VN-200 User Manual UM004

www.vectornav.com 3/47

4.1 Numeric Formats.......................................................................................19

4.2 Single Precision Floating Points .................................................................19

4.3 Fixed-Point Numbers .................................................................................19

4.4 System Commands ....................................................................................20

4.4.1 Read Register Command......................................................................................... 20

4.4.2 Write Register Command ....................................................................................... 20

4.4.3 Write Settings Command........................................................................................ 21

4.4.4 Restore Factory Settings Command ....................................................................... 21

4.4.5 Reset Command...................................................................................................... 22

4.5 System Error Codes ...................................................................................23

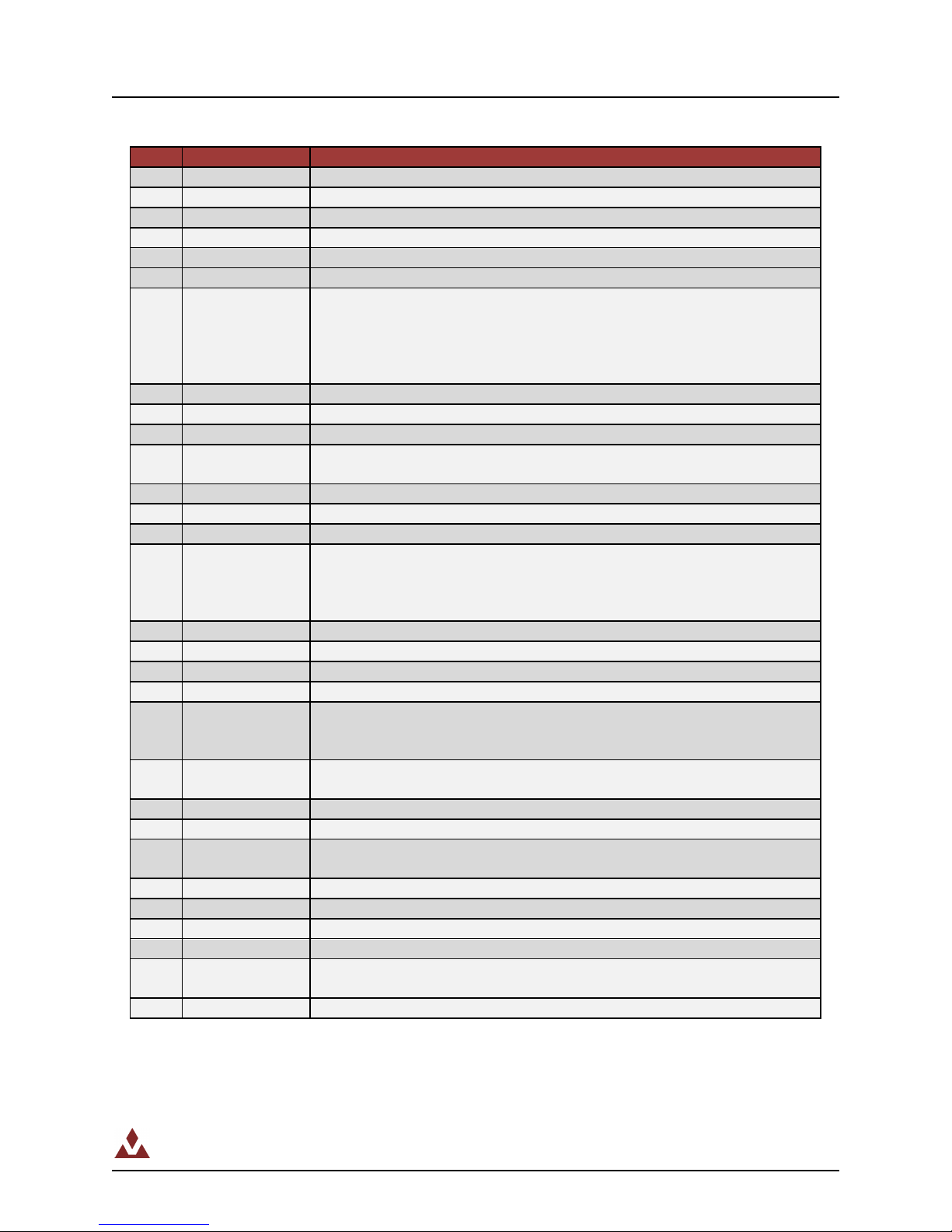

5System Registers ......................................................................... 24

5.1 User Tag Register.......................................................................................25

5.2 Model Number Register ............................................................................26

5.3 Hardware Revision Register.......................................................................27

5.4 Serial Number Register..............................................................................28

5.5 Firmware Version Register ........................................................................29

5.6 Serial Baud Rate Register...........................................................................30

5.7 Async Data Output Type Register..............................................................31

5.8 Async Data Output Frequency Register.....................................................32

5.9 Magnetic and Gravity Reference Vectors ..................................................33

5.10 Reference Frame Rotation .....................................................................34

5.11 Communication Protocol Control...........................................................35

5.11.1 SerialCount.............................................................................................................. 35

5.11.2 SerialStatus ............................................................................................................. 36

5.11.3 SPICount.................................................................................................................. 36

5.11.4 SPIStatus ................................................................................................................. 36

5.11.5 SerialChecksum....................................................................................................... 37

5.11.6 SPIChecksum ........................................................................................................... 37

5.11.7 ErrorMode............................................................................................................... 37

5.12 Synchronization Control .........................................................................38