EN - English - Instructions manual

2 MNVKWASPT_1426_EN

• Use only original spare parts. Non-original spare

parts could cause re, electrical discharge or other

hazards.

• Before proceeding with installation check the

supplied material to make sure it corresponds

to the order specication by examining the

identication labels (4.2 Product markings, page 2).

• A disconnecting device, readily and easily

accessible, must be incorporated in the electrical

system of the building for rapid intervention.

4 Identification

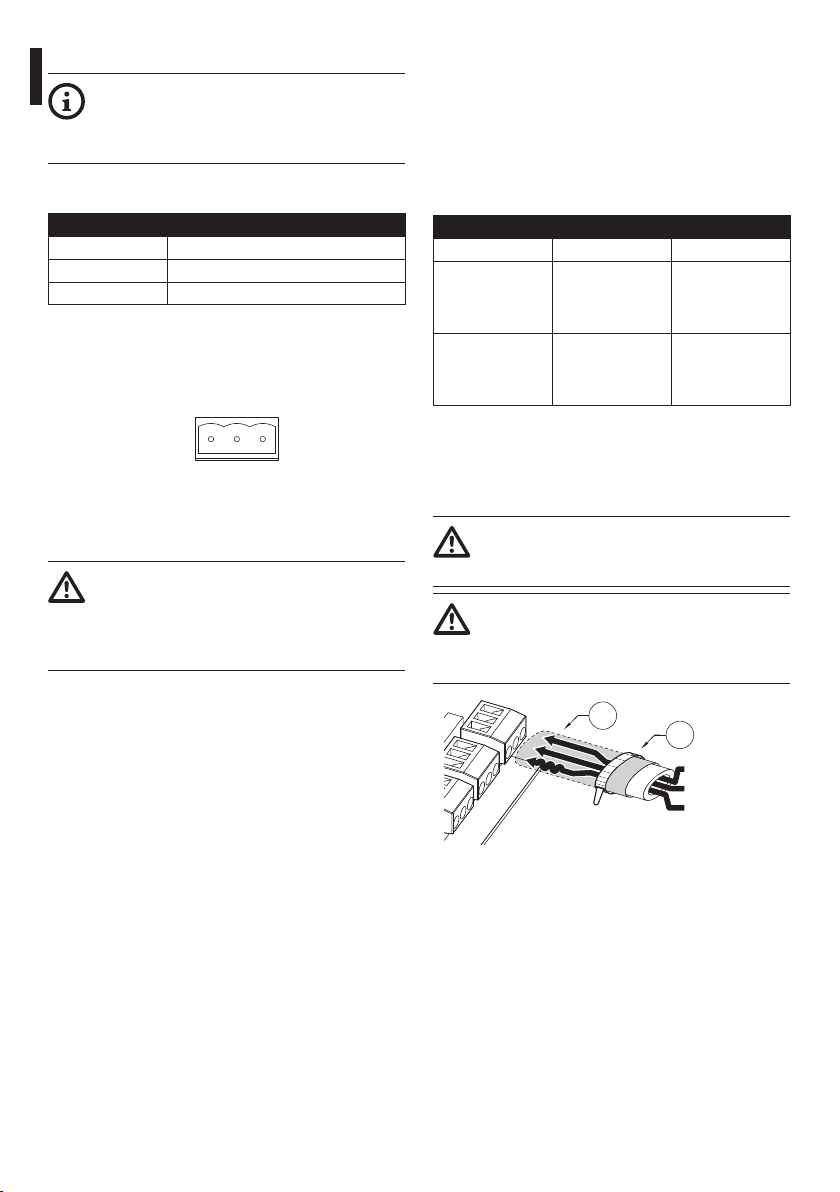

Glass cleaning kit for ULISSE and ULISSE COMPACT

series pan & tilts and housings.

5l (1.3gal) o 23l (6gal) tank. Dierent pumps are

available for delivery up to 5m (16ft), 11m (36ft) or

30m (98ft). Available voltages in 230Vac, 24Vac or

120Vac. Pumps with 30m (98ft) delivery are available

only in 230Vac or 120Vac.

In the 11m (36ft) and 30m (98ft) delivery versions the

lack of liquid in the tank is signalled following the

automatic stop of the pump.

With the stand-alone housing (no P&T and no

telemetry receiver), it is possible to remotely control

via RS-485 the wiper and the washer pump by using

the DTWRX optional board.

See the label attached to the product.

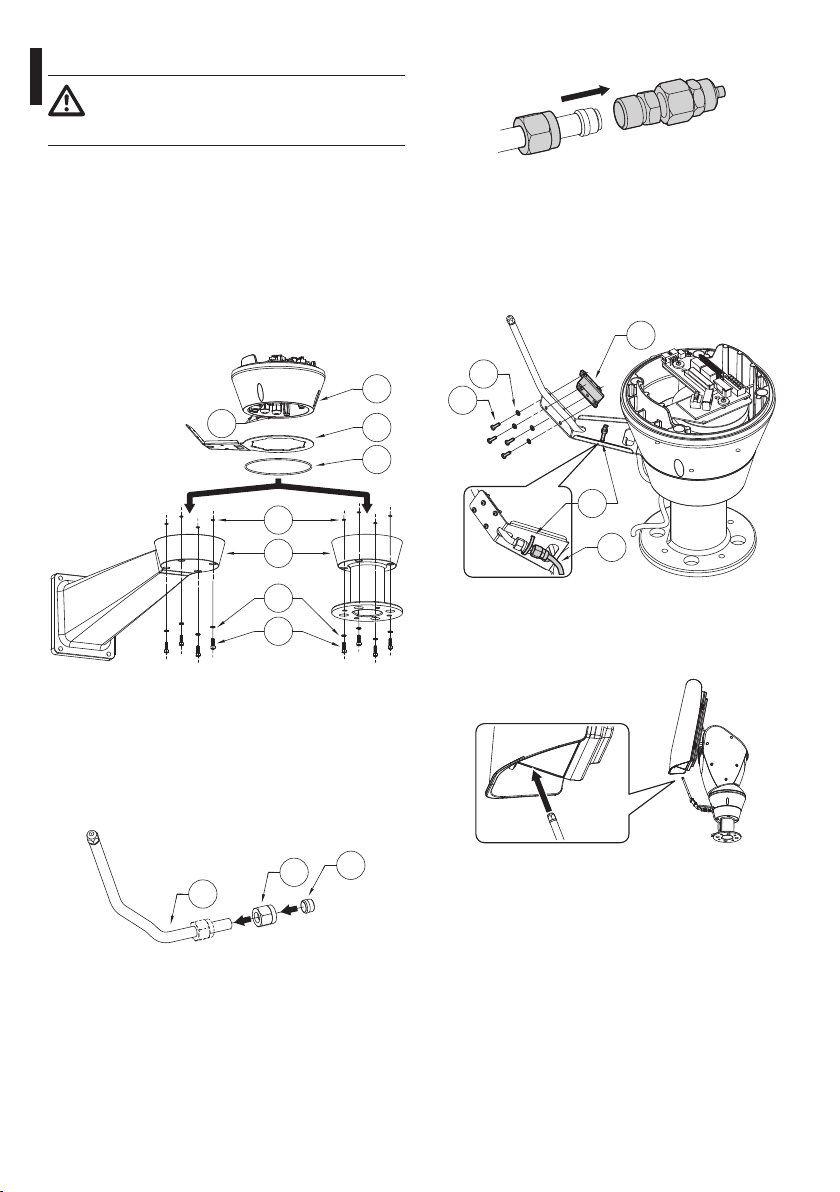

5 Preparing the product for

use

When the product is delivered, make sure that the

package is intact and that there are no signs that it

has been dropped or scratched.

If there are obvious signs of damage, contact the

supplier immediately.

Keep the packaging in case you need to send the

product for repairs.

Check the contents to make sure they correspond

with the list of materials as below:

• Washer kit

• Ties

• Silicon sheath

• Pipe connector

• Washer pipe support

• Locking bracket for pipe support

• Delivery pipe

• Washer pipe (with nozzle)

• Bolts and screws

• Instructions manual

The packaging material can all be recycled. The

installer technician will be responsible for separating

the material for disposal, and in any case for

compliance with the legislation in force where the

device is to be used.

When returning a faulty product we recommend

using the original packaging for shipping.