1. Index

0. Introduction................................................................................................................................................................................... 2

1. Index.............................................................................................................................................................................................3

2. Safety Information.........................................................................................................................................................................4

3. Equipment use and specifications.................................................................................................................................................5

3.1 Electrical Power Requirements:......................................................................................................................................5

3.2 Equipment location.........................................................................................................................................................6

3.3 Equipment features: .......................................................................................................................................................6

Equipment dimensions:.....................................................................................................................................................................6

4. Equipment description ..................................................................................................................................................................7

4.1 Equipment exterior: ........................................................................................................................................................7

4.2 Right side.......................................................................................................................................................................7

4.3 Left side..........................................................................................................................................................................7

4.4 Other elements...............................................................................................................................................................7

4.5 Screen and keyboard .....................................................................................................................................................8

4.6 Type II Water Tank.........................................................................................................................................................8

5 Water purification process description............................................................................................................................................9

5.1 Pretreatment ..................................................................................................................................................................9

5.2 Reverse osmosis............................................................................................................................................................9

5.3 Deionisation ...................................................................................................................................................................9

5.4 Type II Water Storage ....................................................................................................................................................9

5.5 Automatic operation of the equipment ............................................................................................................................9

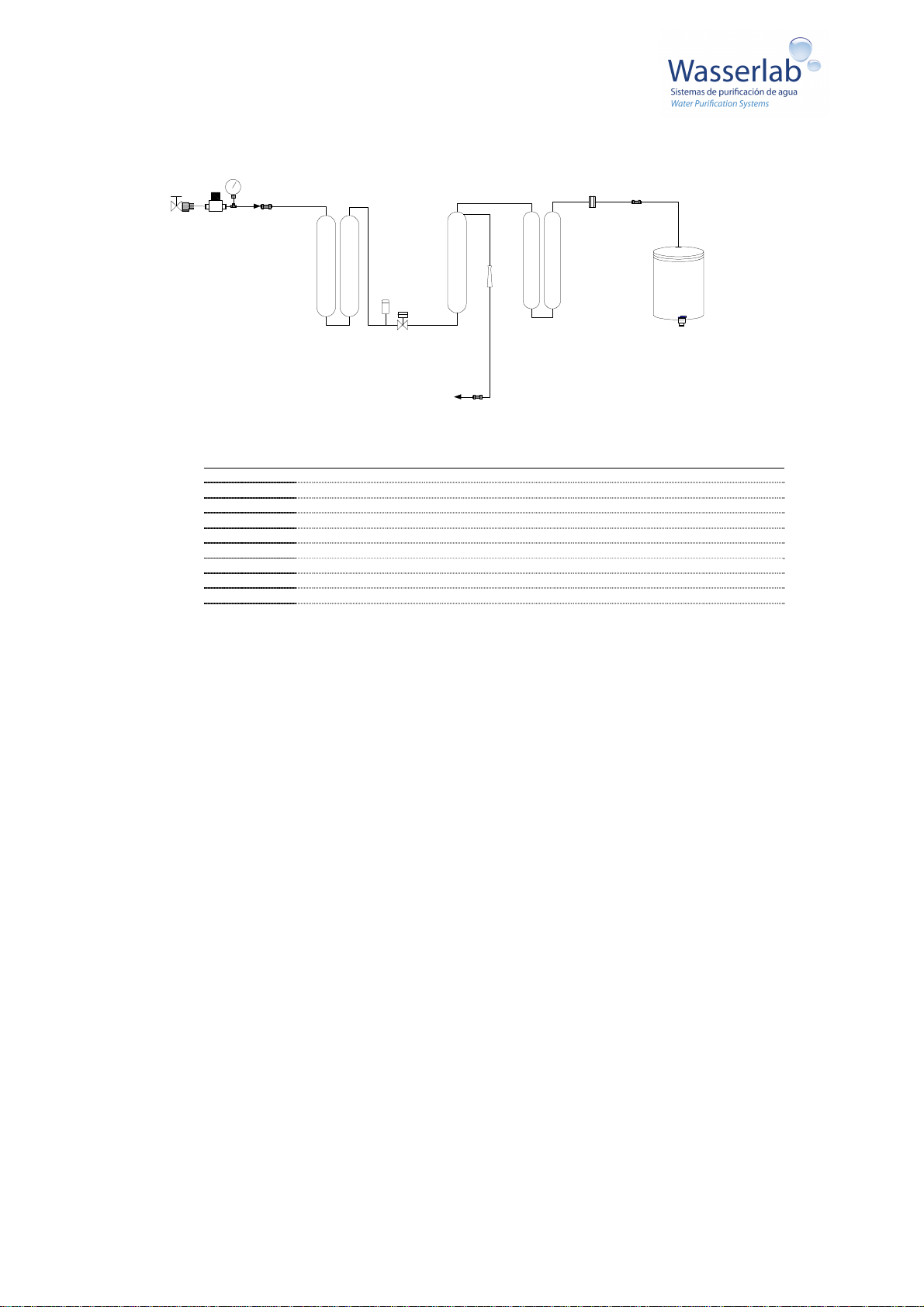

6. Hydraulic diagram.......................................................................................................................................................................10

7. Installation of the equipment.......................................................................................................................................................10

7.1 Unpacking the equipment............................................................................................................................................. 10

7.2 Hydraulic connections ..................................................................................................................................................12

7.3 Equipment start-up....................................................................................................................................................... 13

8. MONITORING ............................................................................................................................................................................ 14

8.1 Symbols and meaning:................................................................................................................................................. 14

8.2 User warnings ..............................................................................................................................................................15

8.3 Entering parameters (set-up menu)............................................................................................................................. 15

9. Maintenance...............................................................................................................................................................................17

9.1 Pretreatment replacement............................................................................................................................................ 17

9.2 Resin cartridge replacement.........................................................................................................................................17

9.3 RO membrane replacement ......................................................................................................................................... 17

10. Calibration ................................................................................................................................................................................18

11. Troubleshooting Guide............................................................................................................................................................. 19

12. EC-Declaration of Conformity....................................................................................................................................................20