SDKIT17-230/734STD

Installation and Operation Manual

Go to Table of Contents PG 3/30 REV: BETA (4/13/2020)

Table of Contents

1. LIST OF FIGURES .................................................................................................................................................5

2. How to Use this Manual .....................................................................................................................................6

2.1. Interactive Manual using Adobe Reader....................................................................................................6

2.2. Your Kit SKU Number and this Manual.......................................................................................................6

2.3. Illustration/Photo Details and Orientation.................................................................................................6

3. Safety First..........................................................................................................................................................7

4. Application Chart................................................................................................................................................8

4.1. Bolt-On Vehicle List ....................................................................................................................................8

4.2. **Excluded Vehicles ...................................................................................................................................8

4.3. Aftermarket Product Compatibility............................................................................................................8

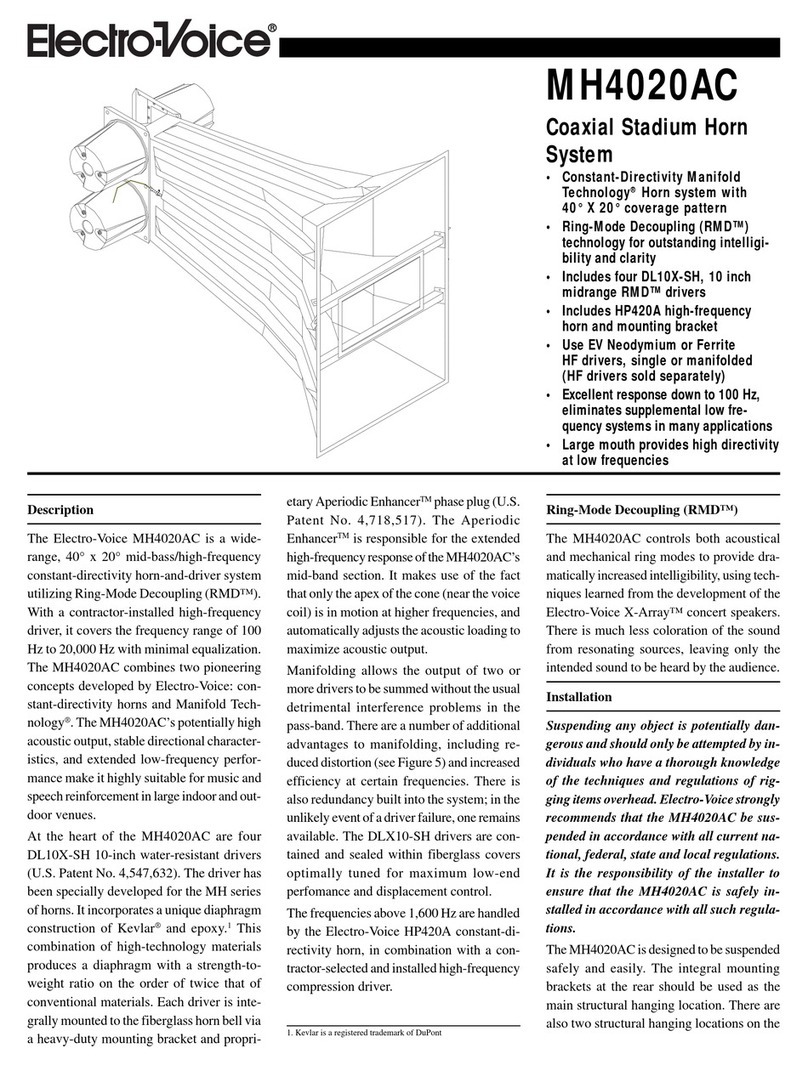

5. Installation Overview..........................................................................................................................................9

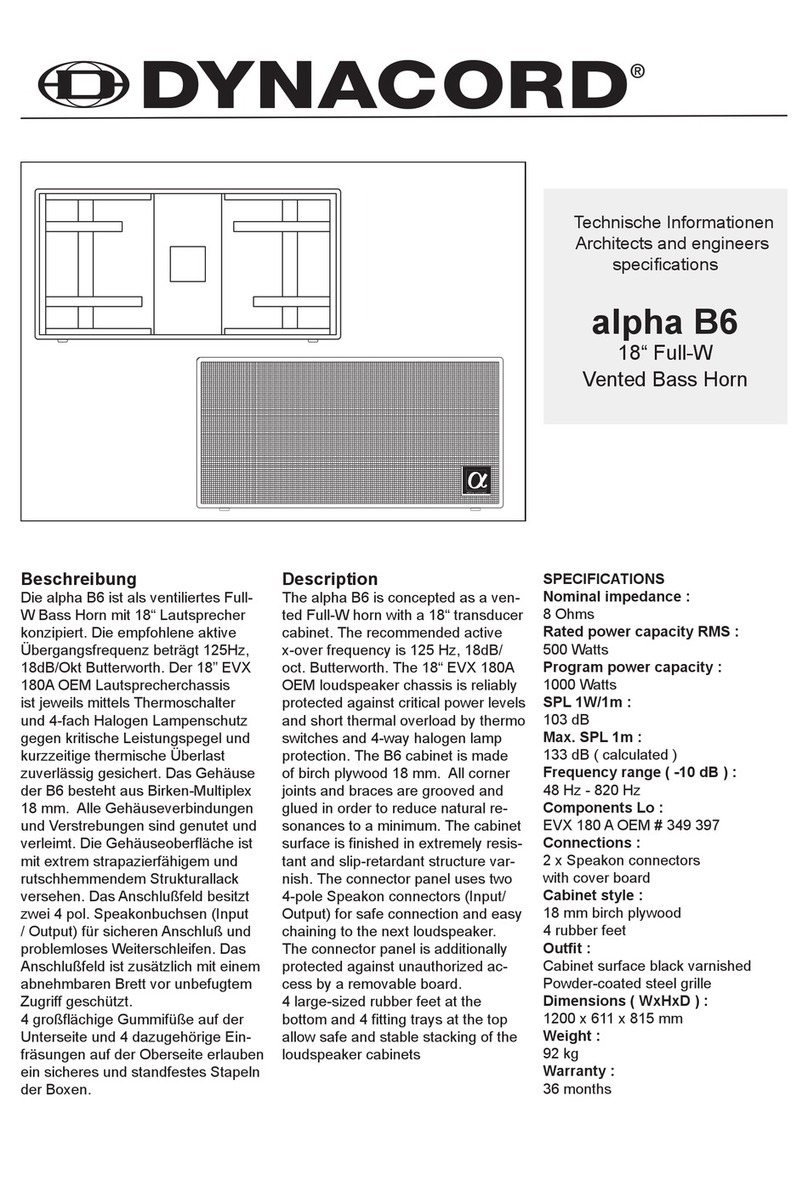

5.1. Kit Layout and System Location(s)..............................................................................................................9

5.2. Install Process Outline.............................................................................................................................. 11

5.3. Approximate Installation Time................................................................................................................ 11

6. List of Tools and Supplies ................................................................................................................................ 12

6.1. Standard Tool List (Required).................................................................................................................. 12

6.2. Special Tool List (Recommended) ........................................................................................................... 12

6.3. Shop Consumables List (Recommended)................................................................................................ 12

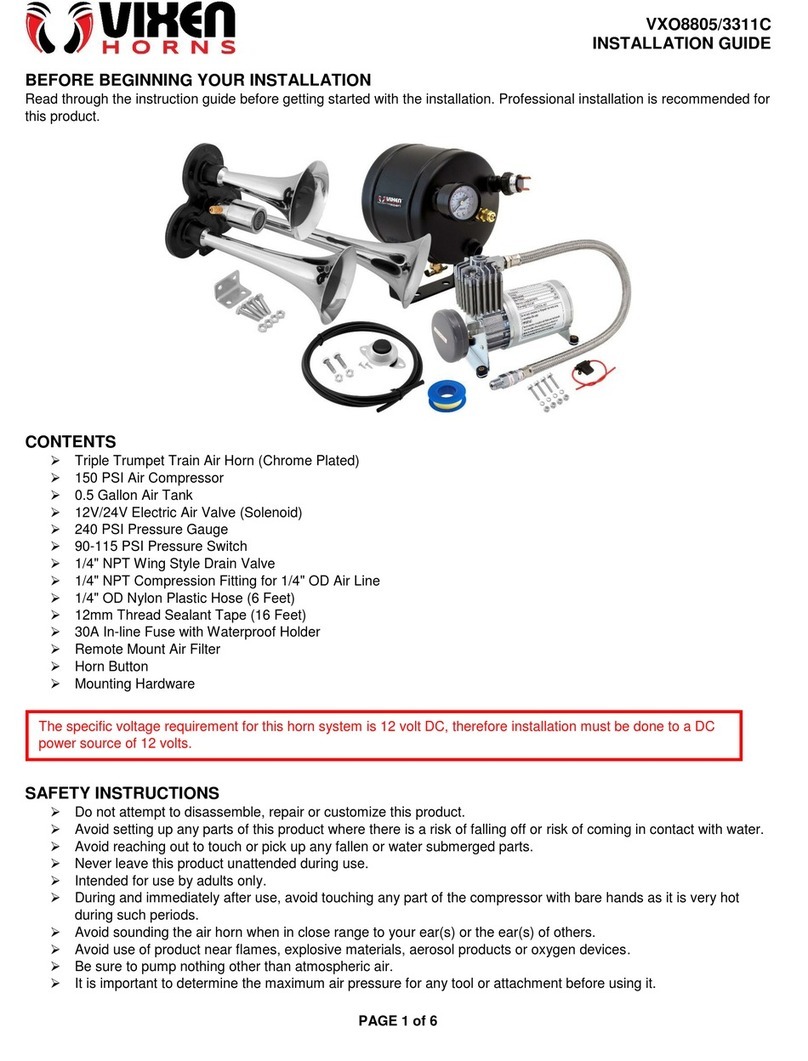

7. Parts List .......................................................................................................................................................... 13

7.1. Before Starting, Review Parts List ........................................................................................................... 13

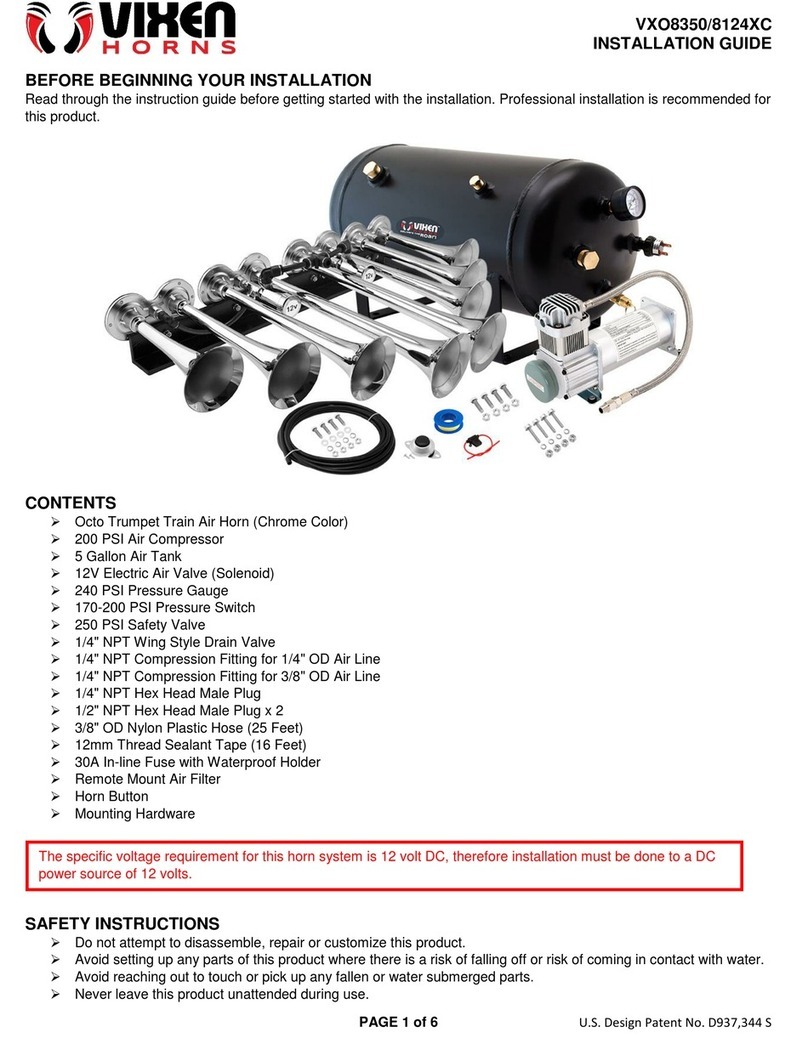

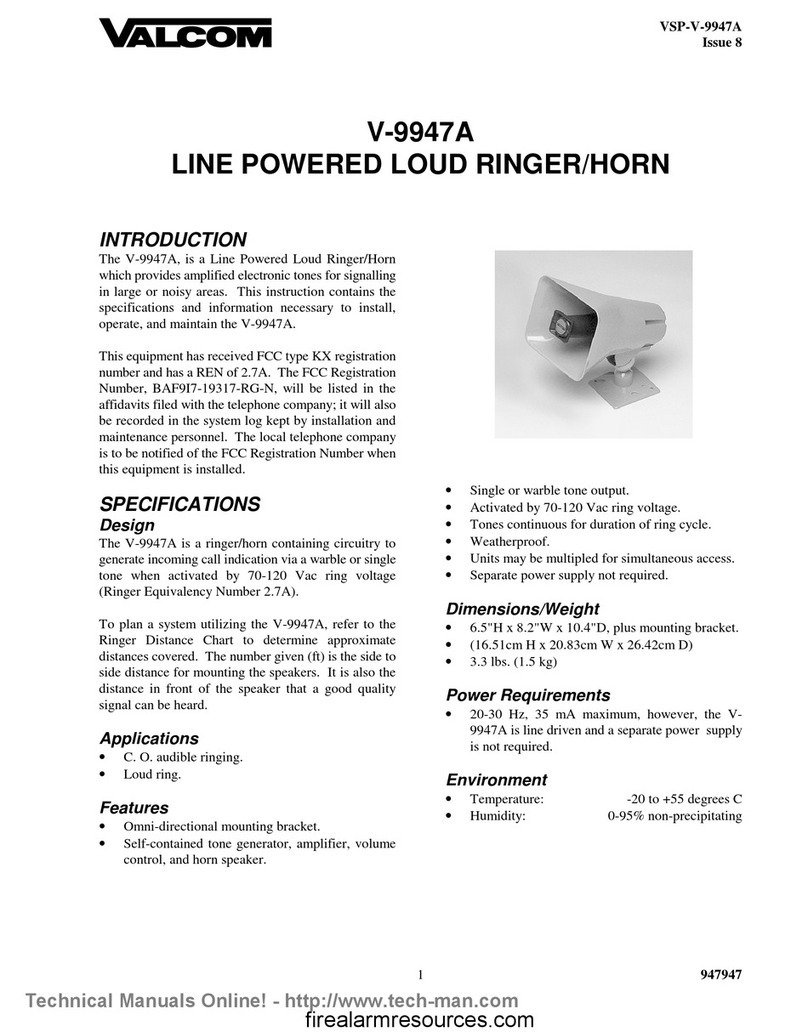

7.2. Pre-Packaged Electro-Mechanical Kit Items............................................................................................ 13

7.3. Air Fittings and Related Items ................................................................................................................. 14

7.4. Electrical Small Components and Related Items..................................................................................... 15

7.5. Bolt-On Mounting Brackets & Special Hardware .................................................................................... 15

7.6. Hardware, Fasteners and Soft Parts........................................................................................................ 16

7.7. Add-On Accessories................................................................................................................................. 16

8. Bench Assembly............................................................................................................................................... 17

8.1. Disassemble Trumpets from Air Horn Drivers......................................................................................... 17

9. On-Vehicle Mechanical Assembly ................................................................................................................... 18

9.1. Remove Spare Tire Lift Mechanism......................................................................................................... 18

9.2. Install Air Horn Bracket (SD17-304)......................................................................................................... 20

9.3. Install Air Horn Ore Support Bracket (SD17-306) –734STD ONLY.......................................................... 21