WELCOME DOUBLE-X 'CR' OWNER

Thank

you

for

p

ur

chasing

the

Team

Losi

Doub

l

e-

X

'CR'.

Th

e

new

D

ouble-

X

'C

R'

represents

the

latest

in R/C off·

road

chassis

design.

At

Team

L

osi

we

strive

to

consta

n

tly

improve

our

products

as

technology

and

materials

evolve.

You

will

find

the

latest

updates

to

the

Double-

X

to

be

simple

,

yet

yield

extraordinary

results.

B

efore

sta

rt

ing

constr

uct

ion

of

your

Doub

l

e-X

'CR'

,

please

t

ake

a

moment

to

read

th

r

ough

these

inst

ructions.

Thi

s will

minimize

building

time

and

get

you

on

the

tr

ack

soone

r.

Additio

n

ally

,

we

have

included

a

tip

section

in

the

back

of

th

e

manual

to

help

you

tune

your

Double-

X

'CR

'

for

optimu

m

performance.

Once

again,

th

ank

you

for

ch

oosing

the

Double-X

'CR'.

T

eam

L

osi

is

racing

to

help

you

win.

TEAM

LOSI

1. INTRODUCTION

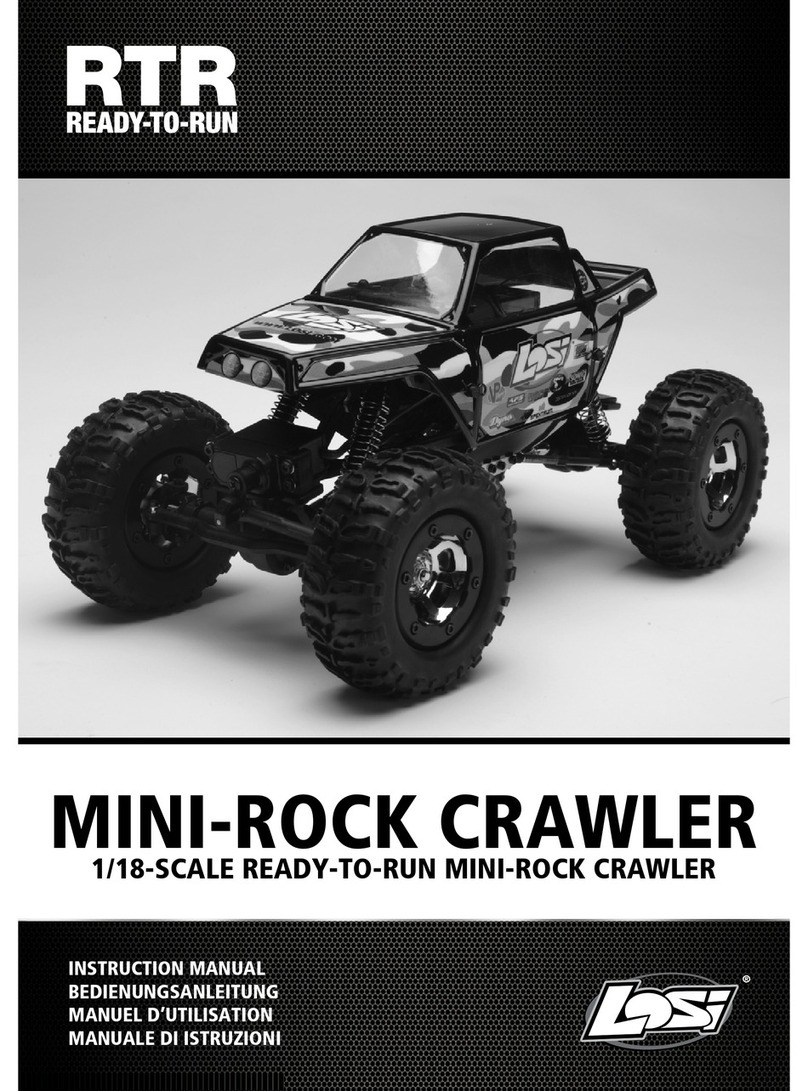

DOUBLE-X 'CR' COMPLETED

KIT

DIMENSIONS

Length:

15

"

Front

Width:

9-5/8"

Wheel

base:

1

0-5/8"

All

dimensions

at

ride

height.

NOTES &SYMBOLS

USED

*Note:

this

is

a commonnote. It

is

used

to

callattention

to

specif

ic

details

of

a certain step in

the

assembly.

e IMPORTANTNOTE:Even ifyou arefamiliarwithTeam

Losi kits, be sure

and

payattention

to

these notes. They point

out

veryimportantdetailsabouta certainstepintheassembly.

Donotignorethese notes!

k This flag designatr1 a performancetip. These tips are

notnecessary,

but

can improvetheperformance

of

yourDouble-

X'

CR

' car.

KIT/MANUALORGANIZATION

The Team Losi Double-X

is

composed

of

different bags

markedA through H. Each

bag

containsall

of

the parts neces-

sary

to

complete a particularsection

of

theDouble-Xcar. Some

of

thesebagshave subassembly

bags

withinthem.It isessen-

tialthatyou openonly

one

bag

at

a time

and

followthecorrect

sequence,otherwiseyoumayfacedifficultiesinfindingtheright

part. It is helpful

to

read through the instructions for an entire

bag prior

to

starting assembly. Key numbers (in circles) have

beenassigned

to

eachpartandremainthesamethroughoutthe

manual.Foryourconvenience,anactualsize hardwareidentifi·

ca

tionguideisincluded with eachstep.

To

checka part, hold it

againstthesilhouette

unt

ilthe correctpart

is

identified.Insome

cases extrahardware has been supplied

to

replace easily lost

parts.To insurethat partsare

not

lostduring construction,

it

IS

recommendedthatyouworkoveratowel

or

mat

to

preventparts

from rolling away.

Rear

Width:

9-7/8"

Height:

6-1/4"

Weight

will

vary

depending

on

accessories.

IMPORTANT SAFETY NOTES

1. Selectanareaf

or

assemblythat isawayfromthe reach

of

small children.The partsin the

kit

aresmall

and

can

be

swal-

lowed

by

children, causing

choking

and

possible

internalinjury.

2.

The shockfluid

and

greasessupplied should

be

kept

out

of

chi

ldren

's

reach.T

hey

were

not

intended

for

humancon-

sumption!

3. Exercisecarewhen using

any

handtools,sharpinstru-

ments,andpowertoolsduringconstruction.

4.Carefullyread

all

manufacturer's warnings

and

cautions

foranyglues

or

paintsthatmaybeusedforassemblypurposes.

TOOLS REQUIRED

Team Losi has supplied all allen wrenches

and

a special

wrench that

is

neededforassembly

and

adjustments.T

he

fol·

lowingcommontoolswill also

be

required:smallflatblade screw·

driver, needlenosepliers,regularpliers, scissors

or

other

body

cutting/trimming tool, 3/16", 1/4

',

and 3/

B"

nut

drivers are

op·

tional.

RADIO/ELECTRICAL

Asuggestedradio layoutisprovidedinthismanual. Your

high

performance RIC center should be consulted regarding

specifics

on

radio/electrical equipment.

HARDWARE IDENTIFICATION

When in question, usethe hardware identification guide

ineachstep.Forscrews,theprefixnumberdesignatesthescrew

sizeand number

of

threads

per

inch (i.e.4-40

is

#4

screwwith

40threads perinch

of

length).Thefractionfollowingdesignates