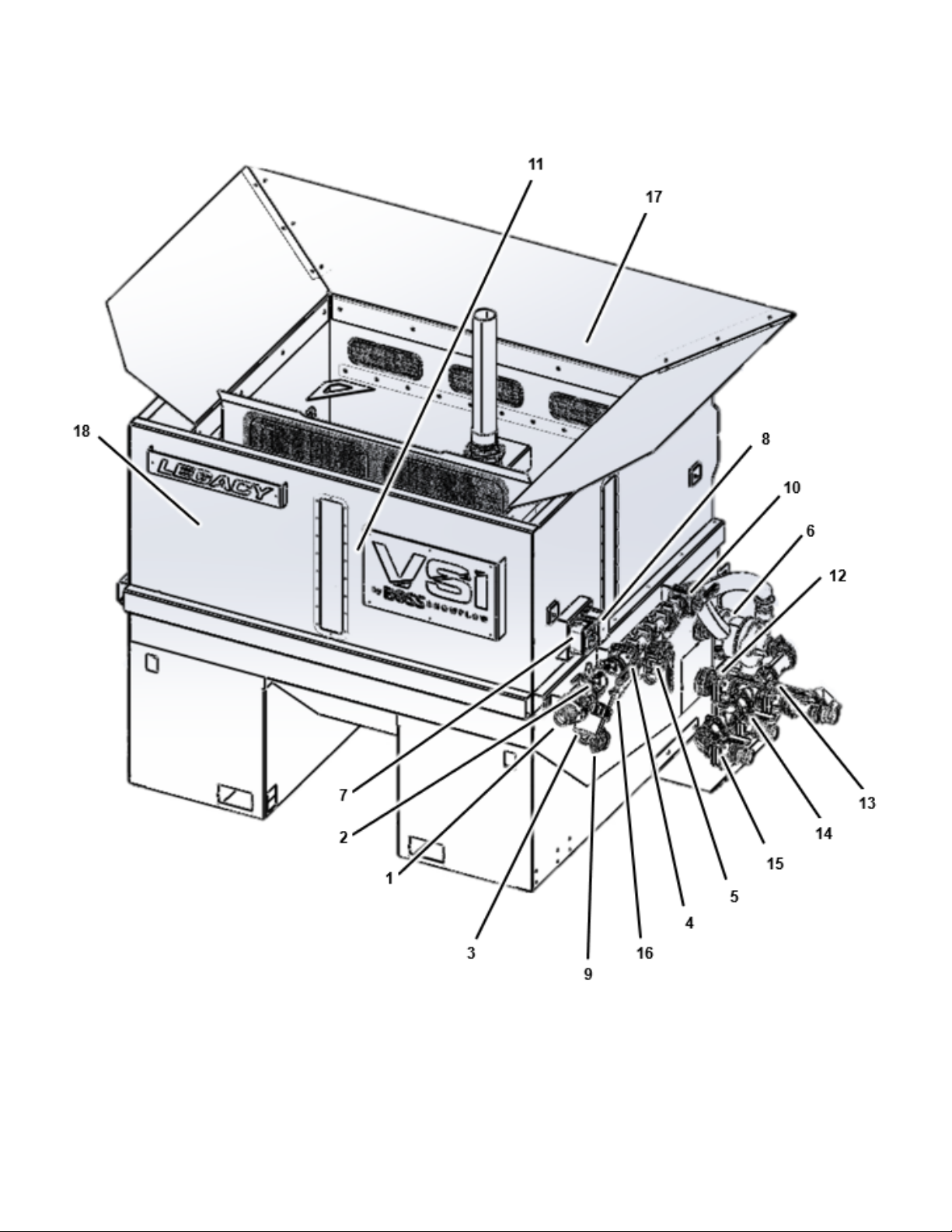

Introduction

This machine is a dedicated ice-control solution

creation system and is intended to be used by

professional, trained operators for creating ice-control

solutions used on residential or commercial

properties. Using this equipment improperly or for

purposes other than its intended use may prove

dangerous to you and others. You are responsible for

operating the equipment properly and safely.

Read this manual carefully to learn how to operate

and maintain your equipment properly and to avoid

injury and product damage.

A digital version of this manual that can be accessed

on the VSI Spray Control app (“Getting Started/FAQ”

button on the Profile” tab).

If service, parts, or additional information is needed

please contact VSI Technical Service

(1-507-252-3033) for more information.

General Safety

This product is capable of causing personal injury.

Always follow all safety instructions to avoid personal

injury.

● Read and understand the contents of this

Owner’s Manual before operating or servicing

the equipment.

● Use your full attention while operating the

machine. Do not engage in any activity that

causes distractions; otherwise, injury or

property damage may occur.

● Use appropriate personal protective equipment

(PPE) to guard against contact with chemicals.

● Do not put your hands or feet near moving

components of the machine.

● Do not operate the machine without all guards

and other safety protective devices in place

and in proper working order on the machine.

● Keep bystanders, children, and pets out of the

operating area.

● Never allow children to operate the machine.

Allow only people who are responsible,

trained, familiar with the instructions, and

physically capable to operate the equipment.

● Shut off the equipment, wait for all movement

to stop, and allow the equipment to cool before

adjusting, servicing, cleaning, or storing it.

Improperly using or maintaining this machine can

result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert symbol. Failure to comply

with these instructions may result in personal injury or

death.

Safety Instructions

● Read the Operator’s Manual.

● All operators should be training before

operating the machine.

● Wear eye protection.

● Do not enter the tank.

● Shut off the machine before walking away.

● Do not put flammable liquids in the tank.

● Only lift an empty tank; do not lift the tank

when full.

Quick-Start Installation

Follow the steps below to set up and prepare the

machine for use.

1. Ensure proper electrical outlet is available

2. Ensure machine is positioned for space and

clearance for loading

3. Download the VSI Spray App

4. Connect to machine via Bluetooth

5. Connect machine to WiFi