concealed within of the reveal

5. With 2-component acoustic foam

Fix VX-2K peripherally in the wall

7. Unit protection against pollution

8. Fassadenabschluss nach Fertigstellung

der Putz- und Malerarbeiten montieren

a) thereto is the enclosed, room-side protection

cover throughout the building phase

use; In addition, we recommend using of

VX-LAL-plaster cover for the flat duct

a) Room-side opening gap between wall and duct

diffusion-tight / permanently elastic sealing

(Ventomaxx assembly sealing adhesive VX-FK)

9. Inside cover only shortly before the completion

of the construction project mounting

b) um Deformationen am Gehäuse zu vermeiden,

Schrauben nur mäßig, gleichmäßig anziehen

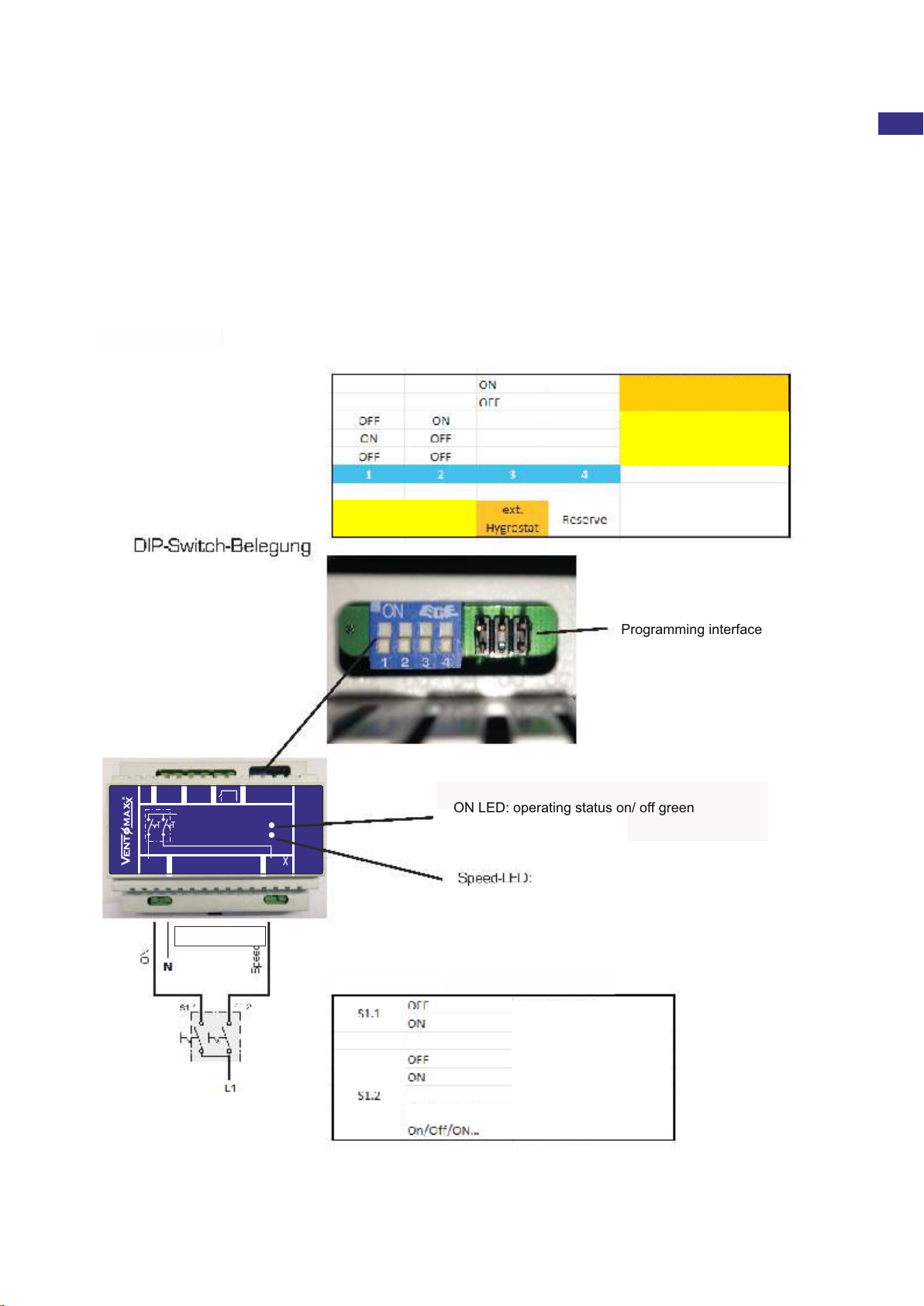

10. Electrical connection

may only be made by a qualified electrician!

a) VBefore starting work, switch off the fuse /

Pull out the plug! Further steps like

Mounting Type LAW; see also the

following pages.

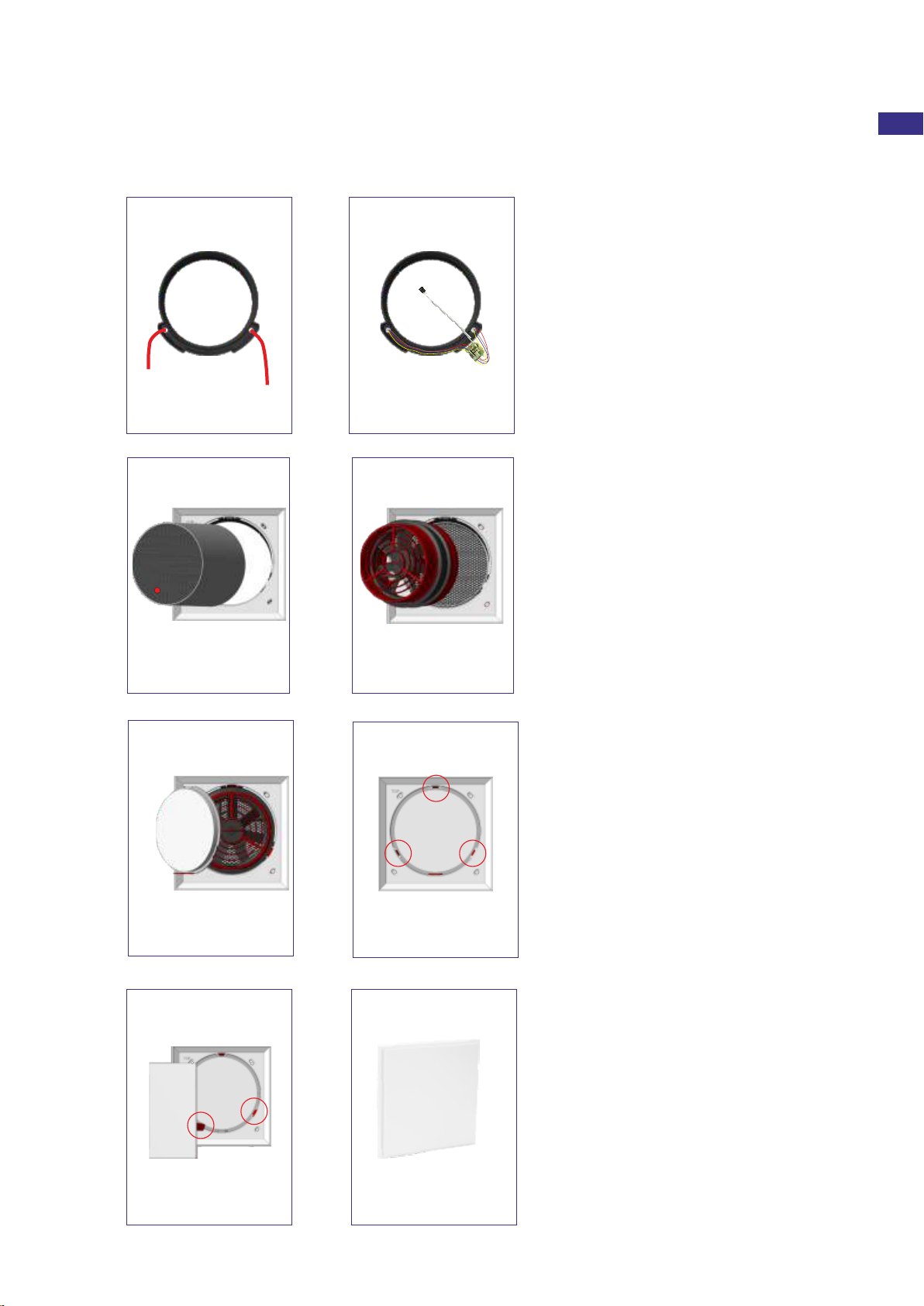

1. Preparing the wall breakthrough

a) Opening round 200 mm or square W/H

200 x 190 mm Making or prepare in

rough construction

b) damit die Systemträgereinheit mit Ventilator

während der Bauphase keinen Schaden nimmt,

sollte diese bis zur Endmontage an einem

geschützten Ort zwischengelagert werden.

a) den verstellbaren Laibungsanschluss bündig

zum späteren Putzniveau der Laibungsecke

einjustieren / umlaufend abkleben

6. Flachkanal-System innerhalb der

Dämmebene einhausen

b) Schnittstelle zwischen Flachkanal, Dämm-

ebene und Putzanschlusses mit Kompriband

andichten

4. For larger openings, cavities

additionally with rock wool, mineral wool

stuffed or isolate expertly

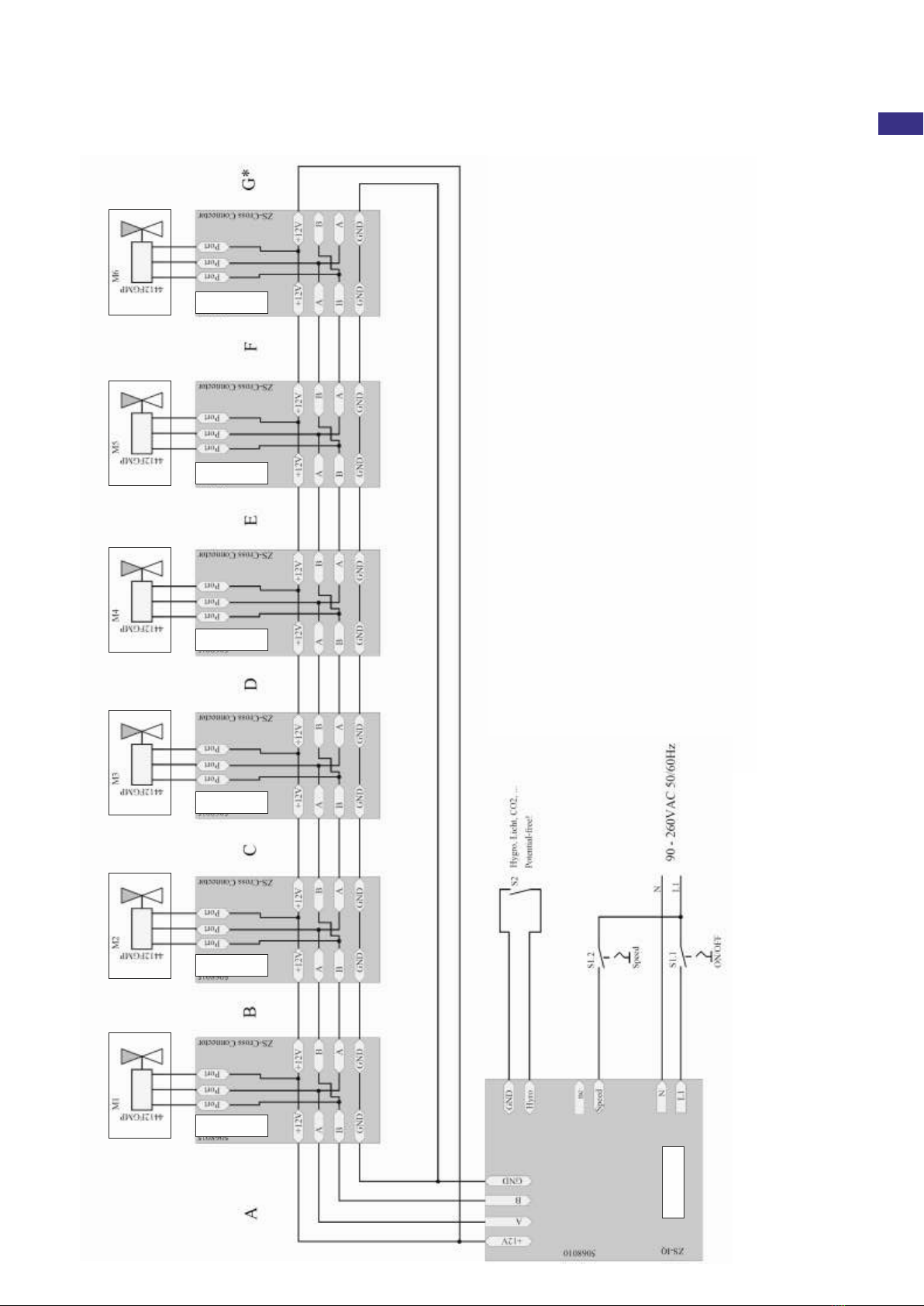

Preparing low voltage cabel

2x2x0,6

a) the room-side design panel can be applied to the

provided fixing points of the RS-LAL or attached

to the wall

2. Manufacture fan length with ring modules

(At desired location within of the reveal)

The standard ring module set is for a

Fan nominal length prepared by about 330 mm;

Ring modules possibly expand; shorten and sealing

Caution: cut only on the outside!

3. Ring Module Set push it into the wall,

aligning and fixing free of tension

c) when LAL-mounting of the telescopic unit has a

incline of approx 1.5-3 ° must be provided from

the inside to the outside; at flat duct it is 5 °(degrees)

d) Flachkanal außenbündig auf Laibungsniveau

justieren; ggf. einkürzen; mittels passendem

Flachkanalhalter an der Außenwand befestigen

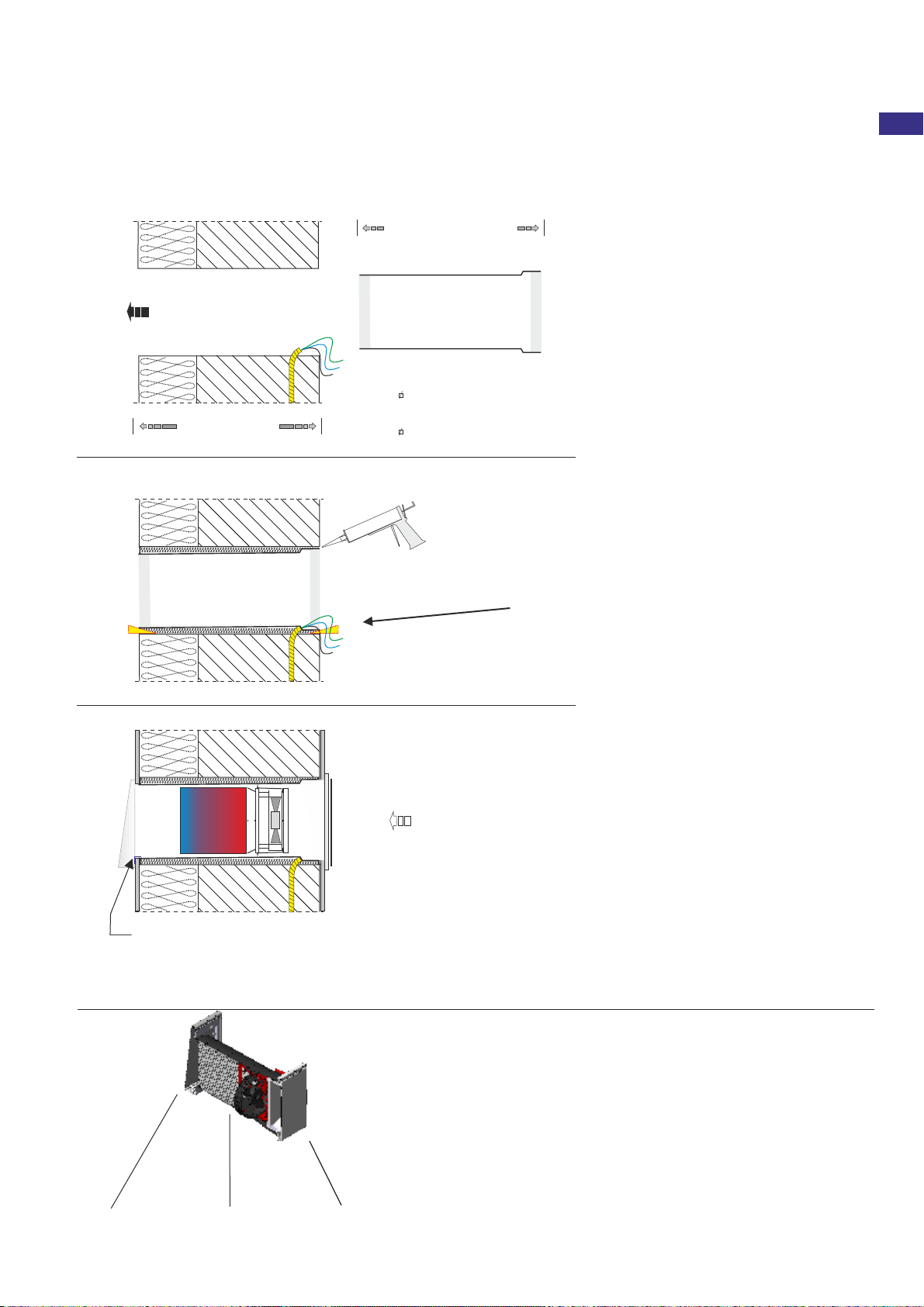

Outside

View sidwise

wall thickness

Manufacture of the

total length

Slide in the operating unit

Plaster cover

RS-LAL

Inside

Outside

cut vertikally

sealing adhesive

1,5 bis 3° slope

by EPS mounting wedges

acoustically decoupled manufacturing

Ord-No: 9500-0030SP

Plaster cover

Outside

Schnitt vertikal

mounting external

wall cover and

inner housing cover

Inside

channel junction with

ventilation tape

sealing encircle

When plaster facades we recommend a flat duct insulation of approximately 30 mm.

b) Empty tube provided or low-voltage cable

2x2x0.6 acc. Wiring plan laying!

b) after adjusting the ring module set to the

Wall thickness (extending over VLE-Ring Module

and if necessary, cut the outer pipe end are still

existing connection jointless diffusion-tight seal

with VX-FK

a) beforehand the cables are in the cable bags

introducing the ring module sets

The illustration shows a

Sectional view of Z-WRG RONDO IQ

in mounted version LAL,

für die verdeckte Integration

concealed within the reveal

Flachkanalhalter FKH

3-dimensional verstellbar

Rough construction

Ring Module Se

RS-LAL

Device unit

Z-WRG RONDO IQ

telescopable façade connection

with integrated condensate drain

Facade border

FA-LAx 37

IQ-Design-Cover

› INSTALLATION INSTRUCTIONS / rough construction mounting Type LAL 7

Cut vertikal

Solid wall + insulation system

Assembly instructions - Z-WRG RONDO IQ - Mounting Type LAW