VIVI DBS WHISPER-0 User manual

1

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

TECH SUPPORT

Europe, Asia, Africa, Australia & New Zealand:

techsupport@vicidbs.com

USA, Canada, Central & South America:

techsupportusa@vicidbs.com

Italy

VICI AG INTERNATIONAL

Parkstrasse 2

CH-6214 Schenkon

Switzerland

tel: +41 41 925-6200

fax: +41 41 925-6201

web: www.vicidbs.com

APPLICABLE MODELS

This manual is applicable to the following models:

• Whisper 0-40

• Whisper 0-80 • Whisper 0-120

Version 1.03.0000

1

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

TABLE OF CONTENTS

1. VERSION HISTORY................................................................................................................................ 2

2. INTRODUCTION.................................................................................................................................... 2

2.1. FUNCTIONALITY.................................................................................................................................2

2.2. SYMBOL DEFINITIONS.......................................................................................................................3

3. SAFETY.................................................................................................................................................. 4

3.1. PERSONAL SAFETY INSTRUCTIONS..................................................................................................4

3.2. INSTRUMENT SAFETY INSTRUCTIONS.............................................................................................4

3.3. WARNING ...........................................................................................................................................4

4. SPECIFICATIONS................................................................................................................................... 5

4.1. TECHNICAL SPECIFICATIONS ............................................................................................................5

4.2. SPARE PARTS ......................................................................................................................................6

4.3. SEPARATION PRINCIPLE ....................................................................................................................6

4.4. COMPONENTS...................................................................................................................................7

4.5. PROCESS DIAGRAM...........................................................................................................................8

5. INSTALLATION ...................................................................................................................................... 8

5.1. TRANSPORT ........................................................................................................................................8

5.2 LOCATION...........................................................................................................................................8

5.3. CONNECTING THE WHISPER-0 TO THE AIR COMPRESSOR ...........................................................8

5.4. CONNECTING THE WHISPER-0 TO THE LC-MS ...............................................................................9

6. OPERATION........................................................................................................................................... 9

6.1. STARTING THE UNIT ..........................................................................................................................9

6.2. STOPPING THE UNIT .........................................................................................................................9

7. TROUBLESHOOTING............................................................................................................................. 9

8. MAINTENANCE................................................................................................................................... 10

8.1. MAINTENANCE................................................................................................................................10

8.2. CHANGING THE FILTERS.................................................................................................................10

9. FLOW SCHEMATIC .............................................................................................................................. 11

2

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

1. VERSION HISTORY

VERSION DATE COMMENT/CHANGE

1.00.0100 01/18/2017 Layout and initial release, VICI DBS

1.01.0000 01/8/2019 Update

1.02.0000 03/20/2019 New layout, images and graphics, VICI Gig Harbor Group

1.03.0000 01/07/2021 New layout, minor copy updates, VICI Gig Harbor Group

2. INTRODUCTION

This manual is an integral part of the product. The manual describes the installation and maintenance

operations as well as user modes and troubleshooting. All information provided in this manual, including

drawings, tables, and technical descriptions, remain the property of the manufacturer and may not be used

(with the exception of the purposes herein), copied, reproduced or published without explicit consent.

Read the manual carefully before starting up the Whisper-0 and familiarize yourself with its contents.

NOTE: Do not make any modications to the Whisper-0 unless explicit written permission has been given by

the manufacturer. If such modications are made without the manufacturer’s consent, the manufacturer denies

any responsibility for eventual consequential damage.

2.1. Functionality

The Whisper-0 separates compressed Air into pure Nitrogen and Oxygen-enriched Air. The separation

principle is based on a special membrane technology.

3

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

2.2. Symbol Denitions

SYMBOL DESCRIPTION

General warning. Caution is necessary when operating the device or control

close to where the symbol is placed, or to indicate that the current situation

needs operator awareness or operator action in order to avoid undesirable

consequences.

The manual must be consulted in all cases where this symbol is marked on

the device.

Risk of asphyxia. Caution is necessary when operating the device in a not

sufciently ventilated area.

Oxidant material. Caution is necessary due to the presence of oxidant material.

WEEE symbol. When discard this product, it must be sent to separate collection

facilities for recovery and recycling.

Fuse. Notify replaceable fuse place.

OR

OR

OR

4

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

3. SAFETY

3.1. Personal Safety Instructions

The Whisper-0 is a nitrogen generator. Do not operate the generator with the nitrogen outlet open

in a small or not sufciently ventilated room. An increase of the nitrogen and a decrease of the

oxygen concentration in the air may cause health problems. It is the responsibility of the user to

check whether the room is appropriate or an O2measurement is necessary.

3.2. Instrument Safety Instructions

The Whisper-0 ejects oxygen as waste. Oxygen concentration in the air could change around the

generator in a small or not sufciently ventilated room. If fuel gases are present, their explosive or

ammable limits could be affected.

3.3. Warning

• The quantity of dust in the ambient air can be very different from one place to

another. We recommend replacement of the dust lters every 4000 hours. In

some dusty areas, this maintenance needs to be performed more frequently.

• Clogged dust lters may damage the generator or give a bad nitrogen quality.

• If the Whisper-0 is used in a way not specied by VICI DBS, the protection

provided by the equipment could be compromised.

5

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

4. SPECIFICATIONS

4.1. Technical Specications

WHISPER 0-40 WHISPER 0-80 WHISPER 0-120

Flow L/min 40 80 120

Purity 97% @ 40 L/min

99% @ 20 L/min

97% @ 80 L/min

98% @ 50 L/min

95% @ 120 L/min

98% @ 50 L/min

Dewpoint -50 ºC

Outlet pressure barg (psig) 7 (100)

Inlet pressure barg (psig) 8.5 to 10 (123 to 160)

Actual inlet air requirement liters 120 210 245

Recommended compressor air inlet 240 420 490

Pressure drop barg (psig) 1.5 (22)

Inlet air quality Clean dry compressed air ISO8573-1:2010 Class 1.2.1

Technology Membrane

Warm up time (minutes) None

Electrical supply None

Noise level None

Dimensions mm (in) 480W x 1300H x 300D (18.9W x 23.2H x 14.7D)

Weight kg (lbs) 15 (33) 18 (40) 20 (44)

Shipping dimensions mm (in) 1600 W x 400H x 590D (63W x 15.7H x 23.2D)

Shipping weight kg (lbs) 22 (49) 27 (60) 27 (60)

Operating temp oC (oF) 15 to 35 (59 to 95)

Inlet connection 3/8” G

Outlet connection 1/4” Compression

Certication CE

OPTIONS

10 liter tank, 10 mt. tube, special 100% Teon tubing

MODELS & SPECS

6

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

A special characteristic of the Whisper 0-Hybrid is the momentary stop of the compressor if the LC-MS is not

using nitrogen. This momentary stop is regulated by a pneumatic control valve pre-calibrated by VICI DBS to

lengthen the life span of the compressor and at the same time help save energy.

4.2. Spare Parts

PART NUMBER DESCRIPTION

DB-WN2-001 Annual Filter Kit (3 lters)

DB-WN2-002 Pneumatic Valve

DB-WN2-003 Manometer

DB-WN2-005 10 liter tank

DB-WN2-006 Tube 10 m

DB-WN2-014 Valveless N2 small membrane

DB-WN2-015 Filter housing for A0035 element without ttings

DB-WN2-016 Filter housing for V0035 and S0035 element without ttings

4.3. Seperation Principle

A

FS

H2O - H2 O2 N2

B

C

ACompressed Air Input BHollow Fiber Membrane CNitrogen Output

Atmospheric air contains nitrogen (78.1%), oxygen (20.9%), argon (1%), carbon dioxide, water vapor, and

traces of inert gases. The compressed air (A) is forced through the hollow ber membrane (B). The various

components of the air permeate the porous membrane walls.

7

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

The speed of permeation varies from gas to gas:

• Oxygen and water vapor have a high permeation speed and pass quickly through the membrane wall

• Nitrogen has a slow permeation speed and passes slowly through the membrane wall

• The resulting nitrogen ow (C) is then forced out of the membrane and used directly

4.4. Components

A

D

B

C

E

A. Active Carbon Filter

B. Air Inlet / Coalescent Filter

C. Coalescent Filter for ne particles

D. Pressure Gauge (outlet pressure)

E. Nitrogen Outlet (coupling for 6 mm diameter tube)

F. Membrane

H. Oxygen Vent

G. Air Saver Valve

G

H

F

8

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

4.5. Process Diagram

Compressed Air Whisper-0 LC-MS (or other)

5. INSTALLATION

5.1. Transport

Transport the Whisper-0 without tipping it in the original packing.

5.2. Location

Install the Whisper-0 in an area with the following characteristics:

• Minimum distance of 10 cm at the front and lateral sides to allow sufcient cooling

• An enclosed (indoor), dry room

• Avoid direct sunlight

• Keep away from heat sources

• Room with adequate aeration/ventilation

• Connect a tube for waste humidity from lter “B”

5.3. Connecting the Whisper-0 to the Air Compressor

There are 2 conguration possibilities:

• If you use a high capacity compressor (like Scroll compressor) without buffer-tank between the Whisper-0

and the LC-MS, then turn the red tap on the back side of the generator as shown in Figure 1 below.

• If you have a normal/standard compressor and a buffer-tank (min 100 lt) between the Whisper-0 and the

LC-MS then turn the red tap on the back side of the generator as shown in Figure 2 below.

Figure 1 Figure 2

9

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

6. OPERATION

6.1. Starting the Unit

1. Connect the Air Inlet “B” (Fig-1) to the Air line from the compressor (oil free)

2. Install a piece of tubing from the Nitrogen Outlet “E” to the LC-MS

3. Slowly open the red tap upstream from the coalescent lter “B”

4. The generator is ready to be used

6.2. Stopping the Unit

To stop the generator, just close the red tap upstream from the coalescent lter “B”

7. TROUBLESHOOTING

ERROR POSSIBLE CAUSE POSSIBLE SOLUTION

Nitrogen ow insufcient or lacking Internal lters are contaminated Replace the lters

The Whisper-0 is off Start the Whisper-0

There is a leak somewhere Check for possible leaks

Nitrogen outlet obstructed Check and clear the nitrogen

outlet

Oxygen concentration is too high Room temperature is less than

10º C

Raise the room temperature

Membrane no longer functions

correctly

Membrane column must be

replaced

5.4. Connecting the Whisper-0 to the LC-MS

ATTENTION: Check that the tubing between the Whisper-0 and the LC-MS is free from dust, grease, drops of

liquid etc, before making the connection.

Connect the Whisper-0 and the LC-MS with stainless steel tubes.

10

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

8.2. Changing the Filters

1. Turn the Whisper-0 off

2. Close the red tap upstream from the coalescent lter “B”

3. Let the generator depressurize till the pressure is 0 bar

4. Remove the cap, unscrew it from the main body (1) and pull it down (2)

5. Remove the lter cartridge by pulling it down (3)

6. Replace the ltering element and reassemble the parts in reverse order

8. MAINTENANCE

8.1. Maintenance

PARTS ACTION FREQUENCY

DB-WN2-001 Replace the internal lters Annually

11

WHISPER-0

USER MANUAL www.vicidbs.com

Version 1.03.0000

9. FLOW SCHEMATIC

System:

Schematic no:

Date:

Created:

Checked:

Released:

THIS DOCUMENT AND THE INFORMATION WHICH

IT CONTAINS SHALL NOT BE USED, EXPLOITED

OR SOLD, AND SHALL NOT BE REVEALED OR

DISCLOSED TO OTHERS WITHOUT THE EXPRESS

WRITTEN PERMISSION OF VICI. THIS DOCUMENT

SHALL REMAIN THE PROPERTY OF VICI AND

SHALL BE RETURNED UPON DEMAND.

R

Rev.:

Sheet:

By:

Description:

ECN no:

Whisper flow

air flow diagram 04.12.20 SBU

1

This manual suits for next models

3

Table of contents

Popular Portable Generator manuals by other brands

Titan

Titan TG 55OOD owner's manual

Teledyne Lecroy

Teledyne Lecroy WaveStation Operator's manual

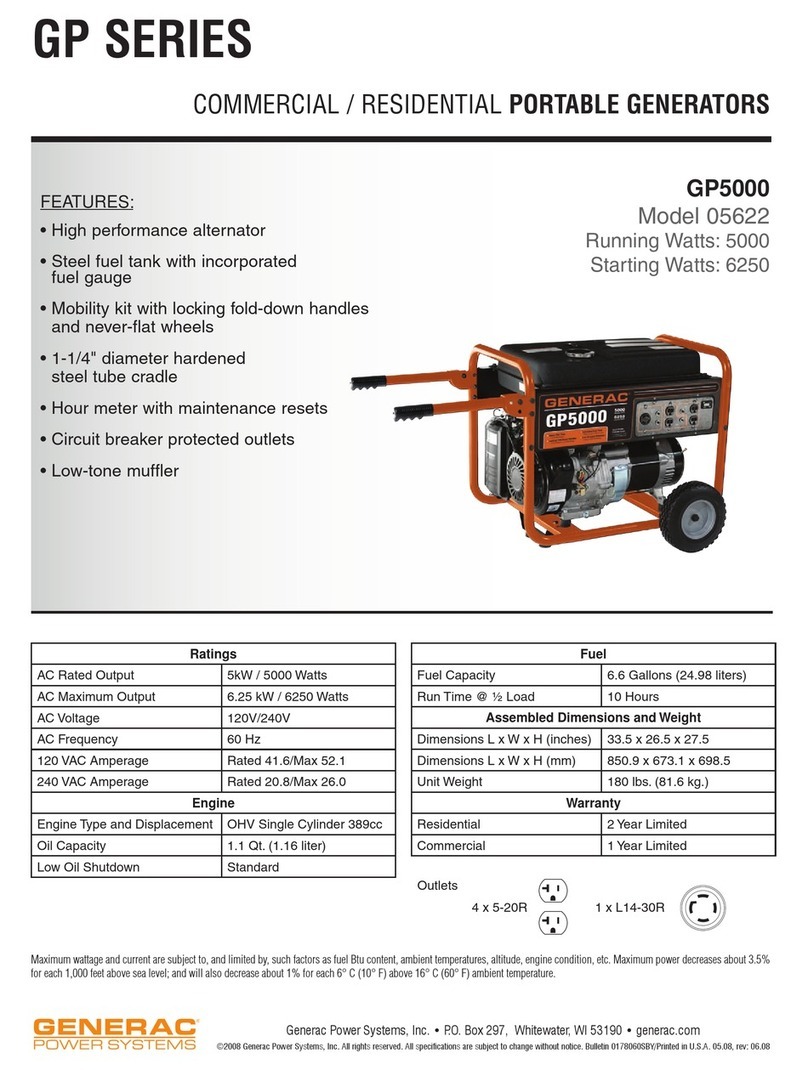

Generac Power Systems

Generac Power Systems 5622 Specifications

Powermate

Powermate PE0401853 user manual

SIGLENT TECHNOLOGIES

SIGLENT TECHNOLOGIES SDG7000A Series user manual

uniview technologies

uniview technologies ES-E2000 Series user manual

Champion Power Equipment

Champion Power Equipment CSA41155E manual

Westinghouse

Westinghouse WGen20000 user manual

GMC

GMC GEN1000 instruction manual

Premier

Premier GEN-3300 instruction manual

Champion Power Equipment

Champion Power Equipment 41351 Owner's Manual and Operating Instructions

Briggs & Stratton

Briggs & Stratton 5000 Watt Operator's manual