General Installation Information................................................................................................ 2

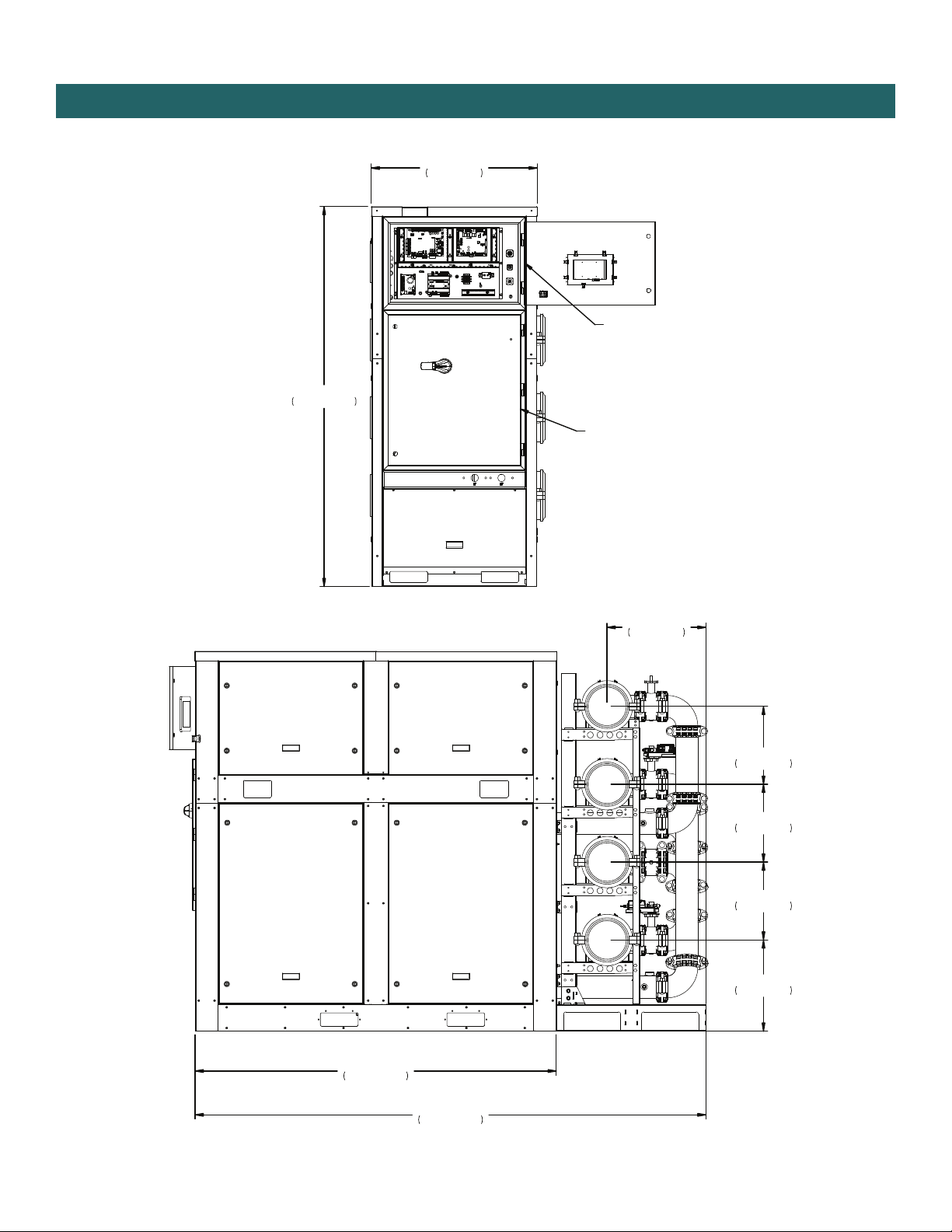

Dimensional Data............................................................................................................................ 3

Physical Data .................................................................................................................................... 9

Installation ......................................................................................................................................... 10

Installation of Bypass/Temperature Headers....................................................................... 14

Removing a Module from the Bank of Units........................................................................ 17

Lifting and Short Distance Transport...................................................................................... 18

High Pressure Refrigerant Relief Venting.............................................................................. 19

Water Connections & Water Quality....................................................................................... 20

Electrical Connections .................................................................................................................. 21

Refrigeration Cycle Analysis....................................................................................................... 22

Revision Guide ................................................................................................................................. 24

This appliance is not intended for use by persons (including

children) with reduced physical, sensory, or mental capabili-

ties, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play

with the appliance.

Maximum altitude for this equipment shall not exceed

2000 m.

For installation only in locations not accessible to the

general public.

Installing and servicing air conditioning and heating equip-

ment can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel

should install, repair or service heating and air conditioning

equipment. When working on heating and air conditioning

equipment, observe precautions in the literature, tags and

labels attached to the unit and other safety precautions that

may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have fire

extinguisher available for all brazing operations.

NOTE: Before installing, check voltage of unit(s) to ensure

proper voltage.

WARNING: Before performing service or maintenance

operations on the system, turn off main power switches to

the unit. Electrical shock could cause serious personal injury.

WARNING: All WaterFurnace products are designed,

tested, and manufactured to comply with the latest publicly

released and available edition of UL 60335-2-40 for

electrical safety certification. All field electrical connections

must follow the National Electrical Code (NEC) guide

standards and / or any local codes that may be applicable

for the installation.

WARNING: Only factory authorized personnel are approved

for startup, check test and commissioning of this unit.

INSTALLER: Please take the time to read and understand

these instructions prior to any installation. Installer must

give a copy of this manual to the owner.

OWNER: Keep this manual in a safe place in order to provide

your serviceman with necessary information.

All TruClimate 700 90-140 Ton product is Safety listed under UL60335-2-40 thru ETL

UL-60335-1 / CAN/CSA- C22.2 No. 60335-1

UL-60335-2-40 / CAN/CSA- C22.2 No. 60335-2-40

CAUTIONWARNING

INSTALLATION GUIDE

TruClimate 700

R-513A

60Hz IG1904WW