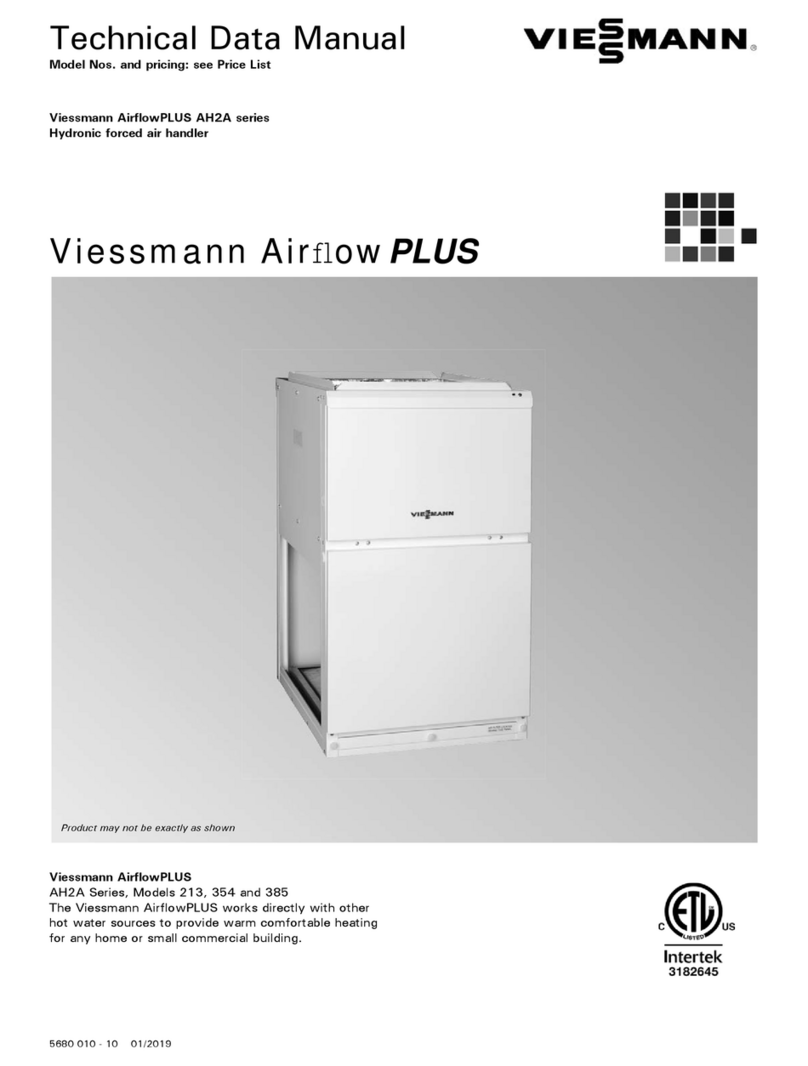

Viessmann AirflowPLUS AH2A Installation, Operating and Service

5680 011 - 23

2

Safety, Installation and Warranty Requirements

Safety

2

Please ensure that these instructions are read and understood before commencing installation. Failure to comply with

the instructions listed below and details printed in this manual can cause product/property damage, severe personal

injury, and/or loss of life. Ensure all requirements below are understood and fulfilled (including detailed information

found in manual subsections).

WARNING

Follow the Viessmann maintenance schedule of the boiler

contained in this manual.

Product documentation

Read all applicable documentation before commencing

installation. Store documentation near air handler in a

readily accessible location for reference in the future

by service personnel.

For a listing of applicable literature,

please see section entitled “Important

Regulatory and Installation Requirements”.

Warranty

Information contained in this and related

product documentation must be read

and followed. Failure to do so renders

the warranty null and void.

Licensed professional heating contractor

The installation, adjustment, service and maintenance

of this equipment must be performed by a licensed

professional heating contractor.

Please see section entitled

“Important Regulatory and Installation

Requirements”.

Advice to owner

Once the installation work is complete, the heating

contractor must familiarize the system operator/

ultimate owner with all equipment, as well as safety

precautions/requirements, shutdown procedure, and

the need for professional service annually before the

heating season begins.

Operating and service documentation

It is recommended that all product documentation such as

parts lists, operating and service instructions be handed

over to the system user for storage. Documentation is to

be stored near air handler in a readily accessible location

for reference by service personnel.

WARNING

Inhaling of fiberglass wool materials is a possible cancer

hazard. These materials can also cause respiratory, skin

and eye irritation.

Fiberglass wool materials

WARNING

Appliance materials of construction, may contain toxic

or harmful substances which can cause serious injury

or loss of life and which are known to the State of

California to cause cancer, birth defects and other

reproductive harm. Always use proper safety clothing,

respirators and equipment when servicing or working

nearby the appliance.

The state of California has listed the airborne fibers of

these materials as a possible cancer hazard through

inhalation. When handling these materials, special care

must be applied.

First aid measures

- If eye contact occurs, flush eyes with water to

remove dust. If symptoms persist, seek medical

attention.

- If skin contact occurs, wash affected areas gently

with soap and warm water after handling.

Suppliers of fiberglass wool products recommend the

following precautions be taken when handling these

materials:

- Avoid breathing fiberglass dust and contact with

skin and eyes.

- Use NIOSH approved dust/mist respirator.

- Wear long-sleeved, loose fitting clothing, gloves

and eye protection.

- Wash work clothes separately from other clothing.

Rinse washer thoroughly.

- Operations such as sawing, blowing, tear-out and

spraying may generate airborne fiber concentration

requiring additional protection.