Designating the Proper Location

-7-

DESIGNATING THE PROPER LOCATION

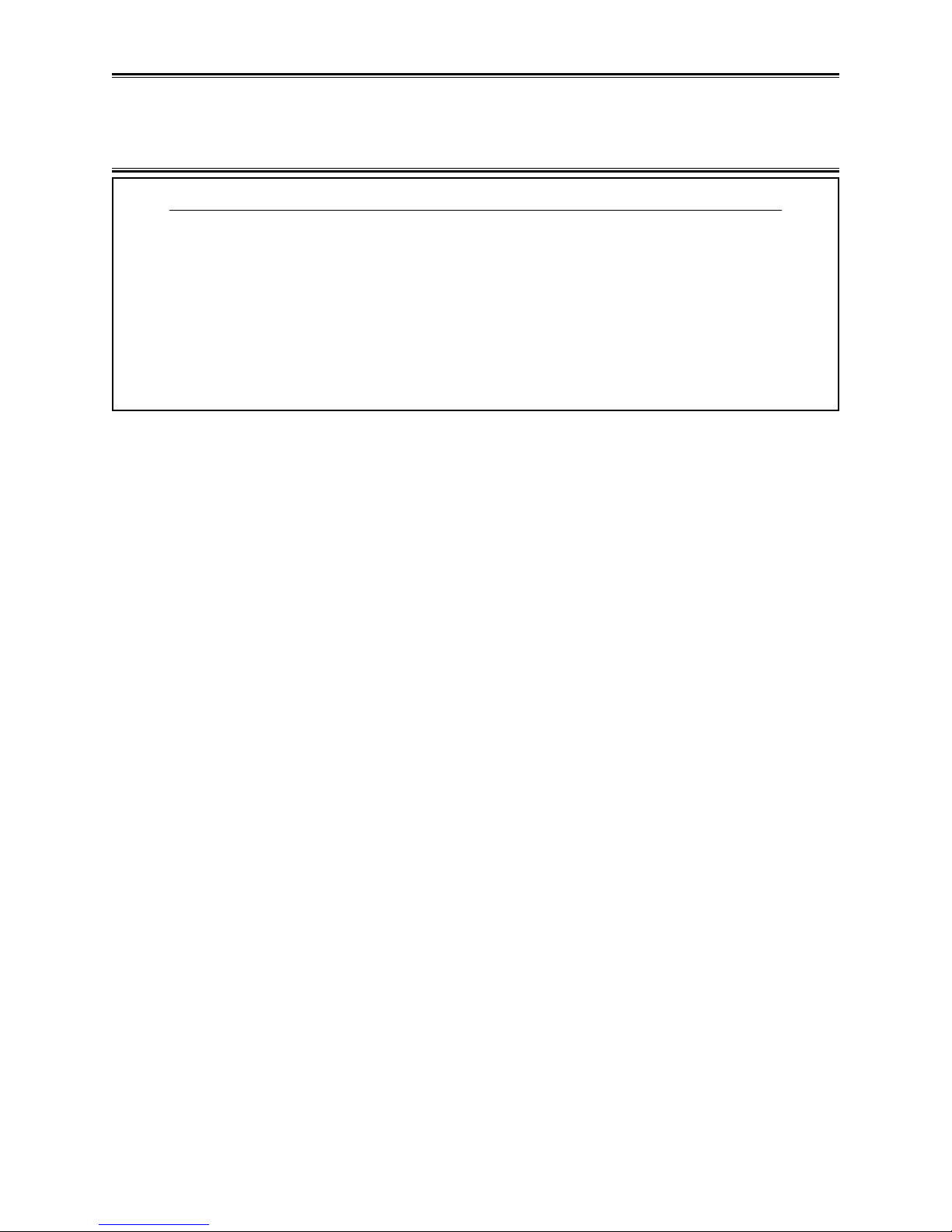

FOR PLACEMENT

capacity weight of bottles

unit size empty weight of bottles (x3 pounds per bottle) = total weight full

150 213lbs 144 432lbs 645lbs

Mignonne 200lbs 220 660lbs 860lbs

320 237lbs 288 864lbs 1101lbs

500 298lbs 440 1320lbs 1618lbs

550 369lbs 468 1404lbs 1773lbs

700 421lbs 572 1716lbs 2137lbs

Credenza 400lbs 252 756lbs 1156lbs

As you can see, the weight load on the flooring can be significant. Be sure the area is sturdy

enough to handle this weight.

TABLE 1. WEIGHT LOAD FACTORS

Designating the proper location for your unit

is important. There are several consider-

ations which need to be made in order to

receive the best performance results from

your unit.

A. Weight factor.

You will need to take into account that the

weight of the unit fully loaded with wine can

be substantial. The chart above specifies the

approximate weights of the units empty and

filled with wine.

B. Ambient temperature factor.

The cooling system in the cabinet has the

ability to cool a maximum of 30°F below the

ambient temperature in the room. Therefore

you want to place the unit in a room which

will not exceed 85°F. Otherwise the unit will

not have the capacity to keep the wine at a

desirable 55°F.

On the other hand, you want to make sure

the temperature in the room does not fall

much below 55°F. The unit only has the

capacity to cool the wine inside and cannot

exceed the ambient temperature of the

room. In addition, the unit is designed only to

cool to a minimum temperature of 50°F.

C. Ventilation factor.

Ventilation is an important factor to consider

when choosing the correct location. The

compressor motor will give off heat, which

will need to dissipate away from the unit. If

the unit is located within a restricted area

and ventilation is not available, then the

ambient temperature of the room will

increase and thus will prevent the unit from

cooling adequately. Be sure to find a location

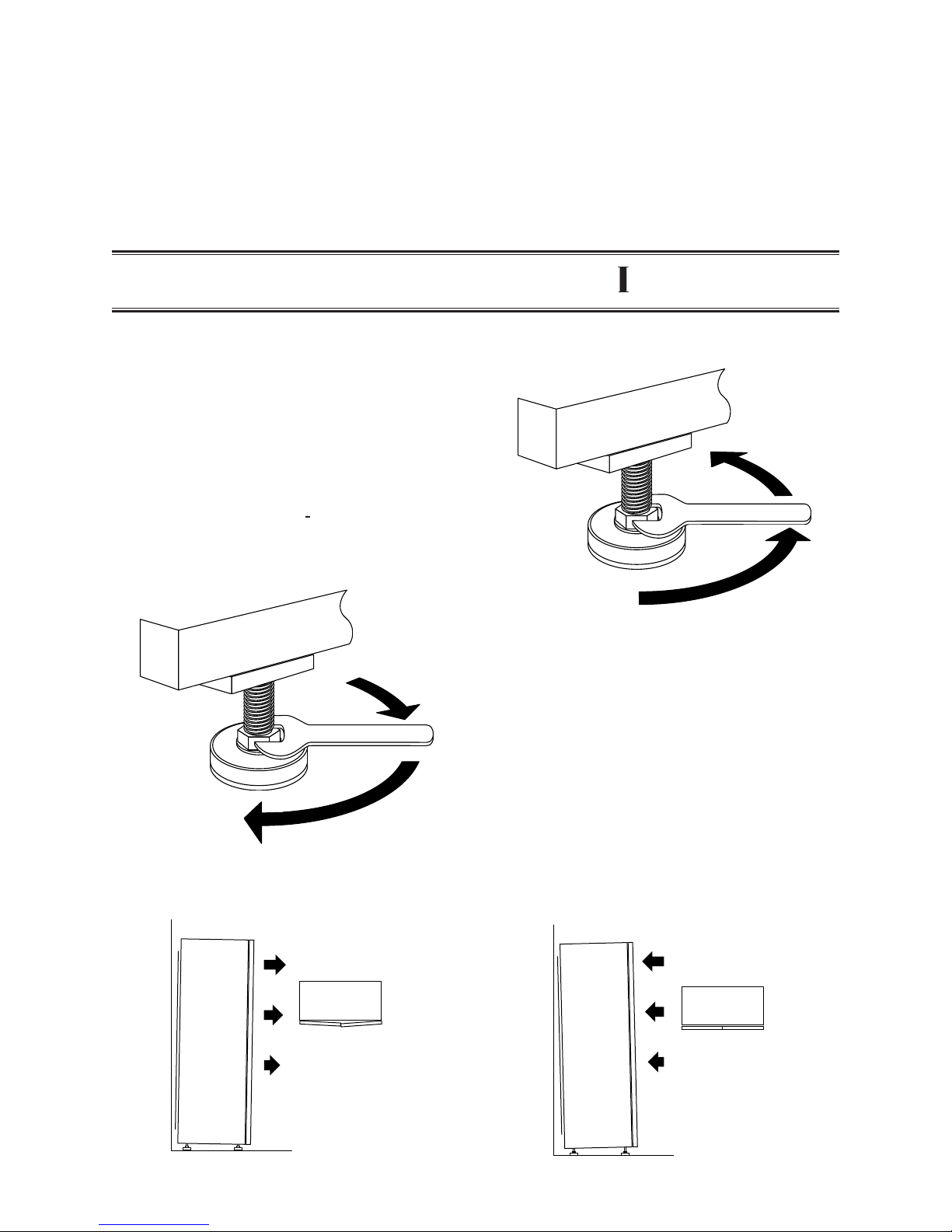

with good ventilation. The rear of the unit

should be placed approximately 2 inches

away from the corresponding wall. In

addition, there should be approximately 12

inches of clearance above the top of the unit

and 6 inches on each side. This will assure

adequate dissipation of heat.

D. Noise factor.

At Vinothèque, we believe that our QT

system is the quietest refrigeration system

available in a wine storage cabinet. How-

ever, these units are motor driven and do

produce a nominal amount of noise while the

compressor and temperature equalizer fans

are in operation. The noise is comparable to

the noise of a refrigerator when it is running.

The unit will run continually during the

initial cool down period when the wine has

first been introduced to the cabinet. After

that time, the unit will run as needed in

order to maintain relative humidity and

precise temperature tolerances. The amount

of time the unit will need to run is based on

the ambient temperature of the room. Front

venting and WhisperKools are louder due to

design.

If the unit is placed on a hard surface such

as tile or hardwood floors, it is recom-

mended that you consider installing a small

piece of carpeting underneath the unit to

prevent the unit’s operating noise from

echoing against the hard surface.

E. Humidity control.

The cabinets are designed to maintain