M1.2.CUT80HFI.NLFREN 09102018

8

NL

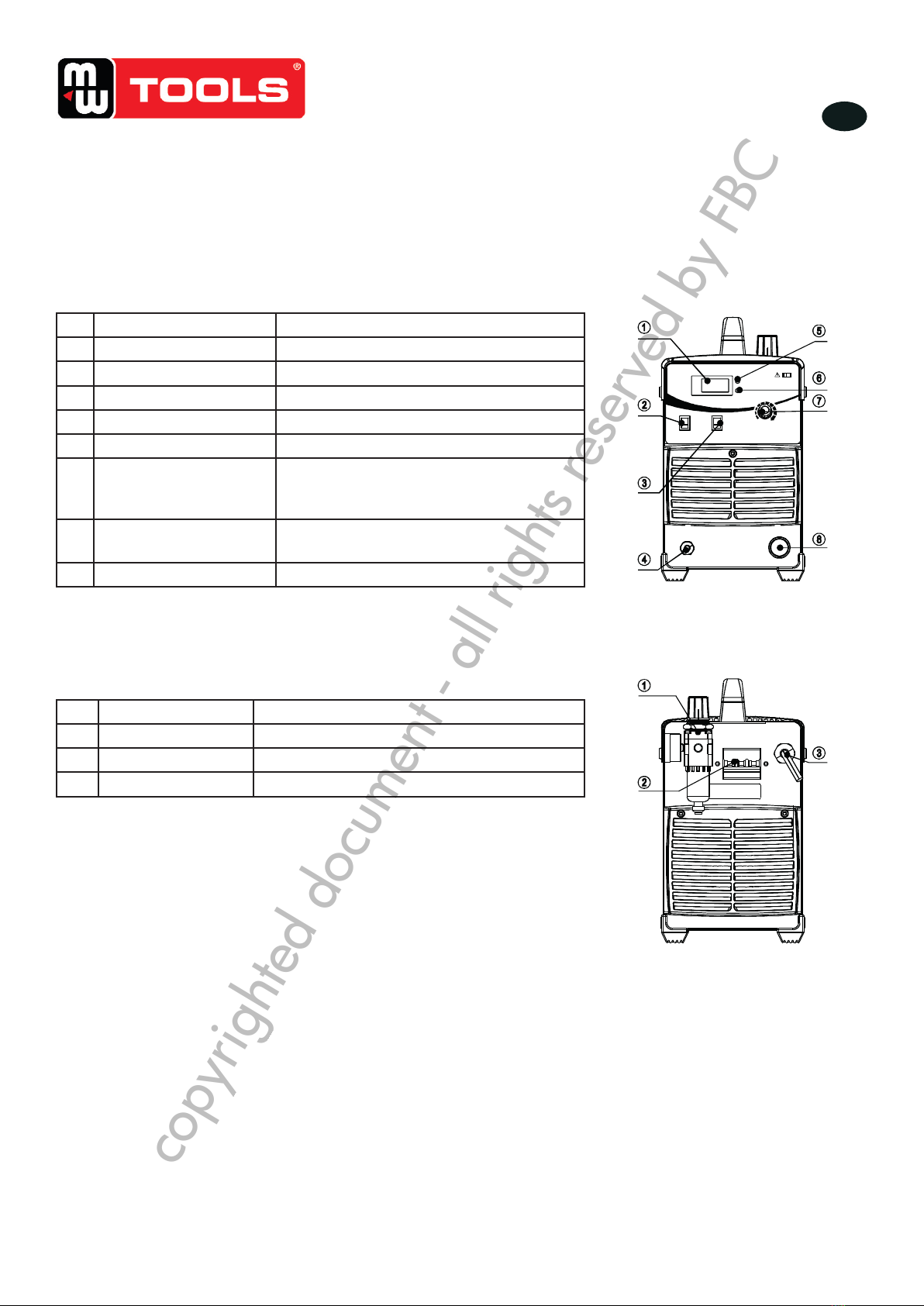

3 Installatie en aansluiting

3�1 Aansluitingsvoorwaarden

1) Aansluiting van de ingangskabel

Voor uw veiligheid, en om elektrische schokken te voorkomen, verbind de machine op betrouwbare wijze aan de aarde,

door de aardingsdraad (geel-groen) van de machine aan de aardingsaansluiting van de schakeldoos aan te sluiten.

Een primaire voedingskabel is beschikbaar voor deze snijmachine. Sluit de voedingskabel aan het nominale

ingangsvermogen aan. De primaire kabel moet aan de correcte stopcontact goed aangesloten worden, om oxidatie te

voorkomen.

Controleer met een multimeter, of de spanning in aanvaardbaar bereik varieert.

De doorsnede van de leidingen in de schakeldoos moet aan de vereisten van de maximale ingangsvermogen van de

machine voldoen.

2) Aansluiting van de uitgangskabel

Aansluiting van de snijtoorts

Verbind de koperen moer op de snijtoorts met de gas-elektriciteit aansluiting op het

voorpaneel van de machine, en draai met de klok mee om gaslekkages te voorkomen.

Steek de snelstekker op de werkstukklem in de “+” uitgang op het voorpaneel van de

machine, en draai deze vast.

Aansluiting van de toortstrekker

Steek de stekker van de trekker op de snijtoorts in de aansluiting van de toortstrekker

op het voorpaneel. Installeer de elektrode in de snijtoorts door deze langzaam te

draaien, en draai deze vast. Installeer vervolgens het mondstuk en de beschermhuls in

de juiste volgorde.

Aansluiting van de aardingskabel

Steek de snelstekker van de aardingskabel in de snelle aansluiting met het symbool

aan de onderkant van het voorpaneel van de machine, en draai deze vast. Klem het

werkstuk met de werkstukklem aan de andere kant van de aardingskabel.

3) Werking van het reduceerventiel

De ingebouwde lterdrukregelaar wordt in de fabriek ingesteld, en moet normaal niet door de gebruiker geregeld

worden. Als deze toch ingesteld moet worden, open de afdekkap van de machine zoals hiernaast afgebeeld, en ga als

volgt te werk:

1. Start de gasstroom.

2. Duw de drukregelknop omhoog.

3. Stel de gasdruk tot de gewenste waarde in, door de knop te draaien (draai naar “+” om de druk te verhogen, draai

naar “-” om de druk te verminderen).

4. Duw de drukregelknop omlaag, om deze te vergrendelen.

5. Voer het water af door de afvoerknop te draaien wanneer er te veel water in de lterbeker.

6

2. INSTALLATION AND CONNECTION

2.1 Installation requirements

In order to ensure personal safety and avoid electric shock, please ground the machine reliably

by connecting the ground wire (yellow-green wire) of the machine to the grounding device in

the switching box.

1)Connection of input cable

A primary power supply cable is available for this cutting machine. Connect the power supply

cable to the rated input power. The primary cable should be tightly connected to the correct

socket to avoid oxidization. Check whether the voltage value varies in acceptable range with a

multi-meter.

The cross section of the leads used in the switching box should meet the requirements of the

maximum input capacity of the machine.

2)Connection of output cable

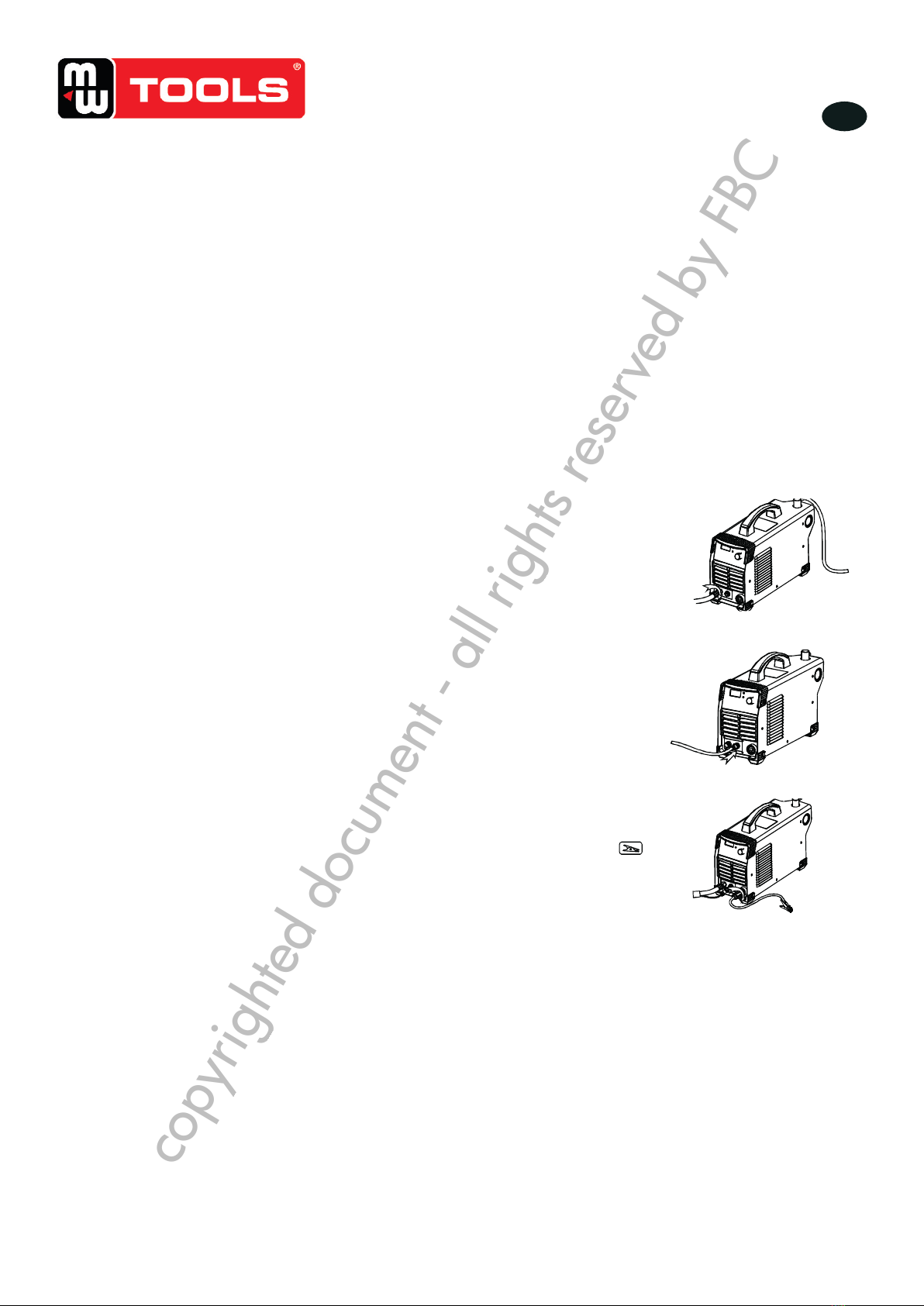

Connection of cutting torch

Connect the copper nut on the cutting torch to the

gas-electric connector on the front panel of the

machine, and tighten it clockwise to avoid gas

leakage. Insert the quick plug on the work clamp

into the “+” output terminal on the front panel of the

machine, and tighten it clockwise.

Connection of the torch trigger

Insert the plug of the torch trigger on the cutting torch

into the socket of torch trigger on the machine panel.

(For models with pilot arc function, connect the pilot

arc wire on the cutting torch to the terminal for pilot

arc wire on the machine panel.) Install the electrode

into the cutting torch by turning it slowly, and tighten

it. Then, get the nozzle and protective sleeve installed

in sequence.

Connection of earth cable

Insert the quick plug on the earth cable into the quick

socket marked with “ ” at the bottom of the front

panel of the machine, and tighten it clockwise. Clamp

the workpiece with the work clamp at the other end of

the earth cable.

6

2. INSTALLATION AND CONNECTION

2.1 Installation requirements

In order to ensure personal safety and avoid electric shock, please ground the machine reliably

by connecting the ground wire (yellow-green wire) of the machine to the grounding device in

the switching box.

1)Connection of input cable

A primary power supply cable is available for this cutting machine. Connect the power supply

cable to the rated input power. The primary cable should be tightly connected to the correct

socket to avoid oxidization. Check whether the voltage value varies in acceptable range with a

multi-meter.

The cross section of the leads used in the switching box should meet the requirements of the

maximum input capacity of the machine.

2)Connection of output cable

Connection of cutting torch

Connect the copper nut on the cutting torch to the

gas-electric connector on the front panel of the

machine, and tighten it clockwise to avoid gas

leakage. Insert the quick plug on the work clamp

into the “+” output terminal on the front panel of the

machine, and tighten it clockwise.

Connection of the torch trigger

Insert the plug of the torch trigger on the cutting torch

into the socket of torch trigger on the machine panel.

(For models with pilot arc function, connect the pilot

arc wire on the cutting torch to the terminal for pilot

arc wire on the machine panel.) Install the electrode

into the cutting torch by turning it slowly, and tighten

it. Then, get the nozzle and protective sleeve installed

in sequence.

Connection of earth cable

Insert the quick plug on the earth cable into the quick

socket marked with “ ” at the bottom of the front

panel of the machine, and tighten it clockwise. Clamp

the workpiece with the work clamp at the other end of

the earth cable.

6

2. INSTALLATION AND CONNECTION

2.1 Installation requirements

In order to ensure personal safety and avoid electric shock, please ground the machine reliably

by connecting the ground wire (yellow-green wire) of the machine to the grounding device in

the switching box.

1)Connection of input cable

A primary power supply cable is available for this cutting machine. Connect the power supply

cable to the rated input power. The primary cable should be tightly connected to the correct

socket to avoid oxidization. Check whether the voltage value varies in acceptable range with a

multi-meter.

The cross section of the leads used in the switching box should meet the requirements of the

maximum input capacity of the machine.

2)Connection of output cable

Connection of cutting torch

Connect the copper nut on the cutting torch to the

gas-electric connector on the front panel of the

machine, and tighten it clockwise to avoid gas

leakage. Insert the quick plug on the work clamp

into the “+” output terminal on the front panel of the

machine, and tighten it clockwise.

Connection of the torch trigger

Insert the plug of the torch trigger on the cutting torch

into the socket of torch trigger on the machine panel.

(For models with pilot arc function, connect the pilot

arc wire on the cutting torch to the terminal for pilot

arc wire on the machine panel.) Install the electrode

into the cutting torch by turning it slowly, and tighten

it. Then, get the nozzle and protective sleeve installed

in sequence.

Connection of earth cable

Insert the quick plug on the earth cable into the quick

socket marked with “ ” at the bottom of the front

panel of the machine, and tighten it clockwise. Clamp

the workpiece with the work clamp at the other end of

the earth cable.

6

2. INSTALLATION AND CONNECTION

2.1 Installation requirements

In order to ensure personal safety and avoid electric shock, please ground the machine reliably

by connecting the ground wire (yellow-green wire) of the machine to the grounding device in

the switching box.

1)Connection of input cable

A primary power supply cable is available for this cutting machine. Connect the power supply

cable to the rated input power. The primary cable should be tightly connected to the correct

socket to avoid oxidization. Check whether the voltage value varies in acceptable range with a

multi-meter.

The cross section of the leads used in the switching box should meet the requirements of the

maximum input capacity of the machine.

2)Connection of output cable

Connection of cutting torch

Connect the copper nut on the cutting torch to the

gas-electric connector on the front panel of the

machine, and tighten it clockwise to avoid gas

leakage. Insert the quick plug on the work clamp

into the “+” output terminal on the front panel of the

machine, and tighten it clockwise.

Connection of the torch trigger

Insert the plug of the torch trigger on the cutting torch

into the socket of torch trigger on the machine panel.

(For models with pilot arc function, connect the pilot

arc wire on the cutting torch to the terminal for pilot

arc wire on the machine panel.) Install the electrode

into the cutting torch by turning it slowly, and tighten

it. Then, get the nozzle and protective sleeve installed

in sequence.

Connection of earth cable

Insert the quick plug on the earth cable into the quick

socket marked with “ ” at the bottom of the front

panel of the machine, and tighten it clockwise. Clamp

the workpiece with the work clamp at the other end of

the earth cable.

copyrighted document - all rights reserved by FBC