Vogel E+471 User manual

Versions of the VOGEL Universal Control Unit

for industrial installations

Designation Brief description

Model E+471 Housing for installation in switchgear cubicle,

selectable operating voltage

100 .. 120 V AC or 200 .. 240 V AC

Model I+471 Housing installed in compact unit,

selectable operating voltage

100 .. 120 V AC or 200 .. 240 V AC

Model E+472 Housing for installation in switchgear cubicle,

operating voltage 20..24V AC or DC

Model I+472 Housing installed in compact unit,

operating voltage 20..24V AC or DC

Our control units conform to the generally applicable standards.

Leaflet overview

Control units for progressive systems 117002US

Control units for oil+air lubrication 117003US

Control units for singleline systems 117004US

Universal Control Unit

www.vogelag.com

for Centralized Lubrication Systems

Functions and Operation of the Universal Control Unit

Control and Monitoring Units

117001US

Introduction

The product described in these instructions is a control and

monitoring unit for VOGEL central lubrication systems on station

ary industrial installations. It is supplied either as a constituent

part of VOGEL's compact lubrication units or individually for

installation in a switchgear cubicle.

The Universal Control Unit is the foundation of all our new con

trol and monitoring units, and it can also replace all the

switchgear cubicle units in use to date. Since the control func

tions can differ considerably, depending on the installation and

application, various models based on the Universal Control Unit

are available with functions corresponding to those of the control

units employed to date. The former designations for the individ

ual models have, for the most part, been retained.

The VOGEL Universal Control Unit for industrial lubrication

systems is built to conform to the generally recognized state of

the art, and it complies with the applicable industrialsafety and

accidentprevention regulations.

Control and Monitoring Units 117001US 2

Application

The Universal Control Unit was designed to control and monitor

VOGEL central lubrication systems used on stationary industrial

installations. That is why it may only be used for the purpose set

out in these instructions.

We cannot assume any liability for damages resulting from im

proper use of the unit. The same applies if the unit is operated in

a defective state or if modifications are made on the unit that

have not been approved by WILLY VOGEL AG.

Versions, designation

The VOGEL Universal Control Unit for industrial lubrication

systems is available in four versions (cf. page 1). The designa

tions Eand Irefer to the place the unit is used, i.e. for I(nternal)

installation in a compact lubrication unit or for E(xternal) installa

tion in a switchgear cubicle.

The designations 471 and 472 reflect the operating voltage range

(voltage key). In contrast to the designations customary to date,

only these two voltage keys will be used in the future.

Scope of delivery

The VOGEL Universal Control Unit is supplied either installed as

part of a compact lubrication unit (version I) or individually for

installation in a switchgear cubicle (version E).

The scope of delivery for version E includes:

• one Universal Control Unit with the configuration ordered,

• two cable jumpers for selection of the operating voltage range

(version E+471 only),

• one set of operating instructions.

Designation New Application

to date designation

E/WT2A01 E/WT2A01E Pulse monitoring

voltage unit

E/WT2A04 E/WT2A04E Pulse monitoring

voltage unit

E/XZT2A02 E/XZT2A02E Singleline systems

voltage E/XZT2A02I Piston distributors

E/XZT2A03 E/XZT2A03E Singleline systems

voltage E/XZT2A03I Piston distributors

E/XZT2A05 E/XZT2A05E Progressive systems

voltage E/XZT2A05I

E/XZT2A06 E/XZT2A06E Progressive systems

voltage E/XZT2A06I

E/XZT2A07 E/XZT2A07E Singleline systems

voltage E/XZT2A07I Piston distributors

IG351 IG35110E Electronic timer for

IG35110I central lubrication

systems

IG383 IG3830I Singleline systems

IGZ3830E Piston distributors

IGZ3830I

IG383S1 IGZ3830E Singleline systems

IGZ3830i Piston distributors

IG542 IG5420E Oil+air lubrication

IG5420I

IG542S1 IG5420S1E Oil+air lubrication

IG5420S1I

IG542S3 IG5420S3E Oil+air lubrication

IG5420S3I

IG542S4 IG5420S4E Oil+air lubrication

IG5420S4I

Designation New Application

to date designation

IGZ362 IGZ3620E Singleline systems

IGZ3620I Piston distributors

IGZ362S6 IGZ3620S6E Singleline systems

IGZ3620S6I Piston distributors

IGZ38M IGZ38M10E Oil+air lubrication

Singleline systems

Piston distributors

IGZ512 IGZ5120E Progressive systems

IGZ5120I

IGZ512S2 IGZ5120S2E Progressive systems

IGZ5120S2I

IGZ512S3 IGZ5120S3E Singleline systems

IGZ5120S3I Piston distributors

IGZ512S7 IGZ5120S7E Progressive systems

IGZ5120S7I

IGZ512S8 IGZ5120S8E Progressive systems

IGZ5120S8I

IZ361 IZ36130E Circulating and

IZ36130I distributor lubrication

IZ383 IZ3830I Singleline systems

IGZ3830E Piston distributors

IGZ3830I

IZ383S1 IGZ3830E Singleline systems

IGZ3830I Piston distributors

IZ522 IZ5220E Chain lubrication

IZ5220I

Overview of available VOGEL control units

Control and Monitoring Units 117001US 3

Safety pointers

The VOGEL Universal Control Unit for industrial lubrication

systems is designed for operation on industrial DC or AC power

mains (cf. Technical Data). Any other use is not permitted.

The electrical connections for the unit may only be made by

trained and qualified staff who are able to recognize shock

hazards. Attention must be paid to local operating conditions

and applicable regulations (e.g. DIN, VDE).

Improperly connected equipment can cause extensive prop

erty damage and personal injury.

All adjustments of the unit may only be made by qualified per

sonnel. Qualified personnel are persons who have been trained,

appointed and instructed by the owner of the systems.

Unauthorized conversion of the unit and the use of non

approved spare parts and aids are not permitted.

The unit's housing must not be opened.

If the unit malfunctions, please contact a VOGEL service outlet.

Operation

The Universal Control Unit installed in a compact unit, ver

sion I, may only be operated by qualified staff who are able

to recognize shock hazards unless the control unit has a

separate power supply that has been installed by trained

staff for parameterization purposes and all the other

exposed parts are dead.

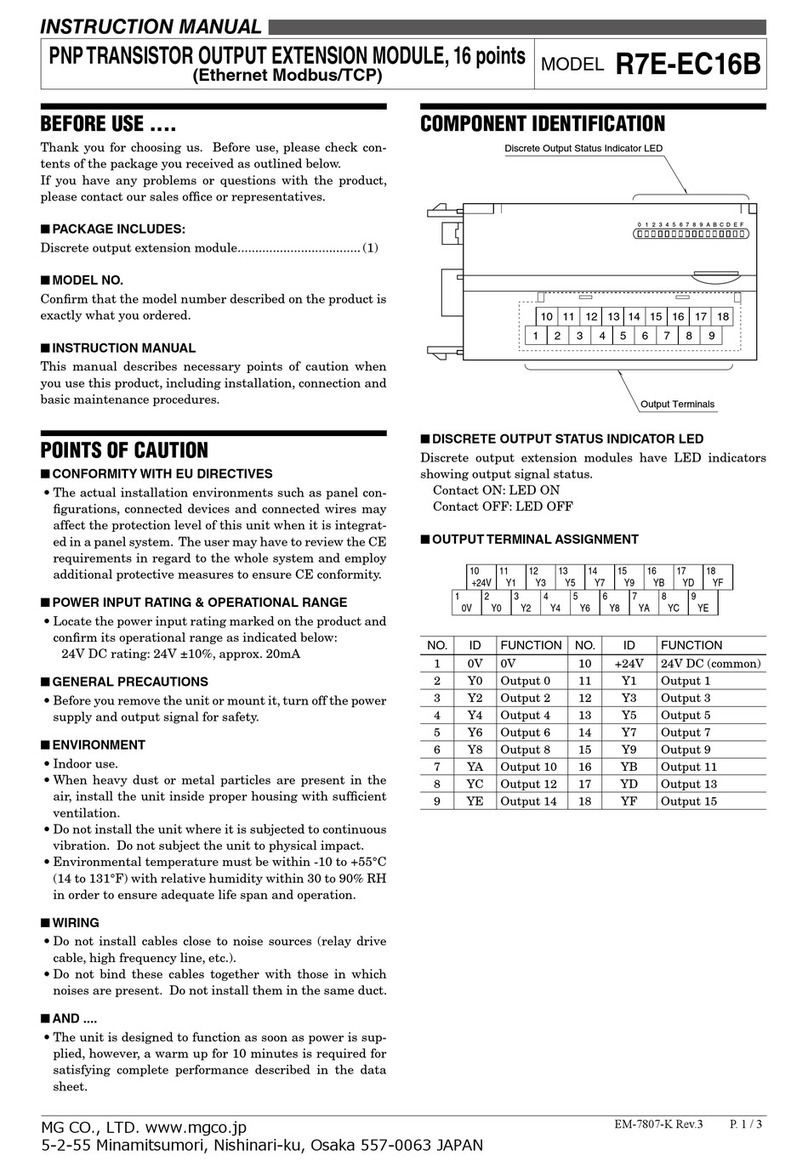

Structure of the operator displays

The illustration shows the operator interface with its display and

control elements. The display elements are the 8place LC dis

play (1) and the LED displays (2). The pushbuttons (3) are the

control elements. The table provides an overview of the display

and control elements.

1LC display 3Pushbuttons

2Lightemitting diodes (LED) 4Service interface

LED display

A burning green LED shows that the power for the unit is on.

If the red LED lights up, that usually indicates a fault state.

Übersicht der Anzeige und Bedienelemente

Element Designation Function

LC display Display function

Status display: shows the states of the inputs and outputs

Parameter display: shows the set and adjustable parameters

Info display: shows the type of unit and loaded software version

Power LED Lights when power to the unit is on

Fault LED Lights in the event of a fault

DK button 1. Trips intermediate lubrication

2. Clears an error message

Select button Change to parameter display,

selection of parameter values to be displayed or changed

UP button Change to info display,

changing of parameter values

Down button Changing of parameter values

Control and Monitoring Units 117001US 4

LC display

The 8place LC display has various display functions:

Status display

Shows states of the inputs and outputs.

Info display

Shows the type of unit and software version.

Parameter display

Shows the set and adjustable parameters.

The status display is the basic display mode. From there it is

possible to change to the parameter display or info display

mode.

The status display

The status display shows the states of the control unit's inputs

and outputs. It is the standard display and is always active when

power is applied to the unit.

Only configured outputs or inputs are displayed. The configura

tion of the inputs and outputs depends on your type of unit.

Example:

Breakdown of the LC status displays

Symbols of the status display

NO contact displays

NO/NC contact open

NO/NC contact closed

Changeover contact displays

Changeover contact in energized position

Changeover contact in deengergized position

The info display

The type of unit and firmware version of the controller can like

wise be shown via the LC display.

The info display is changed to from the status display by press

ing the button.

If the designation is more than eight places long, the rest is

shown by pressing the button in the display once again.

The info display mode is left again by pressing three times.

The parameter display

By pressing the button it is possible to move from the status

display to the parameter display. For reasons of space, the

parameter values are displayed in exponential notation.

100 = 1*102= 1 E 02

The following examples show how to read the displays.

Dispaly value Meaning

TP10E00I interval time 10 (10*100) pulses

TP01E02M interval time 100 (1*102) minutes

TP15E01S monitoring time 150 (15*101)

seconds or 2.5 minutes

Breakdown of the LC parameter display

Status display

Pos. 15 Inputs I1 to I5

Pos. 68 Outputs d1 to d3

Parameter display

Pos. 12 Parameter designation

Pos. 34 Base value

Pos. 5 Symbol E(xponent)

Pos. 67 Exponent

Pos. 8 Unit

Control and Monitoring Units 117001US 5

Adjustment of parameters

Take the type and size of lubrication system into account

when setting the parameters.

Pay attention to the maximum ON times of the motors and

valves in the case of all settings that have an impact on the

pump running time.

To set the parameters, press the button on the parameter

display until the value to be set flashes.

If the displayed parameter cannot be changed, only a static

display of the value will be shown. Which parameters can be

changed will depend on your type of unit.

Select the desired value by pressing or . It is not possible

to enter impermissible parameters, e.g. ones exceeding the

range of values shown in the overview above. Instead, the dis

play will be reset to the preset value.

Press the button after entering the parameter value. The entire

display flashes, confirming that the entered value has been taken

over.

To leave the parameter display, press the button until the sta

tus display is returned to. The new parameters usually take effect

when the next interval begins.

One exception is when the mode of operation (BA) is changed. It

only takes effect after the unit has been switched off and then

started again. Beforehand, the entire display flashes after the

mode is changed. But the normal sequence of functions is still

assured.

Parameter display possibilities *)

LC dispaly Parameter designation Value range Unit

BA Mode of operation A, B, C, D, E

TP Interval time 01 E 00 99 E 04 M(inutes) / S(econds) / I(mpulses)

TU Monitoring time 01 E 00 99 E 03 S(econds)

TN Delay time 00 E 00 99 E 03 S(econds)

TV Lead time 01 E 00 99 E 04 S(econds)

I1 Limit value 1 01 E 00 25 E 04 *0,01 I(mpulses/minute)

I2 Limit value 2 01 E 00 25 E 04 *0,01 I(mpulses/minute)

I3 Limit value 3 01 E 00 25 E 04 *0,01 I(mpulses/minute)

TL Pump running time 01 E 00 15 E 00 S(econds)

TK MK pulse monitoring time 01 E00 12 E 01 S(econds)

MI MK pulse scaling 01 E 00 10 E 00

NH Signal edges (number of strokes) 1 30

NI Number of lube pulses 01 E 00 99 E 03 I(mpulses)

VZ Prelubrication cycles 00 E 00 99 E 00

*) Take the type and size of lubrication system into account when setting the parameters.

Changing parameters

Step Button Display

1 Press The parameter value to be changed flashes

2 Press or until the desired parameter value is reached

3 Repeat steps 12 until all the parameter values have been set.

4 Press the entire display flashes

5 Repeat steps 14 until all the parameters have been set.

6 Press Change to status line

Control and Monitoring Units 117001US 6

Use as a Replacement Unit

The control unit may only be replaced by qualified staff who

are able to recognize shock hazards.

The unit may only be adjusted by trained and qualified staff.

If you want to replace an existing control unit with the Universal

Control Unit, please observe the following pointers.

Before you exchange the units, check whether the mains

voltage is the same as that indicated on the new control unit.

Make a note of the parameter values on the unit to be replaced.

Which values are involved will depend on your type of unit.

Please consult the respective description of the unit for this infor

mation. If necessary, label all the cable conductors to be recon

nected with the previous terminal designations like, for instance,

WS, DS, DS2, MK, DK , +, , etc. The conductors to be recon

nected to relays d1, d2 and d3 must be additionally labeled with

the corresponding terminal numbers.

Now remove the control unit and replace it with the Universal

Control Unit. Connect the inputs and outputs in keeping with

their previous functions. The configuration of the inputs and out

puts can be seen from the sticker attached to the top of the unit

or from the chapter applying to your type of unit.

Make sure the voltage selection described in the assembly chap

ter has been done correctly and only then connect the unit to the

power supply.

The power must switched on and off abruptly.

Then use the keyboard on the Universal Control Unit to transfer

the parameter values from the old control unit.

Please remember that the Universal Control Unit has to be

connected to the power supply before you can change the

parameters.

Check the status display to find out whether the unit is function

ing.

Faults

Fault displays

If a fault detected by one of the monitoring sensors should occur

while the central lubrication system is in operation, the control

unit will display the fault. The red fault LED will light up and the

symbol for the respective input will flash on the display.

Which fault is involved will depend on your type of unit. You will

find further information on this point in the corresponding chap

ter for your type of unit.

After the fault has been remedied, clear the fault display by

pressing the button.

Clear an error message only after its cause has been

remedied.

Equipment faults

Equipment faults are malfunctions that affect the control unit

itself.

Start faults

A start fault is involved when the control unit displays one of the

listed error messages after the power is turned on. In such a

case please contact a VOGEL service outlet.

Error message on Meaning

LC display

ERR1 No configuration loaded

ERR2 Checksum wrong

ERR3 Wrong firmware

Other faults or damages

If your control unit does not function as described in the respec

tive chapter covering your type of unit, please check first

whether the unit and all the leads have been correctly installed

and whether all the lubricant lines are tight.

Also check whether the unit you are using is designed for the

mains voltage available or whether you have correctly selected

the voltage.

If you are unable to remedy the fault in this way, please contact a

VOGEL service outlet.

The housing of the unit must not be opened.

Maintenance and repairs

The Universal Control Unit requires no maintenance.

Nevertheless, you should perform the following checks at regular

intervals to ensure faultless functioning of the control unit

• Check the control unit's basic functions by pressing the

button.

• Check the electrical connections.

Any further work may only be done by an approved VOGEL

service outlet.

Control and Monitoring Units 117001US 7

Technical Data

Version +471 / +472

Rated input voltage Un

Version +471 . . . . . . . . . . . . . 100 ...120 VAC or 200...240VAC

Version +472 . . . . . . . . . . . . . . . . . . . . . . . . 20...24VDC or AC

Rated value of input voltage

Version +471 . . . . . . 0.85 Un to 1.1 Un (85 ...132V / 170...264 V)

Version +472 . . . . . . . . . . . . . . . . . 0.85 Un to 1.1 Un (17...26.4 )

Rated frequency

Version +471 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50...60Hz

Version +472 . . . . . . . . . . . . . . . . . . . . . . . . . . DC or 50...60Hz

Rated value of frequency

Version +471 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49...61 Hz

Version +472 . . . . . . . . . . . . . . . . . . . . . . . . . . DC or 49...61 Hz

Release value of Un . . . . . . . . . . . . . . . . . . . . . . . . . . max. 10%

Recovery time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1s

Residual ripple of input voltage

Version +471 . . . . . . . . . . . . . . . . . . . . . . . . . . . . not applicable

Version +472 . . . . . . . . . . . . . . . . . . . . . . . . . . . . DC: max. 5 %

Max. fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3A

Max. switching current . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A AC

Max. relay switching voltage . . . . . . . . . . . . . . . . . . . . . . 250VAC

Overvoltage category to

DIN VDE 0110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . III

Rated voltage of inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 24VDC

Input impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.4KΩ±10%

Input level low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0V...+ 4 V

Input level high . . . . . . . . . . . . . . . . . . . . . . . . . . . +10V...+ 26.4 V

Coincidence factor for the inputs . . . . . . . . . . . . . . . . . . max. 0.8

Version +471 and +472

Output voltage for inputs

and external loads . . . . . . . . . . . . . . . . . . 24VDC +10 % / 15%

Rated output current ("+" outputs) . . . . . . . . . . . . . . . . . . 110mA

of that figure for external loads . . . . . . . . . . . . . . . . . max. 60 mA

MK input, max. input frequency . . . . . . . . . . . . . . . . . . . . . . 30Hz

Pulse duty factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1:1

Conductor connection (flexible)

with tubular end sleeves . . . . . . . max. 2.5 mm2or 2x0.75 mm2

with twin tubular end sleeves . . . . . . . . . . . . . . max. 2x1.5 mm2

stripped length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 mm

Type of enclosure (version E) . . . . . . . . . . . IP 30, IP 20 terminals

Safety class (version E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II

Rated insulation voltage . . . . . . . . . . . . . . . . . . . . . . . . . 250 VAC

Pollution degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operating temperature . . . . . . . . . . . . . . . . . . . . . . 0 to + 60 °C

Storage temperature . . . . . . . . . . . . . . . . . . . . . . – 25 to + 70 °C

Dimensions WxHxD (version E) approx 70 mm x 75 mm x 110 mm

Voltage endurance to EN 611312 and EN 50178

Power supply / relay contacts . . . . . . . . . . . . . . . . . . . . . 1780 V

Power supply / electronics . . . . . . . . . . . . . . . . . . . . . . . 2830 V

Relay contacts / electronics . . . . . . . . . . . . . . . . . . . . . . 2830V

EMC

Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . EN 6100062

Emitted interference . . . . . . . . . . . . . . . . . . . . . . . EN 5000811

Dynamic strength to EN 6006826 . . . . . . 10 57Hz; 0.075 mm

(amplitude)

Impact resistance to EN 600068227 . . . . 15g; 11 ms (halfsine)

Subject to change without notice! 0000 08/2004

Willy Vogel AG

Motzener Strasse 35/37

12277 Berlin, Germany

P.O.Box 970444 ·12704 Berlin

Tel. +49 (0) 30 7 20 020

Fax +49 (0) 30 7 20 02111

info@vogelberlin.de

www.vogelag.com

Willy Vogel AG

2. Industriestrasse 4

68766 Hockenheim

Germany

Tel. +49 (0) 62 05 27 0

Fax +49 (0) 62 05 27132

info@vogelberlin.de

www.vogelag.com

Vogel France SAS

Rue Robert Amy, B.P. 130

49404 Saumur cedex

France

Tel. +33 (0) 241 404 200

Fax +33 (0) 241 404 242

www.vogelfrance.com

Notice!

All products from VOGEL may be used only for their intended purpose.

If operating instructions are supplied together with the products, the provi

sions and information therein of specific relevance to the equipment must

be observed as well.

In particular, we call your attention to the fact that hazardous materials of

any kind, especially the materials classified as hazardous by EC Directive

67/548/EEC, Article 2, Par. 2, may only be filled into VOGEL centralized

lubrication systems and components and delivered and/or distributed with

the same after consultation with and written approval from VOGEL.

All products manufactured by VOGEL are not approved for use in con

junction with gases, liquefied gases, pressurized gases in solution and

fluids with a vapor pressure exceeding normal atmospheric pressure

(1013 mbars) by more than 0.5 bar at their maximum permissible

temperature.

This manual suits for next models

3

Table of contents