RFS INSTALLATION INSTRUCTIONS

VERIZON HYBRIFLEX CABLE| Revision 1 | APRIL 2019

Visit www.rfsworld.com for the most current product specifications

Page 4 of 33

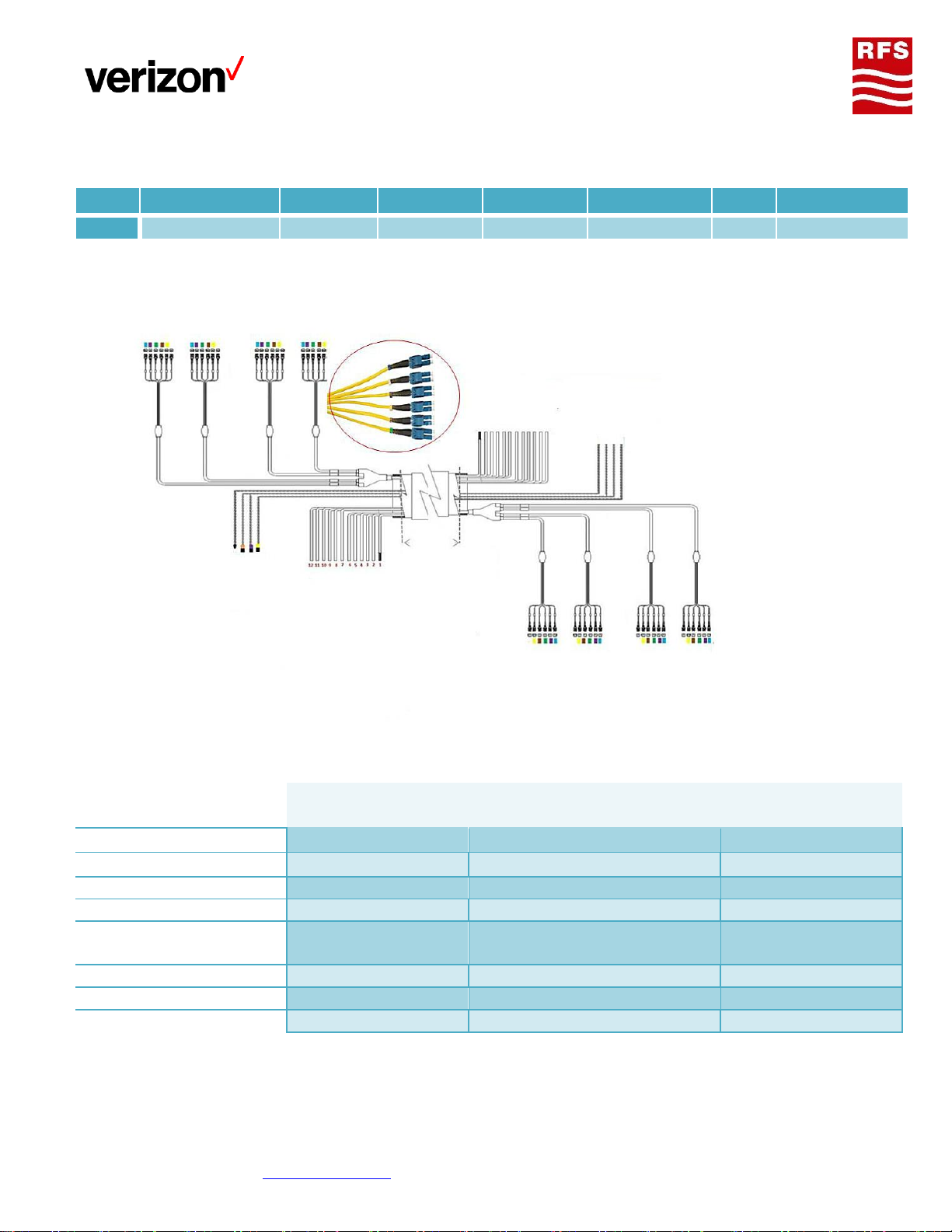

Verizon HYBRIFLEX® cable is unique to its network available

in three Trunk configurations, 2x4 (mainly for rooftop) 6x12

and 12x24. The trunk cable assemblies comprise of 6 AWG

Low Inductance DC wires, nine 18-gauge alarm wires and up

to twenty four (24) pairs of single Mode fiber terminated

with LC-LC connector.

The use of Low Inductance Cable will allow Maintenance

Engineering to extend distances upwards of ~600ft,

eliminating the need to re-locate power cabinets and stay

within the conventional distances supported. Refer, to

previous installation instruction for older traditional Hybrid.

Verizon uses a combination of OVP’s (over voltage

protection) both top and bottom and various hybrid jumpers

configuration for complete installation from BBU to RRH.

HYBRIFLEX® trunk cable assemblies are factory constructed

specifically to suit the Verizon Network, ensuring perfect

Raycap OVP’s compatibility and trouble-free installation.

Additional features that ease installation and ensure

durability service include:

Robust breakout design with Numbering fibers and

power conductors

Stranded construction for easy bending and maximum fiber protection

Corrugated aluminum shield protects from crush and animal damage

Integrated rip cords for length management

Factory test certificate available for every cable assembly

Well packaging, easy fiber End face access for pre-testing

Caution: not to be stored outside

Hybrid jumpers Installation

In general Hybrid jumpers are installed similarly to trunk line or coaxial cable. Used accessories where

applicable.

The Fiber endface must be handling with care and be protected during installation.

DO NOT remove protected tubing and plastic bag until ready to connect the jumper between OVP box

and RRU or BBU.

Followed the bend radius guidelines specify in the product spec sheet

Attach the main cable securely to the structure or equipment using hangers and/or cable ties to

prevent strain on connections from movement in wind or snow / ice conditions.

Ensure all LC optical fiber connectors are seated firmly in the OVP box, RRU or in BBU equipment.

Ensure the weatherproof boots for both fiber and power connections and seated firmly in the RRU

All Hybrid jumpers and risers are individually serialized, for immediate access to test results visit

http://myrfs.rfsworld.com/hybriflex/Default.aspx, Power connector is supplied with the RRU