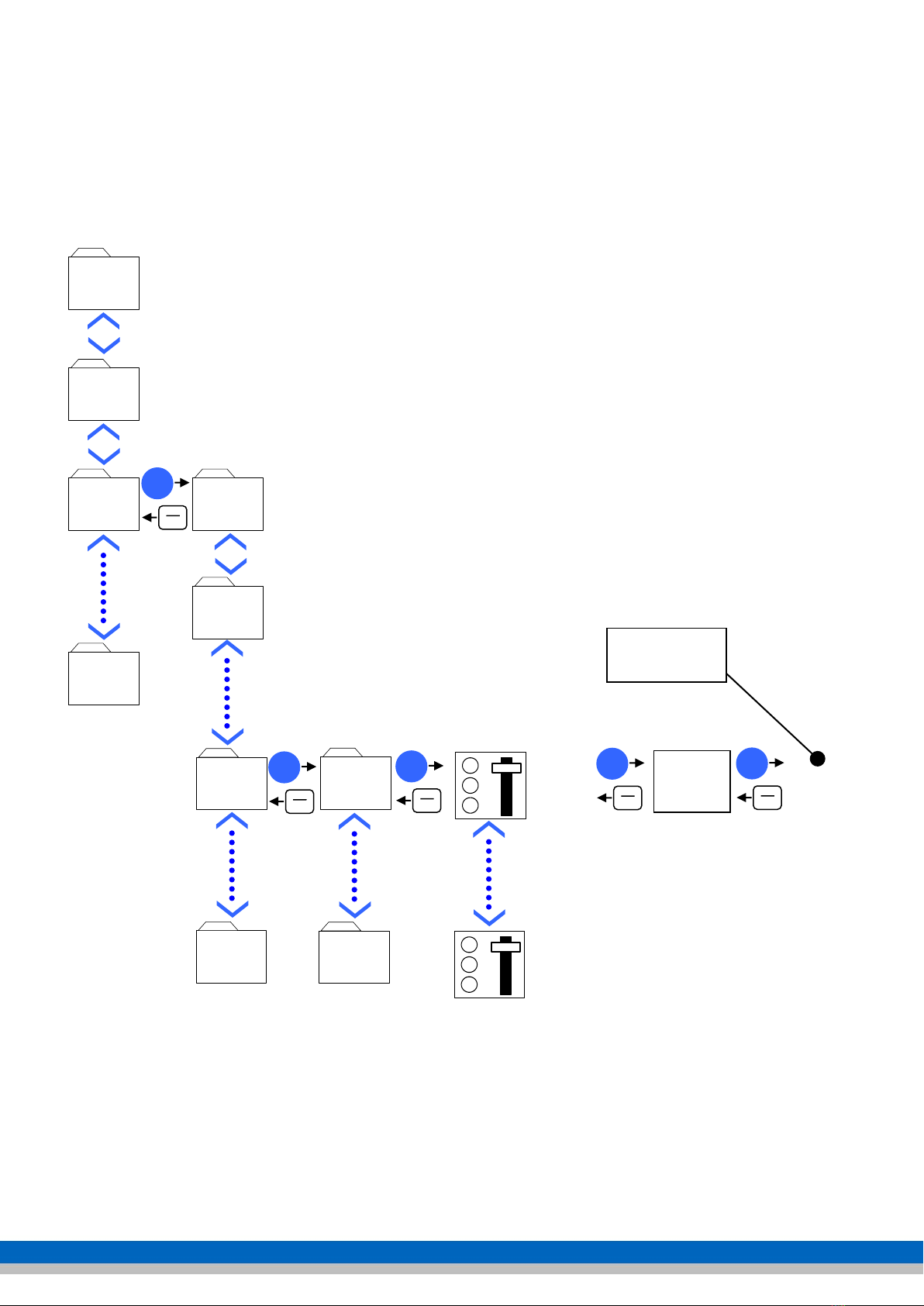

8 Multi-Pump ...............................................................................................................35

8.1 Multi-Pump Single Drive/Multi-Drive ................................................................................... 35

8.2 Multi-pump Multi-drive application (Wizard) ........................................................................ 36

8.2.1 Application example: Multi-pump Multi-drive (Via Multi-pump Wizard 8.2)...................... 37

Notes..........................................................................................................................39