VITAL ENERGY EUROPE vThermt Guide

Installation, Commissioning and Maintenance Manual

Version No: 002

Always keep the instructions close to the HIU and read the operating

instructions carefully before starting any work

15.5

HEAT INTERFACE UNIT CONTENTS

Page 2

HEAT INTERFACE UNIT PRODUCT FEATURES

Page 3

TABLE OF CONTENTS

2.1. General

2.2 Additional documents

2.3 Symbols used in the

document

2.4 Abbreviations

2.5 Liability and warranty

3.1 General

3.2 Regulations and

equipment

5.1 Label information

5.2 Approvals

5.3 BESA test regime

5.4 Design parameters

5.5 Materials

5.6 Noise data

4.1 General function

4.1.1 Keep warm bypass

4.1.2 Domestic hot water

4.1.3 Central heating

4.1.4 Metering

4.1.5 Safety devices

6.1 Transport

6.2 Packing

6.3 Storage

7.1 Location

7.2 HIU fixing

7.3 Hydraulic connection

7.4 Electrical connections

7.5 Wiring installation

7.5.1 Wiring diagram (radiator)

7.5.2 Wiring diagram (underfloor

heating)

8.1 Before filling the HIU

8.2 Filling the HIU with water

8.2.1 Filling the secondary MCW and

DHW system

8.2.2 Filling the secondary heating

system

8.2.3 Filling the primary system

8.3 Finalising the HIU installation

8.4 Final commissioning

8.4.1 DHW and keep warm control valve

adjustment

8.4.2 Heating control valve adjustment

8.4.3 Powering up the HIU

8.4.4 Heating set up

8.4.5 DHW set-up

1. PRODUCT FEATURES

The new space saving vTherm˚Heat Interface Unit (HIU) has been designed to minimise heat losses

and improve the efficiency of your district heating scheme.

The new product range is available in a variety of outputs providing instantaneous Domestic Hot Water

(DHW) and Heating (HTG) for radiators or underfloor heating (UFH) systems in homes.

The HIU provides complete hydraulic separation between the primary circuit and the secondary DHW

and HTG installations.

The HIU is thermostatically controlled to give good and reliable control of temperature which improves

efficiency and lowers return temperature.

Instantaneous hot water is produced via a plate heat exchanger and Pressure Independent Control Valve

(PICV) with actuator, allowing hot water to reach the tap at the desired temperature without delay, even

during low demand periods.

Heating is also produced via a plate heat exchanger and controlled via a PICV with actuator.

The HIU has been designed as a wall mounted product with all connections upwards, however more

options are available.

vTherm˚ can be easily accessed for commissioning and maintenance post-installation as the thermal

insulation casing has been designed in 3 sections to facilitate easy access.

vTherm˚has been independently tested in line with the BESA test regime and the results are BESA

verified.

vTherm˚ has a number of extras that have

been designed to ease installation and improve

efficiency.

1. First fix valve rail to protect the HIU by allowing

the installation to be undertaken without the

HIU on site

2. Fully insulated valve box reduces heat losses

and improves aesthetics

3. Pipe bracket to allow up and down connections

4. Bespoke design to meet your requirements

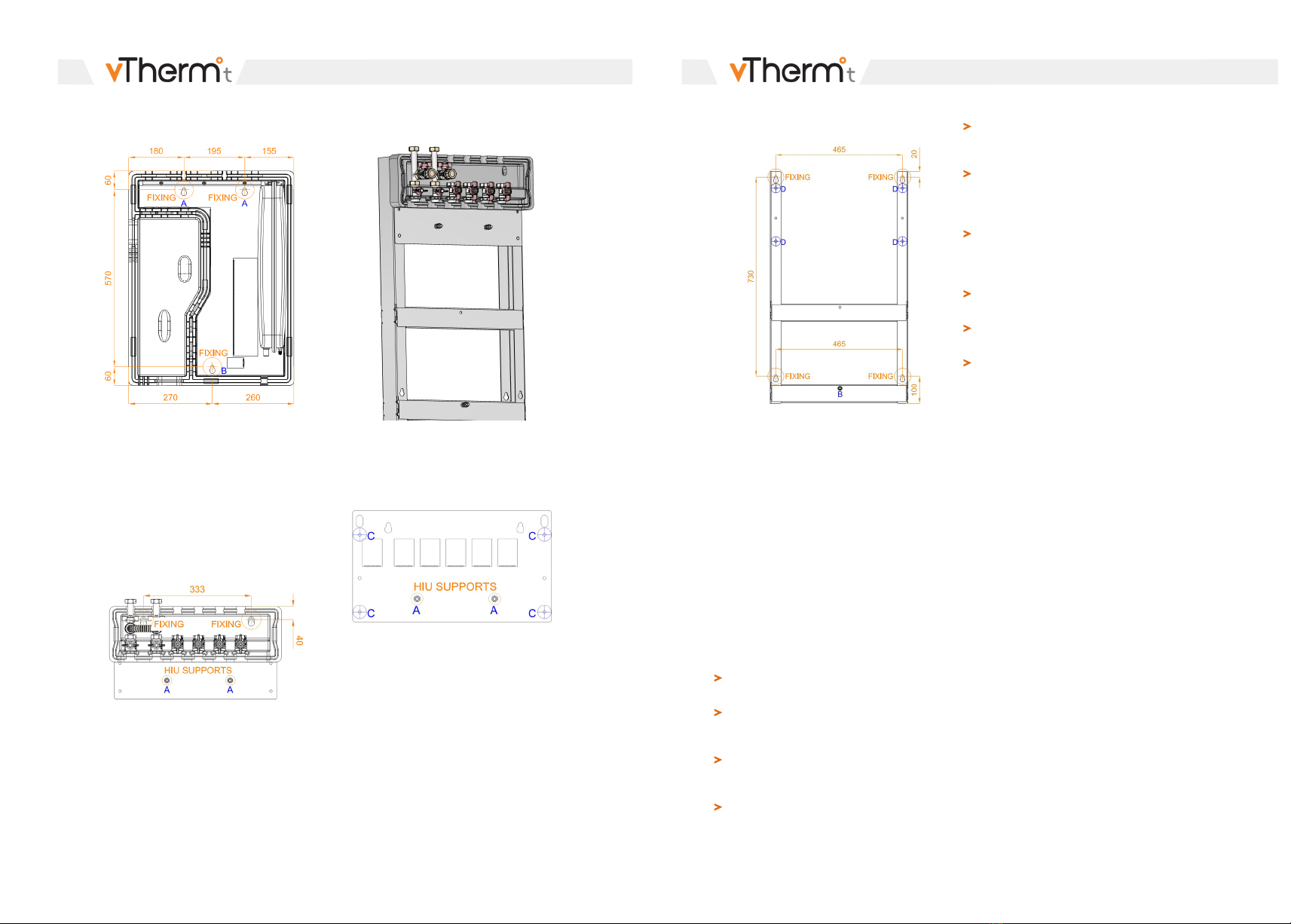

5. vTherm˚is a compact HIU, see drawing

adjacent (Fig. 1)

6. Low overall sound power level of 31.8dB (see

section 5.6)

1. PRODUCT FEATURES Page 3 Page 13-20

Page 21-28

Page 29

Page 30-31

Page 4-5

Page 6-7

Page 8-9

Page 10-11

Page 12

2. INTRODUCTION

3. SAFETY

5. TECHNICAL DATA

4. PRODUCT DESCRIPTION

6. DELIVERY INFORMATION

7. INSTALLATION

8. COMMISSIONING

9. MAINTENANCE

10. TROUBLESHOOTING

Fig. 1

690

434.5 95.5

81

530

2. INTRODUCTION

2.1 General

This manual contains information on the

installation, commissioning, operating and

maintenance of the HIU. As an authorised

specialist personnel, please read it carefully.

Keep the manual with the product at all times

so that information can be found quickly. Ensure

this manual is read in full before undertaking

installation.

Please pay particular attention to the information

given in the safety instructions (section 3), as well

as the notes highlighted in the individual sections

of this document.

The HIU must not be put into operation while it is

dismantled or prior to commissioning.

2.2 Additional Documents

The HIU installation must be undertaken by

qualified/competent mechanical and electrical

engineers. The installation must also be in

accordance with all Building Regulations

applicable to location and the IET Electrical

Regulations.

In addition, regulations applicable to the field of

application of the HIU, local accident prevention

regulations and general safety regulations must

be followed.

The diagrams contained within this manual

are provided to assist the reader with a better

understanding of the written description. The

diagrams used are generic and could be slightly

different from the actual HIU supplied. Do not

scale from the diagrams provided.

The HIU is constructed utilising different products

from numerous manufacturers. Relevant

documentation from those manufacturers must

also be followed with regards to best practices and

safety.

As each manufacturer will have undertaken

independent testing for the components

used within the HIU, it is important that their

documentation is also followed. The declaration of

conformity for each component must be sourced

from the component manufacturer.

2.3 Symbols Used in the Document

The box containing symbol and text is always below

the issue it is advising about.

WARNING

Risk of a dangerous situation causing

physical injury and/or damage. Please

follow the notes for working safely and

take extreme care.

DANGER

Electrical hazard.

Failure to follow safety procedures

can result in severe injury or death.

This work may only be performed by a

trained electrician.

CAUTION

Risk of material damage or

malfunction / failure of equipment if

ignored.

IMPORTANT

Highlights important information that

must be adhered to facilitate efficient

and correct operation.

2.4 Abbreviations

Page 4

HEAT INTERFACE UNIT INTRODUCTION

Page 5

2.5 Liability and Warranty

The HIU is manufactured in compliance with

relevant European Directives and complies with

the CE marking directive. See section 5 of this

document for further information.

Vital Energi reserve the right to modify the HIU to

improve operation and functionality due to further

development and/or improve product safety.

Therefore the information contained within

this document is subject to change without

notification.

It is assumed that the installer of this product is

competent to install, commission and operate the

HIU. Thus, the responsibility of the installation and

commissioning of the HIU lies with the installer.

The installer must adhere to the following

instructions:

Undertake the installation and commissioning

in compliance with all Approved Documents,

British Standards and all other relevant

legislation

Adhere to the instruction manuals in full. If

unsure about any information contained within

the document, consult with Vital Energi

Undertake the commissioning of the HIU in

line with the instructions and complete the

commissioning form

Undertake relevant checks and start up the HIU

Provide training to the end user on the

operation of the HIU

Explain the maintenance requirements to the

end user and make reference to the guidance

in Section 9 of this document

Leave all documentation with the end user

HEAT INTERFACE UNIT INTRODUCTION

BESA Building Engineering Services

Associations

DHW Domestic Hot Water

HIU Hydraulic Interface Unit

HTG Heating

MCW Mains Cold Water

SRV Safety Relief Valve

PCB Printed Circuit Board

PICV Pressure Independent Control Valve

UFH Under Floor Heating

VWART Volume Weighted Annual Return

Temperature

3. SAFETY

3.1 General

The following instructions refer to the standard

design of various versions of Vital Energi HIUs.

This manual should be read carefully before

installation and start-up of the HIU, in particular,

before commissioning. Vital Energi will not

accept liability of damage, faults or instances that

may endanger the user that result from non-

compliance with advised instructions within this

operating manual.

Only competent and authorized persons should

perform installation, operations and maintenance

of the HIU, having received appropriate training

and are knowledgeable/adhere to relevant

legislative requirements. Modifications of any

kind to the HIU as well as add-ons are forbidden.

HEAT INTERFACE UNIT SAFETY

Page 6

HEAT INTERFACE UNIT SAFETY

Page 7

IMPORTANT

For modification activities, always consult with

Vital Energi.

The product is subject to change due to

technological requirements and / or modifications;

therefore the illustrations within this booklet may

vary from the equipment within your possession.

However, the principles of safety will remain the

same. The HIU manual is part of the product and it

is advised that it is kept in a safe place and always

accessible to its current owner.

For safety reasons you must at all times:

Isolate the electrical supply to the HIU, ensuring

reconnection is not possible before performing

any work on the HIU. Always test the appliance to

ensure the electrical supply has been isolated. The

HIU operates at voltages up to 230V

WARNING

Risk of burns due to hot water or steam, hot

pipes and components. Always allow time for

the HIU to cool and always wear protective

equipment.

WARNING

Chemical inhibitors can cause serious injuries.

Always consult manufacturers instructions.

WARNING

Danger due to water and/or steam release under

high pressure. Risk of burns due to hot water

or steam, hot pipes and components. Always

allow time for the HIU to cool and always wear

protective equipment.

Determine the type of chemical inhibitors

within primary and secondary heating circuits,

and use appropriate measures based on the

manufacturer literature

DANGER

Electricity can cause serious and fatal injuries.

Always isolate the electrical supply and test before

commencing work.

Before undertaking any work on the HIU, isolate

from the primary and secondary systems

Remove water and pressure from the HIU before

any work can start

Do not remove or limit any safety devices

Before installation, check the integrity of the

equipment. If the HIU is defective – do not try to

fix or remedy the issue yourself, please contact

your supplier

The HIU can generate a hot stream of fluid if a

valve is open-ended

Allow time for the HIU to cool down

Only replace faulty components with the same

manufacturer and model. Failure to follow this

instruction will invalidate any warranty

WARNING

Danger due to water and/or steam release

under high pressure. Risk of burns due to hot

water or steam, hot pipes and components.

Always allow time for the HIU to cool and always

wear protective equipment.

3.2 Regulations and Equipment

In addition to these installation instructions and

safety notices, local and national legislation and

regulations must be followed to protect persons,

buildings and the environment from injury,

damage and danger.

The client/project lead designer/contractor health

and safety risk assessment must also be read,

understood and followed.

Protective equipment must be used as necessary

when installing the HIU.

The HIU is not intended to be used for any

purpose other than its intended design

purpose. Misuse of the unit may result in

damage of the unit or personal injury

IMPORTANT

Vibrations during transport can loosen

connections and fixings, check and tighten all

fittings before introducing water in to the HIU.

Check all cables and electrical connections.

Check all connection fittings are watertight

and ensure fittings are not overstressed; this

can cause issues with the HIU and could lead to

personal injury

WARNING

Any use of the HIU other than its intended use

may lead to damage and / or injury.

The HIU has a weight of approximately 30-35 kg

depending on configuration

WARNING

Mechanical impact can cause serious injury

(crushing).

The HIU has sharp edges

WARNING

The HIU has sharp edges which may cause injury

if protective gloves are not worn. Always use

protective gloves when working on the HIU.

HEAT INTERFACE UNIT PRODUCT DESCRIPTION

Page 8

HEAT INTERFACE UNIT PRODUCT DESCRIPTION

Page 9

4. PRODUCT DESCRIPTION

4.1 General Function

The design of the HIU is for parallel production of

DHW and HTG.

4.1.1 Keep Warm Bypass

The keep warm function of the HIU is required to

maintain heat to the HIU, this function assists a

fast DHW response time to the DHW outlets.

A bypass is installed across the primary flow and

return pipework to allow a small flow of water

through the HIU without warming the plates. The

flow of water through the bypass is controlled by

a PICV, the PICV is controlled by a thermostatic

actuator with the probe measuring the

temperature at the entry point of the DHW plate.

4.1.2 Domestic Hot Water

The DHW is controlled by two control valves,

which control the flow of primary water through

the plate to generate instantaneous DHW.

1. Taco valve: When a DHW outlet is opened the

valve detects MCW flow, the valve then opens to

allow the primary flow through the plate.

2. Thermostatically controlled PICV. The actuators

thermostat is installed in the DHW flow out of

the plate, the actuator then controls the PICV

and the required primary flow rate through the

plate to maintain the DHW temperature.

The recommended setting is for 55 deg C

domestic hot water. Lower temperatures can

increase the risk of bacteria growth and higher

temperatures can cause scalding and damage

the HIU by increasing limescale formation. It is the

recommendation of CIBSE CP1 and NHBC section

8 that the temperature is set at this level.

4.1.3 Central Heating

The Central Heating Room Thermostat /

Programmer is connected directly to the HIU.

When there is a HTG demand, the primary side

HTG on/off control valve opens to allow primary

water to circulate through the HTG plate, the

heating pump is enabled to circulate water

through the radiators. The thermostatic actuator

controls the flow of primary water through the

PICV and heat exchanger to maintain the heating

flow temperature, which is measured by the

actuators thermostat installed in the outlet of the

HTG plate.

A manometer and thermometer are installed on

the heating flow pipework within the HIU. This

is visible through the front cover of the HIU. This

gauge displays the heating flow temperature and

heating system pressure.

The HIU has an expansion vessel installed on the

heating circuit to accommodate water expansion

as the system heats up. The heating system is

filled through the filling loop with MCW. A suitable

inhibitor should be used to protect the HIU and HTG

system.

4.1.4 Metering

There is a flow meter installed on the primary return

connection which monitors the flow of water to

the HIU. This combined with temperature sensors

allows the energy usage to be calculated. The meter

calculator is positioned on the front of the HIU in

an accessible location to allow usage to be checked

regularly.

4.1.5 Safety Devices

The central HTG system has a safety relief valve

installed, rated at 3bar. This valve has been installed

to protect the HIU and HTG system from over

pressurisation. The valve will require a connection

to drain, refer to approval document G typical

discharge safety valve arrangement.

It is recommended that a high temperature cut

off switch is installed to protect floor construction

when serving UFH. This should be installed on the

flow pipe leaving the HIU serving the UFH manifold.

Note: High temperature thermostat must be

installed on pipework by HIU installer, it is not

installed during manufacture.

The switch should be set 5 deg C higher than

the flow temperature of the UFH, but not higher

than the floor material maximum temperature

specification.

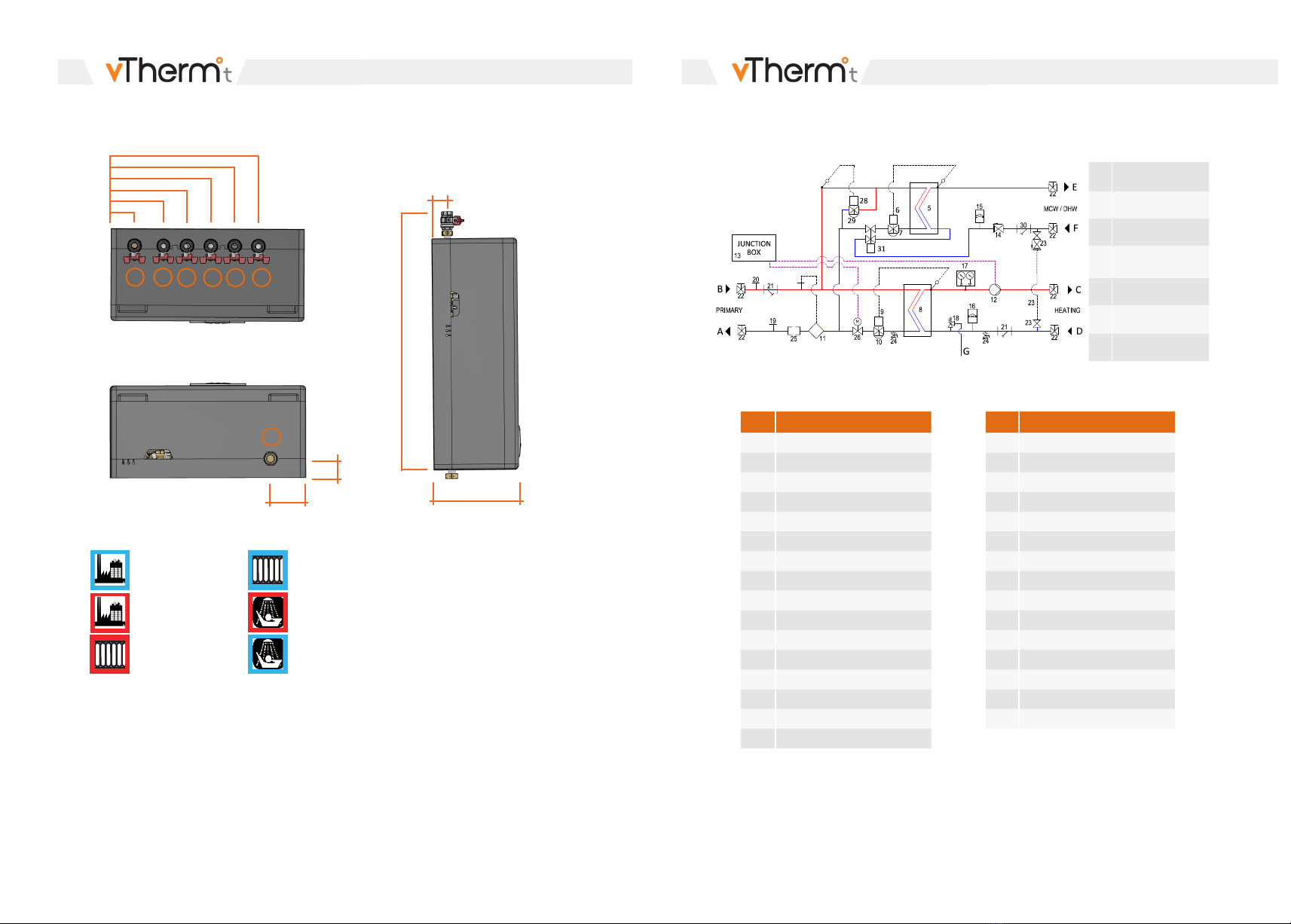

REF COMPONENT

1Backplate

2Bracket (Expansion Vessel)

3Bracket (Pipes)

4EPP Cabinet

5DHW Heat Exchanger

6DHW Actuator

7DHW Control Valve

8Heating Heat Exchanger

9Heating Actuator

10 Heating Control Valve

11 Heat Meter (Flow Sensor)

12 Pump

13 Junction Box

14 Check Valve

15 Mini Expansion Vessel

16 Expansion Vessel

17 Thermomanometer

18 Safety Relief Valve (SRV)

19 Test Point (Blue)

20 Test Point (Red)

21 Strainer

22 Ball Valve

23 Filling Loop Connections

24 Drain Valve

25 Spool Piece For Prepay

Valve

26 Heating On/Off Valve

27 Heat Meter Calculator

28 Keep Warm Actuator

29 Keep Warm Control Valve

30 MCW Strainer

31 Proportional Flow Controller

HIU Components

Fig. 2

HEAT INTERFACE UNIT TECHNICAL DATA

Page 10

HEAT INTERFACE UNIT TECHNICAL DATA

Page 11

5.2 Approvals

vTherm˚ follows BESA testing methodology and

can be tailored for project specific capacities and

parameters.

5.3 BESA Test Regime

Full report available on BESA website.

5.4 Design Parameters

HIU is subject to change in parameters depending

on the design conditions and components used.

Please read the label for details.

General design parameters are stated on the

following page (Table 2).

5. TECHNICAL DATA

5.1 Label Information

Main HIU information can be found on the CE

label that is attached to the HIU and contains the

following information:

Product owner

Manufacturer / address

Item type

Item no.

Production date (year / calendar month)

Order no.

Power supply voltage

PN class

Minimum and maximum operating

temperatures

Working pressure

Capacity

Temperature programme

Volumetric flow

5.5 Materials

Table 3.

Pipes, Fittings, Valves (Primary And Heating) 1.4301 AISI 304, CW617N, CW614N, CW602N,

CW625N, GG15*

Pipes, Fittings, Valves (DHW) 1.4404 (AISI 316L), CW617N, CW617N, CW602N*

Heat Exchanger 1.4404 (AISI 316L) Cu Brazing

Insulation Expanded Polypropylene

* Some other materials are used by component manufacturers such as valves and pumps. These are in sealing, shafts

and other small components of the assembly.

PRIMARY SIDE HEATING DOMESTIC HOT WATER

Maximum Temperature 95°C Maximum Temperature 80°C Maximum Temperature

60°C

Maximum Pressure 10 bar Maximum Pressure 2.5 bar Maximum Pressure 10 bar

Pressure Rating PN10 Pressure Rating PN10 Pressure Rating PN10

Minimum Differential Pressure

50 kPa

Safety Relief Valve Setting 3.0 bar Minimum MCW Pressure

1 bar

Maximum Differential Pressure

200 kPa*

Expansion Vessel 10 litres

Pressure Loss < 50 kPa Pressure Loss < 10 kPa

Available pump head 60kPa

ELECTRICAL

Power Supply 1 X 230V, 5A, 50 Hz

Maximum Power Consumption 60W

* Maximum differential pressure of the taco control valve

Table 2.

5.6 Noise Data

The Sound Power Measurement reported below has been determined following the

recommendations of ISO3744. The measurement was carried out on a parallelepipedic surface with 9

microphone positions, each microphone located 0.5m from the appliance.

APPLIANCE SOUND POWER LEVEL SPECTRUM

DB

OVERALL SOUND

POWER LEVEL DB

125HZ 250HZ 500HZ 1000HZ 2000HZ 4000HZ

VTHERM 21.4 24.3 20.6 18.8 21.2 17.6 31.8

PRIMARY°C OVERALL VWART STANGING HEAT LOSS

70 27 26 WATTS

60 31 39 WATTS

Table 1.

Table 4.

HEAT INTERFACE UNIT DELIVERY INFORMATION

6. DELIVERY INFORMATION

6.1 Transport

HIU dimensions and weights should be

considered to allow installation and access in a

safe manner.

6.2 Packing

HIUs are delivered in cardboard boxes (typical

cardboard box dimensions are 1030 x 630 x

350mm and weigh 35kg), packed individually

and stacked with a maximum of 10 on one pallet

(Fig. 3).

Delivery packaging materials are generally made

up of cardboard, wood and plastics.

If no agreement has been made regarding the

return of packaging material, the packaging

material remains with the customer.

WARNING

The pallet must be transported using approved

lifting equipment.

The HIU is supplied with all of the components

shown on the project schematic.

6.3 Storage

The units should be stored horizontally with the

arrows on the packaging pointing upwards, in a

dry, frost-free location.

The unit must not be exposed to the elements:

water drops; humidity; direct sunlight; heat

sources or high intensity electromagnetic fields.

We recommend covering the HIU to protect it

from dust, dirt and paint.

Page 12

The HIU is designed to be transported

horizontally with the arrows on the packaging

pointing upwards. Care must be taken that the

HIU components and parts in the unit are not

damaged and that cables and wires are not

pulled, trapped or damaged during transport.

During delivery of goods, undertake checks

to determine transit damage and complete

delivery. If there is damage and missing goods,

identify to the delivery company and either

accept conditionally or do not accept delivery.

Identify the damage on the delivery documents

and take pictures. Report issue immediately to

the supplier.

Unforeseen damages found on unpacking the

goods after delivery should be highlighted as

soon as possible. Terms and conditions agreed

to at time of purchase must be followed with

regards to delivery, complaint periods and

reporting methods.

CAUTION

Packaging materials must be disposed

of correctly and recycled. Considering the

environment and relevant waste disposal

regulations

Fig. 3

HEAT INTERFACE UNIT INSTALLATION

7. INSTALLATION

7.1 Location

The HIU must only be installed in a suitable

location that provides protection against moisture

and freezing temperatures. The location must

have sufficient ventilation to prevent heat build up

within the HIU.

The location of the HIU should:

Aim to minimise the length of primary pipework

within the occupied space

Aim to minimise the length of pipework from

the pressure relief valve fitted to the secondary

heating circuit of the HIU to a suitable drain

point (refer to Approved Document G, typical

discharge safety valve arrangement)

Determine pipework configuration from above

or below

Provide sufficient ventilation to the occupied

space to prevent excessive heat build-up

Allow sufficient space around the HIU to

permit dismantling of the insulated cabinet for

maintenance purposes (Table 5)

7.2 HIU Fixing

Always use the appropriate tools to install the

HIU

INSTALLATION MAINTENANCE

CLEARANCES mm

Above* 40

Below* 40

In front* 600

Right side* 30

Left side* 30

* Space for pipe work, including insulation must be considered.

Page 13

Table 5.

WARNING

Incorrect installation and failure to adhere to these

instructions can result in damage to the HIU /

building and serious injury. The installation of the

HIU must be undertaken by qualified/competent

persons in-line with legislation.

HIU fixings are not supplied with the HIU

The fixings should be selected based on the

substrate being fixed in to and selection of the

correct fixing method is the responsibility of the

contractor installing the HIU

If working with walls built using perforated

bricks or blocks or mobile dividing panels

on any masonry walls, a preliminary

static test must be carried out to

determine whether the wall can support the

WARNING

Mechanical impact can cause serious injury

(crushing).

WARNING

The HIU has sharp edges which may cause injury

if protective gloves are not worn. Always use

protective gloves when working on the HIU.

There are three options available for the HIU, which

consider ease of installation, protection of the HIU

and pipework routing up and down (all primary and

secondary connections are on the top of the HIU,

with safety relief connection at the bottom):

1. HIU only option, fixing the HIU directly to the wall.

There are three fixing points on the HIU and all

should be used to secure the HIU. See Fig 4

on the following page, identifying the fixing

positions and dimensions of the HIU:

HEAT INTERFACE UNIT INSTALLATION

Page 14

Fig. 4

HEAT INTERFACE UNIT INSTALLATION

Page 15

2. Valve rail option is installed early during the first

fix with the HIU being installed later. This

approach helps to protect the HIU during the

works. Once the first fix works are complete,

lift the HIU on to the studs (A) on the valve rail

and secure. The lower fixing B (see Fig 4

above) on the HIU will also need to be used for

fixing the HIU. See Fig 5 below, identifying the

fixing positions and dimensions for the valve

rail:

Fig. 5

3. Pipe bracket option: This option should be used

when connections come from below or a

mixture of above and below. See Fig 6 which

identifies the complete assembly, including the

valve rail:

Fig. 6

Step 1. Remove the valves and slide the insulation

off the valve rail to leave the backplate only, see Fig

7:

Fig. 7

Step 2. Construct the pipe bracket frame by

slotting the two horizontal pieces into the two

vertical pieces as shown on opposite page in Fig 8:

Fig. 8

Step 3. Place the backplate onto the frame,

passing the four bolts through C (Fig.7) and then

D (Fig. 8) so the bolt points away from the HIU and

do not foul the valve rail insulation. Tighten all four

nuts and bolts.

Step 4. Fit the frame to the wall.

Step 5. Slide the insulation back onto the valve rail

backplate.

Step 6. Replace all valves.

Step 7. Fit / tighten the nuts and bolts (2 x A and

1 x B), so they are secure in the frame ready for the

HIU installation.

Step 8. When required, lift the HIU on to studs A

and B and use the nuts to secure the HIU.

7.3 Hydraulic Connections

The HIU must be installed by a competent

person(s)

All hydraulic connects are to be made, tested

and filled with the electrical power supply

isolated

Before the HIU is connected hydraulically,

all systems should have been pressure tested,

cleaned and flushed in accordance with BS 7593

Do not flush / back flush through the HIU as this

will result in damage to components

Ensure that pipework connected to the HIU are

self-supported and do not impose stress on the

HIU

Heat from soldering can damage the HIU. Do not

solder final connections or joints close to the HIU

without a break between the appliance and pipe

to prevent heat transfer

All pipework connections must be suitable

for their intended purpose and comply to the

necessary standards. This is the responsibility of

the installer

The isolation valves required for connections A to

F are supplied with the HIU

The connection to the valves supplied with the

HIU for A to F are 3/4” internal thread

The safety relief valve connection G is 1” internal

thread, this connection must be installed in line

with Approved Document G

HEAT INTERFACE UNIT INSTALLATION

Page 16

HEAT INTERFACE UNIT INSTALLATION

Page 17

95.5

53

55

771

65

145

210

275

340

405

A B C D F

G

E

Fig. 9 Top View

Fig. 10 View from Below

Fig. 11 Side View

Connections

ADH Primary Return

BDH Primary Flow

CSpace Heating Flow

DSpace Heating

Return

EDomestic Hot Water

FMains Cold Water

GSRV Discharge

REF COMPONENT

1Backplate

2Bracket (Expansion Vessel)

3Bracket (Pipes)

4EPP Cabinet

5DHW Heat Exchanger

6DHW Actuator

7DHW Control Valve

8Heating Heat Exchanger

9Heating Actuator

10 Heating Control Valve

11 Heat Meter (Flow Sensor)

12 Pump

13 Junction Box

14 Check Valve

15 Mini Expansion Vessel

16 Expansion Vessel

REF COMPONENT

17 Thermomanometer

18 Safety Relief Valve (SRV)

19 Test Point (Blue)

20 Test Point (Red)

21 Strainer

22 Ball Valve

23 Filling Loop Connections

24 Drain Valve

25 Spool Piece For Prepay Valve

26 Heating On/Off Valve

27 Heat Meter Calculator

28 Keep Warm Actuator

29 Keep Warm Control Valve

30 MCW Strainer

31 Proportional Flow Controller

Fig. 12 HIU Hydraulic Arrangement

HIU Connections

HIU Components

250

B. Primary Flow

C. Heating Flow

E. Domestic Hot Water

A. Primary Return D. Heating Return

F. Cold Water

G. Heating Safety Valve

Outlet

HEAT INTERFACE UNIT INSTALLATION

Page 18

HEAT INTERFACE UNIT INSTALLATION

Page 19

7.4 Electrical Connections

Electrical connections must be made by an

authorised electrician only.

Electrical connections must be made in

accordance with current regulations and local

standards.

CAUTION

The HIU installation must be undertaken by

qualified/competent mechanical and electrical

engineers. The installation must also be in

accordance with all Building Regulations

applicable to location and the IET Electrical

Regulations.

DANGER

Electricity can cause serious and fatal injuries.

Always isolate the electrical supply and test before

commencing work.

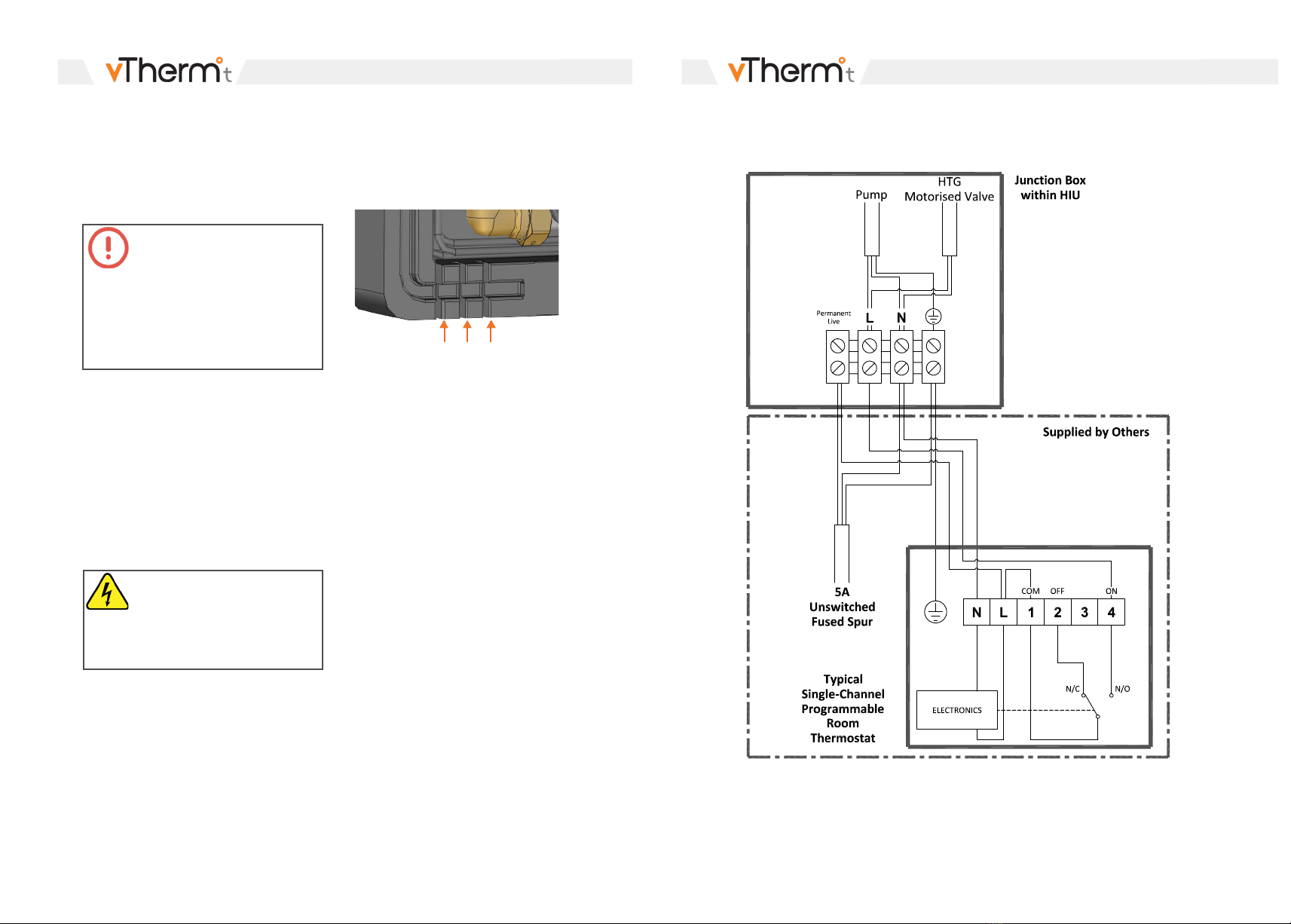

Fig. 13 Guiding Channels

All electrical equipment in the HIU is connected to

the junction box. Before adding power to the unit,

verify that no electrical connections have been

disconnected on the components.

All accessories and main power supply will be

connected in the junction box housing.

Follow the information and wiring diagrams in

Section 7.5.

Check the earth connection; ensure it is sufficient

enough to withstand the power being distributed.

Check the electrical connection reflects the

voltage rating and adheres to current legislation.

Before any electrical work is undertaken, please

refer to safety notes (Section 3).

The HIU should not run via site temporary power

supply. Failure to observe will void the warranty.

HIU must be connected to a 230V un-switched

fused spur fitted with a 5A fuse and wired in

accordance with the BS 7671 Electrical Wiring

Regulations.

Multiple cable guiding channels have been

provided in the insulation casing and must be

used when making the connections to the HIU

(Fig 13).

7.5 Wiring Installation

7.5.1 Wiring Diagram (Radiator)

HEAT INTERFACE UNIT INSTALLATION

Page 20

HEAT INTERFACE UNIT COMMISSIONING

Page 21

7.5.2 Wiring Diagram (Underfloor Heating) 8. COMMISSIONING

Open the kitchen sink DHW tap to allow the

water to flush through the system

Open the DHW isolation valve at the top of the

HIU

Open the MCW isolation valve at the top of the

HIU

8.1 Before Filling the HIU

CAUTION

Flushing and back flushing through the HIU is

strictly prohibited, performing this action will

damage the HIU / Components. Failure to follow

this instruction will invalidate the HIU warranty.

Fig. 14

Refer to Section 3 with regards to tightening of

connections

Obtain pressure test certificates for the MCW,

DHW and HTG systems

Confirm that the Primary side connections

have been completed and are live

Obtain test certificates to show that all

pipework has been flushed / cleaned prior to

connecting the HIU

WARNING

Chemical inhibitors can cause serious injuries.

Always consult manufacturer’s instructions.

Run the water through the kitchen sink tap until

a cold, clean, steady flow of water is achieved

Open each DHW outlet within the property until

all air and any remaining debris has been flushed

through

Check HIU for leaking joints on the secondary

MCW and DHW connections, tighten connections

as required. Do not overtighten the fibre washers

as this will result in damage. Should a fibre

washer become damaged, replace the washer

immediately ensuring to isolate the HIU

mechanically and electrically first

Once all taps have had water drawn off and no

leaks are evident, move to the next step identified

in 8.2.2

Ensure that both drain valves identified in Fig.

14 are closed and end caps are fitted and tight

Confirm that there is an electrical supply to the

HIU which has been isolated

8.2 Filling the HIU with Water

8.2.1 Filling the Secondary MCW and DHW

System

8.2.2 Filling the Secondary Heating System

Open the secondary HTG isolation valves at the

top of the HIU (always open the return valve first

to prevent debris entering the HIU)

Before filling the secondary HTG system introduce

a suitable inhibitor for the type of system

installed, in accordance with the manufacturer’s

instruction and BS 7593

Ensure that both valves identified in Fig 15 are

fully closed

Fig. 15

HEAT INTERFACE UNIT COMMISSIONING

Page 22

HEAT INTERFACE UNIT COMMISSIONING

Page 23

CAUTION

The actuators on the valves must not be

dismantled during operation. This could result in

them being destroyed. Dismantling should only

be carried out when the HIU is isolated from all

systems (mechanical and electrical) and when

the system has cooled down.

Remove end caps and fit flexible hose between

both valves

The secondary HTG circuit pressure should be

typically between 1.0 and 1.5bar, the secondary

HTG system pressure may be read from the

pressure gauge at the front of the HIU

Open the secondary HTG valve first and then

open the MCW valve until the desired pressure

has been achieved

Vent system radiators of all air, top up pressure

after each radiator has been vented

When the system has been fully vented, and

the desired pressure has been achieved, turn

off both valves identified in Fig 15

Remove hose and replace end caps tightly

(always disconnect the filling hose following

use)

Check HIU for leaking joints on the secondary

HTG connections, tighten connections as

required. Do not overtighten the fibre washers

as this will result in damage. Should a fibre

washer become damaged, replace the washer

immediately ensuring to isolate the HIU

mechanically and electrically first

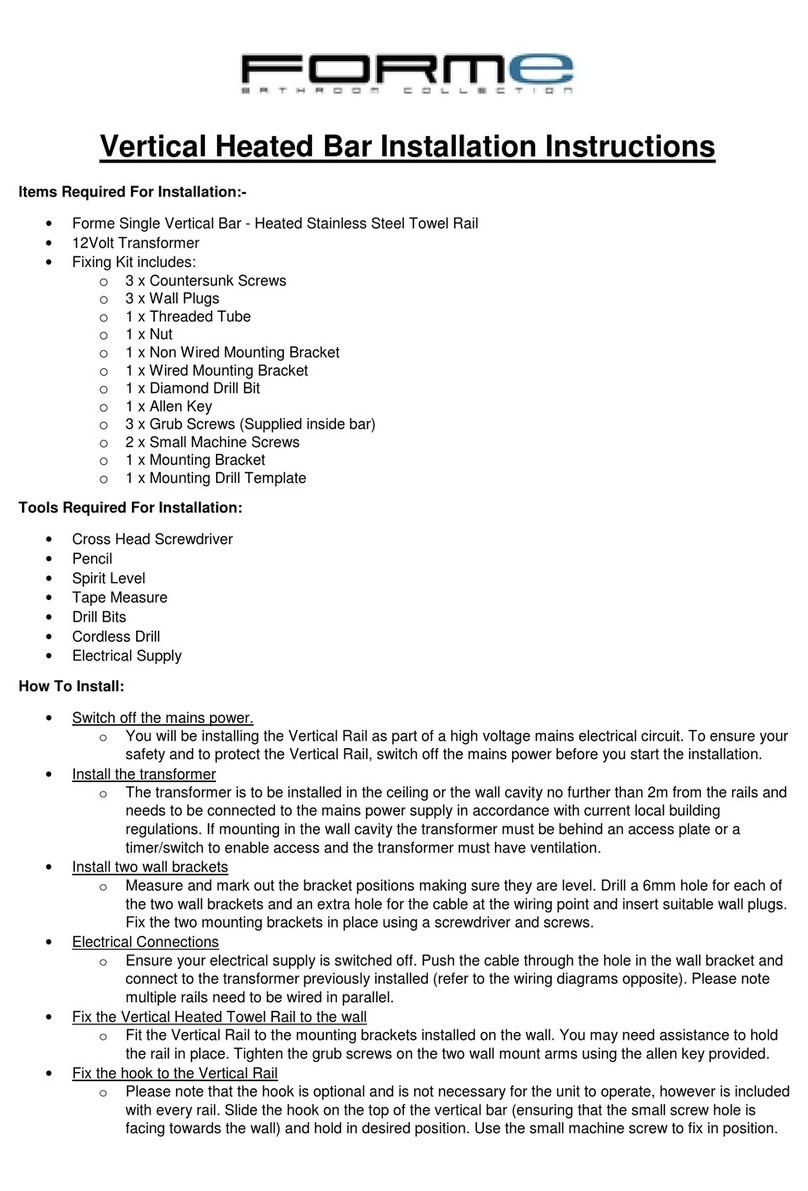

Connect the power cable to the pump (Fig 16).

This cable is removed on purpose to avoid the

pump operating with no water in the system.

To access the pump, move the HIU controller

out of the way

Fig. 16

Once all radiators have been vented, system is at

desired pressure and no leaks are evident, move

to the next step identified in 8.2.3

8.2.3 Filling the Primary System

Only fill the primary system when both

secondary side circuits have been filled as

identified in 8.2.1 and 8.2.2

Open the primary system isolation valves at the

top of the HIU. Always open the flow valve first

to prevent debris entering the HIU

Check HIU for leaking joints on the primary

connections, tighten connections as required.

Do not overtighten the fibre washers as this will

result in damage. Should a fibre washer become

damaged, replace the washer immediately

ensuring to isolate the HIU mechanically and

electrically first

8.3 Finalising the HIU Installation

All joints within the HIU and the final connections

to the HIU are water tight

All DHW outlets have been flushed through to

remove air and debris

All radiators have been vented

Confirm safety relief valve (SRV) has been

connected to drain. Test SRV in line with

manufacturer’s instructions to ensure valve is

operating correctly

WARNING

The safety relief valve is a factory set unit, do

not tamper with the valve. Should the valve not

function when tested or pass water, the valve must

be replaced.

Check all electrical connections are in good

condition and are connected correctly

Confirm all wiring has been completed (power

supply, room stat & programmer) in accordance

with wiring regulations and the HIU has a safe

means of isolating the power supply

8.4 Final Commissioning

Complete correct commissioning form; address,

date, commissioning engineer, HIU details, heat

meter details, confirm any flushing bypass is

closed on the primary connections

Check primary flow temperature is within 5°C of

design set point via the heat meter. If not, wait to

allow hot water to reach HIU

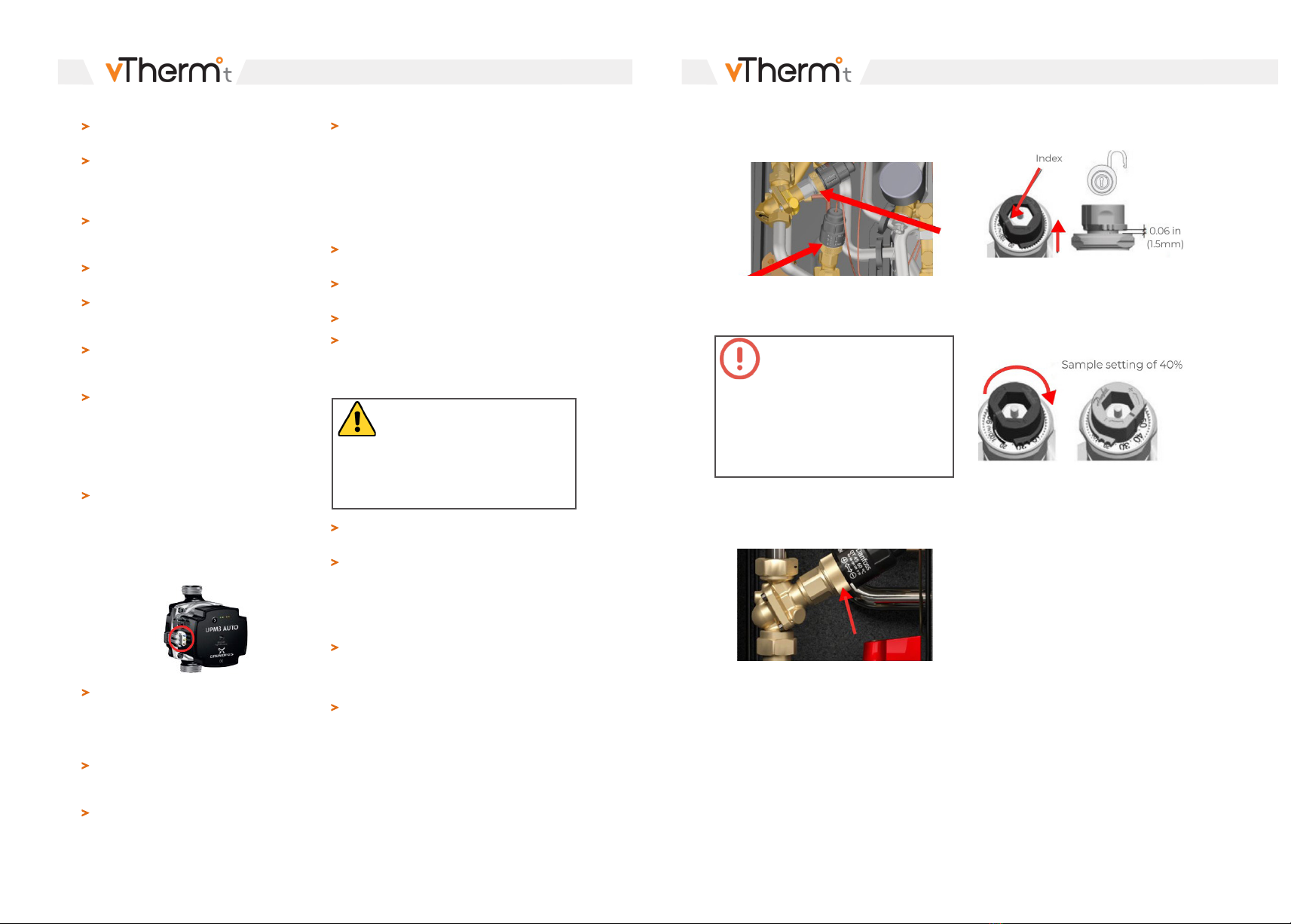

8.4.1 DHW and Keep Warm Control Valve

Adjustment

DHW and keep warm control is provided by Danfoss

AB-QM PICVs. During the commissioning process

the flow rate will need to be checked and adjusted.

See Fig 17 opposite which identifies the location of

(A) DHW PICV and (B) Keep warm PICV.

Fig. 17

Fig. 18

A

B

Before undertaking any of the steps below, close

primary system isolation valves at the top of the

HIU and confirm electrical connection is isolated.

Lift the grey adjustment pointer above the setting

grooves (Fig 19). Located on the adjustment

pointer is a red line which is the index for the

adjustment.

Remove thermostatic actuator by loosening the

brass collar (Fig 18).

Fig. 19

Rotate the pointer to the required flow percentage.

Clockwise to decrease the setting percentage,

counter-clockwise to increase the setting

percentage (Fig 20).

Fig. 20

HEAT INTERFACE UNIT COMMISSIONING

Page 24

HEAT INTERFACE UNIT COMMISSIONING

Page 25

Fig. 21

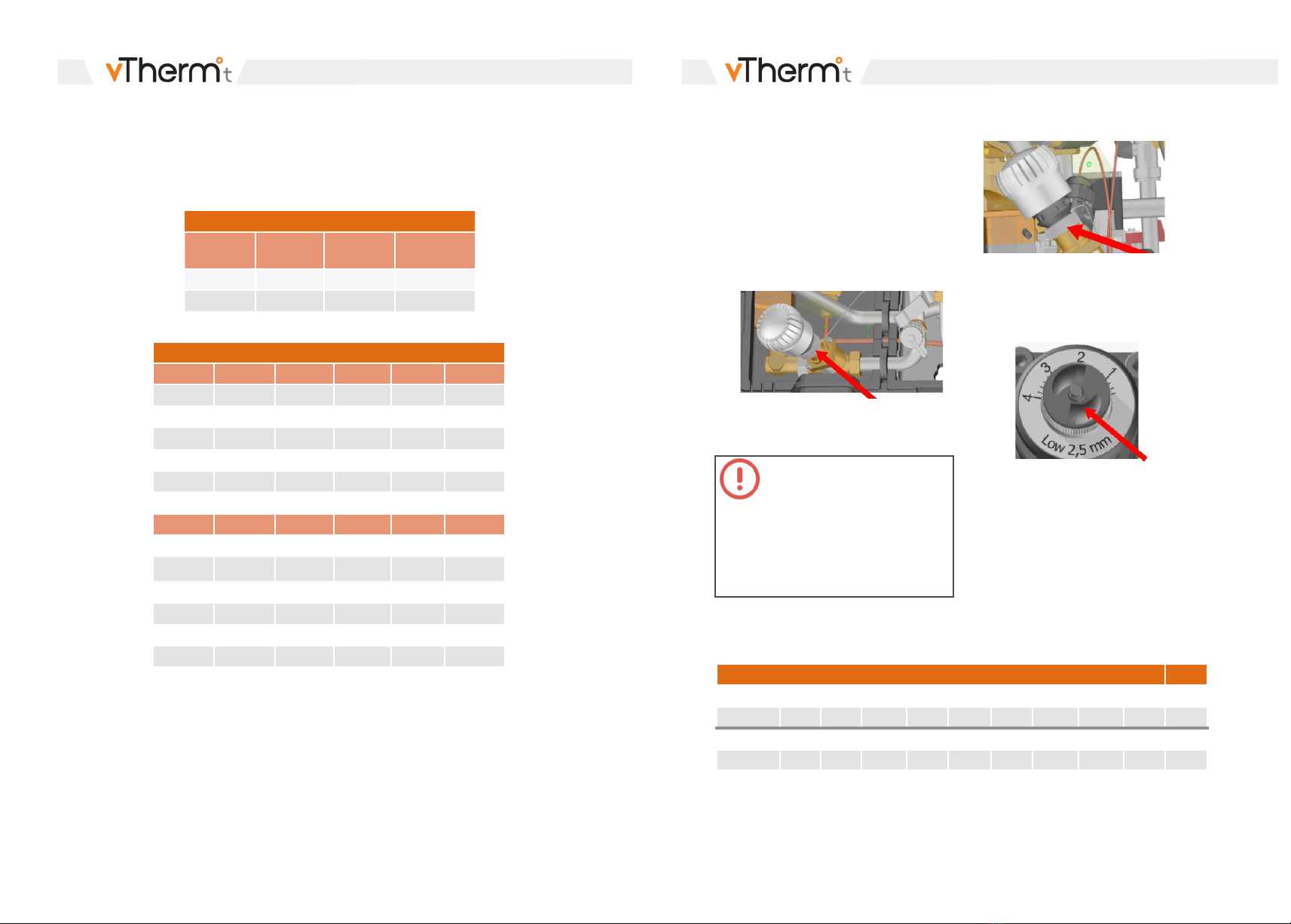

The pre-setting scale indicates values from 100% flow to 0%, the required volume for the DHW control

valve can be found on the HIU label.

The keep warm setting is dependent upon the primary flow temperature, DHW and keep warm valves

model and setting.

VALVE SETTING FLOW RATE LITRES PER SECOND

VALVE 20% 30% 40% 50% 60%

DN10 LF 0.008 l/s 0.013 l/s 0.017 l/s 0.021 l/s 0.025 l/s

DN15 LF 0.015 l/s 0.023 l/s 0.031 l/s 0.038 l/s 0.046 l/s

DN15 NF 0.025 l/s 0.038 l/s 0.050 l/s 0.063 l/s 0.075 l/s

DN15 HF 0.063 l/s 0.095 l/s 0.126 l/s 0.158 l/s 0.189 l/s

DN20 NF 0.050 l/s 0.075 l/s 0.100 l/s 0.125 l/s 0.150 l/s

DN25 NF 0.094 l/s 0.142 l/s 0.189 l/s 0.236 l/s 0.283 l/s

VALVE 70% 80% 90% 100%

DN10 LF 0.029 l/s 0.033 l/s 0.038 l/s 0.042 l/s

DN15 LF 0.053 l/s 0.061 l/s 0.069 l/s 0.076 l/s

DN15 NF 0.088 l/s 0.100 l/s 0.113 l/s 0.125 l/s

DN15 HF 0.221 l/s 0.252 l/s 0.284 l/s 0.315 l/s

DN20 NF 0.175 l/s 0.200 l/s 0.225 l/s 0.250 l/s

DN25 NF 0.331 l/s 0.378 l/s 0.425 l/s 0.472 l/s

Press grey pointer back into lock position when

flow rate set. After click, pre-setting is locked.

Replace actuator.

8.4.2 Heating Control Valve Adjustment

Heating control is provided by a Danfoss Frese

Compact PICV. During the commissioning process

the flow rate will need to be checked and adjusted.

See Fig 21 below which identifies the location of

the heating PICV.

Before undertaking any of the steps below, close

primary system isolation valves at the top of the

HIU and confirm electrical connection is isolated.

CAUTION

The actuators on the valves must not be

dismantled during operation. This could result in

them being destroyed. Dismantling should only

be carried out when the HIU is isolated from all

systems (mechanical and electrical) and when

the system has cooled down.

Table 6.

Fig. 23

Remove thermostatic actuator by loosening the

collar (Fig 22).

Fig. 22

Loosen the brass locking nut on the DHW PICV

(See Fig 23) and turn the dial so the pointer aligns

with the correct flow setting. Ensure the locking

nut is re-tightened following adjustment.

The required flow setting for the Frese Low 2.5

valve can be found below in Table 4, if any other

valve is installed refer to the manufacturer's data

sheet. The required volume for the HTG control

valve can be found on the HIU label, i.e. if the

required flow rate is 0.029 l/s set the valve to

setting 2, always align the pointer with the next

number above the required flow rate.

Ensure brass locking nut has been re-tightened.

Refit the DHW control valve actuator and open

primary valves at the top of HIU.

Table 8.

FRESE COMPACT DN10 DN15 2.5 LOW

SETTING 0.5 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2

FLOW (l/s) 0.008 0.010 0.012 0.015 0.018 0.020 0.023 0.026 0.029 0.031

SETTING 2.4 2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0

FLOW (l/s) 0.034 0.037 0.039 0.042 0.045 0.047 0.050 0.053 0.056

KEEP WARM BYPASS SETUP

PRIMARY

FLOW (°C)

DHW

FLOW (°C)

PICV

SETTING %

ACTUATOR

SETTING NO.

70 55 100 2.5

60 55 100 1

Table 7.

HEAT INTERFACE UNIT COMMISSIONING

Page 26

HEAT INTERFACE UNIT COMMISSIONING

Page 27

8.4.3 Powering up the HIU

Turn on the power to the HIU

DANGER

Electricity can cause serious and fatal injuries.

Always isolate the electrical supply and test

before commencing work.

8.4.4 Heating Set-up

Switch the heating ‘on’ at the thermostat /

programmer and check that the pump is

running, and that the motorised valve opens. If

the pump and the motorised valve do not open,

then check power to the HIU

Press the button on the face of the pump for

more than 2 seconds so that it enters setting

selection mode. The LEDs will flash, showing

the current setting mode. [Note that if the key

lock is disabled, the pump will not switch to

setting selection mode. In this case, unlock the

key lock by pressing the button for more than 10

seconds]

Once in setting selection mode, scroll through

the various options by quick depressions of the

button until the proportional pressure AUTO

ADAPT pattern below is displayed. Release the

button for more than 10 seconds to save the

setting

Check that no water is passing to discharge

through the safety valve

Attach a clip-on temperature sensor onto the

stainless-steel heating flow pipework, as close to

the plate as possible

Adjust the heating actuator until the design

temperature has been achieved and is steady for

three minutes

Complete the ‘Heating’ section of the

Commissioning sheet whilst the HTG is on

Switch the HTG ‘off’ at the room thermostat

and isolate the HIU at the fused spur

Close the secondary HTG isolation valves

WARNING

Risk of burns due to water release under high

pressure and hot surfaces can cause serious burns.

For all operations carried out on the HIU always

wear protective equipment.

COMMISSIONING FORM IMPORTANT NOTE

Before commencement of

commissioning ensure that any

flushing bypass valves are closed

Dwelling Address:

Date:

Commissioning

Engineer:

Heat Interface Unit

Type:

Item:

Cert:

Heat Meter (if installed)

Product name:

Type / size:

Communication

modules:

Serial number:

Initial Reading:

/ (Qp)

(kWh)

Check the secondary side strainer, clean if

necessary and replace

Re-open the secondary heating isolation valves

and re-fill and re-pressurize the system, bleed air

if required

Restore electrical power to the HIU

8.4.5 DHW Set-up

Open either the kitchen sink DHW outlet or

any other outlet without a TMV or thermostatic

control. Using a measuring cap adjust the flow

rate to achieve a constant 12 l/m

Adjust actuator until the DHW temperature of

55° has been achieved at the outlet and is steady

for three minutes

Complete the ‘DHW’ section of the

commissioning sheet whilst the DHW is

running

SECONDARY READINGS PRIMARY HEAT METER READINGS

Flow Temp

(°C)

Return Temp

(°C)

Flow Rate

(m/h)

Flow Temp

(°C)

Return Temp

(°C)

Power

(kW)

HEATING

SECONDARY READINGS PRIMARY HEAT METER READINGS

Location

(Tap DHW

Measured)

DHW Flow

Rate (l/m)

DHW Temp

(°C)

Flow Rate

(m/h)

Flow Temp

(°C)

Return

Temp (°C) Power (kW)

DHW

HEAT INTERFACE UNIT COMMISSIONING

Page 28

HEAT INTERFACE UNIT MAINTENANCE

Page 29

COMMENTS

Commissioning

witnessed by:

On behalf of:

Print name:

Company:

Signature:

Date:

Commissioning

engineer:

9. MAINTENANCE

COMPONENT OPERATION SERVICE FREQUENCY

HIU Check HIU case for damage Every 2 years

Check all HIU fixings are secure Every 2 years

Check all connections for leaks Every 2 years

Check all pipes for mechanical damage and corrosion Every 2 years

Check that the DHW and HTG flow temperatures are correct Every 2 years

Check that the water in secondary systems (take sample)

has been treated in accordance with BS 7593 Code of

Practice for treatment of water in domestic hot water

central HTG systems

Every 2 years

Wiring Check that all electrical wiring is in good condition, tidy and

safe

Every 2 years

Strainers Check and clean all strainers (Primary and Secondary) Every 2 years

Safety Valves Check the safety valve operation Every 2 years

Heating Pressure Check HTG system pressure is between 1.0 and 1.5 bar. Ad-

just pressure if required.

Every 2 years

Heat Meter Check the heat meter for error messages and ensure the

unit is fully functional

Every 2 years

Isolation Valves Exercise all isolation valves, ensuring that they operate

correctly

Every 2 years

Filling Loop Ensure that the space HTG filling valve is in the closed posi-

tion. Flexible hose must be removed after filling

Every 2 years

Bypass If present, check that the flushing bypass valve is closed Every 2 years

Pump Check pump setting is Proportional Pressure Auto Adapt Every 2 years

HTG Control Valve Remove actuator from HTG control valve, check setting of

the valve is correct and matches HIU label, see section 8.4.2

Check that the pin is moving freely before replacing the

actuator

Every 2 years

DHW Control

Valve

Remove actuator from DHW control valve, check setting

of valve is correct and matched HIU label, see section 8.4.1.

Check that the pin is moving freely before the actuator

Every 2 years

ON / OFF Safety

Valve

Remove actuator from keep warm valve, check setting, see

section 8.4.1

Check pin is moving freely before replacing actuator

Every 2 years

Expansion Vessel Test Preloaded Pressure within expansion vessel - 1 bar Every 2 years

Checks When all checks are complete, open valves on HIU and

restore electrical connection:

1. Do not operate heating or DHW, monitor heat meter

return temperature until stable and record temperature

2. Check DHW temperature, see 8.4.5 and record

3. Check HTG temperature, see 8.4.4 and record

Always follow safety instructions with regard to isolation before commencing any work on the HIU.

Isolate mechanically and electronically.

VALVE MAKE SETTINGS (MARK BELOW)

DHW

Temperature (°C)

Danfoss

DHW Flow Setting

(%)

Heating

Temperature (°C)

Danfoss

Heating Flow

Setting (%)

Bypass

Temperature (°C)

Danfoss

Bypass Flow

Setting (%)

20 30 40 60 80

min

1 2 3 4 5 6

0

min

90 10050 70

20 30 40 60 80

min

1 2 3 4 5 6

0

min

90 10050 70

20 30 40 60 80

min

1 2 3 4 5 6

0

min

90 10050 70

HEAT INTERFACE UNIT TROUBLESHOOTING

Page 30

HEAT INTERFACE UNIT TROUBLESHOOTING

Page 31

10. TROUBLESHOOTING

FAULT POSSIBLE CAUSE REMEDY

No Water From DHW

Outlets

1. Mains cold water supply lost / shut off

Check cold water supply to HIU / MCW

outlet / contact local water authority if

necessary

2. Cold water check valve installed in

incorrect direction

Check direction of flow arrows on the valve.

Refit correctly if necessary

3. DHW or MCW isolation valves on HIU

are closed

Open mains cold water and/or domestic hot

water valves on HIU, determine reason for

isolation first to ensure secondary systems

are complete

4. MCW strainer is blocked Remove and clean MCW strainer

Reduced Flow Rate From

Outlets

1. Low mains water pressure Check pressure, consult local water authority

if necessary

2. Plate heat exchanger is partially blocked Remove PHE, clean and re-install or replace

if necessary

3. Size of service pipe to HIU is too small Pipe size should be increased

4. DHW or MCW isolation valves on HIU are

partially closed Open DCW and/or DHW valves on HIU

5. MCW strainer is blocked Remove and clean MCW strainer

1. Check if HIU has power supply

Determine whether HIU is safe, if

determined safe turn power supply on. If HIU

fused outlet is on check local fuse, if fuse is

operating correctly check circuit breakers

No Hot Water

2. HIU primary isolation valves closed Open primary flow and return isolation

valves

3. DHW temperature in actuator is not set

correctly

Check setting of actuator and re-adjust if

necessary

4. DHW PICV / Actuator is not operating or

set correctly

Check setting of PICV, check operation of

actuator and replace if necessary

5. Primary prepayment valve is closed (if

installed)

Check if valve open, check power supply to

actuator, if power present replace actuator

with correct model

6. Local TMV faulty

Check TMV for correct operation, blockages

or setpoint / to confirm TMV issue check

DHW outlet temperature from outlet

without thermostatic mixing

7. No or low flow from primary system Check flow rate on heat meter and consult

network operator if necessary

8. HIU primary strainer is blocked Isolate HIU electrically and mechanically,

allow to cool, remove and clean strainer(s)

9. Low flow temperature from primary

system

Check flow and return temperature on heat

meter to confirm connected correctly, if

connected correctly and flow temperature is

low consult network operator

10. Plate heat exchanger is blocked Remove PHE, clean and re-install or replace

if necessary

FAULT POSSIBLE CAUSE REMEDY

No Heating

1. Check if the HIU has power supply

Determine whether HIU is safe, if

determined safe turn power supply on. If

HIU fused outlet is on check local fuse, if fuse

is operating correctly check circuit breakers

2. Room stat or programmer is incorrectly

set or faulty

Check HTG control operation, replace if

necessary

3. Primary / secondary isolation valves on

HIU are closed Check valves and open if necessary

4. HTG temperature in actuator is not set

correctly

Check setting of actuator and re-adjust if

necessary

5. HTG PICV / Actuator is not operating Check operation of actuator and replace if

necessary

6. Primary HTG On/Off valve is closed

Check if valve open, check power supply to

actuator, if power present replace actuator

with correct model

7. Primary prepayment valve is closed (if

installed)

Check if valve open, check power supply to

actuator, if power present replace actuator

with correct model

8. Low secondary heating system pressure

Connect filling loop and introduce pressure,

vent radiators, remove filling loop when

complete

9. Air lock within HTG system Vent all radiators and top up system

pressure as required

10. HTG circulation pump not working or set

incorrectly

Check HTG pump for correct setting and

operation, replace if necessary

11. High temperature cut-off switch set too

low / is faulty (if installed)

Check setting against design parameters

and operation of cut-off switch / replace if

necessary

12. No or low flow from primary system Check flow rate on heat meter and consult

network operator if necessary

13. Primary or secondary strainers are

blocked

Isolate HIU electrically and mechanically,

allow to cool, remove and clean strainer(s)

14. Low flow temperature from primary

system

Check flow and return temperature on heat

meter to confirm connected correctly, if

connected correctly and flow temperature is

low consult network operator

15. Plate heat exchanger is blocked Check HTG pump for correct operation,

replace if necessary

Water Discharging From

Safety Valve

1. Pressure above 3 bar Shut down HIU, check charge of expansion

vessel and ensure filling loop is closed

2. Faulty Safety Valve Test pressure in space heating if below 3 bar,

replace safety valve if necessary

Pressure Fluctuating

Within Heating System 1. Faulty expansion vessel Check charge (1 bar) within expansion vessel,

re-charge or replace if necessary

HEAT INTERFACE UNIT

Page 32

HEAT INTERFACE UNIT

This brochure is current as from the publication date. This brochure should not be regarded as an infallible

guide and is not an offer for sale of any particular product. Vital Energi Utilities Limited expressly disclaims

any liability in relation to the accuracy or completeness of this information. Any reliance or use of the

information contained within this brochure is at your risk. Vital Energi reserves the right to modify the

technical data and all other information contained within this brochure without notice. All rights reserved.

We strongly recommend you contact Vital Energi to confirm the specifications are to your satisfaction.

[May 2019]

INTENTIONALLY BLANK

viable sustainable energy solutions for the future

For more information about the vTherm˚tHeat Interface Unit (HIU)

www.vitalenergi.co.uk/vTherm

Table of contents

Popular Heater manuals by other brands

Sencor

Sencor SFH 7700WH Translation of the original manual

Forme

Forme HTR-VERTSNGL installation instructions

Toyotomi

Toyotomi Laser 731 Installation and operation instructions

Mathius

Mathius SH6M Installation instructions and user guide

Hyco

Hyco sun king sk1000 instruction manual

USSC

USSC VF30IL user manual