Vitrex AGR900 Installation manual

Angle Grinder

Safety and Operating Manual

Always wear Vitrex Protective Equipment when using

hand or power tools.

Safety First

Waste electrical products should not be disposed of

with household waste.

Please recycle where facilities exist. Check with your

Local Authority or retailer for recycling advice.

Environmental Protection

ANGLE GRINDER

Owner’s Safety and Operating Manual

You must abide by certain safety precautions when using the grinder. In order to prevent injuries

and damages from occurring, you must always read through this operating manual carefully.

This manual must be kept in a safe place so that the information that it contains is always available. This

operating manual must accompany the equipment if it is transferred to somebody else.

We do not accept any liability for accidents or damage arising from ignoring this manual and the safety

instructions.

SPECIFICATIONS

Model No. AGR900 Speed 12000RPM

Power 900W Hand/Arm Vibration 1.5m/s2

Voltage 230V-240V 50Hz Sound Rating Lpa:86dB(A) Lwa:99.6dB(A)

Protection Class Double Insulated Disc Diameter 115mm

SAFETY INSTRUCTIONS

1Tel: 01283 245430

IMPORTANT! Read all the warnings and instructions. Failure to comply with the warnings and

instructions may cause electric shock, re and/or serious injuries. Strict observance of these

warnings with the use of personal protective equipment minimizes risks of accidents but does not

completely rule them out. Use the appliance as described in these instructions. Do not use it for

which it was not intended. These instructions refer to an appliance that is manufactured in several

models and versions. Carefully read and observe the safety standards and operational instructions

provided hereafter. Store all warnings and instructions for future reference.

The term ‘Power Tool’ in the warnings refers to the machine tools operated by means of (wired) connection to

the electric power supply or battery (wireless).

Important! The Angle Grinder is suitable, when used with the appropriate discs, for the

grinding, sanding, wire brushing, polishing and abrasive cutting of materials such as metal,

wood, plastic and dry bricks. It is prohibited to use dangerous materials in environments

with risk of re/explosion.

SPECIFICATIONS

ANGLE GRINDER

Owner’s Safety and Operating Manual

2

SAFETY IN THE WORK AREA

• Keep the work area clean and well lit. Overcrowded and/or badly lit areas may cause accidents.

• Do not operate power tools in explosive atmospheres, e.g. in the presence of ammable liquids,

gases or powders. Power tools create sparks that may ignite powders or fumes.

• Keep children and unauthorised personnel at a distance when operating a power tool.

Distractions may cause you to lose control of the tool.

• Keep the nylon packaging bags in a safe place. Bags can cause suocation and must be kept out

of the reach of children.

• Use the tool in a well-ventilated area. Ventilation is necessary for cooling the tool and for eliminating

air impurities produced when working.

• Do not operate power tools outdoors in the presence of rain, fog, storms, high or low

temperatures, or in damp or wet environments. Use in these conditions may cause electrocution.

Tel: 01283 245430

ELECTRICAL SAFETY

• The power tool plug must correspond to the socket and power supply. Never modify the plug

in any way. Do not use adapters with earthed power tools. Unmodied plugs and suitable sockets

reduce the risk of electric shocks.

• Do not allow the body of the appliance to come into contact with earthed surfaces such as

pipes, radiators, cookers and refrigerators. If the body is earthed, the risk of electric shock increases.

• Do not expose power tools to rain and do not use them in wet environments. Water permeating

into power tool increases the risk of electric shocks.

• Do not let the cable become worn. Never use the cable to transport, pull or disconnect the

power tool from the power supply socket. Keep the cable away from heat, oil, sharp edges or

moving parts. Damaged or twisted cables increase the risk of electric shocks.

• When using a power tool outdoors, use an extension cable suitable for outdoor use. The use of a

suitable cable reduces the risk of electric shock.

• Use an electric power supply protected by a dierential switch (RCD). The use of a suitable

residual current device (RCD) reduces the risk of electric shock. Consult your electrician.

• Frequently check the power supply cable. Do not crush or tread on the power supply cable. A

damaged cable causes electric shock.

• In case of doubt regarding electricity, consult an experienced technician. The unsafe use of

electricity is very dangerous for yours and other people’s safety.

PERSONAL SAFETY

• Never allow yourself to be distracted. Control what you are doing and use your common sense

when using power tools. Never use the tool when you are tired or under the inuence of drugs,

alcohol or medicines. A moment of distraction when using power tools could cause serious personal

injuries.

• Use personal protective equipment. Always wear eye protection. Protection equipment such

as dust repelling masks, anti-slip safety shoes, gloves, safety helmets, or ear protection reduces the

possibility of personal injuries.

• Prevent switching the appliance on accidentally. Make sure that the switch is in the o position

before connecting the tool to the electric supply and/or to battery units and before taking or

transporting it. Carrying power tools with your nger on the switch or connecting them to the electric

power supply with the switch in the on position can cause accidents.

• Remove any adjustment wrench before switching on the power tool. Any key or spanner left

attached to a rotating part of the power tool may cause personal injuries.

• Do not lose your balance. Always keep an appropriate position and balance. This allows better

control of the power tool in unexpected situations.

• Wear appropriate clothing. Do not wear loose clothing or jewellery. Keep hair, clothing and

gloves away from moving parts. Loose clothing, jewellery or long hair may get entangled in the

moving parts.

3

USE AND MAINTENANCE OF POWER TOOLS

• Do not force the power tool. Use a suitable tool for the operation to be carried out. An appropriate

power tool can perform the work with higher eciency and safety without having to exceed the

parameters intended for its use.

• Do not use the power tool if the on/o switch is not activated properly. Any power tool that cannot

be controlled by it’s switch is dangerous and must be repaired before use.

• Disconnect the plug from the power supply and/or from the power tool battery unit before any

adjustment, replace the accessories or store the power tools. These preventive safety measures

reduce the risk of accidental start of the power tool.

• Store unused power tools out of reach of children and do not allow them to be used by any

unskilled people or those who are not aware of these instructions. Power tools are dangerous if

used by unskilled people.

• Carry out the required maintenance on power tools. Check any possible misalignment or

locking of the moving parts, any breakage of the parts and any other condition that may aect

the operation of power tools. If there is any damage, the power tool must be xed before use.

Numerous accidents are caused by improper maintenance of power tools.

• Keep the cutting elements, where tted, clean and sharpened. Cutting elements in good conditions

and with sharp edges are less likely to lock and can be controlled more easily.

• Use the power tool, accessories and abrasive parts, etc. according to these instructions,

considering the work condition and the operation to be performed. The use of the power tool for

operations other than those for which it is intended may cause dangerous situations.

• Keep a safe distance from moving parts. Touching moving parts causes serious injuries.

• Do not modify the power tool. Taking o, replacing or adding components not included in the

instructions is prohibited and causes the warranty to become null and void.

• Do not leave the power tool running unattended. Turn it o before leaving it unattended in order to

prevent any accidents.

• The power tool must never come into contact with water or other liquids. Use in these conditions

may cause electrocution.

Tel: 01283 245430

• If any devices to be connected to dust extraction and collection systems are provided, make

sure that they are connected and used appropriately. The use of these devices may reduce the

risks connected with dust.

• The user is responsible for other people as far as accidents or damage to people or property are

concerned. Improper use causes accidents and damage.

• Never use with bare or wet feet/hands. Use in these conditions may cause electrocution.

• Processing of harmful materials must be performed in compliance with the laws in force. Some

types of dust and material such as metals, wood, paints, etc. are very harmful to health. Protect yours

and other people’s health using suitable protections and devices.

• Do not approach the cooling air ejection slots. The air generated may contain machining residuals

and small parts that are harmful for your respiratory tracts and eyes.

• Do not cover or insert things in the cooling slots. Unsuitable ventilation of the power tool may start a

re. Accessing the internal parts may damage the tool and cause electrocution.

• Do not use the power tool if the guard is open, damaged or missing. Correctly installed guards

protect your health and allow safe use.

4

SAFETY WARNINGS

Safety warnings apply equally to grinding & abrasive cutting:

• Before installing or removing accessories (discs, etc.), unplug the device. Any maintenance must

be performed safely in order to prevent accidents caused by an unexpected start.

• If the electricity isn’t available (i.e. because of a malfunction, an interruption by the supplying

company because of works, an accidental removal of the plug, etc.) the tool must be switched

o (‘o-0’). This way an accidental restart of the tool will be prevented.

• For work on buildings or load-bearing structures, closed pipes or containers it is important to

check, by means of detectors, that there are not any: electrical or telephone cables, liquids or

gases under pressure (that may be inammable or corrosive) pipes etc. Cutting, even partially,

of masonry may weaken the structure of the entire building causing it to collapse. Leaking of liquids or

gases may cause explosions, re and ooding.

• If the tool stops during use, switch it o immediately. Do not force dicult operations for the tool.

• Keep the tool stable with both hands and stand in a safe work position. The strains caused by

working lead to stress which must be contrasted with your force.

• Fasten the item you are working on with a vice or another device. An item held by hand can

suddenly cause an accident.

• This power tool is intended to function as a grinder & cutting machine. Read all safety warnings,

instructions and specications provided with this power tool. Failure to follow all instructions listed

below may result in electric shock, re, and/or a serious accident.

• Do not use attachments which are not specically made or recommended by the tool

manufacturer. The mere fact that a part may be attached to the power tool does not guarantee safe

operation.

• The rated speed of the part must be at least equal to the maximum speed indicator on the

power tool. The parts, if made to run at a speed higher than specied, may break and be thrown into

the air.

• The outside/inside diameter and thickness of your part must be adapted to the characteristics of

the capacity of your power tool. Parts which are not the correct size cannot be adequately protected

or controlled.

• The shape of the grinders, anges, pillows or support of any other part must properly t the

spindle of the power tool. Parts with shaft holes that do not match the mounting hardware on the

power tool will not remain in balance, will vibrate excessively and may cause loss of control.

• Do not use a damaged part. Before each use, examine the parts, such as the abrasive grinders

to check for any traces of chips or cracks, the support cushions to check for any cracks,

lacerations or excessive wear, and the metal brushes to uncover any loose or broken wires. If

the power tool or part has been dropped, examine for signs of damage or install an undamaged

part. After checking and installing a part, distance yourself and any others present from the

scope of the rotating part and run the power tool at maximum no load speed for one minute. The

damaged parts will normally break during this trial.

• Always wear personal protective equipment . Depending on the application, use a face shield,

mask or goggles. Depending on the task, wear a dust mask, hearing protectors, gloves and an

apron to guard against abrasive fragments while working. Eye protection must be able to protect

against ying debris produced by dierent operations. The dust mask or respirator should be able to

lter the particles produced from your work. Prolonged exposure to high noise levels can cause hearing

loss.

• Keep people at a safe distance from the work area. Anyone entering the work area must wear

personal protective equipment. Fragments of the work piece or broken parts may y o and cause

injury in the immediate vicinity of the work area.

Tel: 01283 245430

5Tel: 01283 245430

• Hold the tool only by the insulated gripping surfaces, while performing operations in which the

cutting part may be in contact with hidden wiring, or with its own cord. Contact between the

cutting part and a ‘live’ cable may also cause the exposed metal parts of the power tool to be ‘live’ and

give an electric shock to the operator.

• Position the cord away from the rotating part. If you lose control of the tool, the cord can be cut or

twisted and your hand or arm may be pulled into the rotating part.

• Never store the power tool until all of the parts have completely stopped moving. The rotating part

can grip the surface and draw the power tool out of your control.

• Do not run the power tool while carrying it to the side. Accidental contact with the moving part may

lead to it getting caught in your clothes and can entangle the moving part.

• Regularly clean the ventilation openings of the power tool. The motor fan will draw dust inside the

casing and an excessive accumulation of powdered metal may cause electrical hazards.

• Do not operate the power tool near ammable materials. Sparks could cause these materials to

ignite.

• Do not use parts which require liquid coolants. The use of water or other liquid coolants may result

in electrocution or electric shock.

KICKBACKS

Kickback is a sudden reaction to catches or entanglements of the rotating grinder, brush support cushions or

any other part. The jammed or entangled item causes a rapid blockage of the movement of the part, which

in turn forces the power tool out of control, opposing the direction of movement of the part at the point of

blockage.

For example, if an abrasive grinder is jammed or entangled by the work piece, the rim of the grinder which

comes into contact with the piece may cut into the surface of the material, causing the grinder to jump or

come o. The grinder can jump towards the operator or in the opposite direction, depending on the direction

of the grinder movement when it jams. The abrasive grinders can also break in these conditions.

Kickback is the result of misuse of the power tool or of incorrect procedures or conditions of usage, and can

be avoided by taking proper precautions as specied below.

• Firmly grip the tool and place your body and your arms in such a position so as to resist the

force of the kickback. Always use the auxiliary handgrip, if present, to have maximum control

over kickback or torque reactions during start-up. The operator can control torque reactions and

kickbacks if the appropriate precautions have been taken.

• Never put your hands near the rotating part- kickback from the part can cause injury to your hand.

• Do not place yourself in the area towards which the power tool will move in case of kickback.

The backlash will push the tool in the opposite direction to that of the grinder at the moment of

entanglement.

• Take particular care when working on corners, sharp edges, etc. Avoid making the part jump

or catch. Corners, sharp edges or jumps have a tendency to trap the rotating part and cause loss of

control or kickback.

• Do not connect the blade of a chainsaw for wood, or the blade of a toothed saw to the power

tool. Such blades cause frequent kickback and loss of control.

6

GRINDING AND ABRASIVE CUT-OFF OPERATIONS

• Use only types of grinding wheel that are compatible with your electric tool and the specic

protection of the grinding wheel of your choice. The grinding wheels which were not conceived for

your power tool cannot be adequately protected and are not safe.

• The protection must be rmly xed to the electric tool and safely positioned so that the operator

is exposed to the grinding wheel as little as possible. The protection allows to protect the operator

from fragments of broken grinding wheel and from an accidental contact with the wheel.

• The grinding wheels must only be used for the recommended applications. For example: do

not grind with the side of the grinding wheel to cut something. Cutting grindstones are destined to

peripheral grinding; by pushing on the side of these wheels, they can break.

• Always use anges which are not damaged and whose shape and size are correct for the

grinding wheel of your choice. Adequate anges for grinding wheels support them reducing the risk of

breaking the wheel. Flanges for cutting wheels can be dierent from anges for grinding wheels.

• Do not use used grinding wheels of bigger electrical tools. Grinding wheels destined to bigger

electrical tools are not adequate because of the higher speed of smaller tools: the grinding wheel can

explode.

CUTTING OPERATIONS

• Do not ‘block’ the cutting wheel or push excessively. Do not try to make the cut excessively

deep. By pushing on the wheel, its load increases as well as the chances of twisting or bending the

wheel while cutting and the chances of recoil or breaking the wheel.

• Do not stand next to the rotating wheel or behind it. While working, the grinding wheel separates

from the body and the possible recoil can push it and the electric tool towards you.

• When the grinding wheel bends or when the cutting operation is interrupted for any reason,

remove the power plug of the electric tool and keep it still until the wheel stops. Do not try to

remove the cutting wheel from the cut while it is moving or a recoil can happen. You have to

identify the reasons why the wheel bent and take appropriate measures so that it doesn’t happen again.

• Do not resume the cutting operation of the working item. Let the grinding wheel reach its

maximum speed and carefully insert it again in the cut. If the electrical tool is restarted while inside

the working item, the grinding wheel can stop, go back up or have a recoil.

• Arrange a stand for the panels or any other working piece with big size in order to minimize the

risk that the wheel gets stuck or recoils. Big working pieces tend to bend under their own weight.

Stands must be put under the working piece near the cutting line and near their edge on both sides of

the wheel.

• Be careful especially when doing a ‘groove cut’ on existing walls or other areas that are not

visible. The jutting out grinding wheel can cut water or gas pipes, electrical wires or objects, events

which can cause recoil.

NOISE AND VIBRATIONS

The level of noise and vibrations shown on the attached sheet are average values for the use of the power

tool. The use of dierent attachments, dierent materials, dierent processes such as cutting or wire brushing

and the lack of tool maintenance all have signicant inuence on noise and vibration. Therefore adopt all

the preventative measures necessary to eliminate any possible damage due to loud noises and strain from

vibrations; wear ear phones, anti-vibration gloves, take breaks while working and ensure the power tool and

its accessories are kept ecient at all times.

Tel: 01283 245430

USING A METAL BRUSH ATTACHMENT (NOT INCLUDED)

• When using the brush, even during normal operation, metal bristles may be emitted. Do not

apply excessive weight on the brush. The wire bristles can easily penetrate light clothing and/or skin.

If it is recommended to use protective equipment for wire brushing, do not allow this to interfere

with the metal wire disc or the wire brush in any way. The metal wire disc or the brush may expand

in diameter due to workload and centrifugal forces.

7Tel: 01283 245430

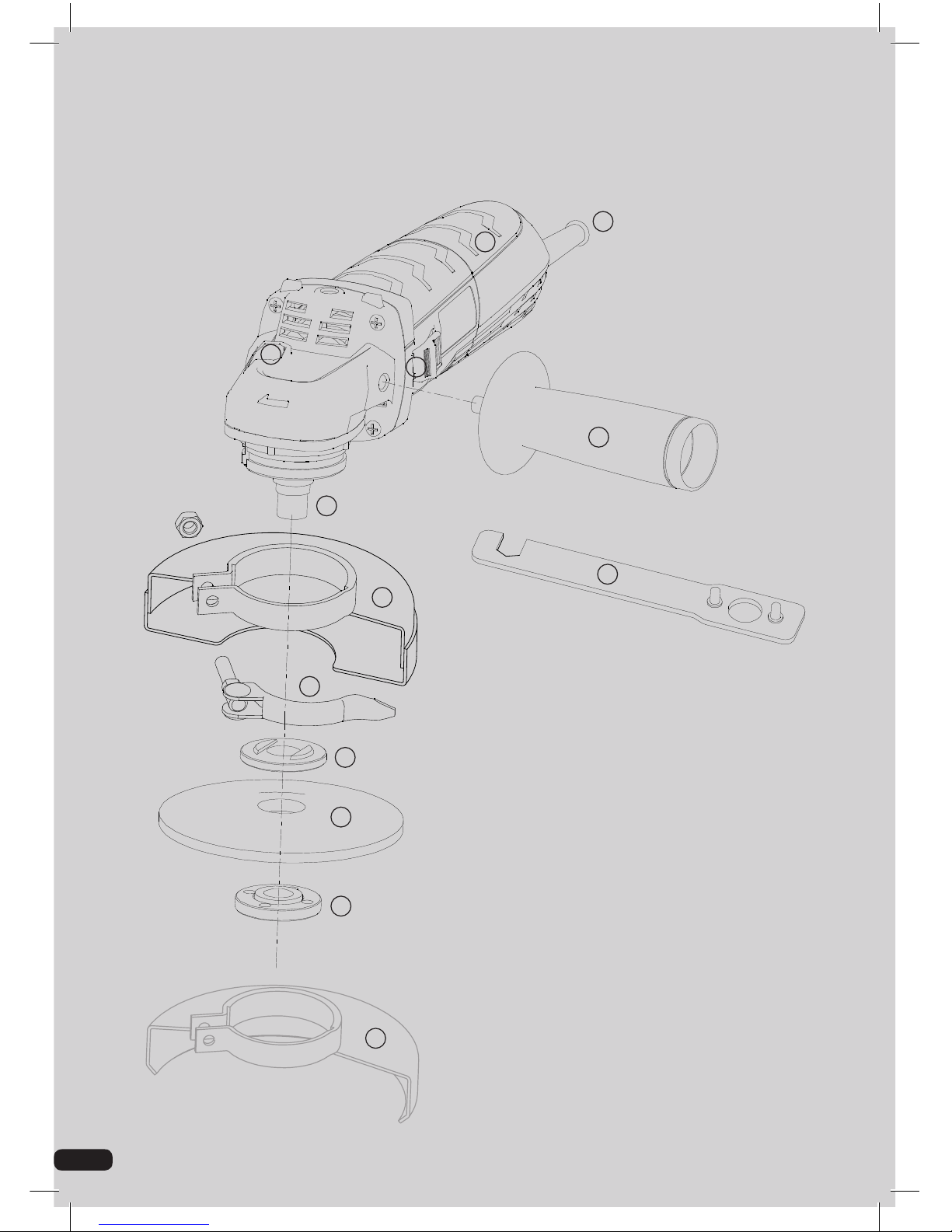

COMPONENTS

Refer to diagram above and the following

gures, attached to these instructions.

1. Power supply plug and cable

2. Main handgrip

3. Start/stop switch

4. Spindle Lock

5. Disc holder shaft

6. Quick release cutting blade guard

7. Quick Release Lever

8. Disc holder ange

9. Abrasive disc (1 x included)

10. Disc lock ange

11. Disc locking key

12. Side handgrip

13. Quick release grinding blade guard

We thank you for having purchased this power tool that will hereafter also be referred to as ‘Angle Grinder’.

These instructions contain information deemed necessary for proper use, knowledge and standard tool

maintenance. It does not provide information on the processing techniques on various material.

1

2

10

3

5

12

11

6

7

4

9

8

13

8

TRANSPORT

Always use the packaging or case provided when transporting the tool; this will protect it from impact, dust

and humidity which can compromise normal operation. During transport, remove the abrasive disc, brush,

etc. from the machine.

HANDLING

Firmly grasp the hand tool (pos. 2) without using the switch; keep the tool well away from your body and after

use place it down gently once the disc has stopped.

STARTING UP

When choosing where to use the power tool, the following should be considered:

- That the area is not damp and is sheltered from the elements.

- That the working area is suciently large and free from obstacles.

- That the area is well lit.

- That the tool is used close to the interrupter switch.

- That the power supply system is earthed and conforms to the standards (only if the power tool is class 1,

and equipped with a plug with earth cable).

- That the room temperature should be between 10° and 35°C.

- That the environment is not in a ammable/explosive atmosphere.

Take out the machine and components and visually check that they are perfectly intact; then proceed to

thoroughly clean them in order to remove any protective oil from metal surfaces.

ASSEMBLING PROTECTION PROVIDED WITH THE ANGLE GRINDER

IMPORTANT! Only use 115mm discs with this Angle Grinder.

Protection already assembled on the Angle Grinder:

Check that the protection has been correctly assembled and xed.

Disassembled protection provided:

Depending on the protection in use, follow the relevant steps below.

SIDE HANDGRIP ASSEMBLY (pos.12)

The lateral handgrip can be assembled on any side on which there is a threaded hole (pos.12); it is usually

secured on the left in order to grab hold with the left hand, but it can be assembled in the position of your

preference (e.g. for left-handed people). Insert the handgrip into the threaded hole of the device and secure

by screwing tightly.

DISC ASSEMBLY (pos.8)

1. Always unplug the Angle Grinder before changing discs.

2. Check that the rotation direction of the disc corresponds to that of the Angle Grinder.

3. Turn the Angle Grinder upside down.

4. Check that the diameter of the seat of the 2 anges and the hole of the disc are the same size;

to this end, it is better to measure using a gauge (not included) and reading the technical data.

5. Temporarily block the rotation of the motor shaft by pressing the button (pos.4) and unscrew the

disc lock ange (pos.10). Do not disassemble the disc hold ange (pos.8).

6. Insert the abrasive disc (pos.9) onto the shaft (pos.5) and place it on the disc hold ange (pos.8). Make

sure the disc hold ange rabbet goes into the disc hole.

7. Correctly place the disc lock ange (pos.10). Screw the disc block ange (pos.10) and x

it carefully using the xture key (pos.11): while doing so, keep the shaft block button pressed (pos.4) The

locking key should be inserted with the two pins, in the disc lock ange holes.

8. Rotate by hand and check that the disc is well centred and well secured by the anges.

9. Keeping the grinder away from the body, carry out a test run without load for 1 minute.

Tel: 01283 245430

9

SPEED CONTROL (pos.18 where tted)

To regulate speed, use the regulator (pos.18 if present) according to the scale:

- low number = high speed

- high number = low speed

Follow any other information on the Angle Grinder and data sheet attachment.

We recommend repeating these operations several times before starting work, in order to familiarise yourself

with the controls as far as possible. If you notice any working defects, switch o the power tool and consult

the chapter ‘Problems, causes and solutions’. When not using the tool, turn it o and disconnect the plug

from the socket.

Tel: 01283 245430

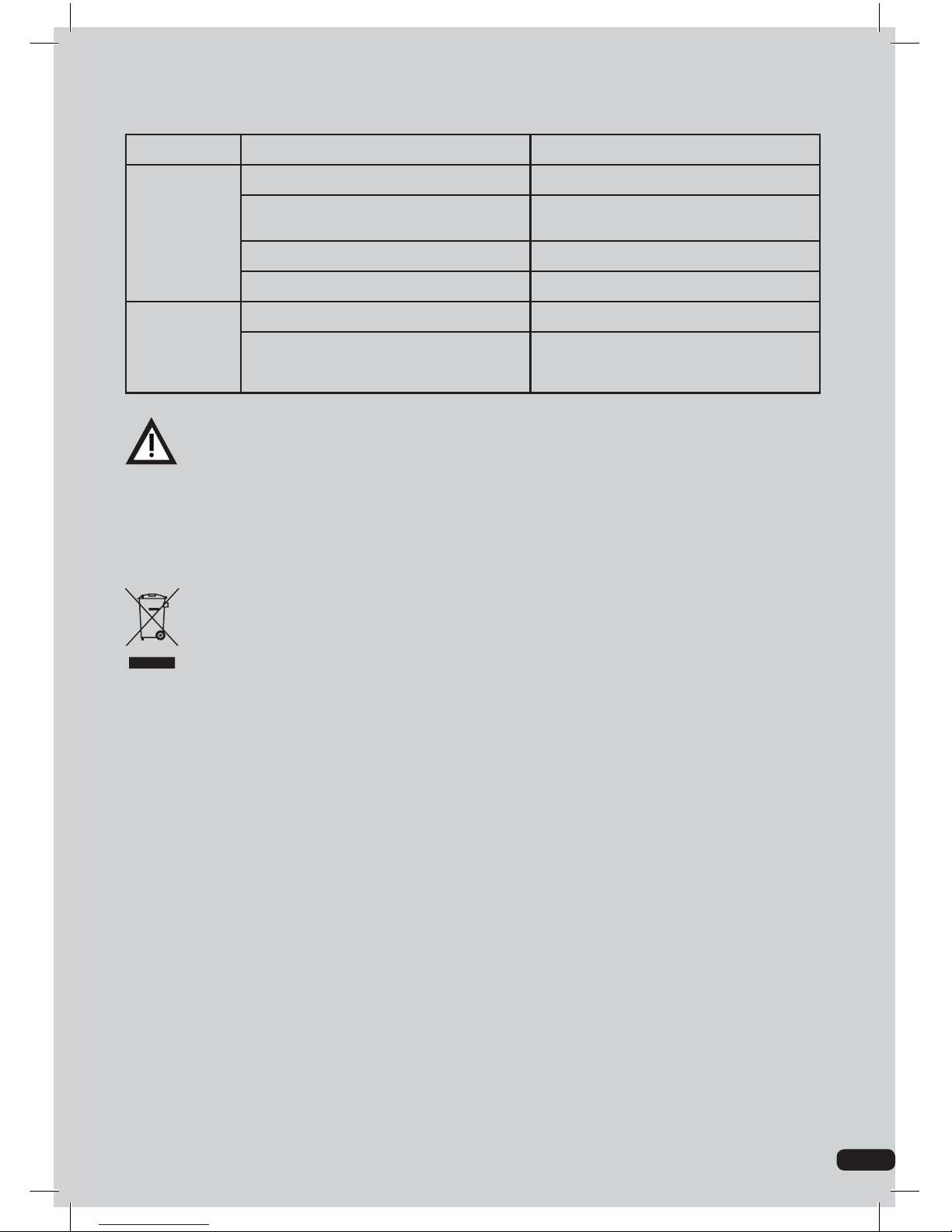

ELECTRONIC SPEED REGULATION (where tted)

You need to assess the type of work, type, diameter and material of the part; perform tests at several speeds

on a scrap part before performing on real parts. In general set the speed according to the following chart,

depending of the type of work and accessory used. Also observe any information provided with the parts;

never exceed the maximum rotation speed indicated.

For the backing pad (pos.19) use only low speeds under 6,000 min-1.

WORKS ACCESSORIES MATERIAL OF THE

PART

High speeds

≥6000 min -1

<15000 min -1

Cut, Grind Abrasive discs for

cutting and grinding

Metals Hardwood

Low speeds

>3000 min -1

<6000 min -1

Brush, polish, clean Rotating brushes,

backing pad with

abrasive paper disc or

fabric disc

Coated surfaces,

plastic, softwood, heat

sensitive materials

CONTINUOUS OPERATION

For single and double-action switches, you can set the xed switch to ‘ON-I’: when it is switched on, press

to block it. To deactivate this function and switch o, simply press ‘OFF-0’ for a short while and release

immediately. In the event the electricity supply is cut o, press the ‘OFF-0’ switch.

ABRASIVE DISCS

Purchase high quality abrasive discs which have the maximum external diameter indicated in the technical

details of the grinder, a suitable hole which ts the requirements of the anges, and which are suitable for the

maximum speed of the grinder and the materials to be processed. Contact your retailer who will be able to

give you the best advice. Thorough use, discs wear thin, lose their calibration and expire after a certain date.

Always make a visual check before using and replace if necessary. For the assembly and replacement, go to

the ‘INSTALLATION- Abrasive disc assembly’ chapter. Handle and store the discs with care, do not subject

them to impact, bending, compression, moisture, high or low temperatures, and direct sunlight.

MAINTENANCE & SUPPORT

IMPORTANT! Before any checks or adjustment unplug the tool from the

electric power supply.

Have the maintenance operations carried out on power tools by qualied technical

personnel only using original spare parts. This will allow the safety of the power tool to be

maintained.

Do not attempt to repair the power tool or to access internal parts. Interventions by

unqualied personnel and unauthorised by the manufacturer could create serious risks and will

cause the warranty to be null and void.

The working life and costs also depend on constant and meticulous maintenance. Take good care of your

power tool and clean it regularly. In this way its eciency will be ensured and its life span extended.

- Remove dust and machining residuals with a cloth or a brush with soft bristles.

- Do not wet or spray water over the power tool - risk of internal inltrations.

- Do not use any inammables, detergents or solvents.

- The plastic parts can easily be damaged by chemical agents.

- Do not use compressed air for cleaning: risk of material ejection!

- Be careful when cleaning the switch, motor fan slots and hand grips.

Protect the unpainted parts with protective oil and use the original packaging or case (where tted) to

protect it.

STARTING AND STOPPING THE DEVICE

Single action switch:

- To start, press the ‘ON-I’ switch forward (pos.3).

- To stop, release the ‘OFF-0’ switch.

Double-action switch:

- To start, press the ‘ON-I’ switch down and then forward (pos.3)

- To stop, release the ‘OFF-0’ switch.

Switch with safety device:

- To start, in sequence press the safety device (pos.4) and then press the ‘ON-I’ (pos.3) switch.

- To stop, release the ‘OFF-0’ switch.

RE-ASSEMBLING THE FLANGES (pos.8-10)

In the event both anges have been removed, pay attention to the reassembling sequence:

1. Insert the disc hold ange (pos.8) into the threaded shaft; this ange has a contoured sear that must be

coupled with the contored shaft.

2. Screw the disc lock ange (pos.10) into the threaded shaft and tighten with the disc locking key.

10

Tel: 01283 245430

IMPORTANT! If the power tool still fails to operate correctly after you have carried out the

above operations, or in the event of anomalies other than those described above, take it

to an authorised service centre with proof of purchase and ask for the spare parts. Always

provide the information shown on the technical data label.

TROUBLESHOOTING

PROBLEM CAUSES SOLUTIONS

The power tool

fails to start

Power supply line disconnected Check the electric power supply line

Plug not inserted Insert the plug in the electric power supply

socket and press the start button

Switch in the ‘OFF - 0’ position Flip the switch to ‘ON - I’

Electrical fault Contact an authorised service centre

The power tool

vibrates a lot

Damaged or unbalanced accessory Substitute the accessory

Incorrectly assembled accessory Disassemble the accessory, clean the

components and reassemble according to

the instructions

DISPOSAL

In order to protect the environment, proceed according to the local laws in force. Contact the relevant

authorities for more information. When the machine is no longer usable or repairable, deliver the machine and

packaging to a recycling centre.

Electric and electronic waste may contain potentially hazardous substances for the environment

and human health. It should therefore not be disposed of with domestic waste, but by means of

dierentiated collection at specic centres or returned to the vendor in the event of purchasing new

equipment of the same type. Illegal disposal of waste will result in administrative sanctions.

WARRANTY

The product is protected by law against all non-conformities with regards to its stated characteristics,

provided that it has been used solely in the way described in this user’s instructions, it has not been

tampered with in any way, it has been stored correctly, it has been repaired by authorised personnel and,

where necessary, only original spare parts have been used. In the event of industrial or professional use or

similar, the warranty is valid for 12 months. To issue a request for intervention covered by warranty, proof of

purchase must be shown to the retailer or authorised service centre.

AMENDMENTS

The text, gures and data correspond to the standards in place on the date of printing the instructions

contained herein. The manufacturer reserves the right to update the documentation if changes are made to

the appliance, without being bound by any obligations.

© No part of this publication and the documentation enclosed with the appliance may be reproduced without

written permission from the manufacturer.

The Maltsters, Wetmore Rd, Burton Upon Trent, Staffordshire, DE14 1LS, UK

Tel: +44 (0) 1283 245 430 www.vitrex.co.uk

Angle Grinder

Safety and Operating Manual

Table of contents