I. Parts Identification - - - - - - - - - - - - - - - - - - i

II. Quick Start Guide - - - - - - - - - - - - - - - - - - ii

1 - Safety Warnings and Cautions - - - - - - - - - - - - - 1

2 - Welcome and Thank You! - - - - - - - - - - - - - - - 2

3 - How it Works - - - - - - - - - - - - - - - - - - - 3

Boiler Pressure Gauge - - - - - - - - - - - - - - - 4

A Quick Science Lesson (no homework required) - - - - - 4

Brew Pressure Gauge- - - - - - - - - - - - - - - - 4

Back to the Machine - - - - - - - - - - - - - - - - 4

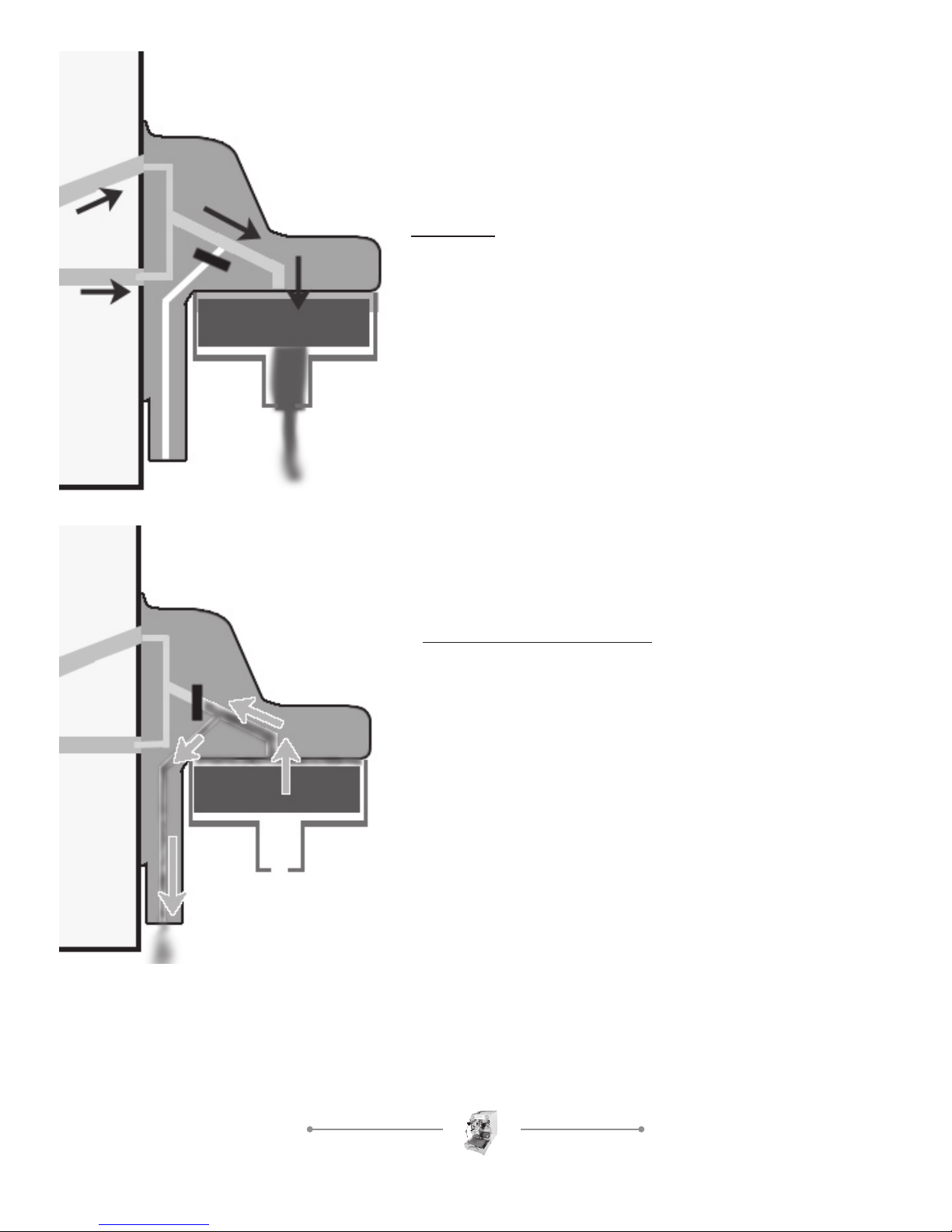

The Grouphead - - - - - - - - - - - - - - - - - - 5

4 - Operation of Each Model - - - - - - - - - - - - - - - 7

Manual Model - - - - - - - - - - - - - - - - - - 7

Semi Automatic - - - - - - - - - - - - - - - - - - 8

Electronic Automatic - - - - - - - - - - - - - - - - 9

5 - Unpacking and Assembly - - - - - - - - - - - - - - - 10

6 - Water - - - - - - - - - - - - - - - - - - - - - - 12

7 - Setup and Startup - - - - - - - - - - - - - - - - - - 13

Portafilter - - - - - - - - - - - - - - - - - - - - 14

8 - It’s About The Coffee - - - - - - - - - - - - - - - - 16

9 - Cooling Flush - - - - - - - - - - - - - - - - - - - 17

10 - Grind, Dose, Tamp - - - - - - - - - - - - - - - - - 18

11 - The Espresso Speedometer - - - - - - - - - - - - - - 20

How Much, How Fast? - - - - - - - - - - - - - - - 20

TOO FAST- - - - - - - - - - - - - - - - - - - - 20

TOO SLOW - - - - - - - - - - - - - - - - - - - 21

At The Speed Limit - - - - - - - - - - - - - - - - 21

12 - Steaming Milk - - - - - - - - - - - - - - - - - - - 22

How To - - - - - - - - - - - - - - - - - - - - - 22

Milk Stretching Tips - - - - - - - - - - - - - - - - 24

13 - Cleaning and Maintenance - - - - - - - - - - - - - - 25

After Each Pull - - - - - - - - - - - - - - - - - - 25

After Each Session - - - - - - - - - - - - - - - - - 25

Once Every One Or Two Weeks - - - - - - - - - - - - 26

Backflushing - - - - - - - - - - - - - - - - - - - 26

As Necessary - - - - - - - - - - - - - - - - - - - 27

Exterior Cleaning - - - - - - - - - - - - - - - - - 27

Grouphead Gasket Replacement - - - - - - - - - - - 27

Hot Water Wand - - - - - - - - - - - - - - - - - - 28

Steam Wand - - - - - - - - - - - - - - - - - - - 28

Long Term Storage - - - - - - - - - - - - - - - - - 28

Placing a Machine Back Into Service After Storage - - - - 29

14 - De-scaling - - - - - - - - - - - - - - - - - - - - 30

How to Descale - - - - - - - - - - - - - - - - - - 30

15 - Hints, Tips, and Tricks - - - - - - - - - - - - - - - - 34

Maximizing Steaming Power - - - - - - - - - - - - - 34

Minimizing Temperature Variations During the Pull - - - - - 34

Electronic Domobar - - - - - - - - - - - - - - - - 34

16 - Advanced Adjustments - - - - - - - - - - - - - - - - 35

Brew Pressure Adjustment - - - - - - - - - - - - - - 35

Pressurestat Adjustment - - - - - - - - - - - - - - - 36

17 - Troubleshooting - - - - - - - - - - - - - - - - - - 37

The machine is not working. - - - - - - - - - - - - - 37

No water can be pumped. - - - - - - - - - - - - - - 37

The grouphead is not getting very warm - - - - - - - - - 37

I can pump water, but the water is always cold. - - - - - - 37

The Coffee Tastes Bad - - - - - - - - - - - - - - - 38

The brew pressure gauge acts erratically - - - - - - - - 38

MAINTENANCE RECORDS: - - - - - - - - - - - - - - - 39

CHAPTER TITLE PAGE#

T

A

B

L

E

O

F

C

O

N

T

E

N

T

S