4

3. SAFETY INSTRUCTIONS AND PRECAUTIONS

Read these instructions very carefully before installing and using this equipment. Installation, connection and maintenance should be carried out

by a qualified technician and in accordance with the local regulations and legislation.

The company shall take no responsibility for the injuries or damaged property if the safety requirements are not followed or the device is modified

without the permission of the manufacturer.

Main safety rules

Danger

• Before carrying out any electrical or maintenance works, make sure that the device is disconnected from the mains and all moving

parts of the device have stopped.

• Make sure that the fans are not accessible through air ducts or branch openings.

• If any liquids on electric parts or connections that bear voltage are noticed, stop the operation of the device.

• Do not plug the device into the mains that differ from the one indicated on the label or on the housing.

• Voltage of the mains should comply with the electro technical parameters indicated on the label.

• The device should be earthed in accordance with the regulations on the installation of electric devices. Turning on and using unearthed

device is not allowed. Follow the requirements specified on the device’s labels that indicate danger.

Warnings

• Connection of electricity and maintenance of the device should be performed by the qualified personnel only and in accordance with the

manufacturer’s instructions and safety requirements.

• In order to reduce the risk during installation and maintenance, suitable protective clothing must be worn.

• Beware of sharp angles while carrying out installation and maintenance works.

• Do not touch heating elements until they haven’t cooled down.

• Some devices are heavy, you should be very careful while transporting and installing them. Use suitable lifting equipment.

• When connecting electricity to the mains, a circuit breaker of suitable size must be used.

Warning!

• If the device is installed in a cold environment, make sure that all connections and tubes are properly isolated. Intake and discharge air

ducts should be isolated in all cases.

• Openings of the ducts should be covered during transportation and installation.

• Make sure not to damage the heater when connecting the piping of the water heater. For tightening up, use a wrench/spanner.

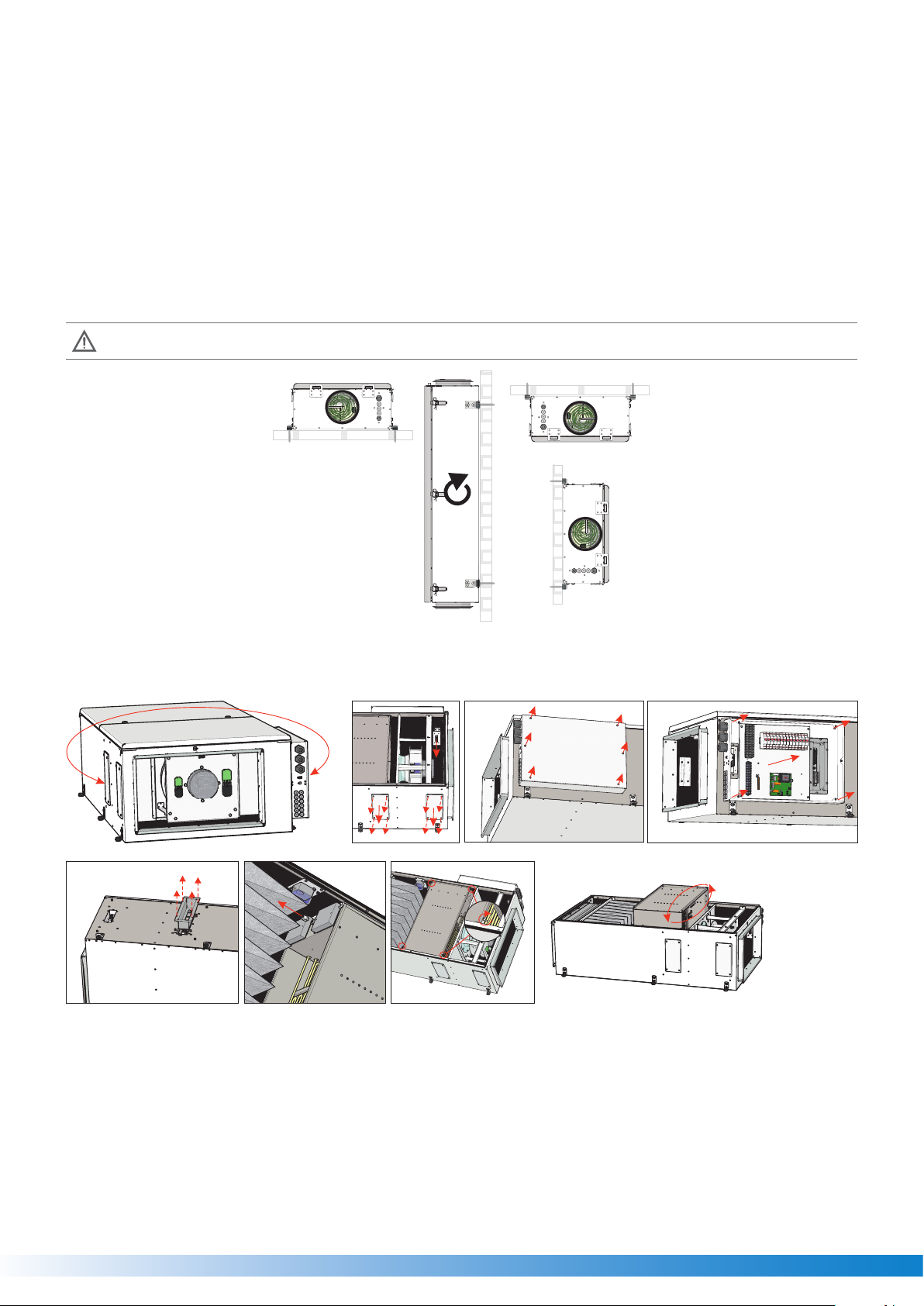

Before starting up the device

• make sure, that there are no strange objects inside;

• manually check fans to make sure they are not stuck or blocked;

• if rotary heat exchanger is installed in the device, make sure that it is not stuck or blocked;

• check the earthling;

• make sure that all components and accessories are connected in accordance with the wiring diagram or provided instructions.

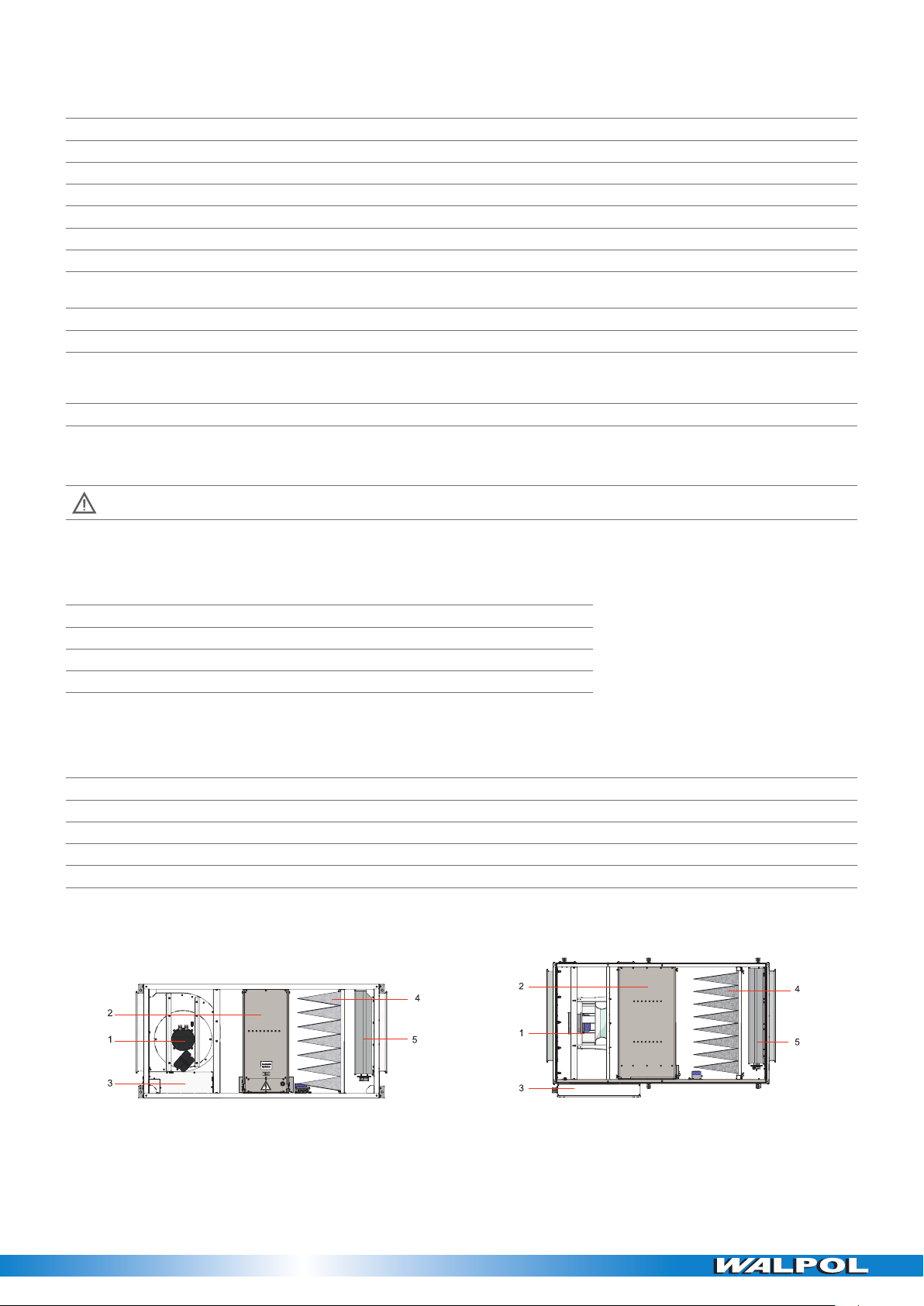

Danger: Fumes

Antifrost system uses dis-balancing of the air flow and it may cause negative pressure in premises. Great care should be taken when

using at the same time in premises as another heating appliance what depend on the air in premises. Such appliances include gas, oil,

wood or coal-fired boilers and heaters, fireplaces, continuous flow or other water heaters, gas hobs, cookers or ovens which draw air

in from the room and duct exhaust gases out through a chimney or extraction ducting. The heating appliance can be starved of oxygen,

impairing combustion. In exceptional cases harmful gases could be drawn out of the chimney or extraction ducting back into the room. In

this case we strictly recommend to turn off Antifrost and use an external preheater for heat exchanger anti-frost protection (see Antifrost

function on the Remote controller manual).