9

•Put ash into inflammable vessels with a cover!

•The consumer mustn’t be used for combustion of waste, rubbish; and no liquid fuels can be used in

any combination! Use only recommended fuels.

•In case of occurrence of a fire of deposits in the chimney, extinguish quickly the fire in the stove by a

dry-power extinguisher or by sand, remove all flammable material situated near the stove and the

chimney body. Close the door, control elements of the stove and the smoke regulating shutter (if it is

installed) and immediately announce the fire to a fire-fighting service!

•Ensure performance of inspection of the pellet stove and flue-gas channel, including the chimney by a

qualified person before repeated commissioning!

•It is not allowed to perform any modification of the product, except of mounting and service works

performed by qualified persons.

•It is possible to use only spare parts approved by the manufacturer for repairs.

In case of non-observance of these conditions, a user loses a right to guarantee repairs.

5.3 Fuel

The guarantee of clean and good combustion is the using of only dry and naturally stocked wood. Fuel is

to be stocked in a dry place.

The stove is determined for firing of high-quality wooden pellets; combustion of, for example, wood chips,

straw or corn is not allowed. Don’t use pellets manufactured from different materials than pressed wooden

matter (for example, from olives, corn, flax, etc.)

Pellets have to comply with at least one of the following directives or norms:

Directive No. 14-2000 of the Ministry of Environment of Czech Republic

DIN 517 31

ÖNORM M 7135

Prescribed granularity of pellets 6 to 8 mm

Water content in fuel max. 12 %

Ash content max. 1,5 %

ATTENTION! Bad fuel quality can significantly negatively influence the power and emission parameters

of the stove.

Quality wooden pellets usually have a smooth sheeny surface, the uniform length and the low share of dust. Low-

quality pellets have longitudinal and transverse cracks, the non-uniform length and the high share of dust. Pellets

quality can be also checked by an easy test. Insert some pellets into a glass with water. If the pellets quality is

good, then they will sag down to the bottom, and if their quality is worse, then they will swim on the water surface.

However, the precisely fuel quality can be only determined with help of proper analyzing devices.

During filling-up pellets into the fuel reservoir, be care about not to contact bags with pellets with the hot

surface of the stove.

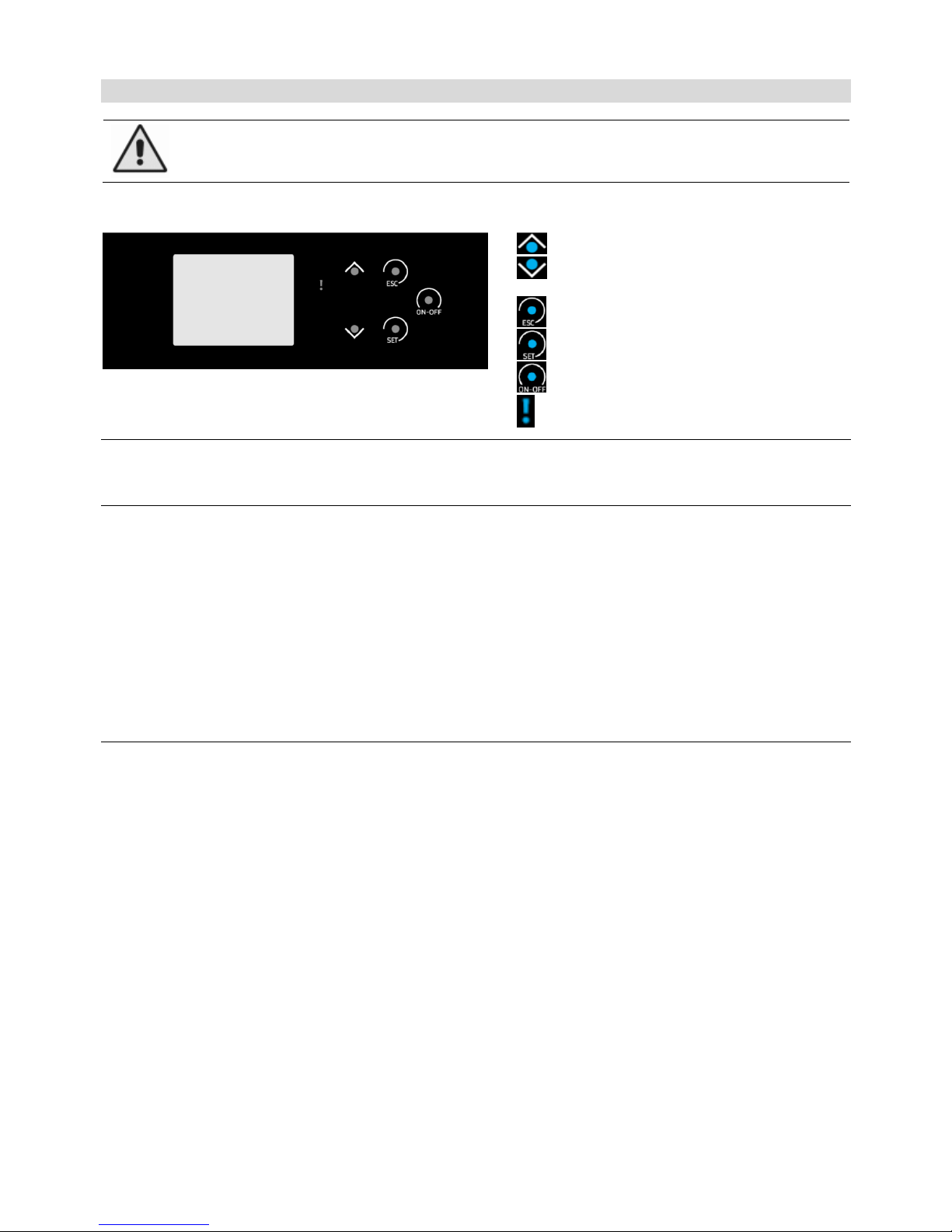

5.4 Main principles of operation

1. The stove and its operation is controlled automatically, by means of an electronic system. The stove cannot be

overloaded (from the point of view of power), if it is operated in accordance with the instructions manual. Don’t

operate the stove with non-prescribed fuel (ref. chapter 5.3). Combustion of other than prescribed fuel and

non-observance of the above mentioned conditions can bring to a damage of components inside the stove or

the entire stove and to canceling of validity of the warranty.

2. Remove ash from the heating chamber and ash-pan before each kindling.

3. In case of season using and at insufficient draught and atmospheric conditions it is necessary to be very

careful during commissioning.

4. After long-term interruption of operation, it is necessary to carry out a check that the flue gas channel is not

impacted.

5. We recommend before each season to perform maintenance, including cleaning according to chapter No. 7.

6. The stove is equipped with a system for automatic cleaning of the burner bowl during operation. This cleaning

is set in the system to one time per hour for the period of 30 sec. The flue exhauster will be switched on to the

maximum rotation speed, by which the burner bowl will be blown-over in order to prevent obstruction of holes

for supply of combustion air on the bottom surface of the bowl. That’s why don’t be surprised, when this

activity automatically occurs during operation.