7

After the installation of the cooker it is attached to the chimney through chimney pipes

ø150 mm. The connections between the separate chimney pipes and the socket should

be tight. The chimney pipe should not enter into the chimney.

4. Cooker operation.

4.1. Fuels.

The most appropriate fuels are dried wood logs and briquettes. The wood logs, stored in the

open under sheds, reach a humidity level of 10%-15% after 2 years, when they are most suitable

for combustion. We recommend to burn wood dried as much as possible. The maximum heat

output is reached after burning wood logs dried for at least 2 years period of time.

The fresh cut wood has little calorific effect, high humidity and burns poorly –they extract a lot

of flue gases and additionally contaminate the environment. This leads to minimizing the

longevity of the cooker and chimney as well. The increased condensate and tar content in the

flue gases leads to blocking up the flue pipes and the chimney, and an appreciable impurity of

the glass. When using them, the heat output of the cooker falls to 50%, and the fuel consumption

grows twice.

It is not recommended to use the following fuels in the cooker: wet or tarred wood, shavings,

culms, high calorific coals, polymers, paper and cardboard (except for the ignition).

Do not use liquid fuels.

Do not use the cooker like a furnace for burning waste matters.

If the cooker is used for burning unalloyed fuels then the warranty is not valid.

4.2. Control devices.

Before the first ignition of the cooker pay attention to the function of all control devices.

The primary air passes through the bottom grate and goes into the firebox. Primary air is

necessary for faster ignition. The quantity of the primary air is done by slightly pulling the

ashpan and its quantity depends from the distance to front panel.

Secondary air provides the fire with the required for the combustion oxygen and assists for the

better combustion of the fuel. The quantity of the secondary air is controlled through the

regulator pos.3, mounted on the front panel. While the cooker is working, the secondary air

regulator ensures control over the combustion process both qualitatively and quantitatively. The

secondary air regulator should not be closed when the cooker is working. In many cases the

secondary air regulator has been closed shortly after the ignition, despite our directions, in order

to reduce the fuel consumption. This leads to limitation of the flow of oxygen, which bothers the

combustion and the glass is covered with soot. Also there are harmful emissions which may

cause burning in the chimney.

We recommend closing primary and secondary air controls when the cooker is not working to

keeping it worm for a longer period.

As the heat output of your cooker depends on the height of the chimney, the precise control of

the necessary air for the combustion is done by trial and error.

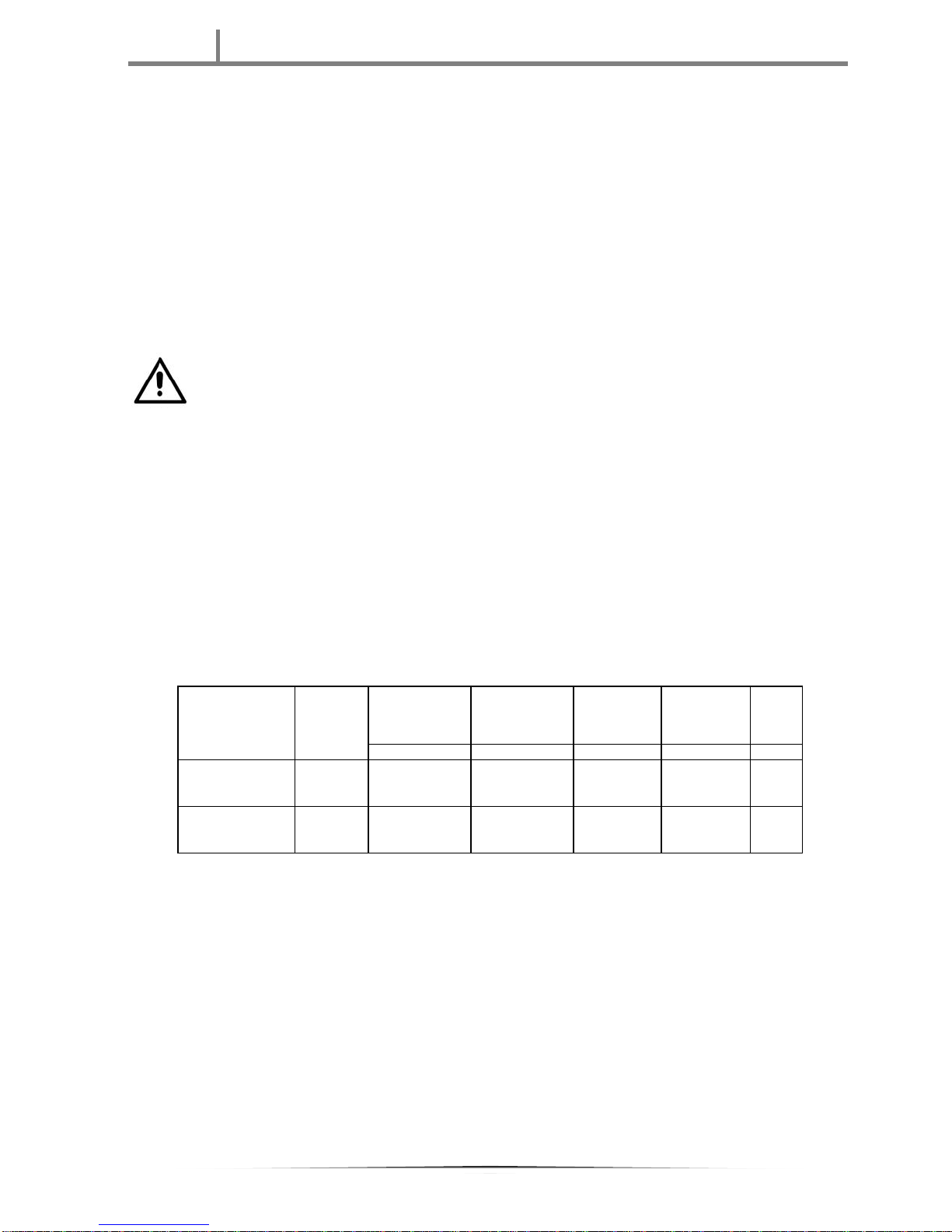

Position of the secondary air inlet control (fig.1) means:

“close” “open”.