1

OUR PLEDGE TO YOU

Your W&H Model 206 is a quality product and is built to last. Our technical support

services are legendary. Call us toll free. We are ready to help you with any maintenance

or operational questions you may have.

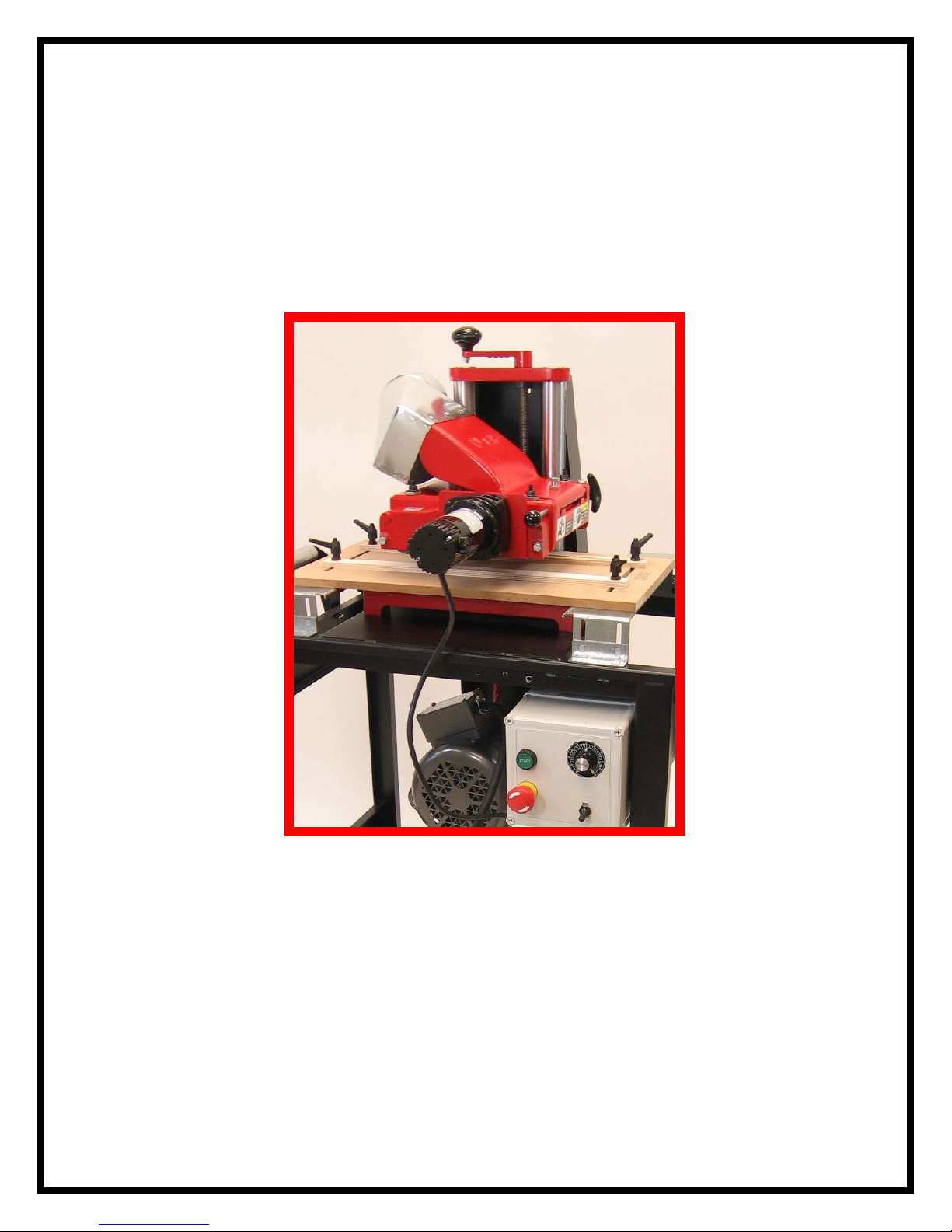

The Model 206 is a new design built in the W&H tradition of ruggedness and durability.

This machine rises above others in its class, in ease of use, compactness, versatility, and

the control over your work that you desire.

Knife changing is so simple that it can be perfectly done in about two minutes, allowing

you to quickly move from job to job.

The machine is manufactured in New Hampshire by people who take pride in making a

superior product. We welcome comments and observations from you on any aspect of the

machine and what you are making with it.

WILLIAMS & HUSSEY MACHINE CO. INC.

70 Powers Street

Milford NH 03055

Or see http://www.williamsnhussey.com

1800 258 1380 603 732 2019 fax 603 732 4048

Customer Service is available Monday-Friday, 8:30 AM- 4:30 PM EST

Complete Revision 6/91

Revised: 12/92

8/95

8/96

6/97

3/03

9/03

10/06