Vivace HART VTT10-FH Quick guide

INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL

July/2019

VTT10-FH

HART® TEMPERATURE TRANSMITTER

field model

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

2

COPYRIGHT

All rights reserved, including translations, reprints, complete or partial reproduction of this

manual, patent concession or model register of use/project.

No part of this publication may be reproduced, copied, processed or transmitted on any manner

or any medium (photocopy, scanning, etc.) without the express permission of Vivace Process

Instruments Inc., not even for training or electronic systems.

HART

®

is a registered mark of HART Communication Foundation.

NOTE

We have reviewed this manual with great care to maintain compliance with the hardware and

software versions described herein. However, due to the dynamic development and version upgrades,

the possibility of technical deviations cannot be ruled out. We cannot accept any responsibility for the

full compliance of this material.

Vivace reserves the right to, without notice, make modifications and improvements of any kind

in its products without incurring in any circumstances, the obligation to make those same modifications

to products sold previously.

The information in this manual is frequently updated. Therefore, when using a new product,

please check the latest version of the manual on the Internet through our website

www.vivaceinstruments.com, where it can be downloaded.

You customer is very important for us. We will always be grateful for any suggestions for

improvements as well as new ideas, which can be sent to the e-mail: contato@vivaceinstruments.com

preferably with the title "Suggestions".

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

3

SUMMARY

1

EQUIPMENT DESCRIPTION ........................................................................................................ 6

1.1.

BLO K DIAGRAM ......................................................................................................................................... 6

2

INSTALLATION ............................................................................................................................ 8

2.1.

ME HANI AL ASSEMBLY ........................................................................................................................... 9

2.2.

ELE TRI AL ONNE TION ...................................................................................................................... 11

2.3.

PRO ESS ONNE TION ........................................................................................................................... 13

3

CONFIGURATION ...................................................................................................................... 14

3.1.

LO AL ONFIGURATION .......................................................................................................................... 14

3.2.

JUMPER ONFIGURATION FOR LO AL ADJUST AND WRITE PROTE TION ...................................... 15

3.3.

LIQUID RYSTAL DISPLAY (L D) ............................................................................................................. 16

3.4.

LO AL ADJUST ONFIGURATION TREE ................................................................................................. 16

3.5.

HART

®

ONFIGURATOR ............................................................................................................................ 17

3.6.

HART ONFIGURATOR PROGRAMMING TREE ...................................................................................... 18

3.7.

FDT/DTM ONFIGURATION....................................................................................................................... 20

4

MAINTENANCE ..........................................................................................................................

4.1.

HART PROGRAMMER DIAGNOSTI S ...................................................................................................... 22

4.2.

ADDITIONAL DIAGNOSTI S ...................................................................................................................... 22

4.3.

ASSEMBLY AND DISASSEMBLY PRO EDURE ....................................................................................... 23

4.4.

SPARE PARTS ............................................................................................................................................ 24

5

CERTIFICATION ......................................................................................................................... 5

6

TECHNICAL CHARACTERISTICS ............................................................................................. 6

6.1.

IDENTIFI ATION ......................................................................................................................................... 26

6.2.

TE HNI AL SPE IFI ATION..................................................................................................................... 26

6.3.

OMPATIBLE SENSORS ............................................................................................................................ 27

6.4.

ORDERING ODE....................................................................................................................................... 28

7

WARRANTY ............................................................................................................................... 9

7.1.

GENERAL ONDITIONS ............................................................................................................................. 29

7.2.

WARRANTY PERIOD .................................................................................................................................. 29

APPENDIX ........................................................................................................................................ 30

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

4

1

It is extremely important that all the safety instructions, installation and operation in this manual are

followed faithfully. The manufacturer is not liable for damage or malfunction caused by improper use

of this equipment.

It is recommended to strictly following the rules and good practice relating to installation, ensuring

correct grounding, noise insulation and good quality cables and connections in order to provide the

best performance and durability to the equipment.

Special attention must be considered in relation to installations in hazardous areas, where applicable.

WARNING

•Appoint only skilled people, trained with process and equipment;

•Install equipment only in operation compatible areas, with the proper connections and

protections;

•Use proper safety equipment for any handling device in field;

•Turn area power off before equipment installation.

SAFETY PROCEDURES

SYMBOLOGY

Caution - indicates risk or error source

Important Information

General or Specific Risk

Electric Shock Danger

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

5

GENERAL INFORMATION

Vivace Process Instruments ensures the operation of this equipment, according to the

descriptions contained in its manual, as well as technical characteristics, not

guaranteeing its full performance in particular applications.

The operator of this equipment is responsible for observing all aspects of safety and

prevention of accidents applicable during the execution of the tasks in this manual.

Failures that might occur in the system, causing damage to property or injury to

persons, shall additionally be prevented by external means to a safe outlet for the

system.

This equipment must be used only for the purposes and methods proposed in this

manual.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

6

1 EQUIPMENT DESCRIPTION

VTT10-FH is the field model for Vivace’s temperature transmitter family, projected to be installed

directly on sensor or on a Ø 2” tube, panel or wall. It attends several sensor types, such as thermocouple,

RTDs, resistance and millivoltage signals.

The transmitter is powered by a 12 to 45 Vdc voltage and modulates communication over a 4-20 mA

output signal, according to NAMUR NE43 standard, using HART

®

protocol. The configuration uses HART®

7 (older versions compatible) communication protocol, already established on the world of industrial

automation for configuration, calibration, monitoring and diagnostics.

Through a HART configurator or any EDDL or FDT/DTM-based tool it is possible to configure sensor

type, measuring range, work unit, calibration and also monitoring measured variables with device status.

Configuration via local adjust is also possible with an auxiliary magnetic screwdriver.

Focusing on high performance and robustness, it was projected with the most recent electronic

component and material technology, offering long-term reliability for every scale systems.

1.1. BLOCK DIAGRAM

Component modularization for transmitter is described on the following block diagram.

Figure 1.1 – Transmitter block diagram.

The sensor signal passes through RF EMI filter and goes to ADC block, where it is converted to a

digital value. This digital value later will be converted in the temperature, according to selected sensor type.

The temperature value is finally converted in a current signal, proportional to the calibrated range.

The sensor signal is galvanic isolated from output signal, avoiding ground loop.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

7

The input block (DC power supply) is responsible for the electric source for all circuits. Current control

block is composed by a circuit to transform digital values generated by microcontroller into 4-20 mA electric

current, proportional to the primary variable value.

HART

®

channel and HART

®

modem blocks provide the interface between microcontroller signals

and HART

®

bus connected to monitored device. Local adjust block enables local configurations by user.

The display board has the controller block to interface LCD and CPU communication signals,

adapting all the messages to be shown on display.

Finally, the CPU block can be seen as the transmitter brain, where all the activities happen, such as

time control, HART

®

machine, besides the common transmitter routines: configuration, calibration and

generation of output current, proportional to the primary variable.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

8

2 INSTALLATION

RECOMMENDATION

When taking the equipment to the installation location, transfer it in the original packaging.

Unpack the equipment at the installation location to avoid damage during transportation.

RECOMMENDATION

Model and specification of equipment are indicated on identification plate, located at the top of

the housing. Check if supplied specification and model correspond to application requirements.

STORAGE

The following precautions should be observed when storing the equipment, especially for a

long period:

1) Select a storage area that meets the following conditions:

a) No direct exposition to rain, water, snow or sunlight.

b) No exposition to vibration and shocks.

c)

Normal temperature and humidity (around 20°C / 70°F, 65% RH)

.

However, it can also be stored under the following temperature and humidity intervals:

●Ambient Temperature: -40°C to 85°C (without LCD)* or -30°C to 80°C (with LCD)

●Relative Humidity: 5% to 98% RH (@ 40°C)

(2) For equipment storage, use original factory package (or similar).

(3) If storing an already used Vivace equipment, dry every moist part and clean all

connections that was in contact with the process. Keep covers and connections closed and

properly protected for its specific application and requirements.

* Only for general use. For explosion proof version, follow product certification requirements.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

9

.1. MECHANICAL ASSEMBLY

VTT10-FH was developed to be installed in the field, thus supporting exposition to several

environment situations, keeping good performance through any temperature, humidity and vibration

variations.

The transmitter’s housing is IP67 protected, being immune to water contact to electronic circuit and

electrical connections, since cable gland or conduit for electrical connection is correctly assembled and

sealed with non-hardening substance. Covers must also be tight to avoid humidity, since housing screws

are not protected by painting.

The electronic circuit is protected by varnish but constant water or corrosion exposure may

compromise this protection and damage the electronic components.

Figure 2.1 shows the dimensional drawing and mounting positions for VTT10-FH.

Figure 2.1 – Dimensional and mounting drawings for VTT10-FH.

To avoid the risk of involuntary loss of VTT10-FH covers due to vibration, for instance, it can be

locked by screw, as shown on figure 2.2.

VTT10-FH is a field device, so it can be installed through a mounting bracket on a 2” tube attached

with a U clip. For best LCD positioning device enables its display to be rotated 4 x 90°, according to figure

2.3. The transmitter can also be attached with the same mounting bracket to a wall or panel.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

10

Figure 2.2 – Front cover lock.

Figure 2.3 – Housing positioning.

VTT10-FH liquid crystal display can be rotate 4 x 90° so indication will be adequate for user

visualization.

Figure 2.4 illustrates rotation possibilities for VTT10-FH LCD.

Figure 2.4 – 4 x 90° LCD rotation.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

11

. . ELECTRICAL CONNECTION

In order to access the terminal block user must remove VTT10-FH rear cover. First, loose cover lock

screw (see figure 2.5) by turning it clockwise.

Figure 2.5 – Rear cover lock.

Figure 2.6 shows the terminals for power supply (PWR BUS) and the sensor terminals (1, 2, 3, 4). It

also shows the grounding terminals (internal and external) and HART communication terminals for VTT10-

FH. For powering the device, it is recommended to use a 22 AWG twisted pair cable.

Figure 2.6 – Terminal connection and description.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

12

Table 2.1 describes VTT10-FH terminal functions.

Table 2.1 – Terminal description.

NOTE

All cables used for connecting VTT10-FH with HART

®

network must be shielded to avoid

interference or noise.

Conduits used for power cables must be assembled in order to avoid water entrance in the device

terminal block. Conduit screws must be sealed according to specific area required standards.

Non-used electrical connection must be sealed with appropriate cover.

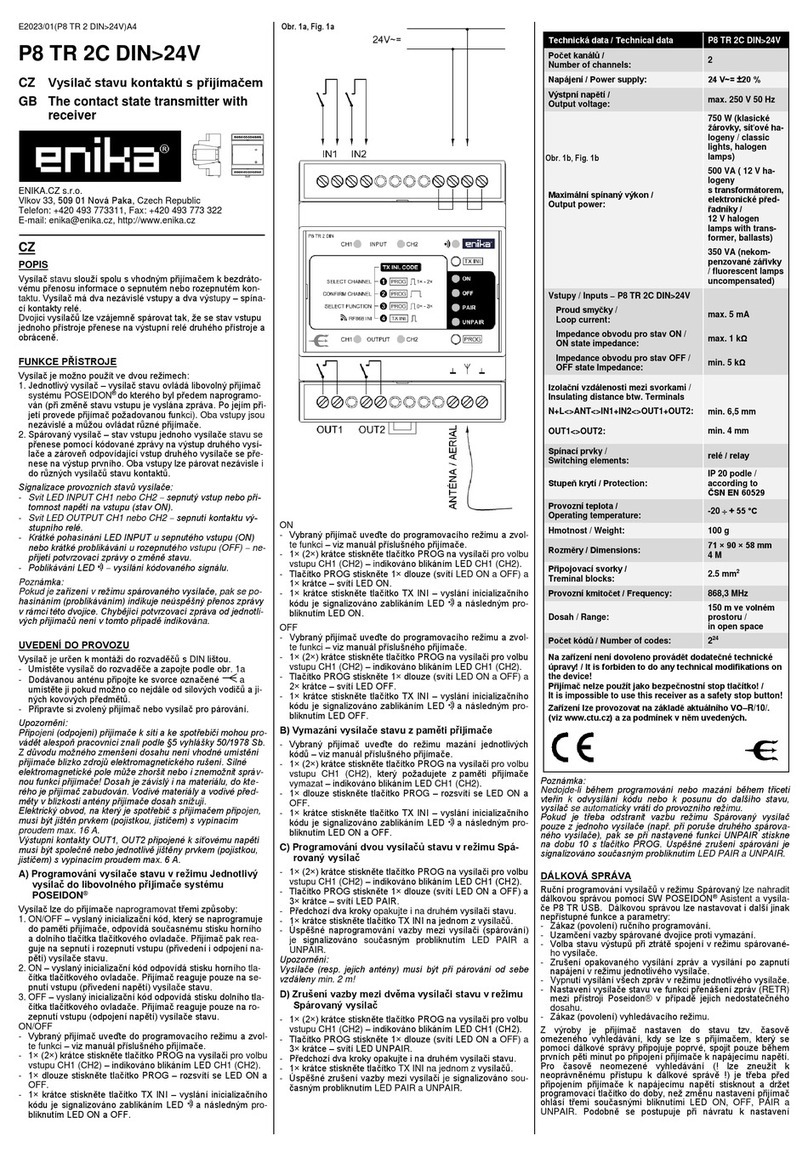

Figure 2.7 shows the correct installation for conduit, in order to avoid the entrance of water or any

corrosive material that may cause damage to the device.

Figure 2.7 – Conduit installation.

Termina

l Description

Power Terminals – PWR BUS - 24 Vdc not polarized

Grounding Terminals – 1 internal and 1 external

Test Terminals – TEST – current loop measurement (4-20 mA) without open circuit

Communication Terminals – COMM – HART

®

communication with configurator

Sensor Terminals – temperature sensor connection terminals

NOTE

It is extremely important to ground the equipment for complete eletromagnetic protection and

also to ensure the correct performance of transmitter on the HART network.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

13

.3. PROCESS CONNECTION

Following are illustrated the VTT10-FH sensor connection for different sensor types:

Figure 2.8 – 2-wire RTD or resistive sensor connection. Figure 2.9 -3-wire RTD or resistive sensor connection.

Figure 2.10 - 4-wire RTD or resistive sensor connection. Figure 2.11 – Differential, maximum, minimum or backup

RTD or resistive sensor connection.

Figure 2.12 – Thermocouple or mV sensor connection. Figure 2.13 - Differential, maximum, minimum or backup

thermocouple or mV sensor connection.

Figure 2.14 – 4–20 mA input connection

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

14

3 CONFIGURATION

The transmitter can be configured by any HART

®

compatible programmer. Vivace offers the

interfaces VCI10-H (USB, Android and Bluetooth) as a solution for configuring and monitoring any HART

®

device. VTT10-FH can also be configured by local adjust using Vivace magnetic screwdriver.

3.1. LOCAL CONFIGURATION

Transmitter’s local configuration is executed by using Vivace’s magnetic

screwdriver on Z and S orifices, located at housing superior side, under

identification plate. Orifice Z starts local configuration and changes the field to

be configured. Orifice S is responsible for changing and saving the new value

on the selected field. Saving after LCD value changing is automatic.

Figure 3.1 shows orifices Z and S for local configuration, stamped on device

housing, and their functions on magnetic screwdriver actuation.

Insert the magnetic screwdriver on Zero orifice (Z). icon appears to indicate

that device has recognized the screwdriver action. Keep the magnetic

screwdriver inside until “LOCAL ADJST” message is shown on display, then

remove it for 3 seconds. Insert the magnetic screwdriver into Z orifice again, so

user can navigate through local adjust parameters.

Table 3.1 indicates actions executed by magnetic screwdriver when inserted

on Z and S orifices.

Table 3.1 – Z and S orifices actions.

Figure 3.1 – Z and S orifices and

magnetic screwdriver.

Some parameters show the icon to allow user configuration on it by inserting the magnetic

screwdriver into Span orifice (S). In case the parameter has pre-defined values, those will be rotate on

display, while the magnetic screwdriver remains into Span orifice (S).

If the parameter is numerical, this field will enter on edition mode and decimal point will start blinking,

and shifting to left. When user removes magnetic screwdriver from S, the least significant digit (in the right)

starts blinking, indicating it is ready for edition. By inserting the magnetic screwdriver into S, user is enabled

to increase the digit value, from 0 to 9.

After the least significant digit edition, user should remove magnetic screwdriver from S in order to

start the edition of the next digit (in the left). User will be able to edit each digit independently, until the most

significant digit (5th digit on the left) is complete. After the 5th digit edition, user can also change the signal

for the numerical value still on S orifice.

During each step of edition, user is able to return to the previous digit (to the right) by inserting the

magnetic screwdriver into Z orifice, so corrections can be made. By removing the magnetic screwdriver at

any time, user will see the digits blinking until the final step, where the edition mode will be finished, saving

the numerical value configured by user.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

15

If the configured value is not acceptable by that device parameter (invalid value), it will be returned

to the last valid value before edition. Depending on the parameter, some values can be shown on numerical

or alphanumerical fields, adjusting the best option view to user.

With the magnetic screwdriver out of Z and S orifices, device will leave local adjust mode after some

seconds and monitoring mode will be shown.

3.2.JUMPER CONFIGURATION FOR LOCAL ADJUST AND WRITE PROTECTION

VTT10-FH has two jumpers on its main board to protect data writing (WP1) and also

enabling/disabling local adjust (ADJL1). Figure 3.2 presents those jumpers.

Figure 3.2 – Jumpers WP1 (write protection) and ADJL1 (local adjust) on VTT10-FH main board.

Default selection for these jumpers is Write Protection DISABLED and Local Adjust ENABLED.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

16

3.3.LIQUID CRYSTAL DISPLAY (LCD)

Main information related to transmitter are indicated on its liquid crystal display (LCD). Figure 3.3

shows the LCD with all its indication fields. Numerical field has 5 digits and is used mainly for monitored

variable indication. Alphanumerical field indicates which variable is being monitored, units or auxiliary

messages. Each indication icon use is described on table 3.2.

Figure 3.3 – LCD fields and icons. Table 3.2 – LCD icon description.

3.4.LOCAL ADJUST CONFIGURATION TREE

Figure 3.4 shows available fields for local configuration and the sequence they are presented by

magnetic screwdriver actuation on Z and S orifices.

Figure 3.4 – Local adjust configuration tree.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

17

3.5. HART

®

CONFIGURATOR

Figure 3.5 exemplifies the use of USB interface with a personal computer that has a HART

®

configurator installed. A 250Ωresistance must be serially connected with the power supply (for voltage

supply and if the power supply does not have this resistance internally) in order to enable HART

®

communication over the 4-20 mA current (Figure 3.5). Vivace interface already has this resistance when

used to power the field device (Figure 3.6).

Figure 3.5 – Transmitter installation for configuration with external power supply and 250 ohms resistance.

Figure 3.6 – Transmitter installation for configuration using VCI10-UH to power the device.

VTT10-FH multidrop connection must be executed according to Figure 3.7. Note that up to 63 devices

can be paralleled connected on the same line. Caution must be taken when many transmitters are

connected on the same power line due to voltage drop on 250 ohm resistor and guarantee power supply

voltage is enough (Figure 3.8).

Figure 3.7 – Multidrop connection for VTT10-FH.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

18

Figure 3.8 – VTT10-FH load curve.

3.6. HART CONFIGURATOR PROGRAMMING TREE

The configuration tree is a structure tree-shaped with the menus for all software resources available,

as shown on figure 3.9.

For online configuration of the transmitter, check it is correctly installed, powered by the adequate

voltage and with the minimum load of 250 Ωimpedance on the line, necessary for communication.

Figure 3.9 – VTT10-FH programming tree.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

19

Information – Main device information can be accessed here.

•HART

®

– Main information about communication protocol are available here, such as:

Manufacturer, Device Type, Device Profile, HART

®

Revision, Software Version etc.

•Sensor – Main information about the sensor are available here, such as: Sensor

Type, Connection (2, 3 or 4 wires), Upper Range, Lower Range and Unit.

Configuration – Configuration of transmitter Work Ranges, Unit, Safe Mode and Damping are available

here.

•Damping is an electronic filter for PV variable which changes transmitter response time in

order to smooth output reading variations caused by input fast variations. Damping value can be configured

between 0 and 60 seconds, and its appropriated value must be adjusted based on process response time,

output signal stability and other system requirements. Default value for damping is 0 seconds.

The damping value affects transmitter response time. When this time is configured as zero, the

damping function is disabled and transmitter output will react immediately to the input variations, so the

response time will be as short as possible.

An increase to the damping value will result on an increase to transmitter response time.

As the settling time constant is defined, transmitter output will achieve 63% of the input variation and

transmitter will continue to approach the input value according to damping curve.

•Sensor – Sensor Type, Sensor Connection and Cold Junction Mode.

•Callendar van Dusen – R0, A, B and C parameters of Callendar van Dusen for RTDs.

Callendar-Van Dusen is an equation which describes the relation between the resistance

(R) and the temperature (t) of RTD platinum resistance thermo-elements.

•Table – Table function with its parameters.

•Display – Configure two variables to be displayed on LCD.

Trim – Enables the adjustment for transmitter output current, input temperature sensor (ohm or mV) and

internal temperature sensor. Figure 3.10 shows the connection for current TRIM on VTT10-FH.

Maintenance – This menu enables transmitter reset, change counter verification/reset, write protection,

data backup/restore and loop test function (fixed current mode).

•Alteration Counter – checks the number of changes executed in several parameters

with the possibility of resetting them.

•Max/Min Values – Shows maximum and minimum values for PV and SV.

Observe – Monitoring view for output current, PV%, PV, SV, TV and QV.

Diagnosis – Monitoring view for device alarm status.

VTT10-FH HART

®

TEMPERATURE TRANSMITTER INSTALLATION, OPERATION, ONFIGURATION AND MAINTENAN E MANUAL

______________________________________________________________________________________________________________________________

20

Figure 3.10 – VTT10-FH current trim configuration.

3.7.FDT/DTM CONFIGURATION

FDT/DTM-based tool (Ex. PACTware

®

, FieldCare

®

) can be used for device information,

configuration, monitoring, calibration and diagnosis with HART

®

technology. Vivace offers the DTM files for

all of its devices (HART

®

and Profibus PA).

PACTware

®

is property of VEGA and can be found on

http://www.vega.com/en/home_br/Downloads.

The following figures exemplifie DTM configuration screens for VTT10-FH using Vivace’s VCI10-UH

interface and PACTware

®

.

Figure 3.11 – DTM work range configuration screen for VTT10-FH.

Table of contents

Popular Transmitter manuals by other brands

rollease acmeda

rollease acmeda Automate MTRF-DCIM-1C Programming instructions

Comnet

Comnet FDC8ISOT1 Installation and operation manual

GME

GME CM60 Series user manual

Siemens

Siemens 7ML5202 operating instructions

Siemens

Siemens Sitrans LR250 operating instructions

Telefunken

Telefunken TF-FMT31BT instruction manual

Linear

Linear DXS-64 operating instructions

FeinTech

FeinTech ABT00102 instruction manual

Speaka Professional

Speaka Professional 2342740 operating instructions

Horizon Fitness

Horizon Fitness HRZ00001 manual

BW Broadcast

BW Broadcast TX V2 quick start guide

GRASS VALLEY

GRASS VALLEY XCU UXF Fiber Series user guide