Shaft end upwards:

For designs with the shaft at the top, the operator must prevent foreign bodies and water from falling vertically

into the shaft. With the shaft end upwards, ingress of water or liquid along the shaft must also be prevented.

When installing surface-cooled motors, it must also be ensured that the condensation water drain holes are

located at the lowest point. If the condensation water drain holes are sealed, sealant must be applied to the

screws when they are replaced after draining the condensation water. In the case of open condensation water

holes, direct exposure to water jets or splash water must be avoided. Careful installation of the motors on a

completely level surface is essential to avoid distortion when tightening them. Precise alignment of any ma-

chines to be connected must be ensured. If possible, flexible couplings should be used.

1.10 General information on operation from the frequency inverter

Operation of explosion-proof three-phase motors from the frequency inverter is only permitted if the motors

are manufactured, tested, approved and separately marked for this type of operation. The separate manufac-

turer’s instructions must be observed.

For the ignition protection type increased safety “eb” and motors for use in zone 21, separate EU (EC) Type

Examination Certificates are required in which operation with the inverter is explicitly approved and in which

the conditions to be observed and parameter settings of the system motor, inverter and protective device are

specified.

In ignition protection type “ec”, motors supplied with power by converters with variable frequency and/or volt-

age must also be tested with the specified converter or a converter that is comparable in terms of output volt-

age and current. Alternatively, the temperature class can be determined by calculation. The necessary pa-

rameters and conditions can be found on the rating plate or in the motor documentation.

To avoid impermissible temperatures, the motors are always equipped with thermal winding protec-

tion, which must be checked with a suitable device. The motors must not be operated as group

drives.

For installation and commissioning of the frequency inverter, the manufacturer’s instructions and operating

manual must be observed.

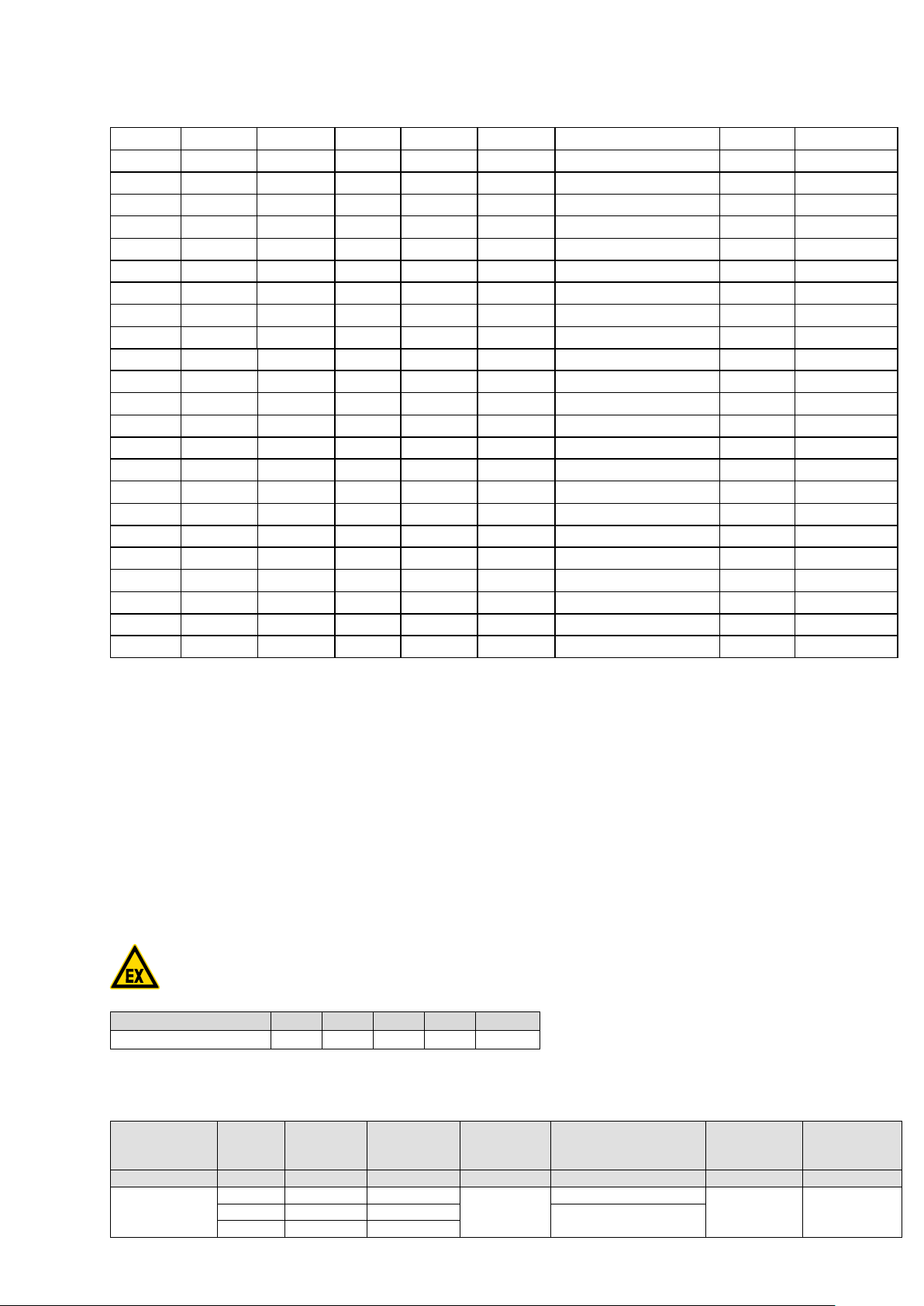

Operation from the frequency inverter for use in zone 2, 22 (Ex II 3G, Ex II 3D)

Operation with the frequency inverter is only permitted within the operating points specified on the rating

plate. Exceeding the rated current for the machine by up to 1.5 times that rated current is permissible for a

maximum of 1 minute within a period of 10 minutes. The specified maximum speed or frequency must never

be exceeded. By selecting the appropriate inverter and/or using filters, it must be ensured that the maximum

permissible pulse voltage at the motor terminals is not exceeded.

It must be ensured that the operating voltage applied to the motor terminals always corresponds to the infor-

mation on the rating plate (note voltage drop across filter!). The thermal winding protection must be checked

either by a separate trigger device or by the inverter.

Operation from the frequency inverter for use in zone 1, 21 (Ex II 2G, Ex II 2D)

Motors for use in zone 1 or 21 must always be certified by an authorised body for operation with a frequency

inverter. Limit values specified on the rating plate and on the EC Type Examination Certificate must be

strictly observed. In particular, this also means monitoring the continuous current as a function of frequency.

Only frequency inverters that meet the requirements specified on the EU (EC) Type Examination Certificate

may be used. Assessment of the integrated thermal winding protection must be carried out using a trigger

unit with the Ex-marking II (2) G which complies with the requirements of Directive 2014/34/EU. The speci-

fied maximum speed or frequency must never be exceeded. It must be ensured that the operating voltage

applied to the motor terminals always corresponds to the information on the rating plate (note voltage drop

across filter!). If the terminal voltage at the motor is lower than the rated voltage specified on the rating plate

due to voltage drops across the frequency inverter, the cables and any chokes or filters, the base frequency

must be set to a lower value corresponding to a linear voltage/frequency assignment. This results in a

smaller speed control range.

1.11 Electromagnetic compatibility

When operating the motors from the frequency inverter, interference emissions can occur depending on the

inverter type. Exceeding the limit values according to IEC/EN 61000-6-3 must be avoided for the drive sys-

tem consisting of motor and inverter. The EMC instructions of the inverter manufacturer must always be ob-

served. On machines with built-in PTC thermistors or other sensors, inverter-induced interference voltages

can occur.