Wake N Grill Page 7

to align with the bottom of the platform.

It can be installed in any rotational

position provided it is the best t for

drilling holes. However, if your swim

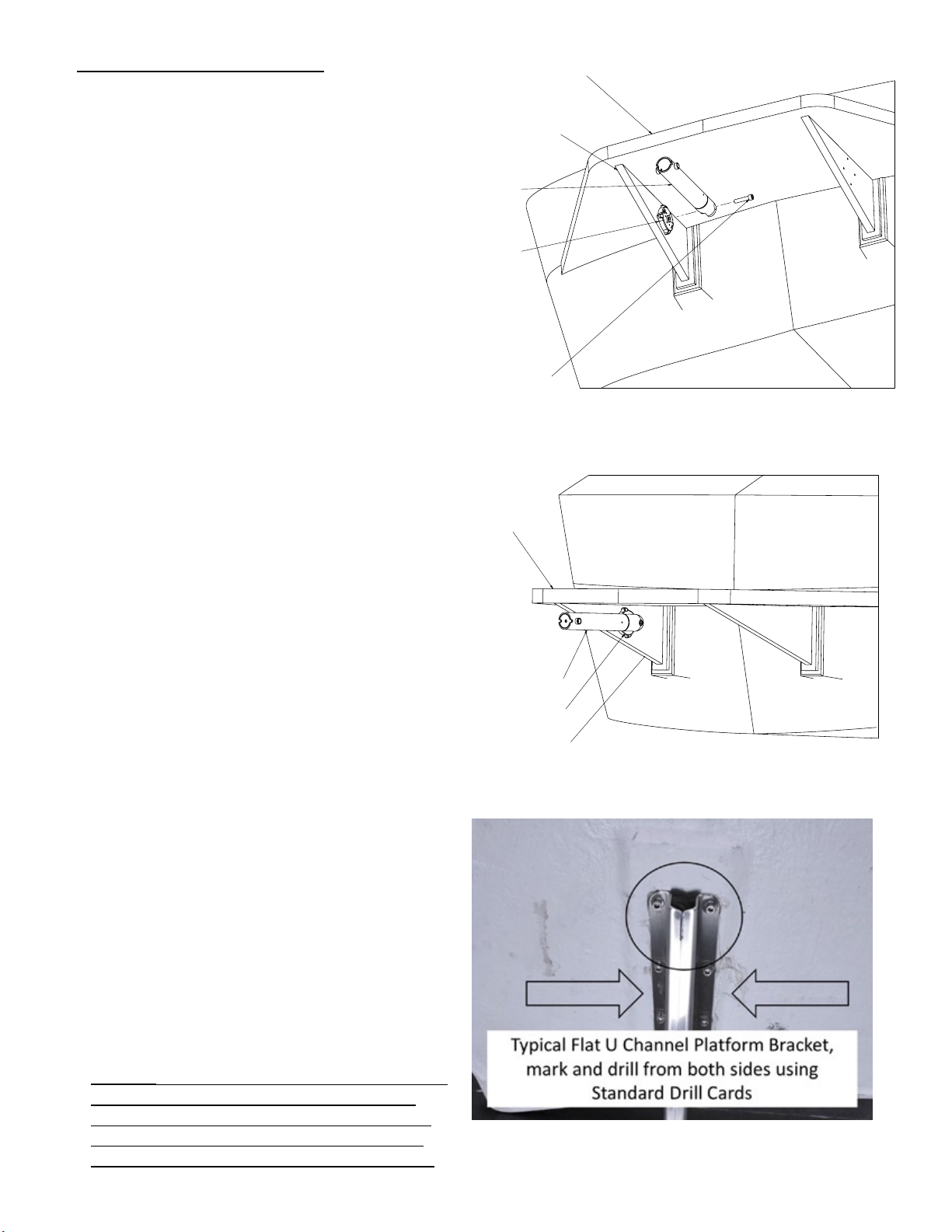

step brackets are U-shaped (or hallow

in the middle) (Figure 10) and require

drilling from both sides, we recommend

“squaring up” the Flat Mount to the

bottom edge on the platform. This

will make it much easier to transfer

measurements to the other side. This

will be further explained in the next few

steps.

Step 4: Mark position. Once desired location of

the Flat Mount and Lower Tube Assembly is found

mark the clamp location on the swim platform

bracket. Remove the temporarily installed Lower

Tube Assembly from the Flat Mount at this time.

For the “U”-channel brackets proceed to Step 5. For

solid brackets, proceed to Step 7.

Step 5: U-Channel Drill Preparation. The next

two steps are necessary to properly drill through

the U-channel. Drilling this type of bracket will

require drilling holes from both sides to prevent

misaligned holes. Using the mark from Step 4,

place the Standard drill card on the marked side

of the swim platform bracket ensuring the top

edge is ush with the platform support edge as

shown in Figure 12. Temporarily tape the card

to the bracket in two places.

Note: Ensuring the card is ush to the bracket

support is important, the same sized card will be

placed on the opposing side of the bracket the

height must be the same to drill a straight hole.

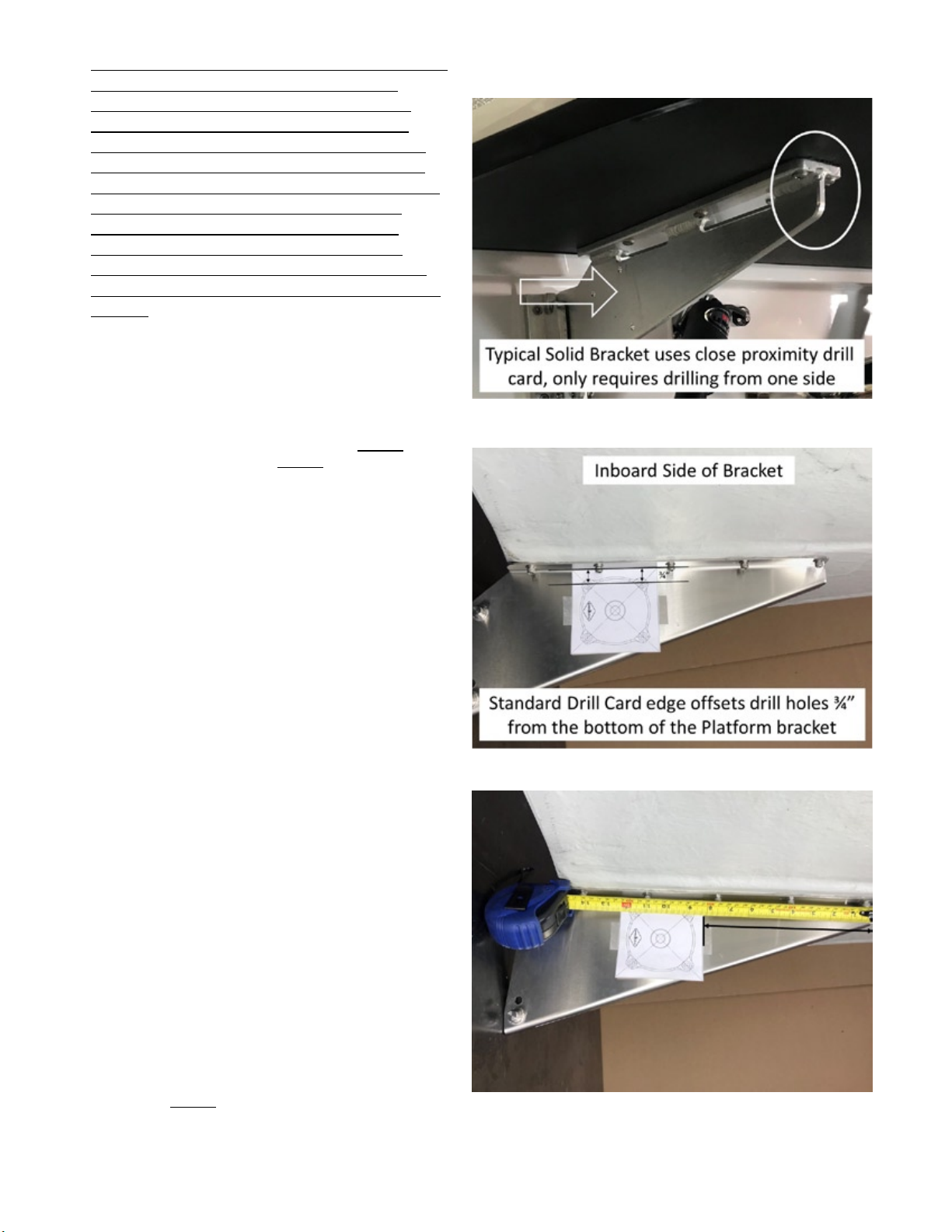

Step 6: Placement of opposing drill card.

Measure and record the distance from edge of the

drill card to the aft edge of the platform bracket.

See Figure 13.

Using the measurement recorded above, measure

and mark the same location on the opposing side

of the swim platform bracket. See Figure 14.

Place the second drill card in the marked location,

and temporarily tape the card to the bracket in

two places. This is a good time to double check

you work on both sides. See Figure 14.

Note: Ensuring the card is ush to the bottom

of the bracket support is important, the drill hole

must align with the opposing side to ensure a

straight hole.

Proceed to Step 8: Center Punch holes.

Solid Swim Step BracketFigure 11.

Standard Drill Card on U-Channel BracketFigure 12.

Measure Card Location to edge of BracketFigure 13.