4) Special Conditions for Safe Use

Special Condition for safe Use as stated on the Type Examination

Certificate DEMKO 14 ATEX 4786493904X / CoC IECEx ULD

14.0004X:

End user shall adhere to the manufacturer’s installation and

instruction when performing housekeeping to avoid the potential

for hazardous electrostatic charger during cleaning, by using a damp

cloth.

The D2xC1 is not to be mounted with the horn facing upwards

The equipment shall only be used in end use with appropriately

certified cable entry devices and blanking plugs

4.1 Installation

The product must only be installed by suitably qualified personnel in

accordance with the latest issues of the relevant standards.

The installation of the units must also be in accordance with any

local codes that may apply and should only be carried out by a

competent electrical engineer who has the necessary training.

The equipment is not to be mounted with the horn facing upwards.

The equipment has not been assessed as a safety-related device (as

referred to by Directive 94/9/EC Annex II, clause 1.5).

The cable entry temperature may exceed +70ºC / the cable

branching point may exceed 80ºC. Therefore suitable heat resisting

cables and cable glands must be used, with a rated service

temperature of at least 90ºC

To maintain the ingress protection rating and mode of protection,

the M20 x 1.5 cable entries must be fitted with suitably rated,

certified cable glands and/or suitably rated, certified blanking

devices during installation. If a high IP (Ingress Protection) rating is

required, then a suitable sealing washer must be fitted under the

cable gland. For use in explosive gas atmospheres a minimum

ingress protection rating of IP54 must be maintained. For use in

explosive dust atmospheres a minimum ingress protection rating of

IP64 must be maintained.

Only the front cover is to be used for access to the enclosure for

installation, service and maintenance. Once the product is opened,

the Type Rating cannot be maintained anymore unless a full

verification of the gasket material is done and there is no damage.

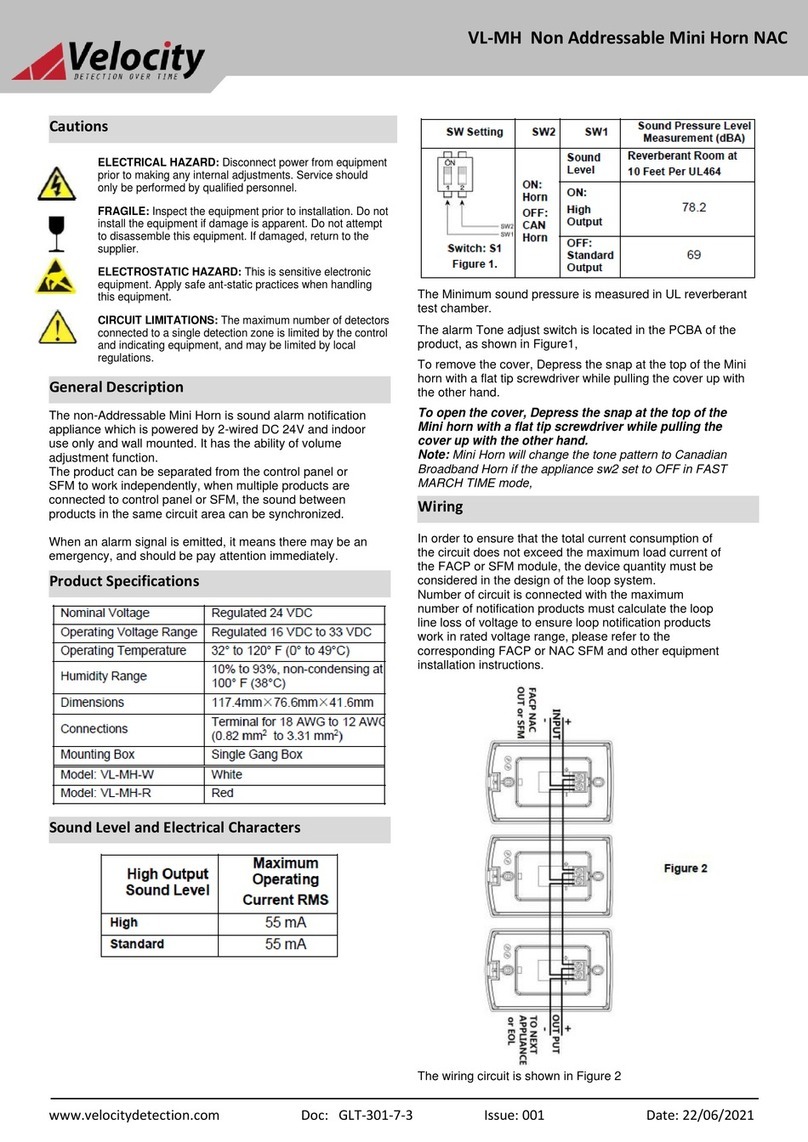

Connections are to be made into the terminal blocks using solid or

stranded wire, sizes 0.5-2.5mm2 / AWG 20-14. Wire insulation

needs to be stripped 6-7mm. Wires may be fitted securely with

crimped ferrules. Terminal screws need to be tightened down with a

tightening torque of 0.56 Nm / 5 Lb-in.

Internal earthing connections should be made to the internal earth

terminal on the PCBA. The earth conductor should be at least equal

in size and rating to the incoming power conductors. The internal

earth bonding wire connects the PCBA earth terminal to the internal

earth terminal in the enclosure back box.

External earthing connections should be made to the M5 earth stud,

using a ring crimp terminal to secure the earth conductor to the

earth stud. The external earth conductor should be at least 4mm2 /

AWG 11 in size.

Check that the earth bonding wire between the two castings is

secure and the ‘O’ ring seal is in place and in good condition.

4.2 Maintenance, Overhaul and Repair

Maintenance, repair and overhaul of the equipment should only be

carried out by suitably qualified personnel in accordance with the

current relevant standards:

EN60079-19 / IEC60079-19 Explosive atmospheres - Equipment

repair, overhaul and reclamation

EN 60079-17/ IEC60079-17 Explosive atmospheres - Electrical

installations inspection and maintenance

Units must not be opened while an explosive atmosphere is present.

If opening the unit during maintenance operations a clean

environment must be maintained and any dust layer removed prior

to opening the unit.

Electrostatic charging hazard - Clean only with a damp cloth

D2xC1 Alarm Horn and Strobe should only be installed by trained

competent personnel.

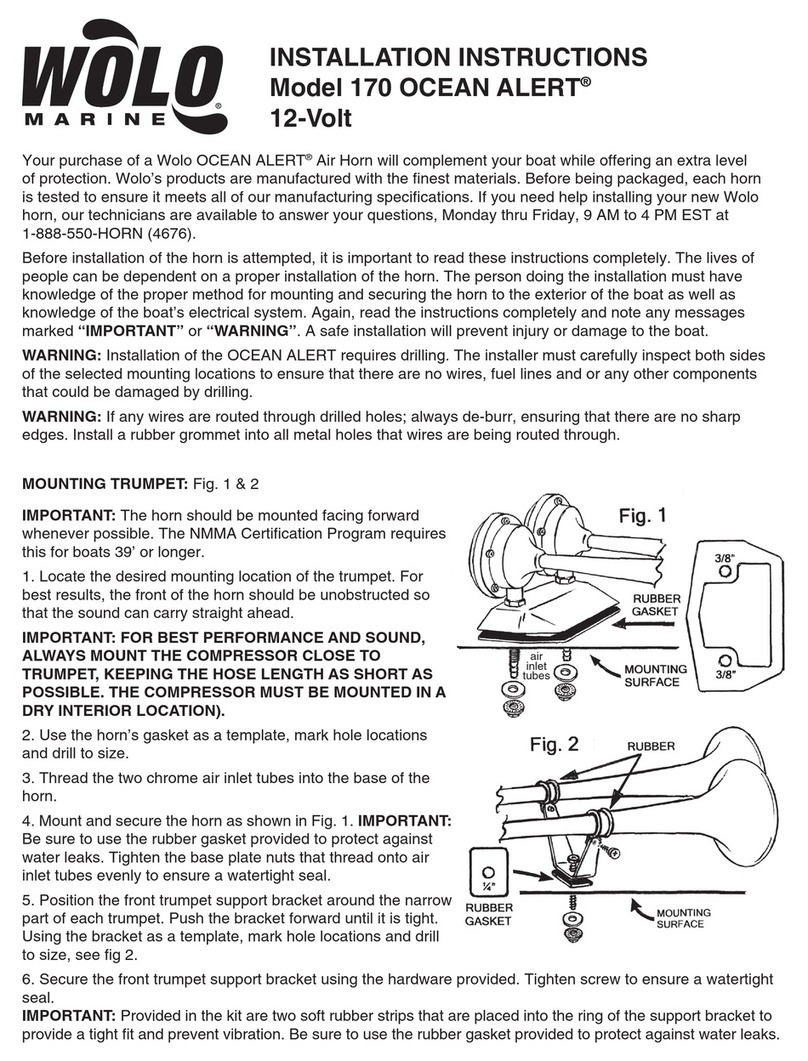

5.1 Mounting

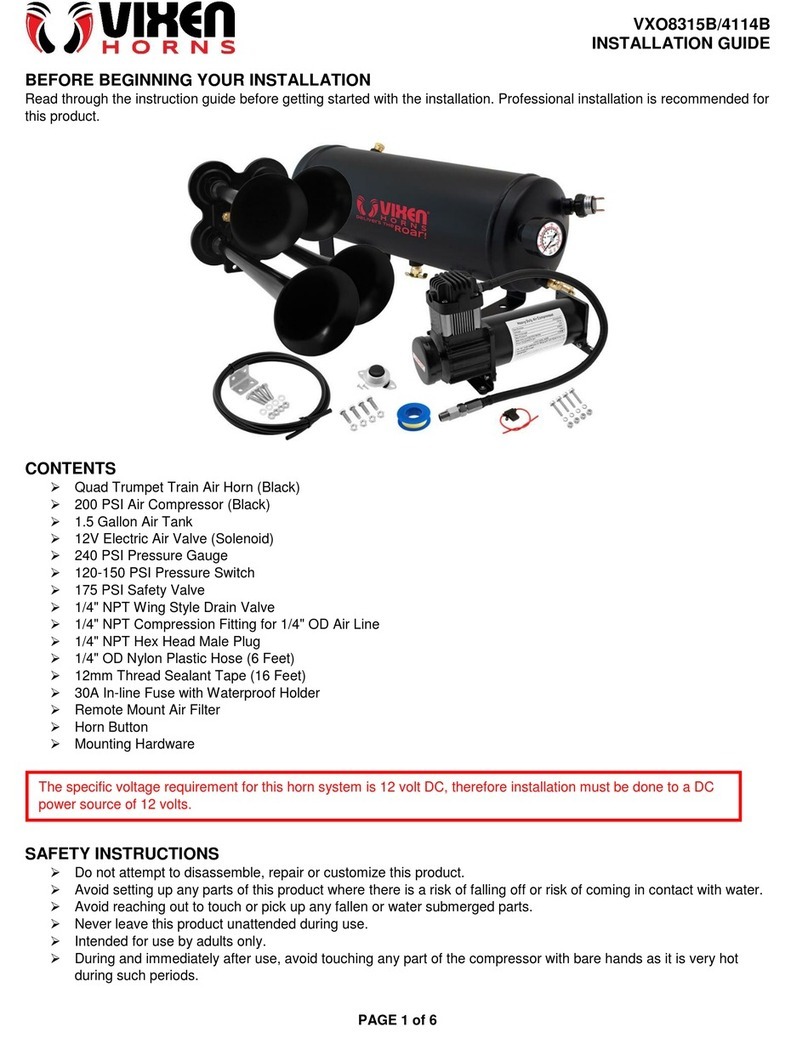

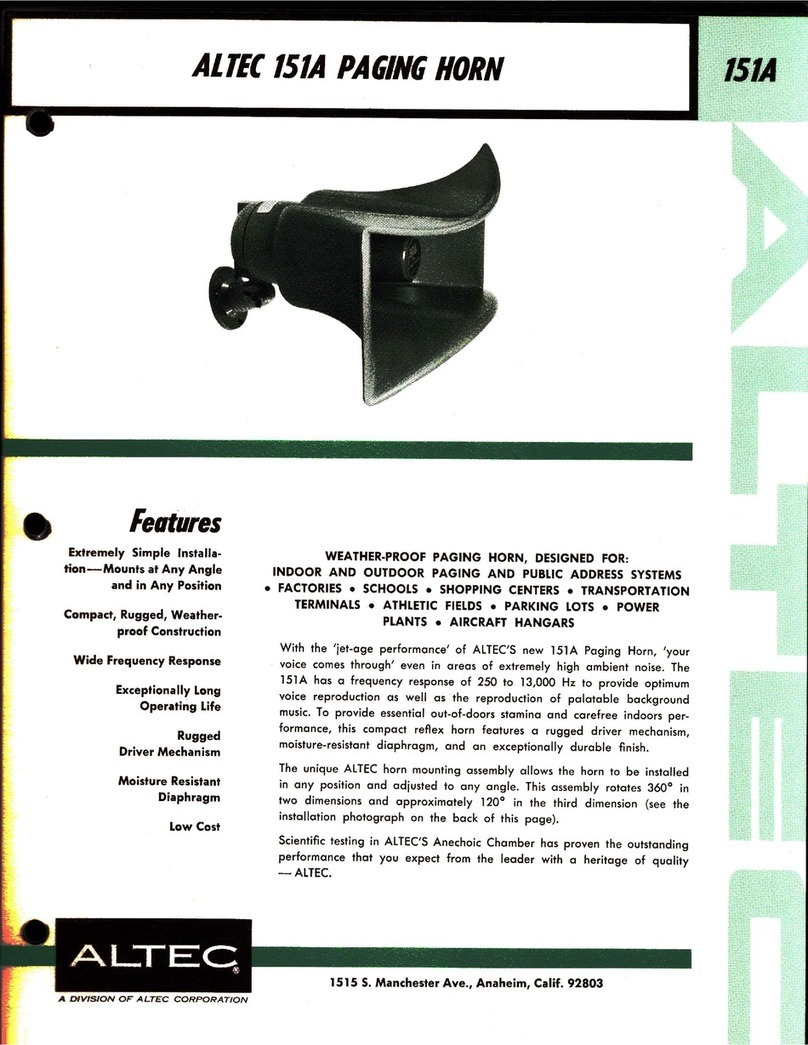

The D2xC1 Alarm Horn and Strobe may be secured to any flat

surface using the two 9.7 x 6.7mm, 147mm pitch fixing holes. The

enclosure provides IP66 protection and is suitable for installation in

exterior locations providing it is positioned so that water cannot

collect in the horn, and the cable entry is sealed.

5.2 Installation procedure

a) Secure the D2xC1 Alarm Horn and Strobe to a flat surface

via the two 9.7 x 6.7mm, 147mm pitch fixing holes in the

mounting feet.

b) Remove the front of the unit by unscrewing the four

captive cover screws and pulling the front away from the

enclosure.

c) Fit an M20x1.5 suitably rated, certified cable gland or

conduit entry into the hole in the enclosure and connect