(2) Please do not disassemble this device or make improvements or repairs.

Doing so may cause sudden fire, electrocution or injury.

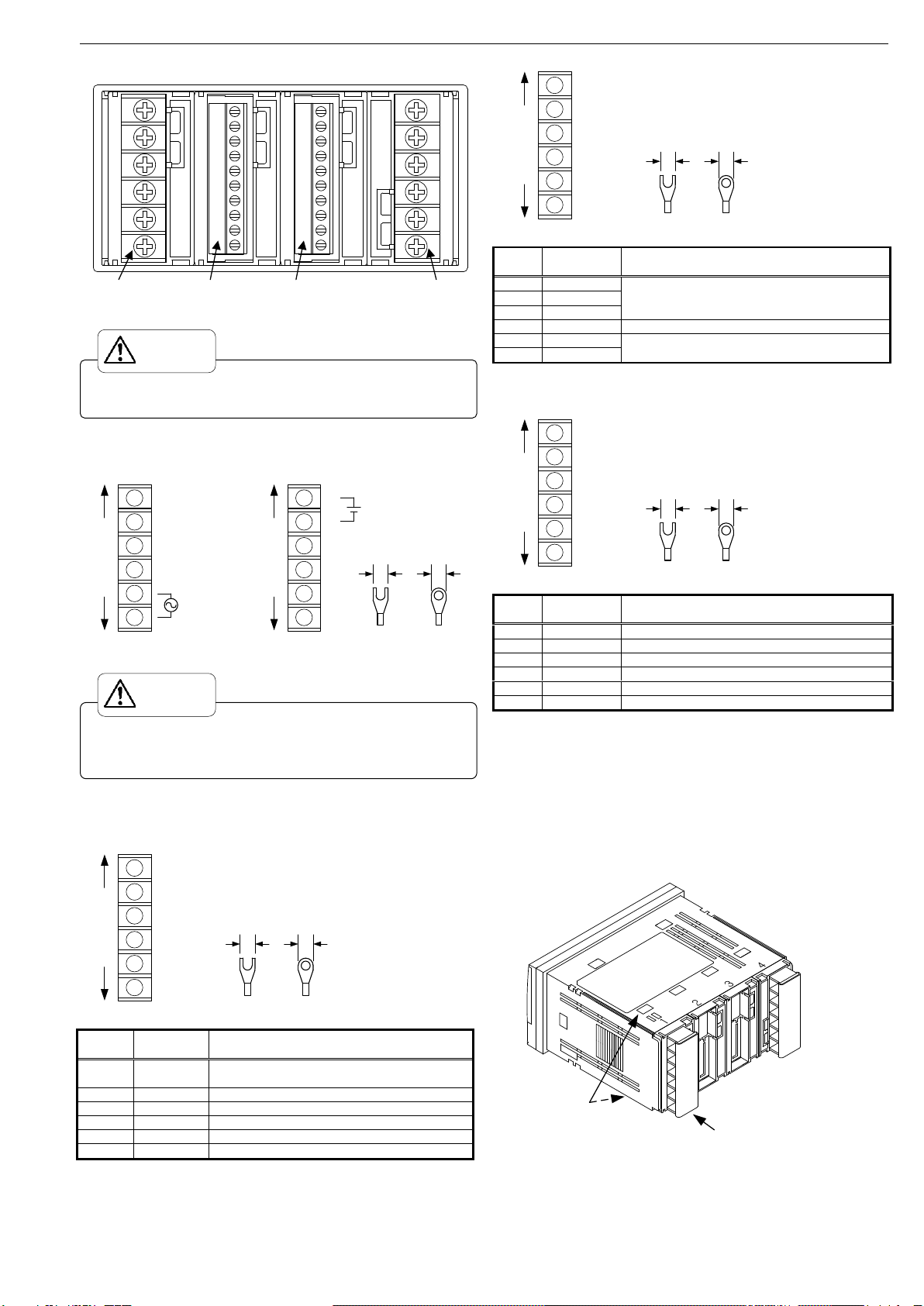

(3) In order to ensure power to equipment, including this device, is cut in

the event of failure, please ensure an external breaker is installed and

appropriately labeled so that it may be used to cut power to this device

when a malfunction occurs.

(4) In order to prevent device damage and failure, please ensure the voltage

used matches the device’s power rating.

(5) In order to prevent electrocution and device failure, please do not turn

the power on until all wiring has been completed.

(6) Before supplying power to this device, please ensure you check that the

device has been correctly wired. Incorrect wiring may cause device

failure, fire, electrocution or malfunction.

(7) In order to prevent electrocution or fire in the equipment, please check

that there is clearance around the device before activating power.

(8) Please do not touch the terminals while power is being supplied to the

device. Doing so may result in electrocution or malfunction.

・Usage Conditions

Place of Installation: Indoors only

Rated Altitude: 2000m or less

Overvoltage Category: II

Pollution Level: 2

Operating Ambient Temperature and Humidity: 0~50°C 35~85%RH

(Non Condensing)

Vibration (durability): 10 to 55 Hz (Half amplitude 0.15mm)

X, Y, Z directions 30 min.

Impact (durability): 100m/s26 directions, 3 times each

(up and down, forward and back, left to right)

Protective Structure: Equivalent to IP40 (front section)

Connecting Wire Length: Input and output signal lines and control line –less

than 30m in length

・Safety Precautions

(1) Watanabe Electric Industry Co., Ltd assumes no responsibility for any

special damage, indirect loss or passive loss caused by this device.

(2) This device has been developed, designed and manufactured on the

premise that it is to be used as general machinery. Please ensure

attention is paid to safety by adopting such means as a fail-safe design

and a redundancy design, and by conducting regular checks on the

device, particularly when it is being used for purposes such as the

following, where safety is of utmost importance.

•Safety devices used for personal protection

•Rail, aviation and vehicular equipment

•Medical equipment

•Incineration systems, nuclear systems

•Other purposes conforming to the conditions above which require high

levels of safety

(3) Please do not use this device for applications which directly affect

human lives.

(4) When this device is to be used in conjunction with other products,

please check for conformance with specifications, provisions of law and

regulations before use to ensure compatibility.

(5) As the operating life of the comparative output relays varies greatly

depending on switching capacity and conditions, please ensure the

relays are used within their rated load and electrical life. Using

deteriorated relays could result in insulation failure between circuits or

burnout of the relays themselves.

(6) This device requires more than 40 minutes warm up time from when

power is activated in order to operate within its degree of accuracy.

(7) Please do not wipe this device with alcohol, paint thinner, benzene,

acetone or other organic solvents. When wiping the device, please use

a neutral detergent.

・Table of Contents

1 BEFORE USE ..............................................................................................2

2 INSTALLATION..........................................................................................2

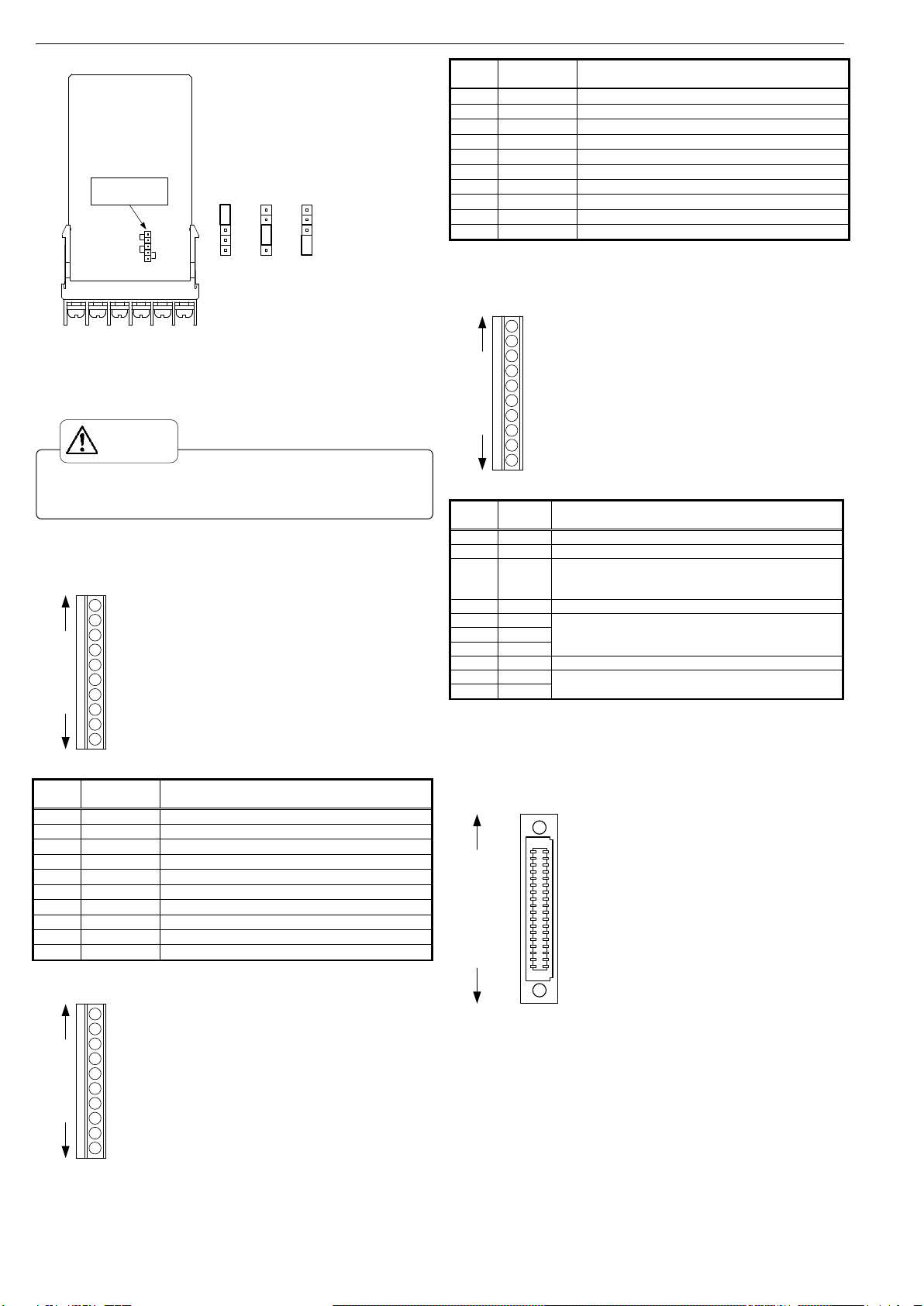

3 TERMINAL DESCRIPTION AND CONNECTION METHOD..................3

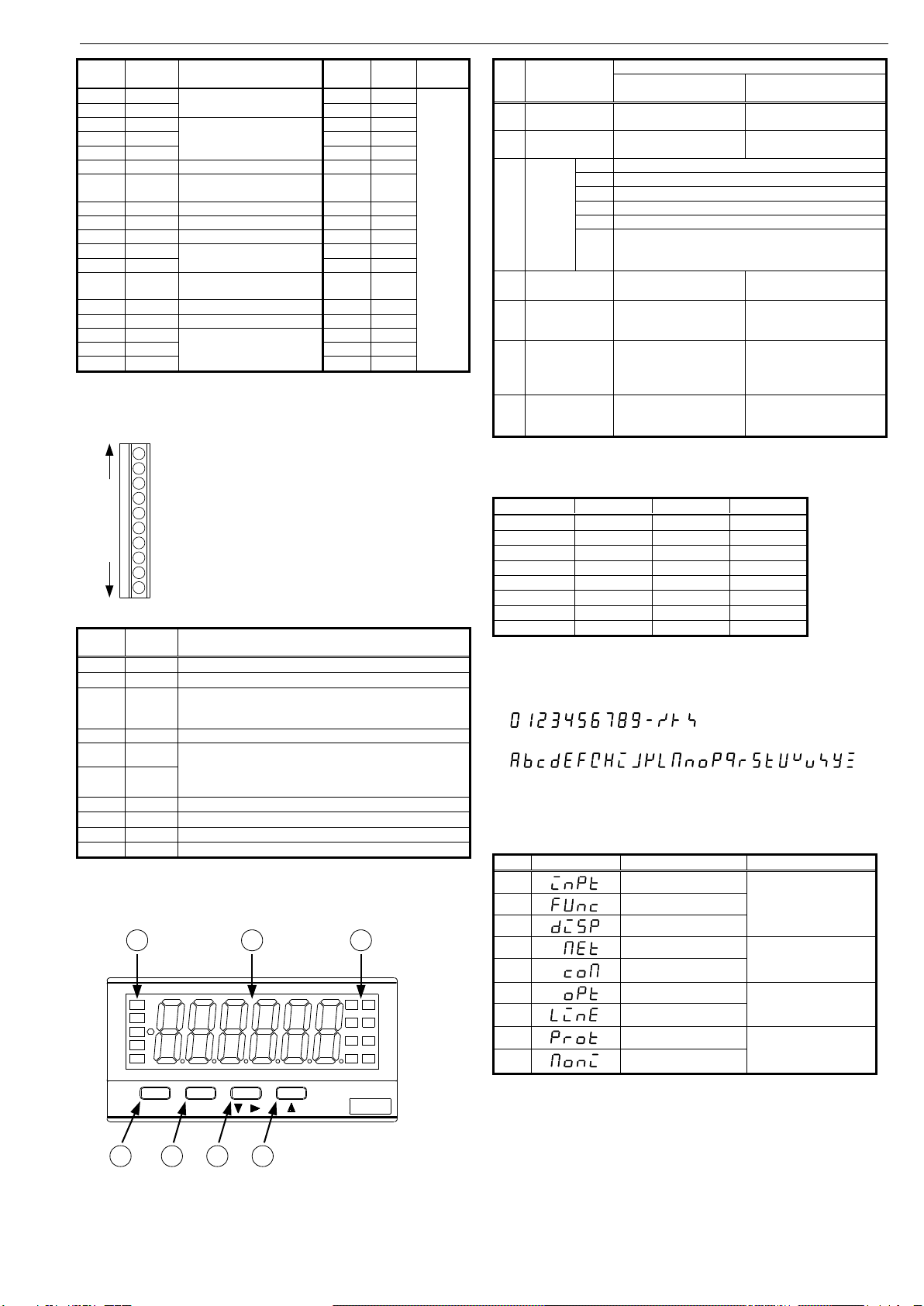

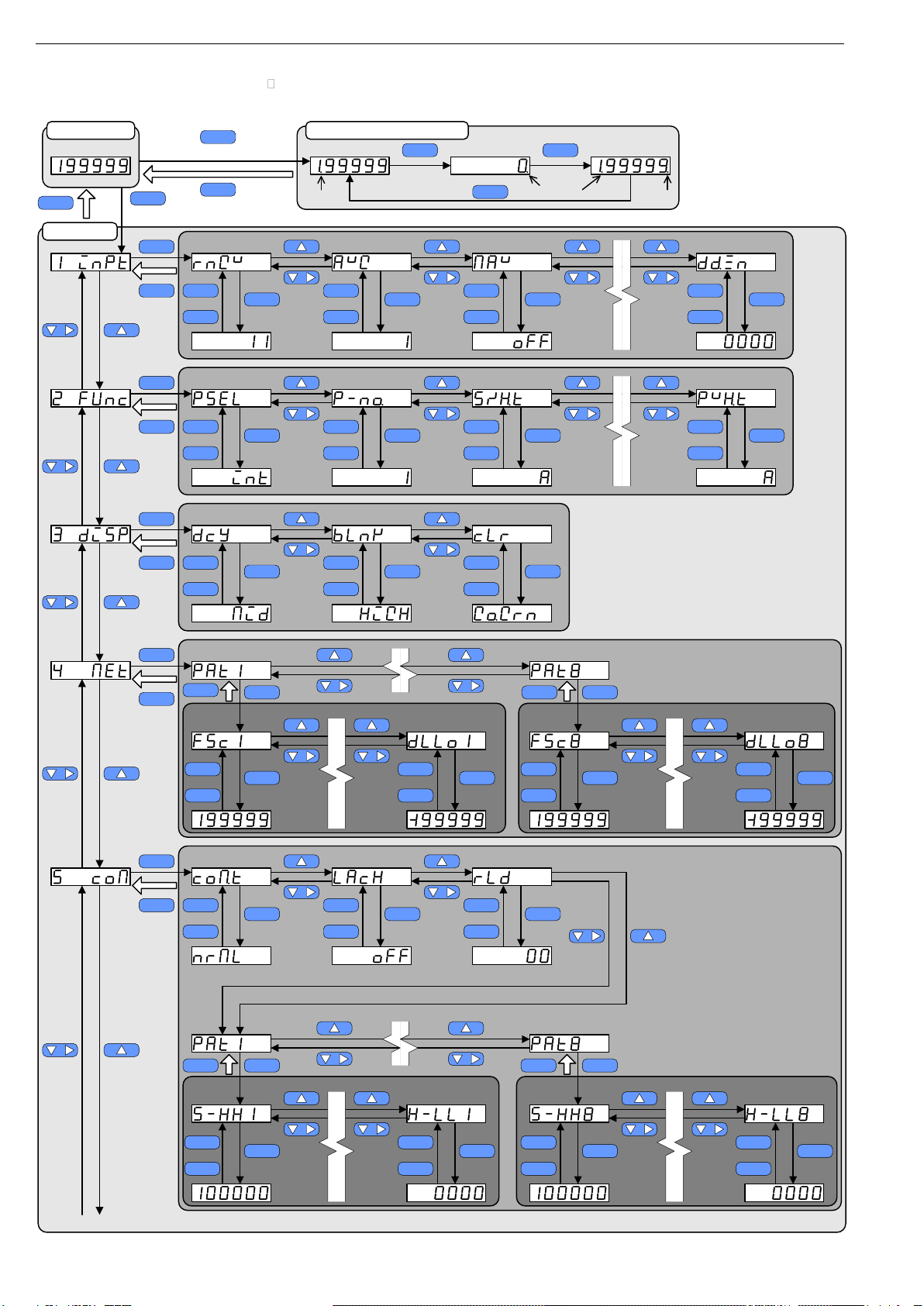

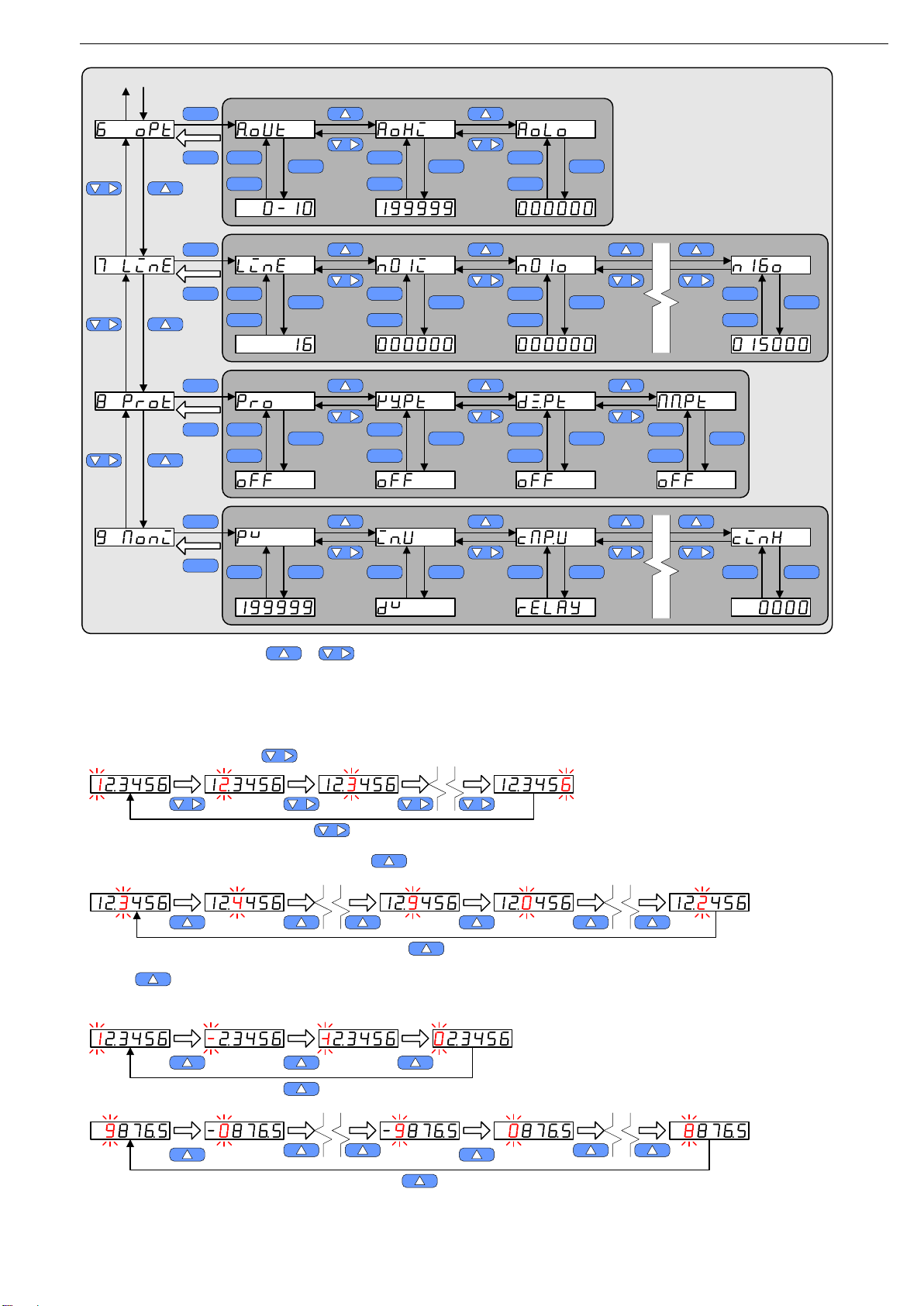

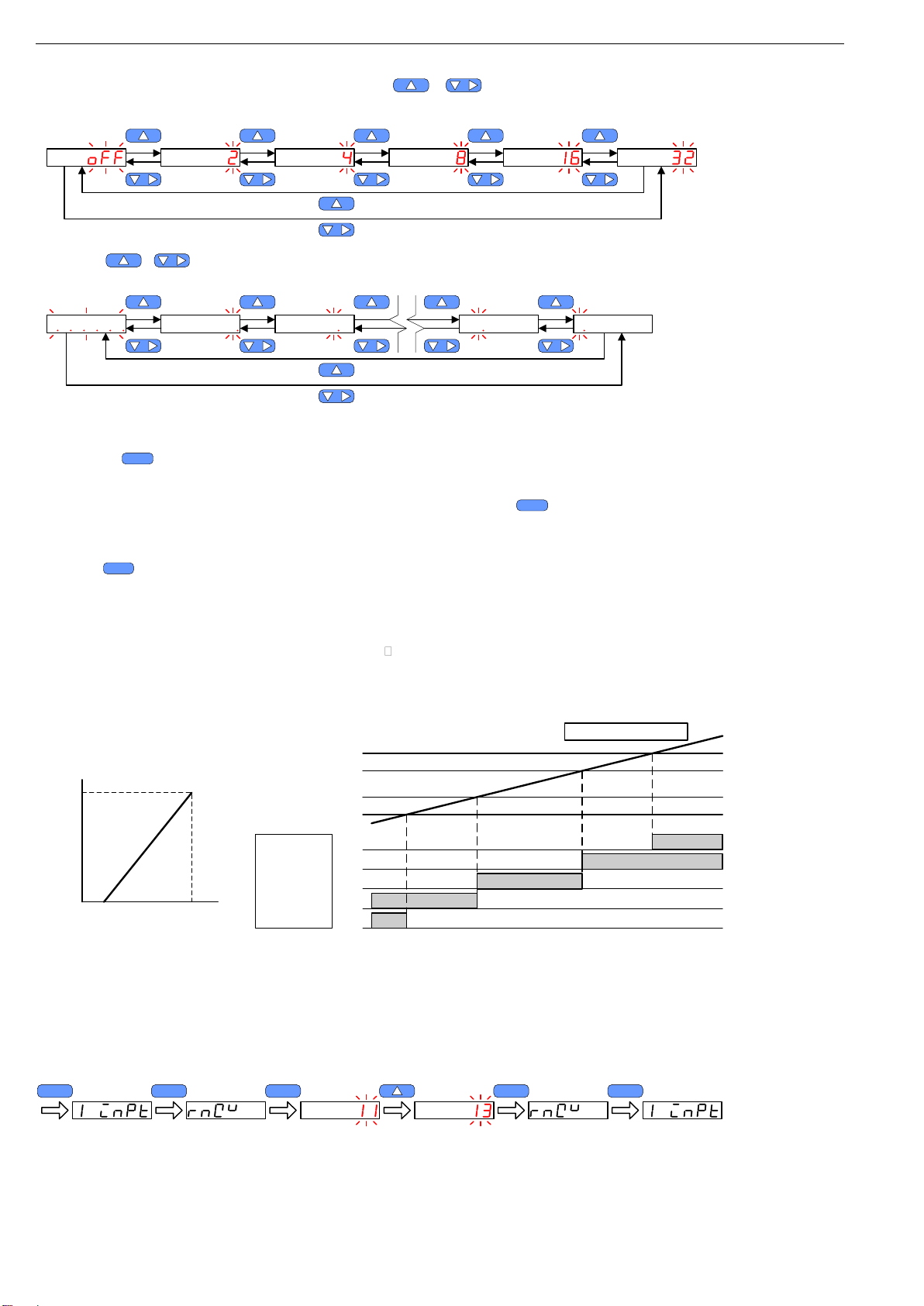

4 SETTING OF PARAMETERS.....................................................................5

5 EXAMPLE DEFAULT SETTING................................................................8

6 PARAMETER LIST...................................................................................10

7 FUNCTION LIST.......................................................................................14

8 SPECIFICATIONS.....................................................................................18

9 TROUBLE SHOOTING.............................................................................19

10 TIMING CHART......................................................................................19

11 WARRANTYAND AFTER-SALES SERVICE .......................................20