1. Overview...........................................................................4

2. Technical Index.................................................................5

2.1 Model Description....................................................5

2.2 Certification..............................................................5

2.3 Model.......................................................................5

2.4 Electrical Index.........................................................5

2.5 Mechanical Index.....................................................6

2.6 Ambient Condition....................................................6

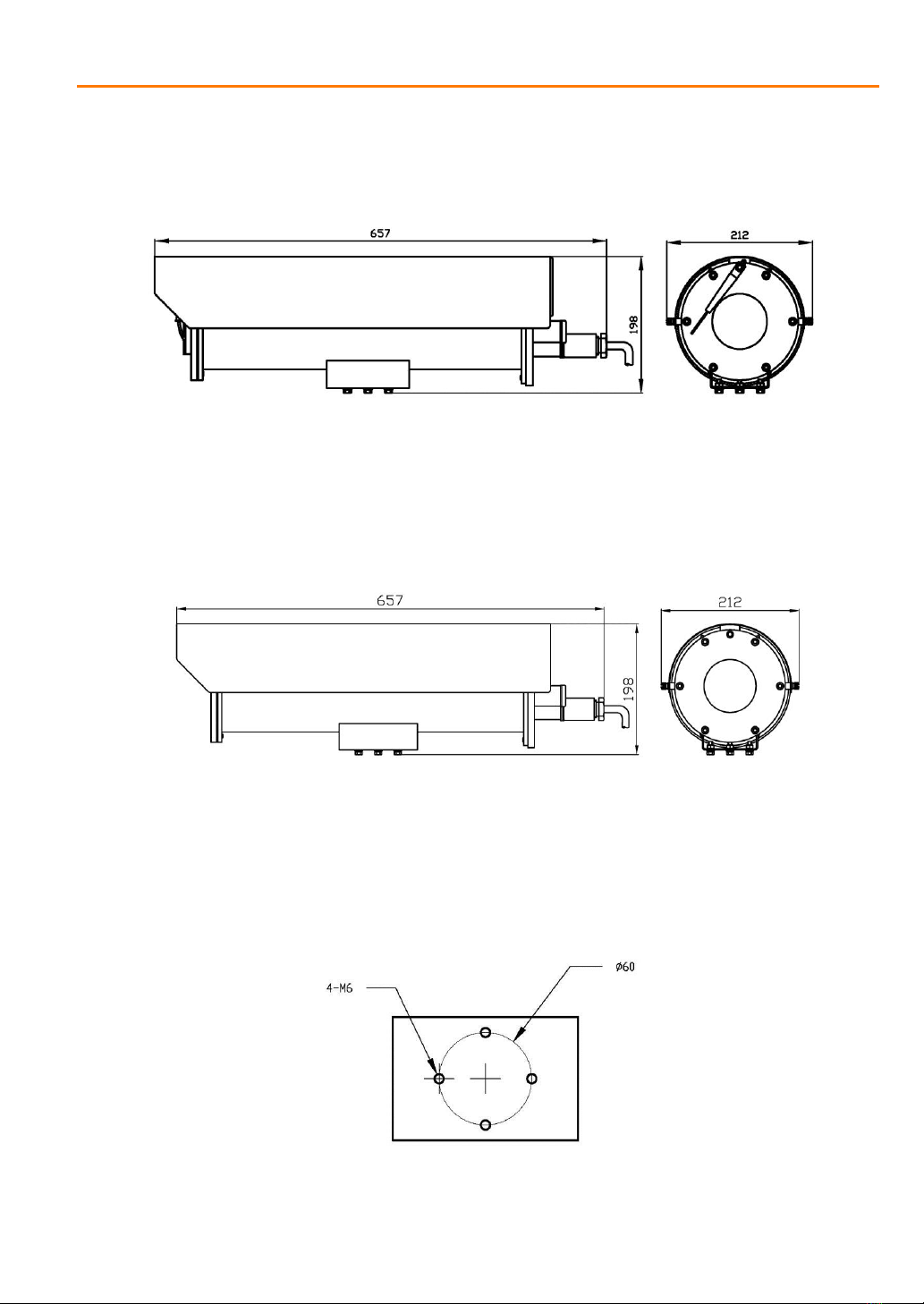

2.7 Product Dimension...................................................6

2.8 Installation Dimension..............................................7

3. Installation.........................................................................8

3.1 Installation of Camera and Lens ..............................8

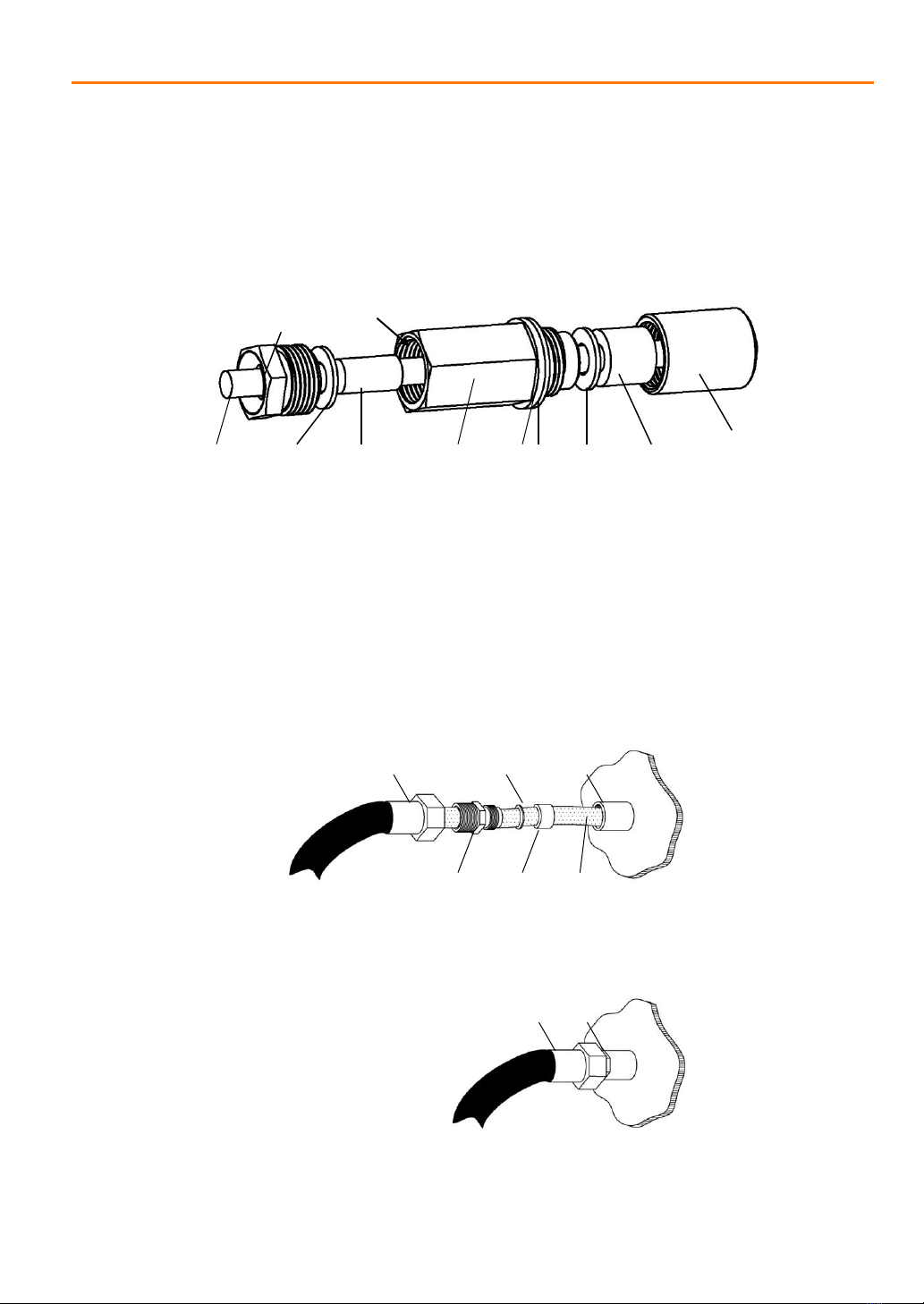

3.2 Cable Treatment......................................................9

3.2.1 Cable Treatment at Delivery.........................................9

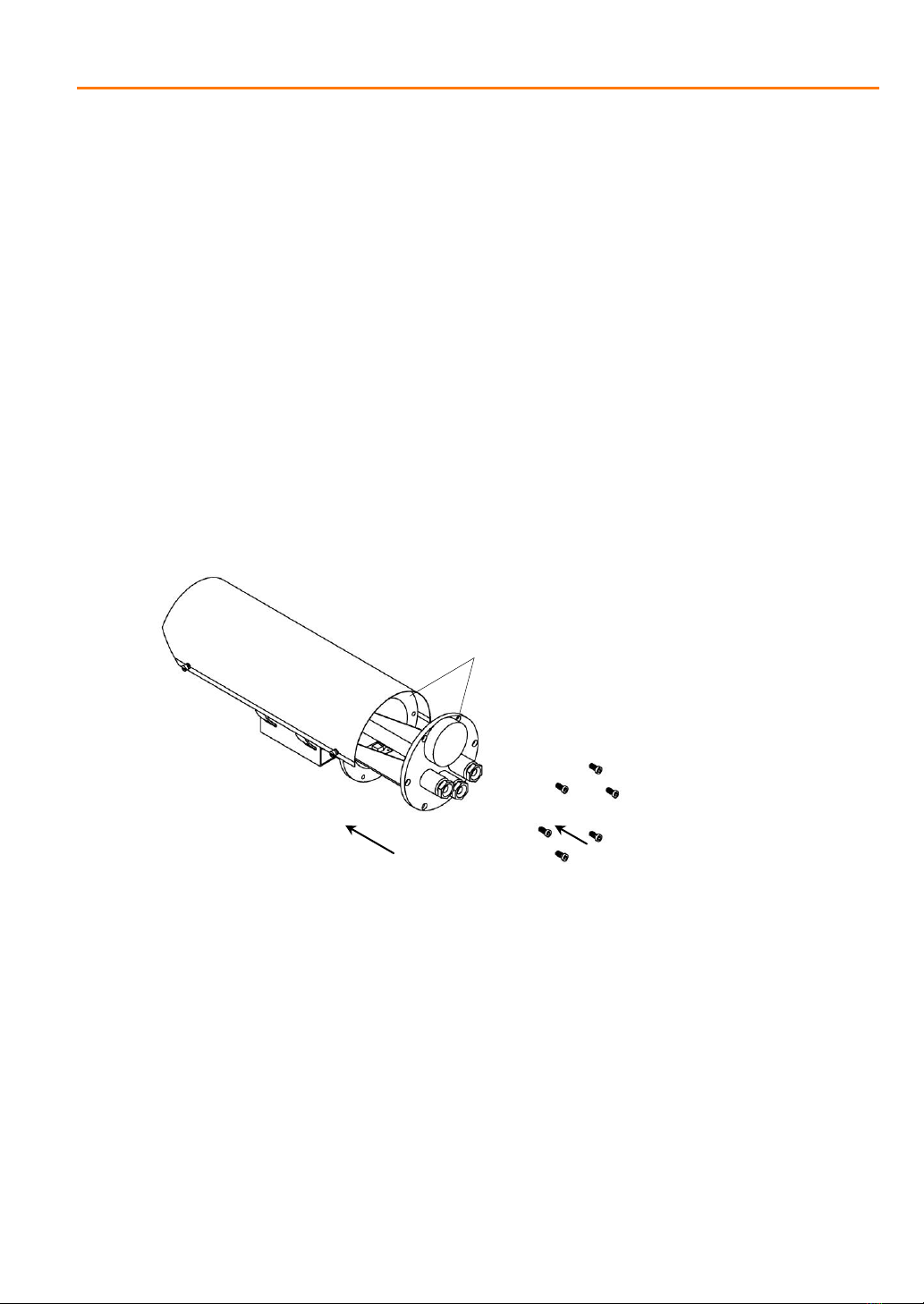

3.3 Installation of Housing Barrel.................................10

3.4Installation of Housing onto Electric Pan-tilt...........11

3.5Installation of Housing onto Fixed Support.............11

3.6Installation Precautions..........................................12

4.Description of Explosion-proof Structure.........................13

5.Troubleshooting ..............................................................13

6.Transportation and Storage ............................................14

7.Installation Accessories...................................................14

8.Quality Assurance...........................................................15

9.Declaration......................................................................15

Appendix I: Lens Adjustment ..............................................15

Appendix II: Use of Desiccant.............................................16

Appendix III: Content Reference Table of Toxic and

Hazardous Substances or Elements...................................17

SVEX-T500A Explosion Proof Camera User Manual.

Content