vision microsystems VM 1000 User manual

lvuzvtEi t trN MttrFtoSYslTEMs ;tNtr.

ADVANCED ELECTRONIC INSTRUMENTATION

PURCHASER I USER AGREEMENT

The purchaser and/or user,'by accepting this equiprnent, agrees to

hold VISION MICROSYSTEMS INCORPORATED, its ownersi

assigns, heirs and employees, free and harmless from all loss,

liability or damage resulting from claims brought by ally, reason of,

alleged failure or defect of any parts supplied by ,.

VISION MICROSYSTEMS INCORPORATED.

VISION MICROSYSTEMS INCORPORATED hAs made every efforl

todocumentthisproductaGcUratelyemctirnptaety.Howeve;,.

VISION MICROSYSTEMS INCORPORATED assurnes no{iability for

errors or for damages that result from the use of this manual or Ih "q

equipment it accompanies.

VISION MICROSYSTEMS INCORPORATED reserves the rl$ht to

make changes to this manual and the product at any time without

notice.

iffiTii TO RECEIVE WARRANTEE COVERAGE I*****t

FILL OUT AND RETURN THE WARRANTEE AGREEMENT.

VISION MICROSYSTEMS INCORPORATED

4071 Hannegan Suite T

BELLINGHAM, WASHINGTON 98226

PHONE (360\ 714-8203 FAX (360) 714-8253

VISION MICROSYSTEMS INCORPORATED

(c) l ees

All rights reserved

VM IO{IO OWNERS MAN[IAL'

(t4 - -t*"t\ U*\

5010002 REV F

TABLE OF CONTENTS

\__i.0 Dpu, swTcH, DtspLAy CABLE |NSTALLATION..............7

1.0.1 DPU MOUNTTNG .....................r.7

1.0.2 DpU WtRtNG..... ........................7'

1.0.3 INDICATOR MOUNTING & WIRING

1.0.4 DTSPLAY CABLE FABR|CAT|ON............ .......................8

1.0.5 MODE SWTTCH |NST.......... .....9.

1.1 TACHOMETER SYSTEM INSTALLATION .........10

1.1.1 TACH XDUCER |NST.......... ...10

\-. 1.1.2 TACHOMETER TRANSDUCER WtRtNG .....................10

1.2 MANIFOLD PRESSURE SYSTEM INSTALLATION ........... 11

1.2.1 MANTFOLD PRES. TRANSDUCER |NST.... .................11

1.2.2 MANIFOLD PRES. TRANSDUCER WIRING ................11

1.3 otL SYSTEM TNSTALLATTON ............12

1.3.1 OIL TEMPERATURE TRANSDUCER INST.......... .......12

1.3.2 olL PRESSURE TRANSDUGER |NST..... ....................12:

1.3.3 otl SYSTEM WtRtNG. ............12

5rlil)002 REv FVMTI}IIO OWNERS MANUAL

TABLE OF CONTENTS

.1.4 FUEL COMPUTER SYSTEM INSTALLATION ....13

"* 1..4.1 FUEL FLow TRANsDUcER rNsr. .........:.. 1g ,--

' ' 1.4.1 FUEL PRES. TRANSDUCER INST. (P/N 3010016, 171...................14

''-'r'.3.3 FUELcoMpurERxDucERWtRtNG ............,...;.........14

,.

1:s cvtrNDER ANALvZER tNsrALLATtoN ............15

il

"'1.5.1 CYLINDER HEAD TEMP PROBE INST. .....15

-1.5.2 EXHAUST GAS TEMP PROBE |NST.......... ..................15

r l.'

- 1.5.3 CYLINDER HEAD PROBE WIRING ............16

.*:*.s.n EXHAUST GAS PROBE WIRING ...............17

rF, .' j

lHe' elecrRtcAl sysrEM tNsrALLATloN ............................ 1 8 -

*t.e.t ELEcTRTcAL sysrEM tNsr.......... ........... 18

!.

'"*.r.6.2 VoLTAGE sENsE wrRE tNsr.......... .........18

^.':

t'i.6.3 AMp TRANsDUcER INST.......... ................ i8

.f:t,0.4 ELECTRICAL SYSTEM WIRING ..............,.18

iSrf..AlR TEMP SYSTEM INSTALLATION....'.. ...........19

,.7.7.1AlRTEMPlNDlcAToRlNsT.(P/N40100t0)

d'*1.7.2 O.A.T. TRANSDUCER INST. (P/N 30100201...................................19

'st.7.g c.A.T. TRANsDUcER rNsr. (p/N 30100201............... ..19 --

Stlt{Xt02 REv F

!.: VM II}I}II OWNERS MANUAL

TABLE OF CONTENTS : ,: i.

1.8 CHRONOMETER SYSTEM TNSTALLATTON :.::.,20

\--, 1.8.1 CHRONOMETER |ND|CATOR |NST.......... .............,:._ 20

1.8.2 CHRONOMETER MODE SWTTCH |NST.......... ........." 20

1.9 EClOO INSTALLATION ,_i

1.9.1 ECl00 |ND|CATOR NSTALLAT|ON......... ..........:.,,21

1.9.2 ECl00 TO DpU CONNECT|ON............. .......................21

:

1.9.3 EC100 WtRtNG .........,.............21

.i; a:.

1.10 FUEL LEVEL SYSTEM lNSTALLATlON.......rrr-r.r-rrirri .*"i22

1.10.1 FUEL LEVEL SYSTEM INDICATOR INST..........

\, LEVEL SYSTEM |ND|CATOR tNST.........................,.:lE:..8,ff

1.10.2 FUEL LEVEL MOUNTING KIT !NST.... .....................:.22

.l

1.10.3 FUEL PROBE |NST......... .................::.=s..,2;4

1.10.410 BOARD WtRtNG..... ...,.::,r.rZS

2.1 tNtTtAL SYSTEM SET-UP.:.............. ..............;,;;,27

2.2 TACHOMETER OPERAT!ON.......... ....2$

;.\ t,.

2.3 MANTFOLD PRESSURE OPERAT|ON....... .........29

l.;

.*-2.4 OIL SYSTEM OPERATION ....."....,....,.30

5010002 REV FVMTOOO OWNERS MANUAL

't'A Bt,E Otr coN'l'liN'l's

2.5 FUEL COMPUTER SYSTEM OPERATION ,........32

2.5.1 INITIAL SET UP OF THE FUEL COMPUTER ...............3:\_/

..2.5.2 ADDTNG FUEL TO THE FUEL COMPUTER .................34

2.5.3 FUEL COMPUTER NORMAL OPERATION MODES...................... 35

2.6 CYLINDER ANALYZER SYSTEM OPERATION ..,..............36

2.6.1 LEANING YOUR ENGINE:.... ......................37

2.7 ELECTRICAL MONITORING SYSTEM OPERATION.........38

ZS AIR TEMPERATURE SYSTEM OPERATION......................39

{i

4P CHRONOMETER OPERArION.......... .................4c

"2.9.1 CHRONOMETER SET UP ........41

':2.9.2 CHRONOMETER NORMAL OPERATION:.............. .....43

, 2.9.3 STOP WATCH OPERAT1ON................ .......44

2.10 ECl00 oPERATION ...............,.......... ................45

:::'

2.11 FUEL LEVEL SYSTEM OPERATION.......... ......46

; ""t

2.11.1 FUEL LEVEL SYSTEM CAL|BRATION............ .......... 46

2.12 'AUTOTRACK'TM SVSTEM OPERATION ......48

2.13 FLIGHT DATA RECORDER SYSTEM OPERATION ........50

5t) ilt002 REv FVM II)I}II OWNERS MANUAI,

\_/

TABLE OF CONTENTS ,.i

3.1 INDICATOR CARE AND MAINTENANCE...... .....51

5010002 REV F VMIOOO OWNERS MANUAL

ii.

SECTION I INSTALLATION 7

1.0 DPU, SWITCH, DISPLAY CABLE INSTALLATION

1.0.1 DPU MOUNTING

The unit should not be mounted in the engine compartment, but

v installation and removal. NOTE: lf you have a'Fuel Level System'

you may want to calibrate it before mounting the DPU. (See section

on FUEL LEVEL SYSTEM OPERATION.)

1.0.2 DPU WIRING

All power, ground and transducer wires (except fuel level transducers

connect) to the DPU terminal blocks. See each respective

installation section for conneclions.

= DO NOT: connect J4-16 to the same aircraft circuit breaker as

J4-1 5.

- DO NOT: allow wire insulation or foreign objects into the

position being connected to.

- DO NOT: over tighten the set screw onto the wire. lnstead,

the wire needs to be securely held, but not crushed to the

point of separation. Test the wire for security after tightening.

The use of a 'Jewelers Screwdrive/ will provide enough

\--l torque for the job.

3 DO NOT: allow bare wires touch the metal case or adjacent

leads.

= DO NOT: bend the wires where they exit the terminal block

position, instead, form a radius away from the terminal block

position.

::) DO NOT: allow static electricity to contact any terminal.

Always discharge yourself to ground first !

DPU 'J4'TO POWER CONNECTIONS (Use 16 AWG wire)

All other DPU connections are described in each system installation

section.

50t0002 REv FVMI(}OO OWNERS MANUAL

DPU

TERM. WIRE

COLOR CONNECT

TO DESCRIPTION

J4-14 BLK GND BUS ACFT GROUND BUS

J4-15 RED 5 AMP BRKR ACFT POWER DIST SYSTEM

J4-16 WHT LITE CNTRL ACFT PANEL DIMMER SYSTEM

CASE BLK GND BUS ACFT GROUND BUS

SECTION I INSTAI,[,A'T'ION

1.0.3 INDICATOR MOUNTING & WIRING

The indicator is mounted to the panel from the back side. Four

mounting screws are provided for this purpose. Do not use longer

screws or damage to the instrument will result. The supplied screws

will accommodate panel thicknesses from 0.062 to 0.050 inches. lf a

panel thickness of other than this is required, then determine the

difference in thickness and procure new screw length accordingly.

Test your new screw lengths by finger tightening them into the panel

and indicator. The screws should tighten against the panel only and

should not 'bottom out' in the indicator. Be careful not to cross thread

the screws or the indicator bezel will be permanently damaged. The

indicator cut-out and mounting space requirement's information is

provided in 'SECTION 5 ILLUSTRATIONS'.

To wire indicators to DPU simply plug any display cable connector

into the back of the indicator observing the keying tab to notch.

1.0.4 DISPLAY CABLE FABRICATION

(P/N 401000s)

STEP 1: Carefully move the connectors into the positions required on

the flat. ribbon cable for your panel layout. They may face

either up or down. Look for the small embossed arrowhead on

the cable connectors that points to an edge of the cable.

MAKE SURE ALL CONNECTOR ARROWHEADS POINT TO

THE SAME EDGE OF THE CABLE AS THE INSTALLED DPU

CABLE CONNECTOR I

STEP 2: The connector is secured to the ribbon cable by closing it in

clean smooth jaws of a vise until ine sides 'snap over' into

position. Make sure the cable connector is SQUARE TO THE

CABLE before any closing takes place. Once installed,

connectors and cable cannot be re-used !

STEP 3: Once all connectors are installed, trim any excess cable

away by using a new SHARP pair of scissors. lnspect the cut

to insure that adjacent wires are not touching each other.

INSURE that once installed, the trimmed ends of the cable do not

touch anything.

50lr)002 REv FVM IIIIIII OWNERS MANUAL

SECTION I INSTALLATION

1.0.5 MODE SWITCH INST.

(P/N 3010023)

The mode selector switch assembly can be mounted anywhere within

reach of the indicator connector.

STEP 1: Once the switch hole has been located and drilled, remove

the paper backing and vinyl front covering from the switch

plate. The switch plate has an adhesive backing to aid in

placement of the plate. Press the plate into position.

STEP 2: Rotate the switch shaft as far counter-clockwise as it will

travel (as viewed facing the shaft). The switch comes with the

lock washer and nut loosely installed. When removing the nut,

DO NOT remove the silver ring underneath. lf you have

accidentally moved the silver ring, it should be placed back

onto the switch with the tab inserted into the hole between

switch position numbers '9' and '10'. This tab acts as a stop to

only allow 9 possible switch positions.

STEP 3: lnsert the switch assembly (switch, silver ring and lock

washer) through the back of the panel. Place the nut on the

switch and finger tighten. Place the knob over the shaft such

that one of the two set screws is perpendicular to the 'flat' on

the shaft. Tighten this set screw. Now rotate the entire switch

assembly until the slotted line on the knob is aligned with the

left lower white line on the switch plate.

STEP 4: lf necessary, carefully remove the knob without disturbing

the current switch assembly location. Now CAREFULLY

tighten the nut (too much force will break the switch) . lf

necessary, reinstall the knob as before and tighten both set

screws. Verify correct alignment with all switch plate positions.

Plug the switch assembly connector into the small connector

on the appropriate indicator.

5010002 REv FVMIOOO OWNERS MANUAL

IO SECTION I INSTAL,I,ATION

1.1 TACHOMETER SYSTEM INSTALLATION

1.1 .1 TACH XDUCER INST.

(P/N 3010004 BENDIX, 3010005 SLICK)

The transducer is screwed into the 'magnet vent port' nearest the

magneto mounting flange, where the magneto attaches to engine. Do

not mistake the 'rotor vent port' nearest the spark plug harness

assembly for it.

lf possible, install xducer to the non impulse coupled magneto. See

engine manual for correct location.

Once properly identified, remove the existing vent plug and screw the

sensor in its place, then tighten.

lf you are connecting to an Electronic lgnition, only connect the

manufacturers 'tach signal output' to J4 -12 and install blocking diode

(such as 1 N914) in series with cathode (bar) going to ignition side.

*** CAUTION*** Always discharge yourself to ground before wiring,

1.1 .2 TACHOMETER TRANSDUCER WIRING

DPU

TERM. CABLE

COLOR XDUCER

WIRE XDUCER

DESCR. XDUCER

PART NO.

J4-10 BLK BLK .RPM XDCR 301 0004 / 5

J4-11 RED RED 3t |t

J4-12 WHT WHT It

NOTE: Connect cable bare shield wire to cable BLK wire at DPU and

snip off shield wire excess at sensor end.

5t)il)t)02 REV F VMll)tlll OWNERS MANUAL

SECTION I INSTALLATION

1.2 MANIFOLD PRESSURE SYSTEM INSTALLATION

1.2.1 MANIFOLD PRES. TRANSDUCER INST.

(P/N 3010015)

The transducer is mounted in the cabin area. The mounting block is

tapped with 10-32 UNF-28 threads for mounting. The pressure port

snubber (hex brass part) is tapped 1/4 NPT for plumbing.You will

typically procure and install a reducer (114 NPT male to 1/8 NPT

female) into the snubber, then plumb 1/8 hose to the manifold

pressure pick off port of the engine. NOTE: The snubber is shipped

loose with the manifold sensor assembly and MUST be final installed

with an aircraft fuel resistant pipe thread sealant I adhesive.

The transducer pressure port is connected to the engine manifold

pressure port via a fabricated hose and fitting assembly. See engine

manual for this location.

= DO NOT: remove or drill snubber inner silver filter

- DO NOT: mount the transducer near extremely hot areas such

as heater ducts, etc.

= DO NOT: mount the transducer where fluids may contact it

during operation or maintenance.

+ DO NOT: mount the transducer in the engine compartment.

=) DO NOT: mount the transducer lower than the engine manifold

access port, or accumulated fuel in the hose will not run back

into the engine.

= DO NOT: solder onto terminal lugs of the transducer.

*"*CAUTION*** Always discharge yourself to ground before wiring.

1.2.2 MANIFOLD PRES. TRANSDUCER WIRING

DPU

TERM. CABLE

COLOR XDUCER

WIRE XDUCER

DESCR. XDUCER

PART NO.

J3-9 WHT WHT MAN PRES 301 001 5

J3-10 GRN GRN

J3-11 RED RED al aa

J3-12 BLK BLK 3t l3

NOTE: Connect cable bare shield wire to cable BLK wire at DPU and

snip off shield wire excess at sensor end.

5010002 REv FVMIOOO OWNERS MANUAL

ll

I2 SECTION t INSTALI,ATION

1.3 OIL SYSTEM INSTALLATION

I.3.1 OIL TEMPERATURE TRANSDUCER INST.

(P/N 3010021)

The transducer is mounted on the engine and is designed for

mounting according to MS28034-1. Consult your engine manual for

the proper installation location. A gasket is supplied for use with the

temperature transducer. This gasket is designed to be used only

once.

1.3.2 OIL PRESSURE TRANSDUCER INST.

(P/N 3010018)

= Do NOT: MOUNT TRANSDUCER DIRECTLY ON ENGINE.

:) DO NOT: mount the transducer where fluids may contact it

during operation or maintenance.

:) DO NOT: solder onto terminal lugs of the transducer.

Mount the transducer in cabin or engine area using the provided

'Adelt' clamp to a STATIONARY location then safety wire it to the

clamp. Connect using the appropriate aircraft grade hose and fittings.

The transducer has a 1/8 NPT externalthread to accommodate many

plumbing options. BE CAREFUL not to dent or deform the transducer

in any way or improper operation will result. Do not block the tiny -\-./

vent hole centered on the back of the transducer between the

lerminals. Use only aircraft grade fittings and hoses. Refer to your

engine manual for the proper oil pressure connection port location.

"*" CAUTION**" Always discharge yourself to ground before wiring.

1.3.3 OIL SYSTEM WIRING

DPU

TERM. CABLE

COLOR XDUCER

PIN / WIRE .XDUCER

DESCR. XDUCER

PART NO.

J4-1 RED RED OIL TEMP 301 0021

J4-2 BLK BLK 3a

J3-1 WHT PIN 1OIL PRES 301 001 I

J3-2 GRN PIN 3t3 c

J3-3 RED PIN 4a3 $

J3-4 BLK PIN 233 33

NOTE: Connect cable bare shield wire to cable BLK wire at DPU and

snip off shield wire excess at sensor end.

s010002 REv F VMl0ll0 OWNERS MANUAL

\J

SECTION I INSTALLATION 13

1.4 FUEL COMPUTER SYSTEM INSTALLATION

1.4.1 FUEL FLOW TRANSDUCER INST.

(P/N 3010019, 32)

The inlet and outlet of the transducer are tapped with 1/4 inch

internal NPT. Use only aircraft grade hoses and fittings when

adapting to the 1/4 NPT. Wrap the transducer with a heat barrier

material such as 'FIRE SLEEVE'. The transducer should be mounted

where only filtered, clean fuel flows through it and on the enqine

pressurized sidg of the fuel svstelrn. The primary considerations

for mounting are:

=) DO NOT: mount the transducer where 'upstream turbulence'

exists (such as sharp bends or any disturbances in the fuel

line). A minimum straight run of 5 inches of inlet fuel line is

recommended after these types of disturbances to settle fuel

flow.

::) DO NOT: ground the flow transducer body to any part of the

engine or aircraft if possible, os this forms a'ground loop'path

through the grounded body of the transducer and may affect

the transducer signal. lf this cannot be complied with then

INSURE that the engine is EXTREMELY well grounded to the

same point as the DPU. Proper engine grounding is facilitated

by the use of a common ground BUS bar and heavy gauge (H

or lower AWG) wire. See your aircraft manual.

ORIENTATION

TRANSDUCER P/N 3010019 (CARBURETED) the transducer is

mounted with the arow on the side pointing straight UP and

also with the fuel flow in the proper direction (lN to OUT).

TRANSDUCER P/N 3010032 (INJECTED) mount the transducer

so that the three WIRE LEADS exit the transducer straight UP

and also with the fuel flow in the proper direction (lN to OUT).

The transducer is mounted 'in-line' between the fuel flow

controller and the flow divider and away from extreme heat.

50t0002 REv FVMIOOO OWNERS MANUAL

14 SECTION I INS'I'ALLA'I'ION

1.4.1 FUEL PRES. TRANSDUCER INST. (P/N 3010016,171

The transducer is mounted in the cabin area or engine compartment,

at your option.

+ DO NOT: MOUNT TRANSDUCER DIRECTLY ON ENGINE.

- DO NOT: mount lhe transducer where fluids may contact it

during operation or maintenance.

=) DO NOT: solder onto terminal lugs of the transducer.

Mount the transducer using the provided 'Adell' clamp to a

STATIONARY location then safety wire it to the clamp. Connect

using the appropriate aircraft grade hose and fittings. The transducer

has a 1/8 NPT externalthread to accommodate many plumbing

options. BE CAREFUL not to dent or deform the transducer in any

way or improper operation will result. Do not block the tiny vent hole

centered on the back of the transducer between the terminals.

FOR CARBURETED ENGINES, the fuel pressure should be

measured near the carburetor inlet.

FOR INJECTED ENGINES, the fuel pressure is measured at lhe fuel

inlet to the fuel controller assembly ( NOT at the fuel flow divider)

The iransducer has a 1/8 NPT external pipe thread to accommodate

many plumbing options. Use only a'ircraft grade fittings and hoses

and proper techniques.

'** CAUTION*** Always discharge yourself to ground before wiring'

1.3.3 FUEL COMPUTER XDUCER WIRING

DPU

TERM. CABLE

COLOR XDUCER

PIN / WIRE XDUCER

DESCR. XDUCER

PART NO.

J4-7 BLK BLK FUEL FLOW 301 0032

J4-8 RED RED ta

J4-9 WHT WHT $3a

J3-5 WHT PIN 1FUEL PRES 301 001 7

J3-6 GRN PIN 3a3 3l

J3-7 RED PIN 4tt ta

J3-8 BLK PIN 2aa al

NOTE: Connect cable bare shield wire to cable BLK wire at DPU and

snip off shield wire excess at sensor end.

5I}III(IO2 REV F VMIOOI} OWNERS MANUAL

\/

SECTION I INSTALLATION l5

1.5 CYLINDER ANALYZER INSTALLATION

1.5.1 CYLINDER HEAD TEMP PROBE INST.

(PlN 1020061)

lnstall the probe assemblies in the tapped holes located on the

underside of the cylinders. The threads in the holes may require

cleaning. Proceed carefully to prevent damaging the threads.

Route wires away from exhaust stacks and other heat sources with

enough slack to allow for engine vibration, etc. Do not route the leads

creating stress where they exit the probe. A gradual radius away from

the spring is best.

1.5.2 EXHAUST GAS TEMP PROBE INST.

(P/N 1020060)

Drill an adequate access hole, for the probe tip, in the exhaust pipe,

at a location 3.5 to 4 inches (if possible) down from the exhaust pipe

flange, such that the lead wires will exit the probe smoothly without

creating sharp bends, while remaining away from exhaust stacks and

other heat sources. Angle the probe assembly inward and toward the

back of the engine allowing the leads to be secured as they travel

back along the side of the engine oil sump.

lnstall the probe by opening the clamp ring and placing the probe into

the exhaust pipe drilled hole. Close and tighten the clamp ring using

a screwdriver. Do not over tighten clamp or clamp failure may

eventually occur. Make sure the clamp is not crooked on the exhaust

pipe or it will loosen up during flight.

Secure the wires along their paths to the DPU, to prevent vibration

and abrasion with enough slack to allow for engine vibration, etc.

Route wires away from exhaust stacks and other high heat sources.

Do not route the leads creating stress where they exit the probe. A

gradual radius away from the spring is best.

Use standard aircraft wiring techniques and materials.

50111002 REv FVMIOI}O OWNERS MANUAL

I6 SECTION I INSTAI,I,A'TION

1.5.3 CYLINDER HEAD PROBE WIRING

Utilizing the white and red color coded thermocouple extension wire

and terminals (contained in kit 30100021 31, connect probes at DPU

J1 connector as follows:

*** CAUTION*** Always discharge yourself to ground before wiring.

NOTE: Probe shorter lead is RED, and the longer is WHITE'

DPU

TERM. CABLE

COLOR XDUCER

WIRE XDUCER

DESCR. XDUCER

PART NO.

{t:1-

J1-2 Wil

RED wr[_

RED qul-1EB9qE._ 10_29q61

lt

J1-3 WHT WHT CHT 2 PROBE 1 020061

J1-4 RED RED ll 3a

{J:s-

J1-6 Wil

RED wr[_

RED 9Ut9 EB9qE -10?9q6J

3a

J1-7 WHT WHT CHT 4 PROBE 1 020061

J1-8 RED RED 3a tl

J1-9 WHT WHT CHT 5 PROBE 1 02006 1

-Jr:r o -RED RED

J1-1 1WHT WHT CHT 6 PROBE 1 020061

J1-12 RED RED

NOTE: For4 cyl engines, jumperJl-9 to J1-10 and J1-11 to J1-12.

SIIIO(IO2 REV F . VMI(}I}II OWNERS MANUAL

SECTION I INSTALLATION 17

1.5.4 EXHAUST GAS PROBE WIRING

Utilizing the yellow and red color coded thermocouple extension wire

\---, and terminals (contained in kit 3010002 / 3), connect probes at the

DPU J2 connector as follows:

*** CAUTION*** Always discharge yourself to ground before wiring.

NOTE: Probe shorter lead is YELLOW, and longer RED.

J-'..--,,

NOTE: For4 cyl engines, jumper J2-9to J2-1 0 and J2-11 lo J2-12.

5010002 Rf,v FVMIOOO OWNERS MANUAL

DPU

TERM. CABLE

COLOR XDUCER

WIRE XDUCER

DESCR. XDUCER

PART NO.

J2-1 YEL YEL EGT 1 PROBE 1 020060

J2-2 RED RED 3t $

J2-3 YEL YEL EGT 2 PROBE 1 020060

J2-4 RED RED

J2-5 YEL YEL EGT 3 PROBE 1 020060

J2-6 RED RED $

J2-7 YEL YEL EGT 4 PROBE 1 020060

J2-8 RED RED aa

J2-9 YEL YEL EGT 5 PROBE 1 020060

J2-10 RED RED at

J2-11 YEL YEL EGT 6 PROBE 1 020060

J2-12 RED RED al

I8 SECTION I TNSTAI,I,A-TION

1,6 ELECTRICAL SYSTEM INSTALLATION

1.6.1 ELECTRICAL SYSTEM INST.

Follow the instructions below to install the volt and amp functions.

1.6.2 VOLTAGE SENSE WIRE INST.

The sense wire can be connected directly to the main bus, the

avionics bus, or any other point for voltage measurement, as long as

the voltage does not exceed +36 VDC.

1.6.3 AMP TRANSDUCER INST.

(P/N 3010022)

The amp system functions as an'alternator load meter'displaying

current flow FROM the alternator TO the aircraft electrical system

allowing you to see if a load (such as pitot heat) is really drawing

current.when turned on. The transducer is mounted in the cabin area.

Route the wire connecting the alternator output (usually marked

'BAT') through the transducer so that it EXITS ON THE

TRANSDUCERS BLACK PLASTIC SIDE then continues ultimately to

the breaker / main bus. lf properly installed, the AMPS readout will

increase as more electrical loads are turned on and the alternator is

active. Shielded alternator wire is OK.

1.6.4 ELECTRICAL SYSTEM WIRING

DPU

TERM. CABLE

COLOR XDUCER

WIRE COLOR XDUCER

DESCR. XDUCER

PART NO.

J4-13 RED N/A (ACFT +BUS) N/A

J3-13 GRN GRN AMP XDUCER 301 0022

J3-14 WHT WHT a3

J3-15 RED RED

J3-16 BLK BLK ll at

NOTE: Connect cable bare shield wire to cable BLK wire at DPU and

snip off shield wire excess at sensor end.

5OT(IOO2 REV F VMIOI}O OWNERS MANUAL

SECTION I INSTALLATION I9

I.7 AIR TEMP SYSTEM INSTALLATION

1.7.1 ArR TEMP INDICATOR INST. (P/N 4010010)

\r' The indicator is simply installed by following instructions in section

titled DPU, INDICATOR and MODE SWITCH installation.

1.7.2 O.A.T. TRANSDUCER INST. (P/N 3010020)

Mount the transducer in an area of outside air that is undisturbed and

not affected by engine or cabin heat. The transducer thread is 114-28

UNF-2A. Do not over tighten the transducer or damage will result.

1.7.3 C.A.T. TRANSDUCER INST. (P/N 30100201

The transducer is mounted in the forward side of the carburetor via

an access hole that is cast into the carb body (see SECTION 5

ILLUSTRATIONS). lf this hole is filled with a lead ball plug, it will

have to be removed, counter-bored and tapped. The transducer

thread size is 114-28 UNF-2A. Consult a licensed A&P mechanic for

this operation. lf it has a lhreaded plug, remove it. lnstall an internal

lock washer over the lransducer (not included) and insert the

transducer. lnsure that it turns completely into the threads and

\---l 'bottoms out'against the flat surface on the carburetor. Remove

again and apply a thread qealant with light locking properties on only

the last three threads nearest the hex head of the probe and re-

install. Do not over tighten the transducer or damage will result. We

recommend finger tightening the transducer, then carefully tightening

a max of 1/6 to 1/4 additionalturn.

***CAUTION*** Always discharge yourself to ground before wiring.

DPU

TERM. CABLE

COLOR XDUCER

WIRE XDUCER

FUNCTION XDUCER

PART NO.

J4-3 RED RED O.A.T 301 0020

J4-4 BLK BLK ll

J4-5 RED RED c.A.T. 301 0020

J4-6 BLK BLK lt

NOTE: Shield wire not connected

5010002 REv FVMIIIOO OWNERS MANUAL

20 SECTION I INSTALI",A-[ION

1.8 CHRONOMETER SYSTEM INSTALLATION

1.8.1 GHRONOMETER INDICATOR INST.

(P/N 401'001 1)

The indicator is simply installed by following instructions in section

titled DPU, INDICATOR and MODE SWITCH installation

1.8.2 CHRONOMETER MODE SWITCH INST.

(P/N 3010023)

See SECTION titled 'DPU, lndicator and Mode Switch installation'.

5OIIIOO2 REV F VMIOIIO OWNERS MANUAL

Other manuals for VM 1000

1

Popular GPS manuals by other brands

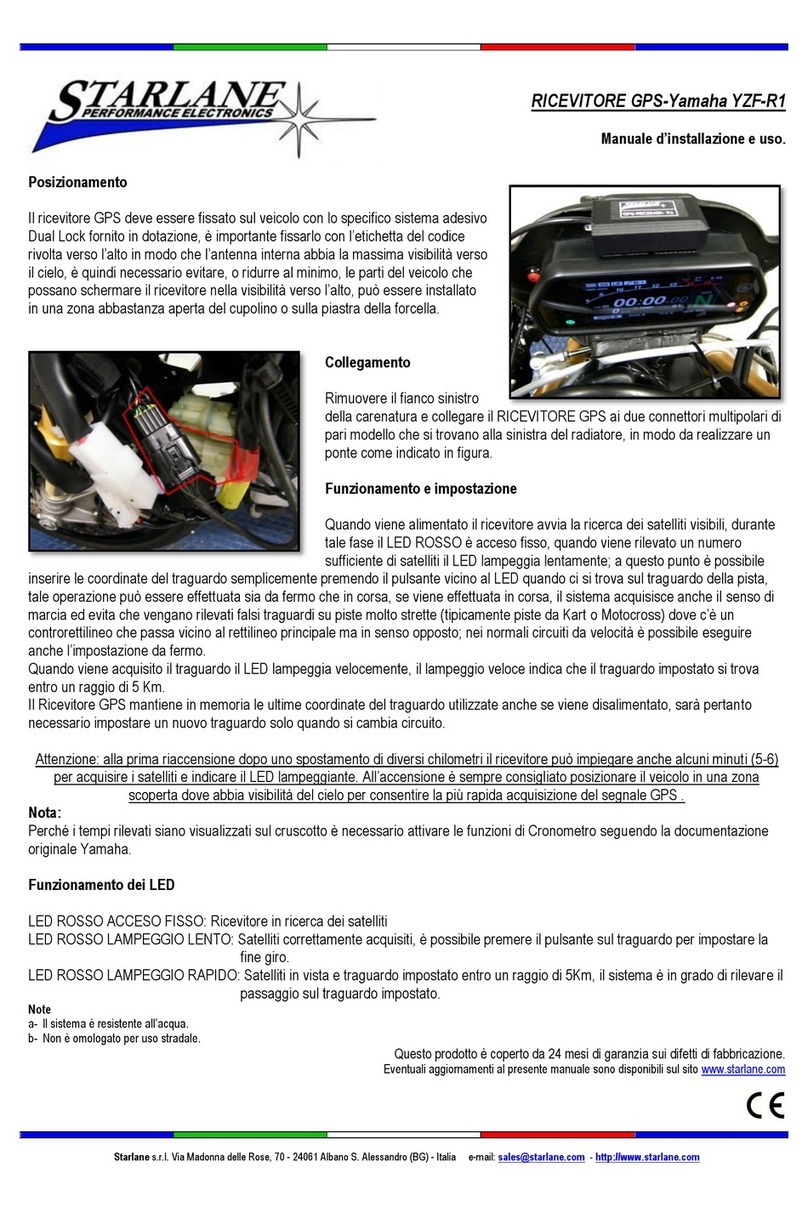

STARLANE

STARLANE Yamaha YZF-R1 Installation and instruction manual

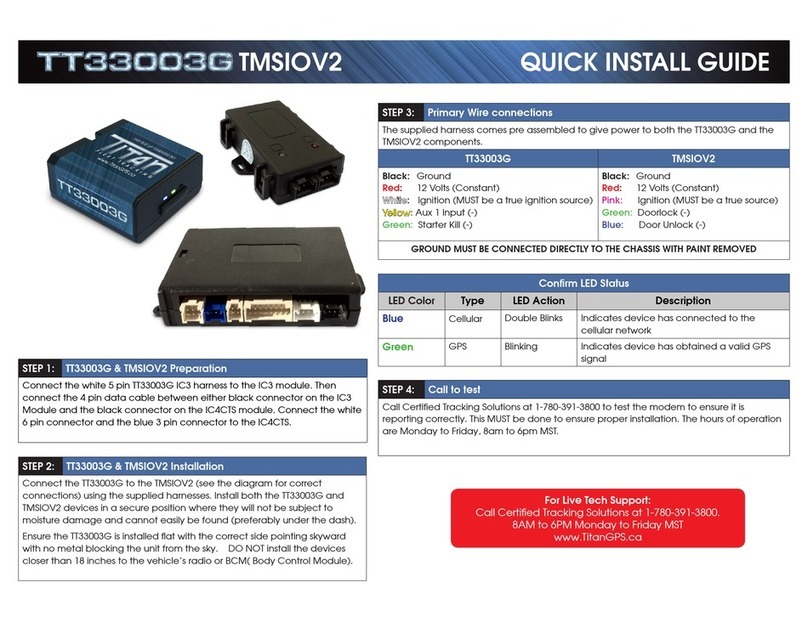

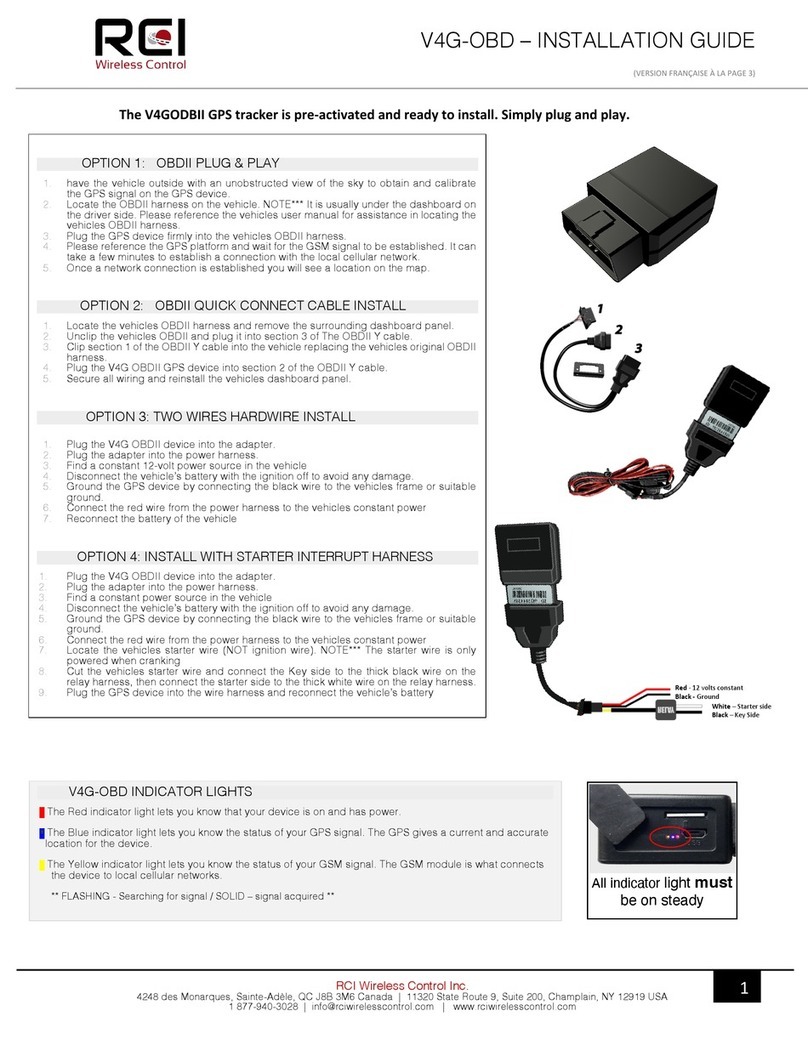

RCI

RCI V4G-OBD installation guide

PS Engineering

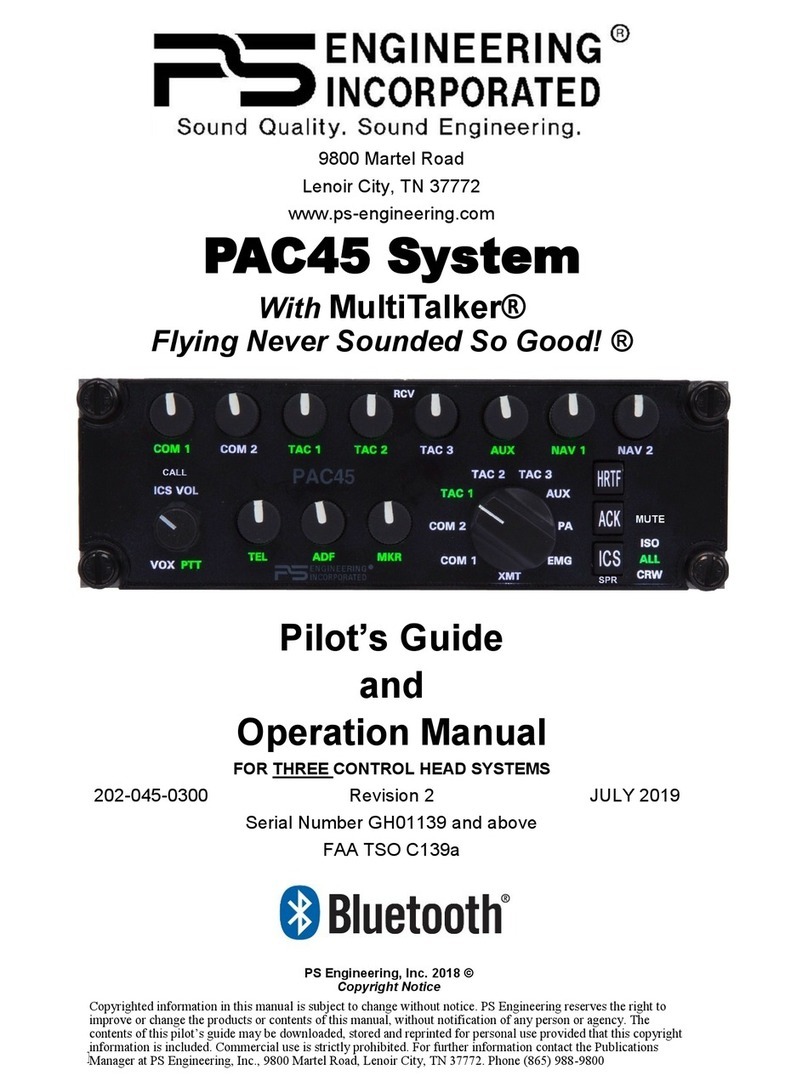

PS Engineering PAC45 System With MultiTalker Pilot's guide and operation manual

Arec

Arec TP-100 user manual

Queclink

Queclink GL501MG user manual

Haicom

Haicom REAL-TIME TRACKER HI-602 Operation manual