VKAR Bison User manual

VKAR Hobby Co.,Ltd

WWW.vkarracing.com

INSTRUCTION MANUAL

1:10 Scale Electric 4WD Off Road Race Truggy

Bright LED light.Secure wheelie bar set.

All rubber covered bearing throughout.

.

Adjustable rear wing.

Sealed,tunable limited-slip differentials.

All terrain tires & agreessive electroplate wheel.

Oil-filled ultra AL shocks with progressive dual-springs.

Fully assembled and Ready-To-Run.

.

Thank you for purchasing VKAR product.This manual contains instructions

on operating and maintaining the Bison .Please take a monent to read

through this manual to familiarze yourself with this model.

Tools lncluded

Requires

11

INTRODUCTION

532mm

380mm

218mm

330mm

Charger

Transmitter

Hex Key

4 PCS AAA Batteries

(For Transmitter)

Scale:1/10

Drive System:4WD

Power Battery

FEATURES

PRODUCT CONTENTS

22

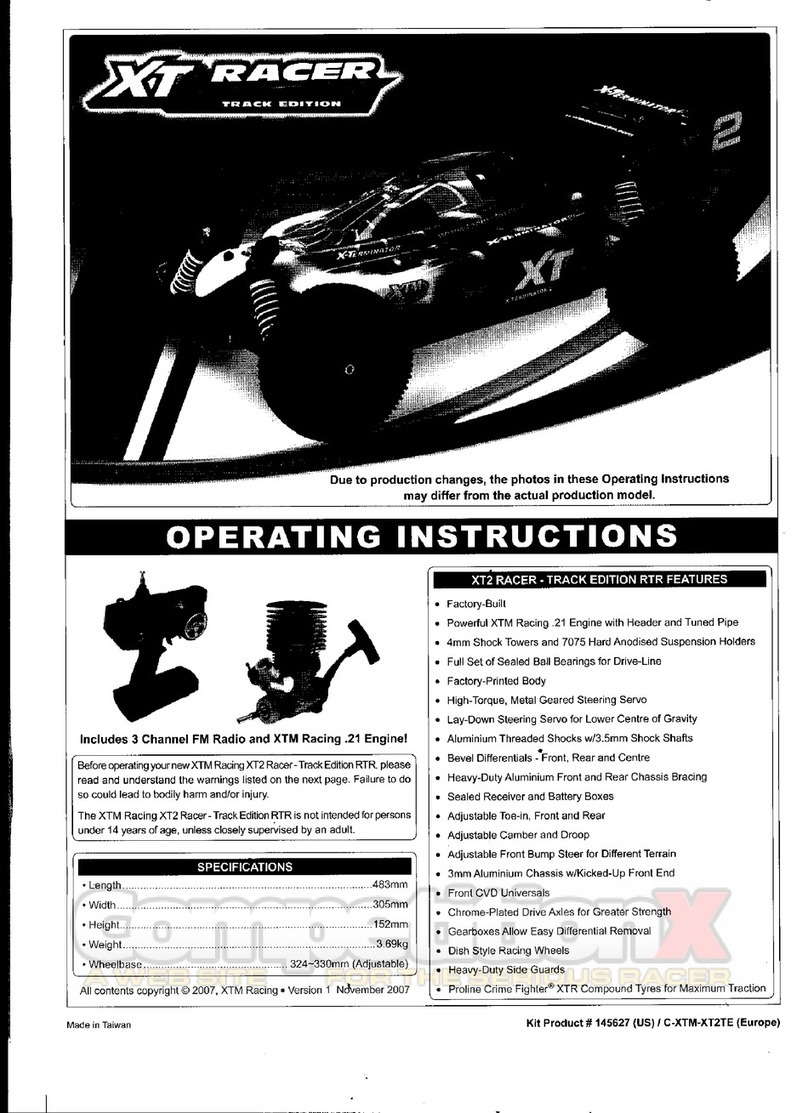

IMPORTANT INFORMATION

The Bison is a powerful RC car that will bring much

enjoyment.Howewever,improper use can cause damage

and bodily injuries.Please read the following information

carefully to avoid casualties.

This model can be operated with Ni-MH or Lithium Polymer

batteries. Due to the battery’s high energy,density,please pay

attention to the following information to avoid injuries or

damages.

WARNING:

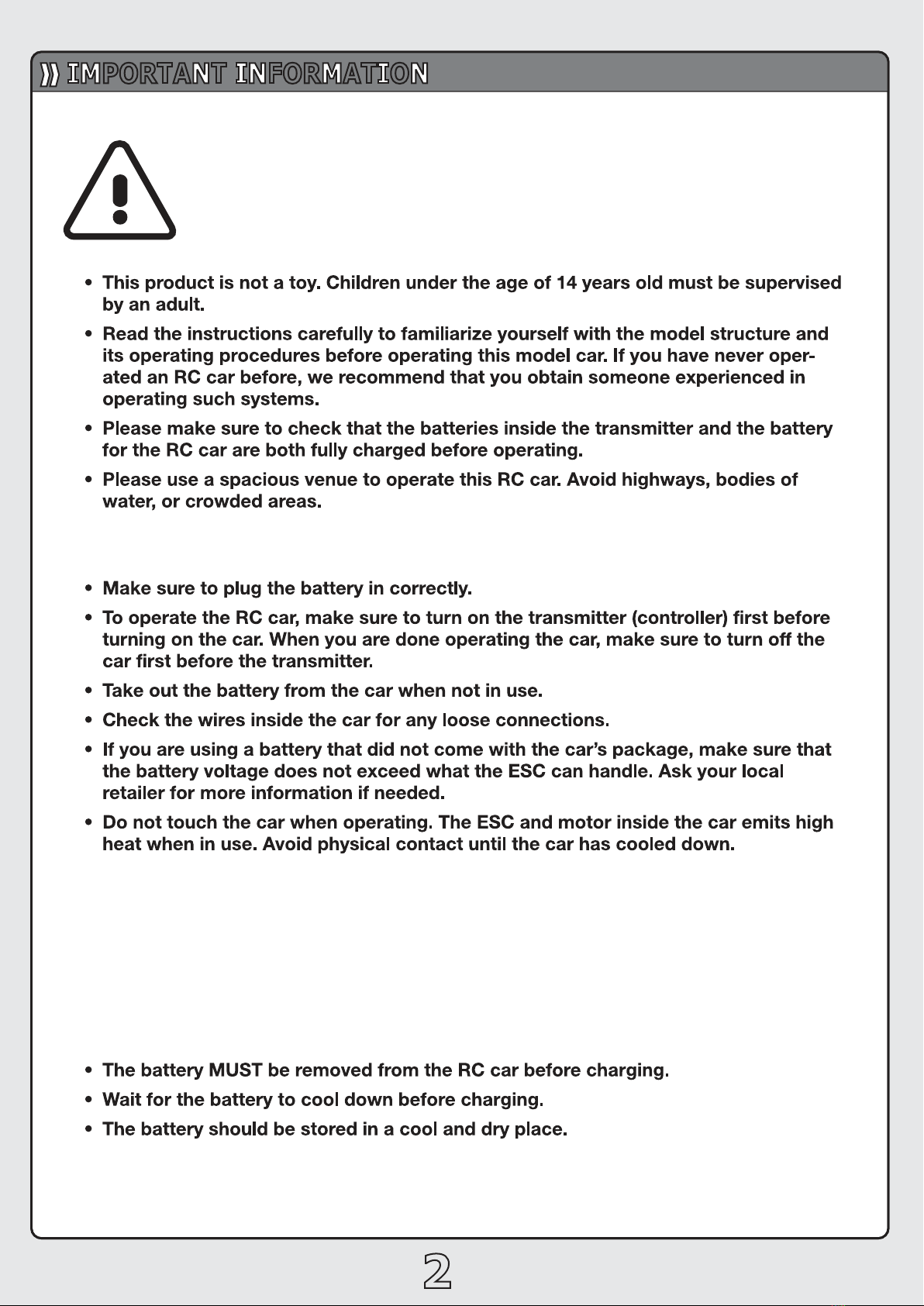

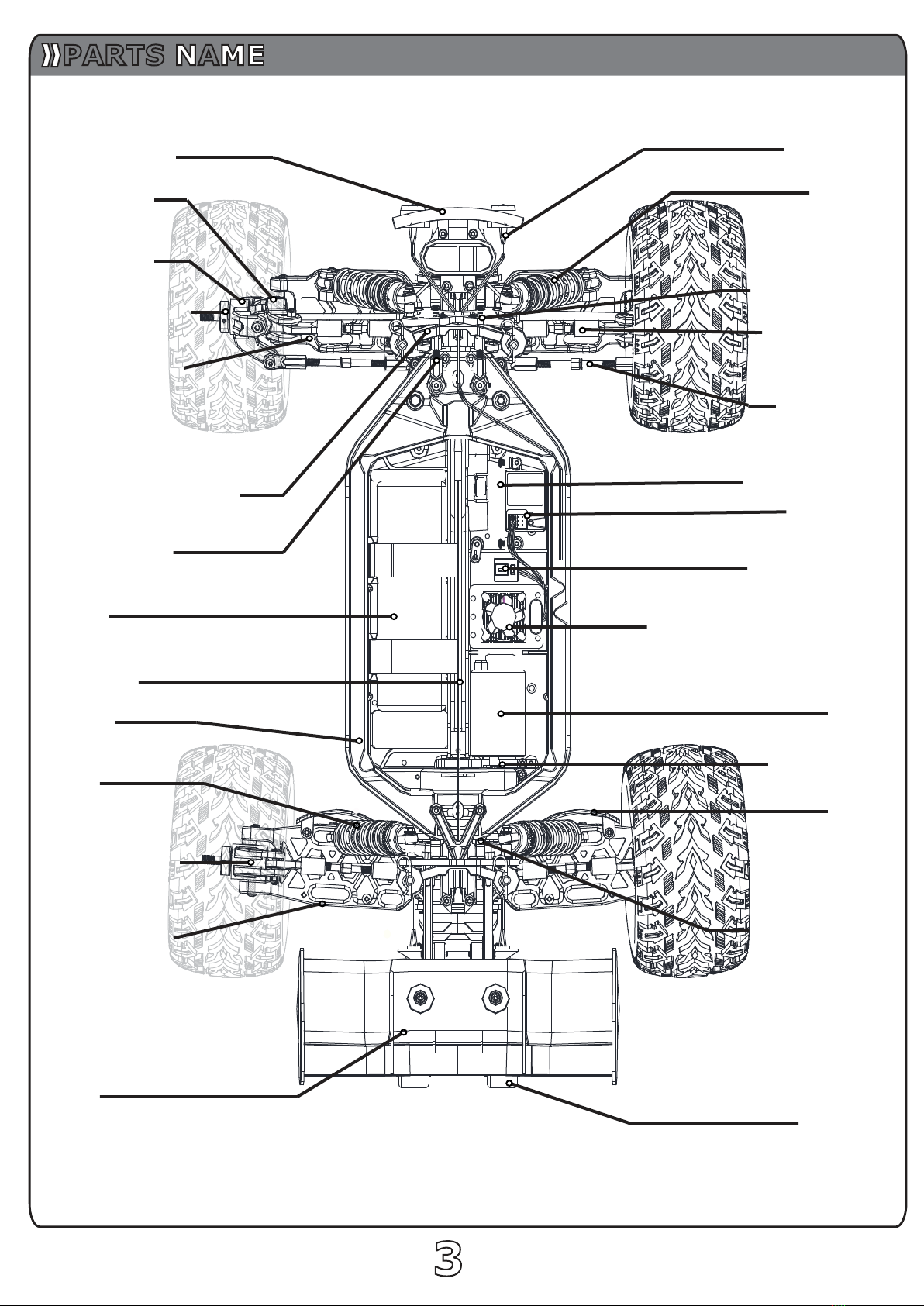

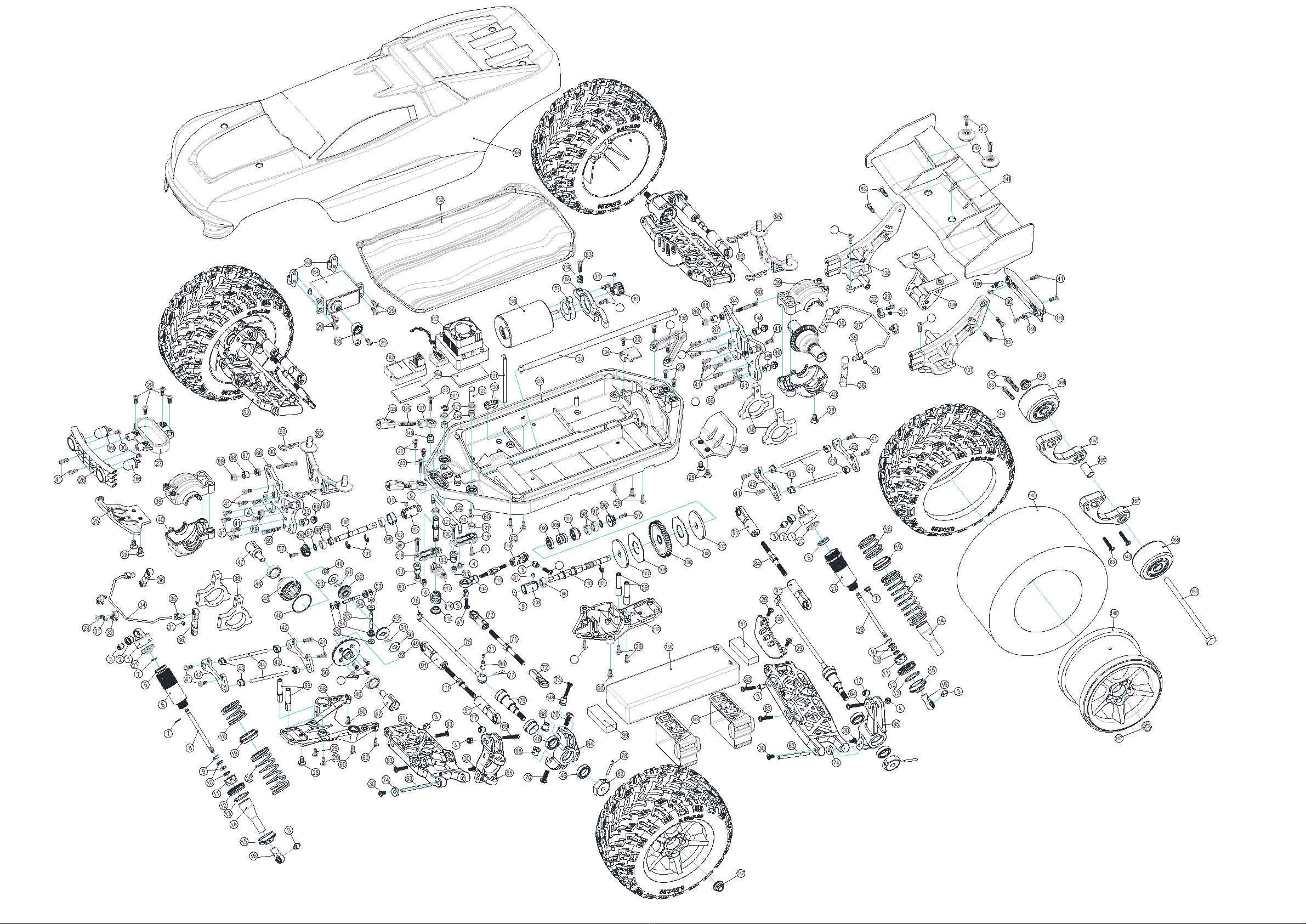

Front Bumper

Hub Carrier

Steer Block

Wheel Hex Hub

Body Mount Bracket

Chassis

Battery

Rear Hub Carriers

WING

Motor

Electronic Speed Control

Receiver

Turnbuckle

(toe Link)

Tailwheel

Shock

Front Shock Stay

Suspension Arm

Shock

Rear Shock Stay

Motor Mount

33

Support Bracket

Power Switch

Steering Servo

Turnbuckle

(Camber Link)

LED Light

Fender

Suspension Arm

Center Shaft

PARTS NAME

SYSTEM INSTRUCTION

4

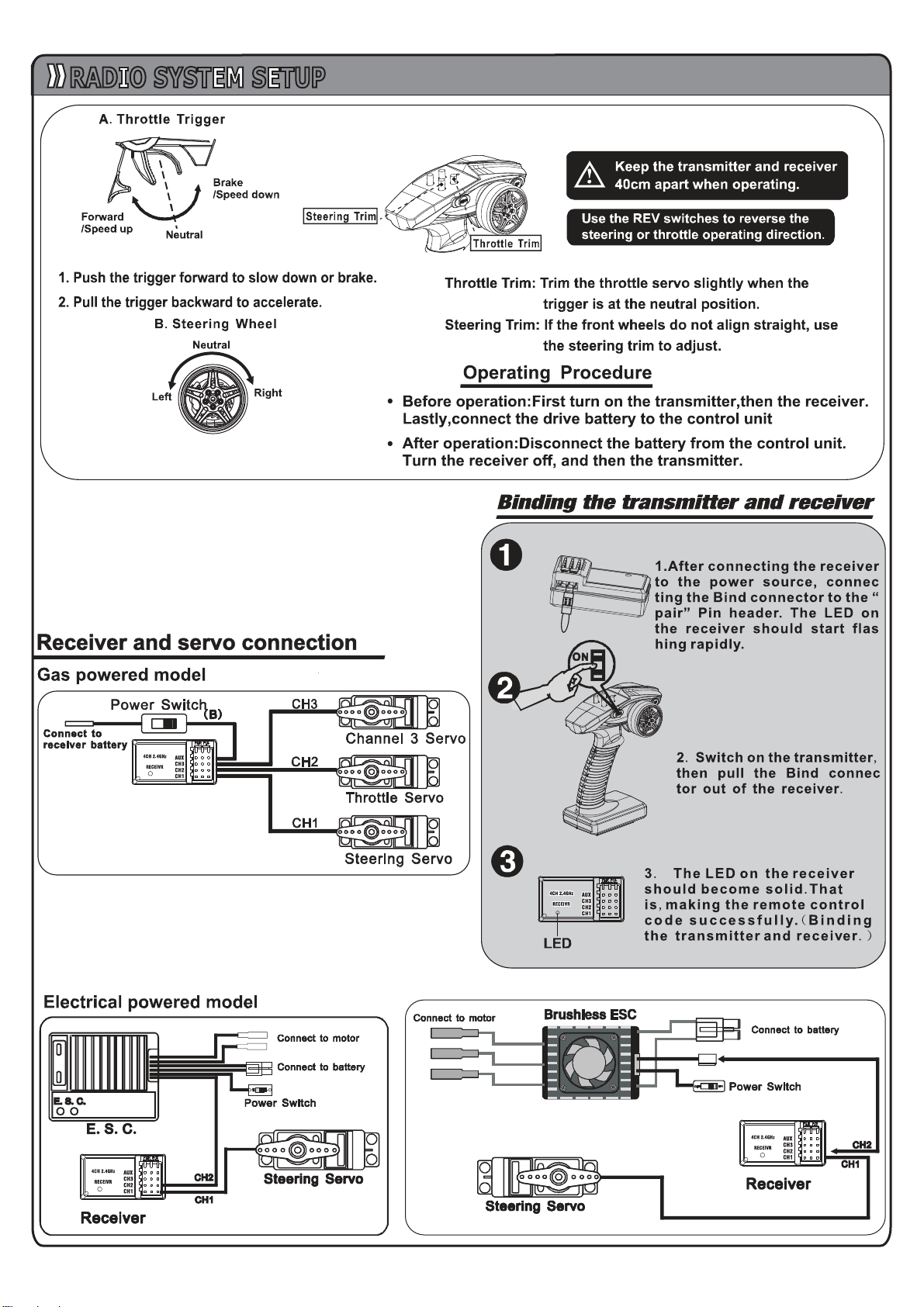

RADIO SYSTEM SETUP

5

【BEGIN TO USE THE NEW ESC】

1. Connect the ESC, motor, receiver,

battery and servo according to the

following diagram

“+”and “-”wires of the ESC are

connected with the battery pack, and #A,

#B and #C are connected with the motor

wires. The “SET”button is used for

programming the ESC.

The control cable of the ESC (trio wires

with black, red and white color) is

connected with the throttle channel of the

receiver (Usually CH2).

1The #A, #B, #C wires of the ESC can be

connected with the motor wires freely

(without any order). If the motor runs in

the opposite direction, please swap any

two wire connections.

Note: You can use the transmitter to

set the throttle channel to

the“Reverse”direction, and then the motor will run oppositely. Please calibrate the throttle range again

after changing the direction of throttle channel.

2. Throttle Range Setting (Throttle Range Calibration)

In order to make the ESC match the throttle range, you must calibrate it when you begin to use a new ESC, or a

new transmitter, or after changing the settings of the neutral position of throttle channel, ATV or EPA parameters,

otherwise the ESC cannot work properly.

There are 3 points need to be set, they are the top point of

“fo

rward”,”

backward”and the neutral point.

The following pictures show how to set the throttle range with a FutabaTM transmitter.

Note2: If you don’t release the “SET”key after the

red LED begins to flash, the ESC will enter the

program mode, in such a case, please switch off

the ESC and re-calibrate the throttle range again

from step A to step D.

A) Switch off the ESC, turn on the

transmitter, set the direction of throttle

channel to ”REV”, set the “EPA/ATV”

value of throttle channel to “100%”, and

disable the “ABS”brake function of

your transmitter. (*Note2)

B) Hold the “SET”key and then switch on

the ESC, when the red LED begins to

flash, release the key immediately.

(Please check the picture on the right side)

C) Set the THREE points according to the

steps shown in the picture on the right

side.

1) Neutral point

2) End point of forward direction

3) End point of backward direction

D) When the process of calibration is

finished, the motor can be started after

3 seconds.

SETUP

6

3. The LED Status in Normal Running

a) When the throttle stick is in the neutral range, neither the Red LED nor the Green LED lights up.

b) When the car moves forward, the Red LED solidly lights; the Green LED also lights up when the throttle stick is

at the top position (100% throttle).

c) When the car brakes, the Red LED solidly lights; the Green LED also lights up when the throttle stick is at the

bottom position and the maximum brake force is set to 100%.

d) When the car reverses, the Red LED solidly lights.

【ALERT TONES】

1. Input voltage abnormal alert tone: The ESC begins to check the input voltage when power on, if it is out of the

normal range, such an alert tone will be emitted: “beep-beep-, beep-beep-, beep-beep-”(There is 1 second

time interval between every “beep-beep-”tone).

2. Throttle signal abnormal alert tone: When the ESC can’t detect the normal throttle signal, such an alert tone

will be emitted: “beep-, beep-, beep-”(There is 2 seconds time interval between every “beep-”tone).

【PROTECTION FUNCTION】

1. Low voltage cut-off protection: If the voltage of a Lipo battery pack is lower than the threshold for 2 seconds,

the ESC will cut off the output power. Please note that the ESC cannot be restarted if the voltage of each Lipo

cell is lower than 3.5V.

For NiMH battery packs, if the voltage of the whole NiMH battery pack is higher than 9.0V but lower than 12V,

it will be considered as a 3S Lipo; If it is lower than 9.0V, it will be considered as a 2S Lipo. For example, if the

NiMH battery pack is 8.0V, and the threshold is set to 2.6V/Cell, it is considered as a 2S Lipo, and the

low-voltage cut-off threshold for this NiMH battery pack is 2.6*2=5.2V.

2. Over-heat protection: When the temperature of the ESC is over a factory preset threshold for 5 seconds, the

ESC will cut off the output power. You can disable the over-heat protection function for competition race.

3. Throttle signal loss protection: The ESC will cut off the output power if the throttle signal is lost for 0.2 second.

7

SETUP

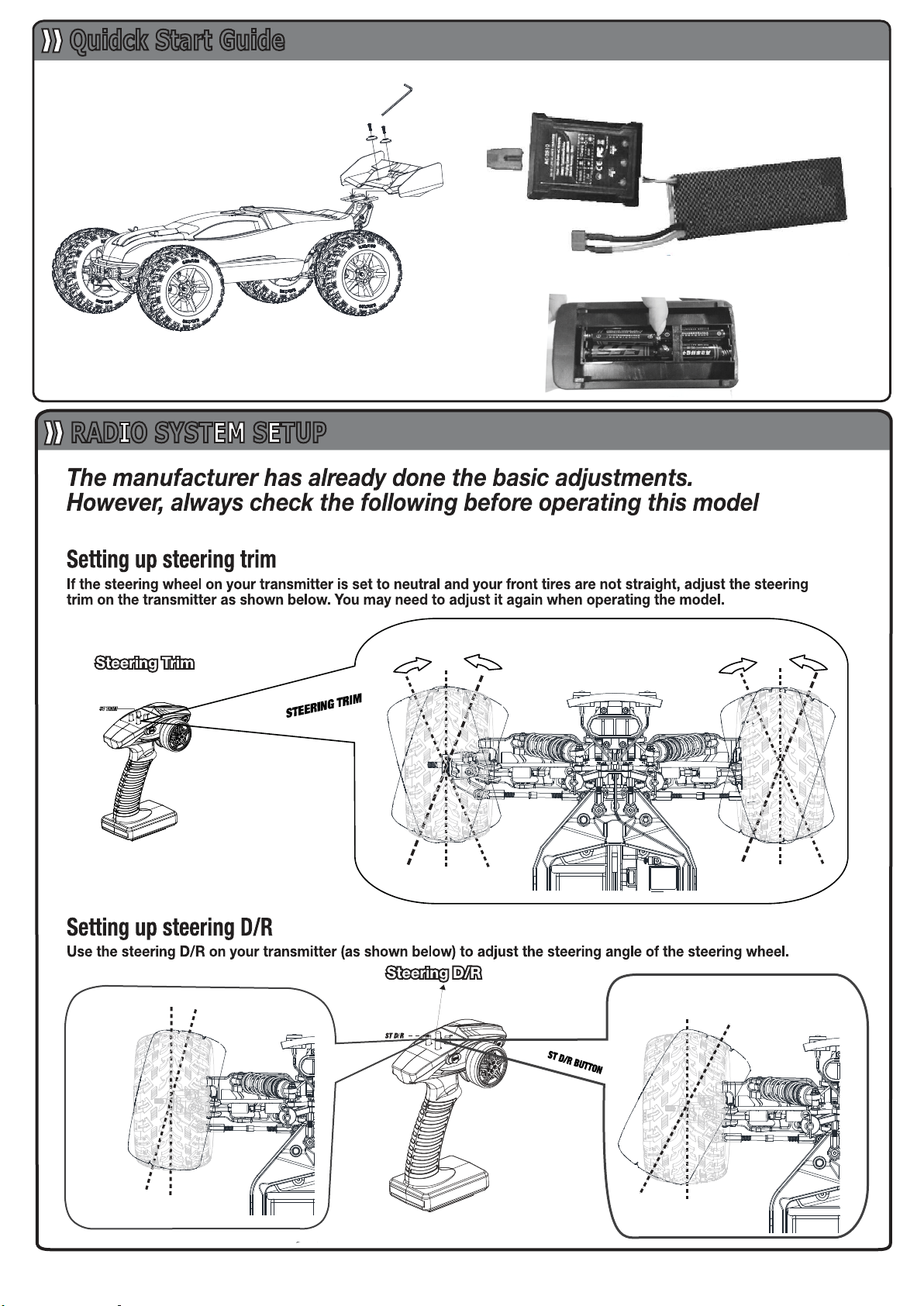

Steering angle

is more

Steering angle

is less

2. Charging the Battery

3. Loading the Battery

1. Wing Assembly

Quidck Start Guide

RADIO SYSTEM SETUP

8

9

47

46

45

48

50

52

51

55

54

52

50

51

49

49

170

56

170

46

47

M2.5x12

10x15x4mm

10x15x4mm

103

99

98

96

57

31

102

101

100

5x10x4mm

4mm

5x10x4mm

M3x3mm

M2.5x8mm

101

4mm

97

102

9

Differential Assembly

Front Driver Shaft Assembly

CORRECT WRONG

10

107

108

109

98

31

103

108

107

110

98

104

105

106

98

97

96

47

3.5mm

M2.5x8

5x10x4mm

5x10x4mm

M3x3mm

11T

Rear Driver Shaft Assembly

TIPS:The slipper clutch adjstment short cut

Use 1.5mm hex key,Insert the hold as the picture below.

Grasp the both sides of rear wheels,rotate in the same direction.

Adjusting the Slipper clutch

NOTE: the slipper clutch adjustment too loose or tight

may result in damsge the gear during racing.

M2.5x8

SW201

M2.5x12

SW201

10x15x4mm

BB103

8x12x3.5mm

BB104

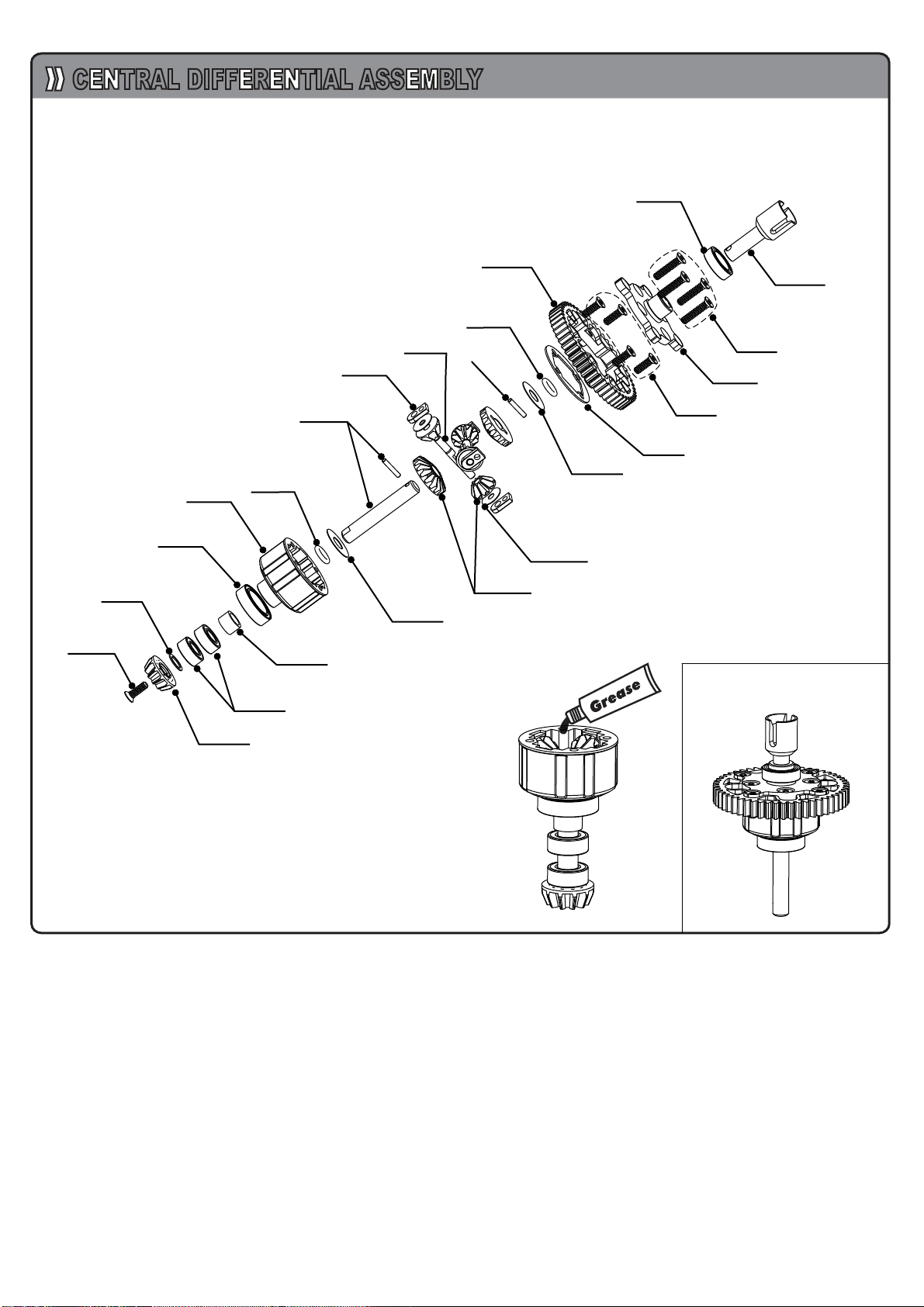

CENTRAL DIFFERENTIAL ASSEMBLY

ET1088

OR102

ET1091

ET1091

ET1096

ET1088

ET1081

ET1093

SH102

5X10X4

BB1102

OR102

ET1090

M2.5x8

SW201

SH103

5X12X0.3

SH103

5X12X0.3

SH101

2.5X7X0.3

ET1082

AC001

MA328

ET1092

2.0X8.8

2.0X8.8

11

M3x15

160

109

12

156

157

160

159

158

41

41

31

161

4

4

33

4

118

69

101

60

4

41

41

102

124

123

121

132

120122

124

121

119

33

117

115

116

5x8x2.5mm

5x8x2.5mm

5x8x2.5mm

5x8x2.5mm

121

69

4.0mm

M3x20mm

M3x20mm

M3.0mmM3.0mm

M3x10mm

M3x10mmM3.0mm

M3.0mm

M3x8mm

Steering Assembly

Motor Mount Assembly

NOTE: Rotating the nut 115 to seek

suitable degree of tightness.

NOTE: Rotating the nut 115 to seek

suitable degree of tightness.

NOTE: Look out the interval between motor gear 161

and spur gear 109 if the screw is loosened 160 please adjust it.

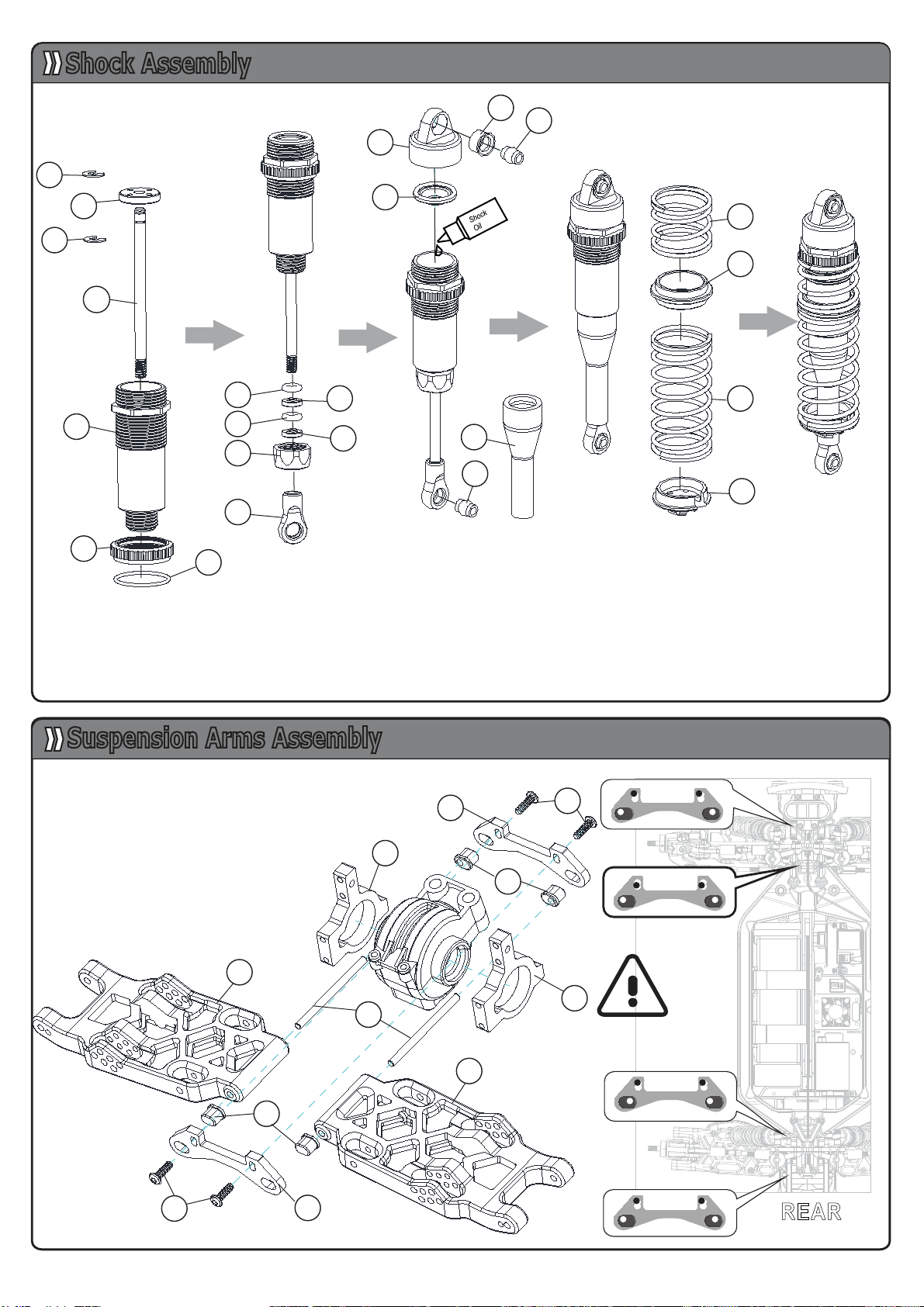

1.Fill shock body with 4/5 silicone fluid(purchase seperately),pump the shock shaft

up and down to remove any air bubbles.

2.Wait the air bubbles pumped out,then pull down the shock shaft to the bottom,fill

the silicone fluidup to 2 mm,after that,tighten the shock head1.

3.Install the spring,shock assemblingfinished.

Shock Aaaembling Steps:

FRONT

REAR

13

12

13

22

23

7

7

12

1

3

2

16

11

910

10

3

11

15

24

19

18

5

9

43

13

61

61

44

28

43

13 41

28

41

Shock Assembly

Suspension Arms Assembly

NOTE:Pay attention to choose

the right hole when installing

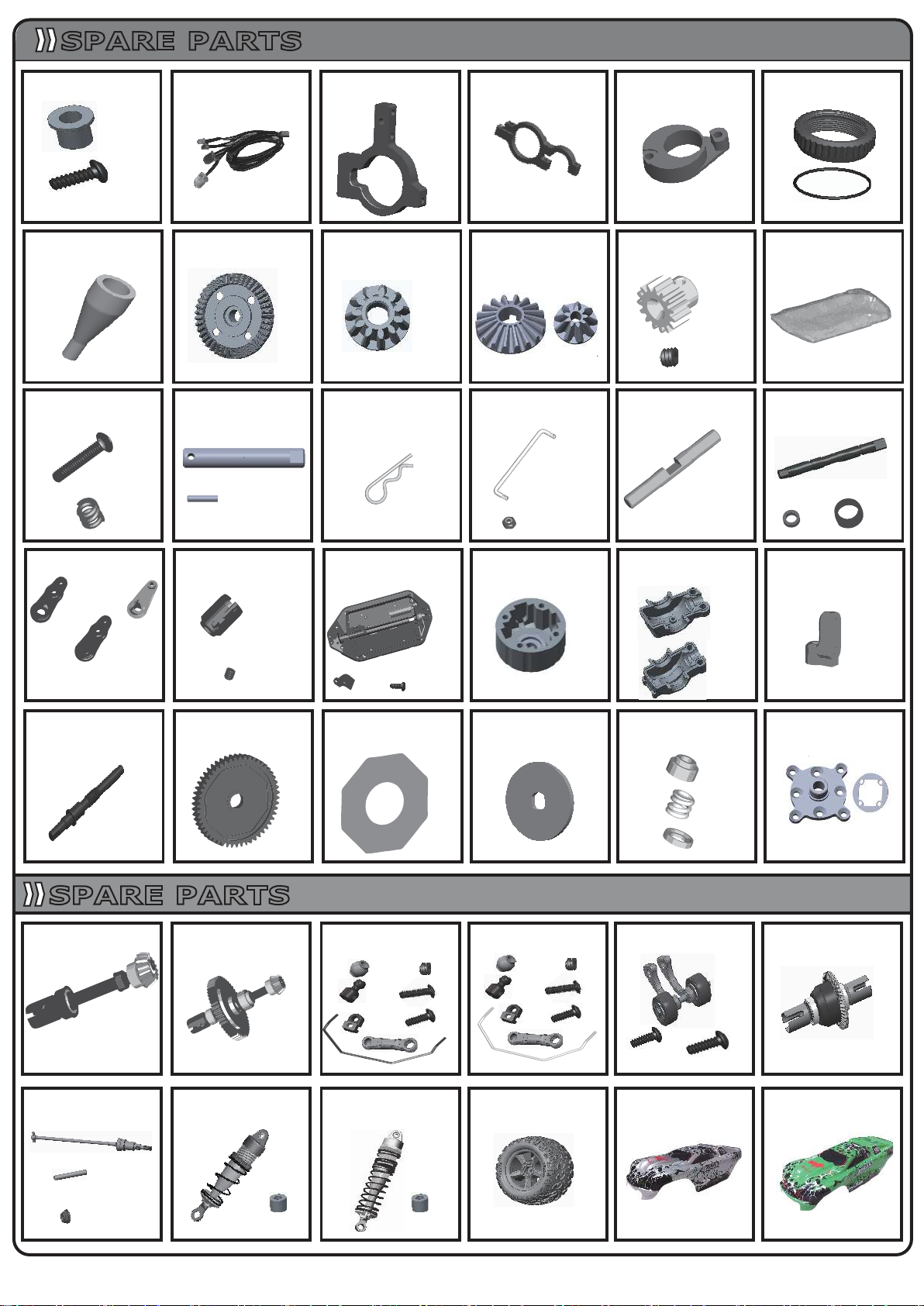

ET1001 ET1002 ET1003 ET1004 ET1005 ET1006

ET1007 ET1008 ET1011

Front

Rear Front Rear

ET1012

ET1013 ET1014 ET1015 ET1016 ET1017 ET1018

ET1019 ET1020 ET1021 ET1022 ET1023 ET1024

ET1025

ET1041

ET1029 ET1030

ET1031 ET1033 ET1034 ET1035 ET1036

ET1037 ET1038 ET1039 ET1040

x6

x2

x1

x1

x2

x1

x3 x8

x4

M3x8

M3x8

M3x10

x2

x2

x1

Front

x2 x2

ET1028

x1

x4

SPARE PARTS

ES1022 ET1010

x1

x1

x1

x1

x4

x4

M3x8

x1

x1

ET1026 ET1027

x2

ET1032

x4

x1 x1

x2 x2

x4

x1

x1

x4

Rear

x1

x2

x2

x2

x2 x2

x2

x2 x2

x2

x1

6.8mm 6.8mm 5.8mm

x2

x1

x1

M4X10

Left

Right Right

Left

Front Rear

Left

Right

x2

x1 x1

x1 x1

x1

x1 x2

x1

x1

x2

x2

x2

x2

x2

x2 x2

M4x10

M3x6

M3x8 M3x10

M3x8

M3x15

x1

x1

x1

x2

x2 x2

x2

x2

x2

x2

x2

x2

x2

x2

x1

x4

x1

x1

x4

x2

x2

x2

3x46mm

3x40mm

Front

Rear

x2

x2

x2x2

ET1042

x1

x1

M5

M5X85

x2

x2

M3x16

x2 x2

M4x15

x1

YELLOW

2X16.8

20X225

14

ES1001 ES1002 ES1003

ET1043 ET1044

ET1045 ET1046 ET1047

SPARE PARTS

ET1082

MA311

MA316

MA319

MA320 MA321 MA328 MA330

MA331

ET1095

MA337

ET1084 MA349 MA350

MA354-B

MA355 MA357

MA358

ET1098 ET1099

x1

x1

x1

x1

x1

x10 x2

x1

x2 x1 x1

x1

x1

x1

x1 x2

x1

x1

x2

x1

x1

x1

x1 x2

x1

x1

x1

x2

x1

x1

x1

x1

x4

x4

x2 x2

x1

M3x16 M4x15

x4x2

x2

x2

x2

x2

x2

x1

Front

x2

x2

x2

x2

x1

Rear

ET1049

ET1048

M4x12

M3x16

M3x16

M3x8 M3x8

ET1052

x2

ET1050 ET1051

x1 x1 x1

2x16.8

M5

x2

x2

x1 x1

SPARE PARTS

x1

x4

x2

x2

Front Rear

x1 x1 x2

x1

x1 x1 x2 x4

x1

x1

x1

Φ5

MA310B

x1 x1

ET1025S ET1025G

SILVER

GREEN

32T 11T

ET1080ES1046

ES1040

ET1081

ET1091

2*8.8mm

ET1092

15

16

Number Name Sp ec if ic ation Dosage Number Name Specification Dosage Number Name Specification Dosage

1 Hydraulic top button 1 4 58 Lower Deck-F 1 115 Saver Spring 1

2

Hydraulic ball head c overed

4 4 59 Box Post 4 116 Saver Spring 1

3 Universal _Ball 5.8 14 60 Screw M3x1 18 117 Servo Saver-B 1

4 Nylon Nut M3 8 61 Front Suspension Arm 2 118 Servo Saver-A 1

5 Shock_picston 4 62 Rear Suspension Arm 2 119 Steering Arm 1

6 Shock_body-F 2 63 PIN 3X40 4 120 Steer Post-R 1

7 E-Clip 2.5 8 64 Steer Holder L 1 121 Bearing 5X8X2 .5 4

8 Shock Shaft 2 65 Steer Block L 1 122 Steer Link 1

9 O-ring3x2 10 66 Steer Block R 1 123 Steer Post-R 1

10 Shock_Support 8 67 Steer Holder R 1 124 Sleeve 4.5 2

11 Shock_Cap 4 68 Kinpin Case 4 125 Bumper F 2

12 Shock Ring 4 69 Screw M3x20 6 126 Screw M4x20 2

13 O- Ring 16x1 4 70 Screw M4x12 4 127 Support Bracket F 2

14 Dust Cover 4 71 Push-pull Rod 2 128 Fender L 1

15 Slingshot stop 4 72 Ball Cup 24 4 129 Fender R 1

16

Hydraulic ball head buckle

4 73 Screw M3x15 2 130 Antenna Mount 1

17 6.8 Ball Screw B 2 74 Washer 3x6x2 4 131 Tube 1

18 Shock_Spring-S 4 75 CVD shaft 1 132 Main Chassis 1

19 Shock_Plastic Parts 4 76 PIN 2X12 1 133 Iron Center Shaft 1

20 Shock Spring-F 2 77 PIN 2X16.8 1 134 Gear Cover 1

21 Air Vessel 4 78 PIN 3X12.7 1 135 Bumper 1

22 Shock_Body-R 2 79 CVD Holder 1 136 Bumper 1

23 Shock Shaft 2 80 Fixed pin 1 137 Holder_L 1

24 Shock Spring-R 2 81 CVD Ring 1 138 Holder_R 1

25 Bumper 1 82 Wheel Hub 1 139 Holder 1

26 Bumper 1 83 Screw M3x16 16 140 Fixed dam 1

27 Bumper 1 84 Push-pull Rod 50 2 141 Wing 1

28 Screw M4X10 6 85 Rear Hub Carriers 2 142 Pressure_pad 2

29 Screw M3X8 26 86 Shock Stay-F 1 143 Screw M4x15 2

30 Screw M3X6 12 87 Nut M3 4 144 Rally_tyes 4

31 Screw M3x3 11 88 Washer 4 145 Tire Inner 4

32 Pressure_pad 4 89 Nut M3 8 146 Wheel 4

33 6.8 Ball Screw_C 2 90 Screw M3x23 4 147 Nut M5 M5 5

34 Front Anti-roll Bar 1 91 Ball Cup 34 8 148 6.8 Ball Screw_B 8

35 4.8_Ball-Sleeve 4 92 Body Mount Bracket-F 1 149 Magic Tape 2

36 Ball Cup 26 4 93 Spring Lock 4 150 LI-PO Battery 1

37 Rear Anti-roll Bar 1 94 Shock Stay-R 1 151 Sponge Block 1

38 Bulkhead 4 95 Body Mount Bracket R 1 152 Mantle 1

39 Gear Box 2 96 Differential gear 11T 2 153 Servfo Stay 2

40 Gear Box 2 97 Spacer 2 154 SERVO 9KG 1

41 Screw M3X10 28 98 Bearing 5X10X4 5 155 Servo_Arm 1

42 Arm Holder 4 99 Sponge Block 1 156 Motor 3660 2500KV 1

43 Pin Cap 8 100 Drive Shaft-F 1 157 Motor Mount-B 1

44 Pin 3x46 4 101 E-Clip 4.0 4 158 Motor Mount-A 1

45 Differential Housing 2 102 Bearing bush 1 159 Screw Spring 1

46 Bearing 10X15X4 12 103 Drive cup 2 160 Screw M5X85 1

47 CVD Holder 1 104 Slipper Screw 1 161 Motor Gear 1

48 2 105 Saver Spring 1 162 Receiver 1

49 O_Ring 4.5x1.5 4 106 Pre Ring 1 163 ESC 60A 1

50 Spacer 5X12X0.3 4 107 Driver Disc 2 164 Post 2

51 PIN 4 108 Slipper Sheet 2 165 Painted Body 1

52 Differential gear 18T 4 109 Spur Gear 52T 1 166 LED 1

53 Spacer 2.5x7x0.2 8 110 Driver Shaft-R 1 167 Tail Wheel Holder 2

54 Differential gear 9T 8 111 Push-pull Rod 2 168 Tail Wheel 2

55 Differential pin 4 112 Lower Deck-R 1 169 Tail Wheel Holder 1

56 Drive the cone gear 32T 2 113 Servo Rod 1

57 Screw

Screw

M2.5x8 10 114 Ball Cup 16 2

Bill Of Material

170 M2.5*12

15T-Φ5

2.0X8.8

2

ASBESTOS CUSHION

17

EXPLOED VIEW

170

29

29

41

41

60

41

41

18 19

Tel:0769-88039076

0769-88030083

Fax: 0769-81620956

Address:302,Building A,Yiben Industrial park,No.124 BBK road ,Usha community, Chang'an town,

Dongguan City,Guangdong Province,China 523860.

R

Other manuals for Bison

1

This manual suits for next models

1

Table of contents

Other VKAR Motorized Toy Car manuals

Popular Motorized Toy Car manuals by other brands

Reely

Reely "Cyclone" 4WD RtR operating instructions

Serpent

Serpent VIPER 990 instruction manual

HOMCOM

HOMCOM Lambo V12 Vision Gran Turismo Assembly instruction

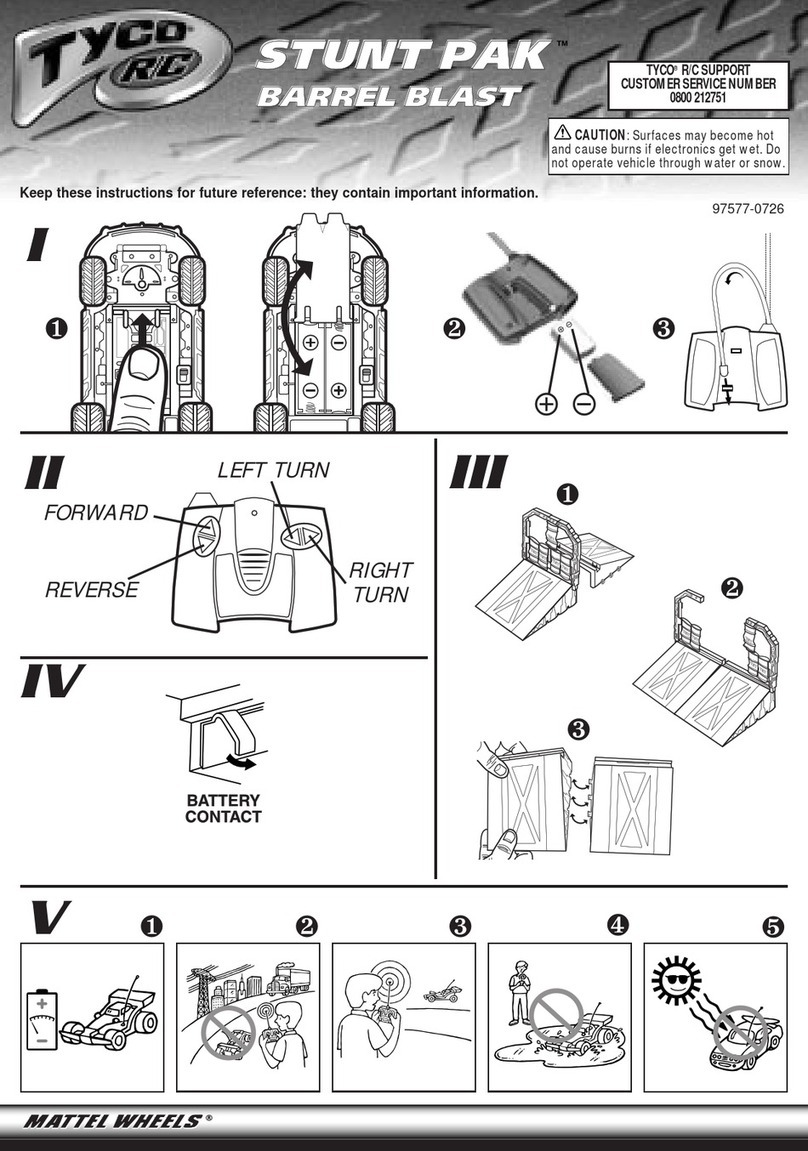

Mattel Wheels

Mattel Wheels Tyco R/C STUNT PAK BARREL BLAST instructions

Kyosho

Kyosho EP JETSTREAM888 VE instruction manual

Aosom

Aosom 370-259V00 quick start guide