2

Assembly and installation information

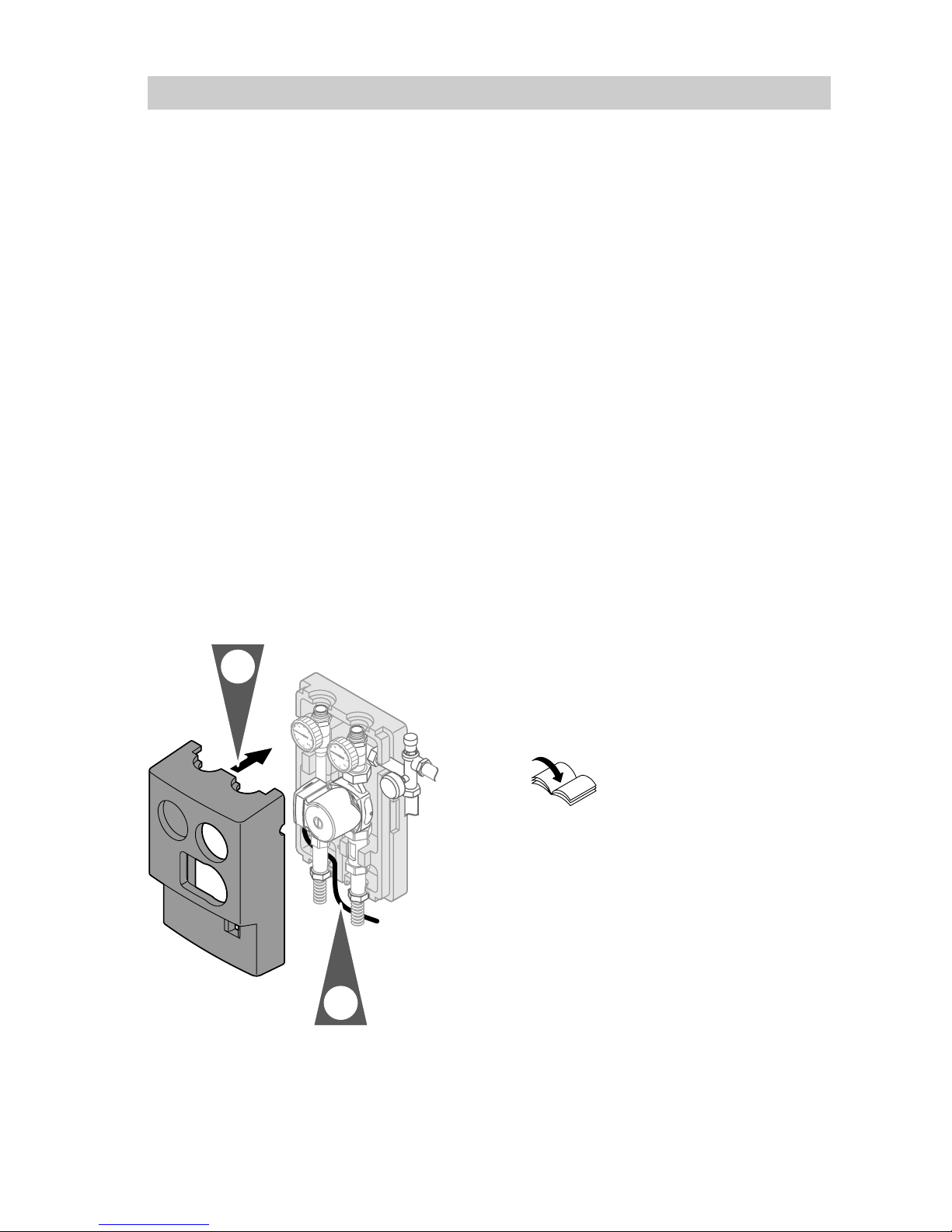

HThe Solar−Divicon comprises:

pre−assembled and sealed valves

and safety assembly

Flow regulating valve to control

the solar heating system during

the initial start−up and operation

Non−return valve in the flow and

return pipe

HAlways install Solar−Divicon so that

steam cannot enter the expansion

vessel in the event of stagnation.

HThe Solar−Divicon and the solar

circuit pump line are not suitable

for direct contact with swimming

pool water.

HFlush the system with process

medium after draining.

HIf the expansion vessel is installed

as high or higher than the

Solar−Divicon, a thermal insulation

loop is required.

HA pre−cooling vessel connection is

fitted to the flow line to protect the

expansion vessel against excess

temperatures.

HUse only gunmetal, brass fittings,

copper pipes or Viessmann

stainless steel solar circuit pipes

for the installation. Never use

galvanized/zinc−plated pipes,

fittings or graphitised gaskets. Use

hemp only in conjunction with

pressure and temperature−resistant

sealants (e.g. ViscotexSolarpaste,

Locher & Co. AG, CH9450Altstätten).

Components that come in contact

with process medium must be

resistant to the medium.

HCheck the sealing surfaces for

cleanliness and damage before

assembly.

Installation of the locking ring fittings

HAll pipes must be cut at a right

angle and deburred.

HInsert the support sleeves into the

pipework.

HPush the union nut and the locking

ring onto the pipe and lightly

lubricate the threads with oil.

HPush the pipe into the locking ring

fitting as far as it will go.

HInitially turn the union nut by hand,

then tighten with an open ended

spanner by a further ¾ turn.

HNever fit annealed copper pipes

onto the locking ring fittings.

5862810GB