Vislink ADVENT DCU5000 User manual

TECHNICAL OPERATION HANDBOOK

for

The Document is supplied on the express terms that it is to be

treated as confidential and that it may not be copied, used or

disclosed to others for any purpose except as authorised by

Advent Communications

ADVENT COMMUNICATIONS

Preston Hill House

Nashleigh Hill

Chesham

Bucks HP5 3HE

England

Telephone: National 01494 774400

Fax: 01494 791127

24 Hour Support International +44 1494 810410

ADVENT DCU5000 DRIVE CONTROL UNIT

Advent Communications

209297 – DCU5000 Drive Control Unit Page 2 of 42

AMENDMENT RECORD SHEET

ISS DATE ECR PAGE DESCRIPTION

A 01/03/07 Initial release.

B 12/08/08 Correction to F20 alarm description.

Advent Communications

EMC DECLARATION

209297 – DCU5000 Drive Control Unit Page 3 of 42

Advent Communications

WARNINGS AND HAZARDS

Failure to operate and use the equipment other than instructed in the

manual may result in ELECTRIC SHOCK.

HAZARDOUS WARNING LABELS

Hazardous AC voltages present

NON-IONISING RADIATION

Possible source of radiation hazard, normally located

at waveguide connections, waveguide joints and

antennas.

CAUTION – HEAVY ITEMS

Some items of equipment may weigh in

excess of 25kg, do not attempt to move

or lift without assistance

CAUTION – MOVING PARTS

During operation of the antenna there

will be moving parts; do not touch

whilst in motion

209297 – DCU5000 Drive Control Unit Page 4 of 42

Advent Communications

209297 – DCU5000 Drive Control Unit Page 5 of 42

CONTENTS

AMENDMENT RECORD SHEET 2

EMC DECLARATION 3

WARNINGS AND HAZARDS 4

CONTENTS 5

1.INTRODUCTION 7

2.SPECIFICATION 8

2.1.PHYSICAL 8

2.2.ANGULAR POSITIONAL DISPLAY 8

2.3.ANGULAR CONTROL 8

3.REAR PANEL 9

3.1.AC POWER 9

3.2.ACU I/F 9

3.3.SENSORS 1 10

3.4.SENSORS 2 11

3.5.AZIMUTH, ELEVATION AND POLARISATION MOTOR CONNECTORS 12

4.FAULT CODES 13

4.1.FAULT NUMBER CODING 13

4.2.F1: DCU POWER SUPPLY VOLTAGE LOW 14

4.3.F2: DCU MOTOR SUPPLY FAILURE 14

4.4.F3: MOTOR DRIVE MODULE INHIBIT 14

4.5.F4: INCLINOMETER FAILED 14

4.6.F5: INCLINOMETER SUSPECT 14

4.7.F6: STALL DETECTED 14

4.8.F7: FREEWHEEL DETECTED 15

4.9.F8: END OF TRAVEL DETECTED 15

4.10.F9: TX POL SWITCH FAILED 15

4.11.F10: AZIMUTH STOW SENSOR FAILED 15

4.12.F11: ELEVATION STOW SENSOR FAILED 15

4.13.F12: POL STOW SENSOR FAILED 15

4.14.F13: EL DP SENSOR FAILED 15

4.15.F14: FA DP SENSOR FAILED 15

4.16.F15: EL STOWED SENSOR FAILED 15

4.17.F16: FPGA PROGRAMMING FAILED 16

4.18.F17: MANUAL BRAKE OVERRIDE ON 16

4.19.F18: AZIMUTH STOWING FAILED 16

4.20.F19: ELEVATION STOWING FAILED 16

4.21.F20: POL STOWING FAILED 16

4.22.F21: EL DP STOWING FAILED 16

4.23.F22: FA DP STOWING FAILED 16

4.24.F23: POWER UP STATE SUSPECT 16

4.25.F24: STOW SENSOR POWER FAILED 16

4.26.F25: MRD POWER FAILED 17

4.27.F26: INCLINOMETER POWER FAILED 17

4.28.F27: FPGA WATCHDOG TRIGGERED 17

4.29.F28: GPS COMMS. FAILURE 17

4.30.F29: COMPASS COMMS. FAILURE 17

4.31.F30: FEED DRIVE FAILURE 17

Advent Communications

209297 – DCU5000 Drive Control Unit Page 6 of 42

4.32.F31: HHC OVERIDE ACTIVE 17

4.33.F33: FIN 1 OVER TEMPERATURE 17

4.34.F34: FIN 2 OVER TEMPERATURE 17

4.35.F35: FIN 3 OVER TEMPERATURE 17

4.36.F36: FIN 4 OVER TEMPERATURE 17

4.37.F37: FIN 5 OVER TEMPERATURE 17

4.38.F38: WGS POWER SUPPLY ALARM 17

4.39.F39: FAN POWER SUPPLY ALARM 18

4.40.F40: BRAKE POWER SUPPLY ALARM 18

4.41.F41: FEED POWER SUPPLY ALARM 18

4.42.F42: GPS/COMPASS POWER SUPPLY ALARM 18

4.43.F43: STATUS POWER SUPPLY ALARM 18

4.44.F44: AZ BRAKE DISCONNECTED 18

4.45.F45: EL BRAKE DISCONNECTED 18

4.46.F46: POL BRAKE DISCONNECTED 18

4.47.F47: AXIS 4 BRAKE DISCONECTED 18

4.48.F48: AXIS 5 BRAKE DISCONNECTED 18

4.49.F49: MAIN UNIT FAN SERVICE 18

4.50.F50: HEATSINK FAN SERVICE 18

4.51.F51: E2PROM CHECKSUM ERROR 18

4.52.F52: SOFTLIMIT DATA ERROR 18

4.53.F53: WOODED AREA DATA ERROR 19

4.54.F54: CAL. AREA DATA ERROR 19

4.55.F55: FPGA COMPATIBILITY WARNING 19

4.56.F56: EXT FLASH ERROR 19

4.57.F58: HEATSINK FAN STALL DETECTED 19

4.58.F59: HMR3300 TEMPERATURE WARNING 19

4.59.F60: HMR3300 TEMPERATURE ALARM 19

4.60.F61-F64 ALARM ERROR 19

5.REMOTE CONTROL 20

5.1.INTRODUCTION 20

5.2.SET UP 20

5.3.PACKET STRUCTURE 20

5.4.COMMANDS, QUERIES AND RESPONSES 21

5.5.REMOTE COMMANDS 23

6.MAINTENANCE & FAULT FINDING 37

6.1.PERIODIC MAINTENANCE 37

6.2.ELECTROSTATIC SENSITIVE DEVICES (ESD!) 37

6.3.TEST/ALIGNMENT OF UNITS FITTED WITH AC/DC POWER SUPPLY 37

6.4.SATELLITE TRANSMISSION EQUIPMENT 37

7.WARRANTY 39

7.1.WARRANTY INFORMATION 39

7.2.CLAIM FOR DAMAGE IN SHIPMENT 39

7.3.FIELD SERVICE 39

7.4.SHIPMENT OF REPAIR PARTS TO FIELD 39

7.5.RETURN PROCEDURES 39

7.6.TRANSPORTATION AND PACKAGING 40

7.7.AUTHORISATION FOR EVALUATION 40

8.FIGURES 41

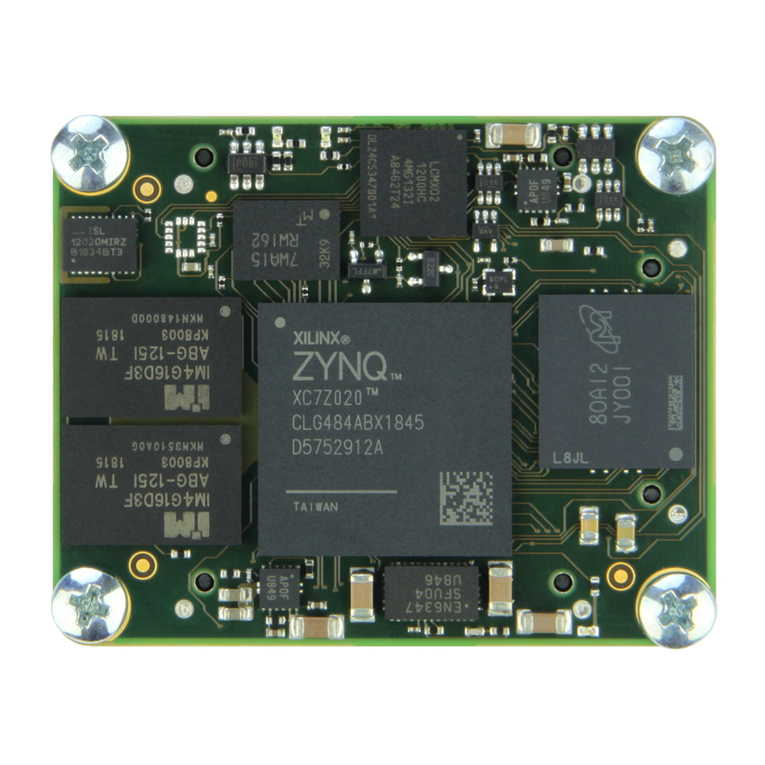

FIGURE 1 – DCU5000 LAYOUT 42

Advent Communications

209297 – DCU5000 Drive Control Unit Page 7 of 42

1. INTRODUCTION

The DCU5000 is a drive control unit designed to drive any of the current Advent range of

motorised antennas.

The unit is a 1U high, half width, 360mm deep chassis and is mains powered. (90-264V AC.

47-63 HZ. <100VA). The DCU5000 has a RS485 serial communications interface allowing the

unit to be controlled using a SatFinder, ACU4XXX, or ACU5XXX to implement the autoSearch

and autoTrack control of an antenna system.

Advent Communications

209297 – DCU5000 Drive Control Unit Page 8 of 42

2. SPECIFICATION

This section is for illustrative purposes only and does not form the basis for any contractual

obligation.

2.1. PHYSICAL

Dimensions Half width, 1U chassis x 360 mm deep.

Weight 2.0 kg approx.

Power Connector 3 Pin IEC plug with dual fusing

AC Supply 90-264V AC. (47-63Hz)

Consumption < 100VA

Temperature Range -20 to +50°C operating.

-40 to +80°C storage.

2.2. ANGULAR POSITIONAL DISPLAY

Azimuth ±0.1°

Elevation ±0.1°

Polarisation ±0.1°

2.3. ANGULAR CONTROL

The maximum angular rates are determined by the antenna type and version the

DCU5000 is controlling.

Advent Communications

3. REAR PANEL

!CAUTION: The side ventilation grills must be kept clear to allow adequate airflow

3.1. AC POWER

Power in the range 90 – 264Vac is connected by means of a 3 pin IEC connector at

the rear panel.

Live & Neutral conductor fusing is employed.

The two fuses integrated into the IEC connector should be ceramic at T6.3A rating

each.

The total power consumption is typically less than 100watts.

!NOTE:A separate EMC earth should be connected to the earth point provided.

3.2. ACU I/F

This is designed to directly connect to the serial communications cable from an Advent

SatFinder, ACU4XXX or ACU5XXX control unit.

Detailed descriptions are beyond the scope of this manual. Contact Advent

Communications for further guidance and information.

Connector: 15-pin female D-type.

Pin Number Signal description

1 RS485 RX-A.

9 RS485 RX-B.

2 RS485 TX-A.

10 RS485 TX-B.

3 GND

4 Stow Switch COM

11 Stow Switch NC

12 Stow Switch NO

13 TX Switch COM

5 TX Switch NO

6 TX Switch NC

7 Manual Brake Override Azimuth axis.

8 Manual Brake Override Elevation axis.

14 Manual Brake Override Polarisation axis.

15 GND

209297 – DCU5000 Drive Control Unit Page 9 of 42

Advent Communications

209297 – DCU5000 Drive Control Unit Page 10 of 42

3.3. SENSORS 1

This interface is designed to interface with any position, limit switches or sensors fitted

to the antenna.

Detailed descriptions are beyond the scope of this manual. Contact Advent

Communications for further guidance and information.

Connector: 25-pin male D-type.

Pin Number Sensor Signal description

1

Sensor 1 +12V DC supply.

2 Signal input.

14 GND

3

Sensor 2 +12V DC supply.

15 Signal input.

16 GND

4

Sensor 3 +12V DC supply.

5 Signal input.

17 GND

6

Sensor 4 +12V DC supply.

18 Signal input.

19 GND

7

Sensor 5 +12V DC supply.

8 Signal input.

20 GND

9

Sensor 6 +12V DC supply.

21 Signal input.

22 GND

12 TX Position

micro-switch NO

13 NC

25 Common

24 Stow Position

micro-switch NO

23 NC

11 Common

Advent Communications

209297 – DCU5000 Drive Control Unit Page 11 of 42

3.4. SENSORS 2

This interface is designed to interface with any antenna fitted compass, GPS,

inclinometer or waveguide switch.

Detailed descriptions are beyond the scope of this manual. Contact Advent

Communications for further guidance and information.

Connector: 25-pin female D-type.

Pin Number Sensor Signal description

1

Compass

RS232 – TX

2 RS232 – RX

3 Compass +12V DC power. (0.5A max.)

4 GND

5 GND

6

GPS

GPS +12V DC power. (0.5A max.)

7 RS232 – TX

8 RS232 – RX

9 GPS Enable

10 GND

14

Inclinometer

Trigger 1.

15 Trigger 2.

16 Delta Pulse Width.

17 Angle sign.

18 Pulse width 1.

19 +12V DC supply.

20 Pulse width 2.

21 GND

22 GND

23

Waveguide

Switch

Drive position 1.

11 Drive GND.

24 Drive position 2.

12 Monitor position 1.

25 Monitor GND.

13 Monitor position 2.

Advent Communications

209297 – DCU5000 Drive Control Unit Page 12 of 42

3.5. AZIMUTH, ELEVATION AND POLARISATION MOTOR CONNECTORS

This interface is designed to directly drive an Advent standard stepper motor drive.

These use 2-phase stepper motors with an MRD (motor rotation detector) PCB and an

optional brake.

Detailed descriptions are beyond the scope of this manual. Contact Advent

Communications for further guidance and information.

Connector: 15-pin male D-type.

Pin Number Signal description

1 Motor phase +A.

2 Motor phase -A.

9 Motor phase +A.

10 Motor phase -A.

3 Motor phase +B.

4 Motor phase -B.

11 Motor phase +B.

12 Motor phase -B.

5 Brake active pull down.

13 Brake supply (+12V DC)

6 MRD +5V DC supply.

7 MRD GND.

14 MRD signal.

15 MRD GND.

8 Motor presence detector

Advent Communications

209297 – DCU5000 Drive Control Unit Page 13 of 42

4. FAULT CODES

4.1. FAULT NUMBER CODING

DCU5000 Fault List

Fault Code Alarm Latched Brief Description

F1 9+12V power supply voltage low.

F2 9+36V DC motor supply failure.

F3 Motor drive module inhibited.

F4 9Inclinometer failure.

F5 9Inclinometer suspect.

F6 9Drive stall detected.

F7 9Drive freewheel detected.

F8 Drive end of travel detected.

F9 9Waveguide polarisation switch failure.

F10 Azimuth sensor failure.

F11 9Elevation sensor failure.

F12 Polarisation sensor failure.

F13 Elevation deployment sensor failure. (Lynx 2000)

F14 Feedarm deployment sensor failure. (Lynx 2000)

F15 Elevation stow sensor failure. (Lynx 2000)

F16 FPGA programming failure.

F17 Manual brake override on.

F18 Azimuth axis stowing failure.

F19 Elevation axis stowing failure.

F20 Polarisation axis stowing failure,

F21 Elevation deployment axis stowing failure. (Lynx 2000)

F22 Feedarm deployment axis stowing failure. (Lynx 2000)

F23 9Power up state suspect.

F24 Stow sensor power supply alarm.

F25 MRD power supply alarm.

F26 Inclinometer power supply alarm.

F27 FPGA watchdog triggered.

F28 GPS comms. failure

F29 Compass comms failure.

F30 Feed drive failure.

F31 Handheld Controller override active.

F32 Alarm Error.

F33 Fin 1 over temperature.

F34 Fin 2 over temperature.

F35 Fin 3 over temperature.

F36 Fin 4 over temperature. (DCU4000 only)

F37 Fin 5 over temperature. (DCU4000 only)

F38 WGS power supply alarm.

F39 Fan power supply alarm.

F40 Brake power supply alarm.

F41 Feed power supply alarm. (DCU4000 only)

F42 GPS/Compass power supply alarm.

F43 Status power supply alarm.

F44 Azimuth brake disconnected.

F45 Elevation brake disconnected.

F46 Polarisation brake disconnected.

F47 Axis 4 brake disconnected.

F48 Axis 5 brake disconnected.

F49 Main Unit fan service warning.

F50 Heatsink fan service warning.

F51 E2PROM checksum error.

F52 Softlimit data error. Reverted to defaults.

F53 Wooded Area data error. Reverted to defaults.

F54 Calibration data error. Reverted to defaults.

F55 FPGA compatibility warning.

F56 External flash erasing/writing error.

F57 Antenna Type alarm.

F58 Heatsink fan stall detected.

F59 HMR3300 temperature warning.

F60 HMR3300 temperature alarm.

Advent Communications

209297 – DCU5000 Drive Control Unit Page 14 of 42

The standard Advent antenna controllers decode the DCU alarms to give a text

description and a fault code number as shown in the table above. The fault code

makes the communication of the faults seen to Advent Customer support less

ambiguous.

4.2. F1: DCU POWER SUPPLY VOLTAGE LOW

The internal +12V supply has been measured at below 9.5V. The voltage supplied

from the 12V nominal supply is approaching the minimum required to drive the

antenna.

This alarm is latched, and has to be cleared through the alarm clear menu option.

4.3. F2: DCU MOTOR SUPPLY FAILURE

The antenna +36V motor supply is out of specification. This means the motor power

may not be sufficient to drive the motors so the antenna may stall if moved.

4.4. F3: MOTOR DRIVE MODULE INHIBIT

The stepper motor drive module has inhibited itself.

Possible causes:

Over temperature. The module has overheated due to a combination of high

ambient temperature and long driving periods of the motors. Check for an over

temperature alarm, and check the current fin temperatures.

Check that the side ventilation grills are clear to allow adequate airflow

A short circuit of one of the stepper motor windings also causes the motor

module to inhibit.

4.5. F4: INCLINOMETER FAILED

The inclinometer, if fitted to the elevation axis, has stopped responding to data

requests. The RF angle will be estimated using the systems internal elevation axis

based on motor turns and pulse counting. Possible causes:

Inclinometer broken.

Inclinometer disconnected, or wire crimp failure.

4.6. F5: INCLINOMETER SUSPECT

The RF angle calculated from the inclinometer, if fitted, and the internal elevation axis

disagree by more than 15°. Possible causes:

Antenna base on a very steep slope.

If the elevation axis display on antenna controller is continuously approximately

45°±5° and no inclinometer error is reported, possible inclinometer connector crimp

failure.

4.7. F6: STALL DETECTED

A drive axis stall has been detected. It is possible that a stall on an axis can clear itself

and this alarm shows the cause of the axis becoming uncalibrated.

Possible causes:

Axis hitting physical end stop.

Moving antenna under high wind or snow loading.

This alarm is latched, and has to be cleared through the alarm clear menu option.

Advent Communications

209297 – DCU5000 Drive Control Unit Page 15 of 42

4.8. F7: FREEWHEEL DETECTED

A drive axis freewheel has been detected. It is possible that a freewheel on a drive

display can clear itself and this alarm shows the cause of the axis becoming

uncalibrated.

Possible causes:

Axis hitting physical end stop.

Moving antenna under high wind or snow loading.

This alarm is latched, and has to be cleared through the alarm clear menu option.

4.9. F8: END OF TRAVEL DETECTED

A drive axis travel limit has been detected. The axis causing this will become

uncalibrated.

Possible causes:

Severe axis stall or freewheel causing the calculated angle which the soft stop

uses to be seriously in error.

4.10. F9: TX POL SWITCH FAILED

The TX polarisation switch, if fitted, has been detected in an illegal state or will not

respond to switch commands. Possible causes:

Manual operation of the switch with the DCU on will trigger this alarm.

Switch is disconnected.

Switch is stuck or jammed.

4.11. F10: AZIMUTH STOW SENSOR FAILED

The sensor used to detect the azimuth tab markers has failed. Possible causes:

Sensor disconnected.

Sensor failure.

Metal stuck in sensor.

4.12. F11: ELEVATION STOW SENSOR FAILED

The sensor used to detect the elevation tab markers has failed. Possible causes:

Sensor disconnected.

Sensor failure.

Metal stuck in sensor.

4.13. F12: POL STOW SENSOR FAILED

The sensor used to detect the polarisation markers has failed. Possible causes:

Sensor disconnected.

Sensor failure.

Metal stuck in sensor.

4.14. F13: EL DP SENSOR FAILED

Currently not used in the DCU5000 system. If seen please report the occurrence to

Advent Communications customer support.

4.15. F14: FA DP SENSOR FAILED

Currently not used in the DCU5000 system. If seen please report the occurrence to

Advent Communications customer support.

4.16. F15: EL STOWED SENSOR FAILED

Currently not used in the DCU5000 system. If seen please report the occurrence to

Advent Communications customer support.

Advent Communications

209297 – DCU5000 Drive Control Unit Page 16 of 42

4.17. F16: FPGA PROGRAMMING FAILED

The field programmable gate array IC has failed to be programmed. Possible causes:

FPGA IC failure.

FPGA IC connection failure.

4.18. F17: MANUAL BRAKE OVERRIDE ON

The manual brake override is in use.

Possible causes:

The manual brake override switch has not been put back into the automatic

position.

4.19. F18: AZIMUTH STOWING FAILED

The system failed to detect the correct azimuth stow sensor. The system will search

±10° from its expected stow position for the tab marker. Possible causes:

Excessive stall or freewheel has uncalibrated the axis so much the systems azimuth

angle is in error by more than 10°. Action: re-calibrate axis.

The stow marker is not present.

The stow sensor or drive circuit has failed.

4.20. F19: ELEVATION STOWING FAILED

The system failed to detect the elevation stow sensor in at its expected position.

Possible causes:

Excessive stall or freewheel has uncalibrated the axis so much the systems internal

elevation angle is in error by more than 2°. Action: re-calibrate axis.

The stow marker is not present.

The stow sensor or drive circuit has failed.

4.21. F20: POL STOWING FAILED

The system failed to detect the polarisation stow sensor in at its expected position.

Possible causes:

Excessive stall or freewheel has uncalibrated the axis so much the systems

polarisation angle is in error by more than 2°. Action: re-calibrate axis.

The stow actuator is not present.

The stow sensor or drive circuit has failed.

The polarisation calibration data has been corrupted.

4.22. F21: EL DP STOWING FAILED

Currently not used in the DCU5000 system. If seen please report the occurrence to

Advent Communications customer support.

4.23. F22: FA DP STOWING FAILED

Currently not used in the DCU5000 system. If seen please report the occurrence to

Advent Communications customer support.

4.24. F23: POWER UP STATE SUSPECT

The system has been powered down when not physically stowed. The alarm warns the

user that the system is not physically stowed.

This alarm is latched, and has to be cleared through the alarm clear menu option.

4.25. F24: STOW SENSOR POWER FAILED

The stow sensor power supply is out of specification. Either the supply has been

shorted on the antenna, or an internal DCU5000 supply rail has failed.

Advent Communications

209297 – DCU5000 Drive Control Unit Page 17 of 42

4.26. F25: MRD POWER FAILED

The MRD power supply is out of specification. Either the supply has been shorted on

the antenna, or an internal DCU5000 supply rail has failed.

4.27. F26: INCLINOMETER POWER FAILED

The inclinometer power supply is out of specification. Either the supply has been

shorted on the antenna, or an internal DCU5000 supply rail has failed.

4.28. F27: FPGA WATCHDOG TRIGGERED

The hardware watchdog in the FPGA has timed out. All motor drive and brake outputs

are disabled. The system will not be able to be driven. Power cycling the DCU5000 will

reset the FPGA watchdog.

This alarm is triggered by a serious software timing error which should never

occur. If seen, please report the occurrence to Advent Communications

customer support.

4.29. F28: GPS COMMS. FAILURE

Serial communications with the GPS unit has been lost.

4.30. F29: COMPASS COMMS. FAILURE

Serial communications with the compass unit has been lost.

4.31. F30: FEED DRIVE FAILURE

The polarisation mode compensation feed drive has detected an illegal state.

4.32. F31: HHC OVERIDE ACTIVE

An HHC option is not available with the DCU5000. This alarm should never be

triggered, if seen please report the occurrence to Advent Communications customer

support.

4.33. F33: FIN 1 OVER TEMPERATURE

The measured temperature of heatsink fin 1 has exceeded 90°C. The operating

temperature of the unit is out of specification, the unit side ventilation grills are blocked,

or the units cooling fan have failed.

4.34. F34: FIN 2 OVER TEMPERATURE

The measured temperature of heatsink fin 2 has exceeded 90°C. The operating

temperature of the unit is out of specification, the unit side ventilation grills are blocked,

or the units cooling fan have failed.

4.35. F35: FIN 3 OVER TEMPERATURE

The measured temperature of heatsink fin 3 has exceeded 90°C. The operating

temperature of the unit is out of specification, the unit side ventilation grills are blocked,

or the units cooling fan have failed.

4.36. F36: FIN 4 OVER TEMPERATURE

The DCU5000 does not have a heatsink fin 4. This alarm should never be triggered, if

seen please report the occurrence to Advent Communications customer support.

4.37. F37: FIN 5 OVER TEMPERATURE

The DCU5000 does not have a heatsink fin 5. This alarm should never be triggered, if

seen please report the occurrence to Advent Communications customer support.

4.38. F38: WGS POWER SUPPLY ALARM

The waveguide switch power supply is out of specification. Either the supply has been

shorted on the antenna, or an internal DCU5000 supply rail has failed.

Advent Communications

209297 – DCU5000 Drive Control Unit Page 18 of 42

4.39. F39: FAN POWER SUPPLY ALARM

The internal heatsink fan power supply is out of specification.

4.40. F40: BRAKE POWER SUPPLY ALARM

The brake power supply is out of specification. Either the supply has been shorted on

the antenna, or an internal DCU5000 supply rail has failed.

4.41. F41: FEED POWER SUPPLY ALARM

The DCU5000 does not have a feed power rail. This alarm should never be triggered, if

seen please report the occurrence to Advent Communications customer support.

4.42. F42: GPS/COMPASS POWER SUPPLY ALARM

The GPS/Compass power supply is out of specification. Either the supply has been

shorted on the antenna, or an internal DCU5000 supply rail has failed.

4.43. F43: STATUS POWER SUPPLY ALARM

The DCU5000 does not have a status power rail. This alarm should never be triggered,

if seen please report the occurrence to Advent Communications customer support.

4.44. F44: AZ BRAKE DISCONNECTED

The DCU5000 is expecting a brake to be fitted on the azimuth axis. The brake has not

been detected on power-up.

4.45. F45: EL BRAKE DISCONNECTED

The DCU5000 is expecting a brake to be fitted on the elevation axis. The brake has not

been detected on power-up.

4.46. F46: POL BRAKE DISCONNECTED

The DCU5000 is expecting a brake to be fitted on the polarisation axis. The brake has

not been detected on power-up.

4.47. F47: AXIS 4 BRAKE DISCONECTED

The DCU5000 does not have an axis 4 drive. This alarm should never be triggered, if

seen please report the occurrence to Advent Communications customer support.

4.48. F48: AXIS 5 BRAKE DISCONNECTED

The DCU5000 does not have an axis 5 drive. This alarm should never be triggered, if

seen please report the occurrence to Advent Communications customer support.

4.49. F49: MAIN UNIT FAN SERVICE

The main unit fan run time has exceeded the service time programmed. Consider

replacing the DCU5000 main cooling fan, contact Advent Communications customer

support for further information.

4.50. F50: HEATSINK FAN SERVICE

The heatsink fan run time has exceeded the service time programmed. Consider

replacing the DCU5000 heatsink cooling fan, contact Advent Communications

customer support for further information.

4.51. F51: E2PROM CHECKSUM ERROR

A checksum error has been detected in a page of the E2PROM memory area.

4.52. F52: SOFTLIMIT DATA ERROR

An error has been detected whilst reading the units softlimit settings. The values have

been set to their default values. If the antenna system requires restricted antenna

movement, check values and confirm the safe operation of the antenna system.

Advent Communications

209297 – DCU5000 Drive Control Unit Page 19 of 42

4.53. F53: WOODED AREA DATA ERROR

An error has been detected whilst reading the units wooded area settings. The values

have been set to their default values. If the system requires restricted wooded area

antenna movement, check values and confirm the safe operation of the antenna

system.

4.54. F54: CAL. AREA DATA ERROR

An error has been detected whilst reading the units calibration settings. The values

have been set to their default values.

4.55. F55: FPGA COMPATIBILITY WARNING

The FPGA version is not compatible with the unit software installed. If seen please

report the occurrence to Advent Communications customer support.

4.56. F56: EXT FLASH ERROR

An error has been detected erasing or writing to the DCU5000 flash memory chip.

4.57. F58: HEATSINK FAN STALL DETECTED

The heatsink fan on the motor drive output stage has been detected to be not turning.

This could result in the output stage overheating and shutting down to prevent thermal

damage.

4.58. F59: HMR3300 TEMPERATURE WARNING

The HMR3300 compass unit, if fitted, has detected a device temperature below -10°C

during this session of operation.

4.59. F60: HMR3300 TEMPERATURE ALARM

The HMR3300 compass unit, if fitted, has detected a device temperature below -20°C

during this session of operation.

4.60. F61-F64 ALARM ERROR

These alarms should never be triggered, if seen please report the occurrence to

Advent Communications customer support.

Advent Communications

209297 – DCU5000 Drive Control Unit Page 20 of 42

5. REMOTE CONTROL

5.1. INTRODUCTION

The DCU5000 is designed to be operated remotely by a SatFinder, ACU control

system. The unit is controlled using a remote command set, which is documented

here.

The remote command set enables control of all operational functions of the unit and

querying of the current status of the unit.

The complete list of user commands and queries available with this unit is listed in the

following tables.

5.2. SET UP

5.2.1. INTERFACE

The DCU5000 only has an RS485 remote interface. See section 3.2 for RCM

connector wiring.

5.2.2. BAUD RATE

The DCU5000 remote interface has a fixed baud rate of 9600.

5.2.3. ADDRESS

The DCU5000 has a fixed address of 180.

5.2.4. SETUP INSTRUCTIONS

Any remote control and monitoring software (not supplied) must have the following

parameters set:

•RS485 interface. (4 wire version)

•Address: 180.

•Baud rate: 9600.

•8 data bits, no parity, 1 stop bit.

5.3. PACKET STRUCTURE

Advent uses a non-printable packet format. This means that the full range of 255

ASCII characters can appear in the message.

The format of all messages is:

[STX] [BYTE COUNT] [ADDRESS] [DATA....] [CHECKSUM] [ETX]

STX (start of transmission)

STX is the ASCII character 2. It is one byte in size and is used to represent the start of

each message.

BYTE COUNT

The BYTE COUNT is one byte in size and is the total number of bytes in the packet,

i.e. number of data bytes plus five (one each for STX, BYTE COUNT, ADDRESS,

CHECKSUM and ETX).

ADDRESS

The ADDRESS is one byte in size. This is the address of the equipment to which the

packet is being sent. Unique addresses can be in the range 001 to 255.

DATA

This is the actual data being sent to the equipment. In any one packet, the maximum

number of data bytes is 250. The DATA section includes the remote command and

any associated parameters.

Table of contents