6Waterford E65-1 Emerald Direct Vent Freestanding Gas Stove

IMPORTANT:

SAVE THESE

INSTRUCTIONS

The EMERALD Direct Vent Freestanding Gas

Stove must be installed in accordance with

these instructions. Carefully read all the in-

structionsinthismanualfirst.Consultthebuild-

ingauthorityhavingjurisdictiontodeterminethe

needforapermitpriortostartingtheinstallation.

Note: Failure to follow the instructions

could cause a malfunction of the

heaterwhichcouldresultindeath,

seriousbodilyinjury,and/orprop-

erty damage. Failure to follow

these instructions may also void

your fire insurance and/or war-

ranty.

Note: These instructions take prece-

dence over Simpson Dura-Vent

instructions.

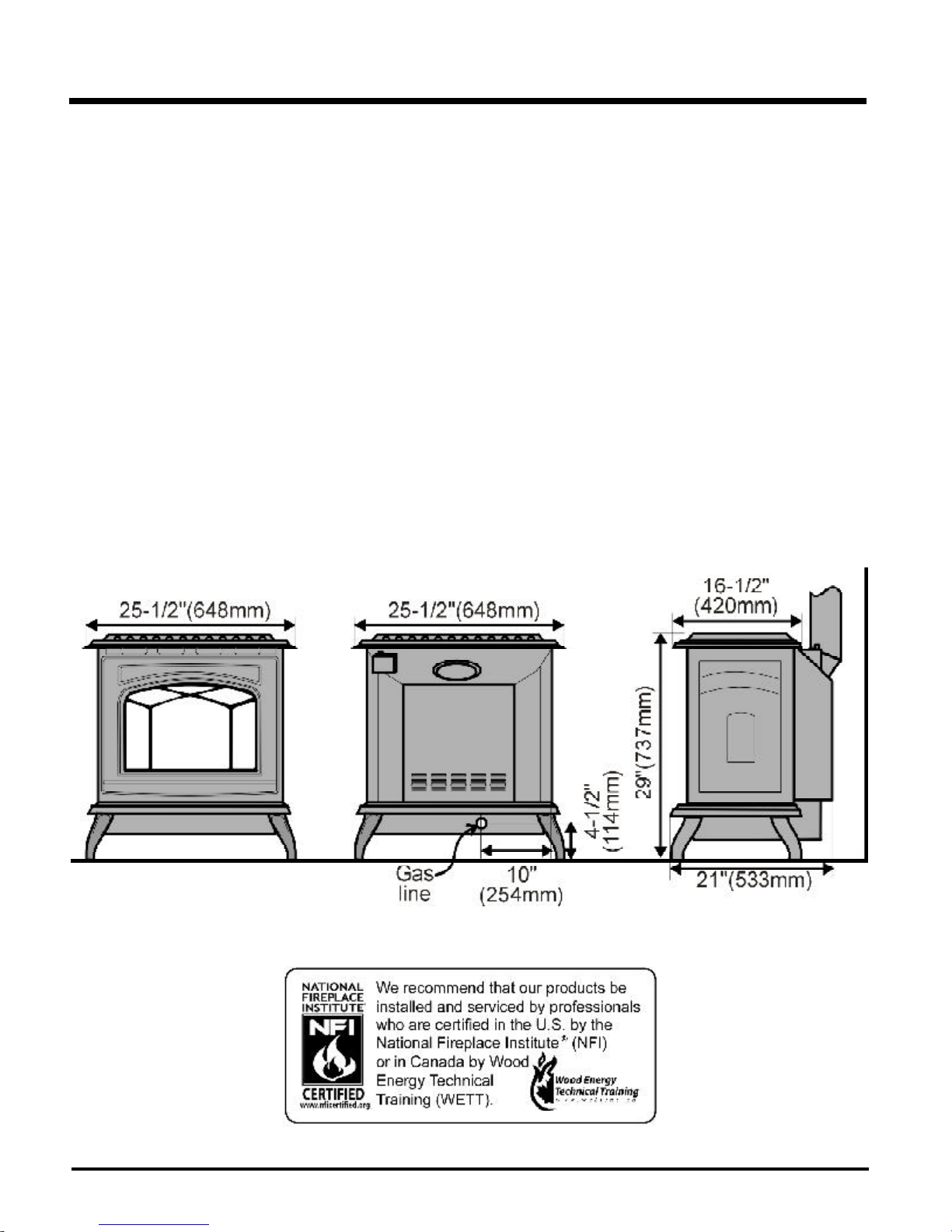

SPECIFICATIONS

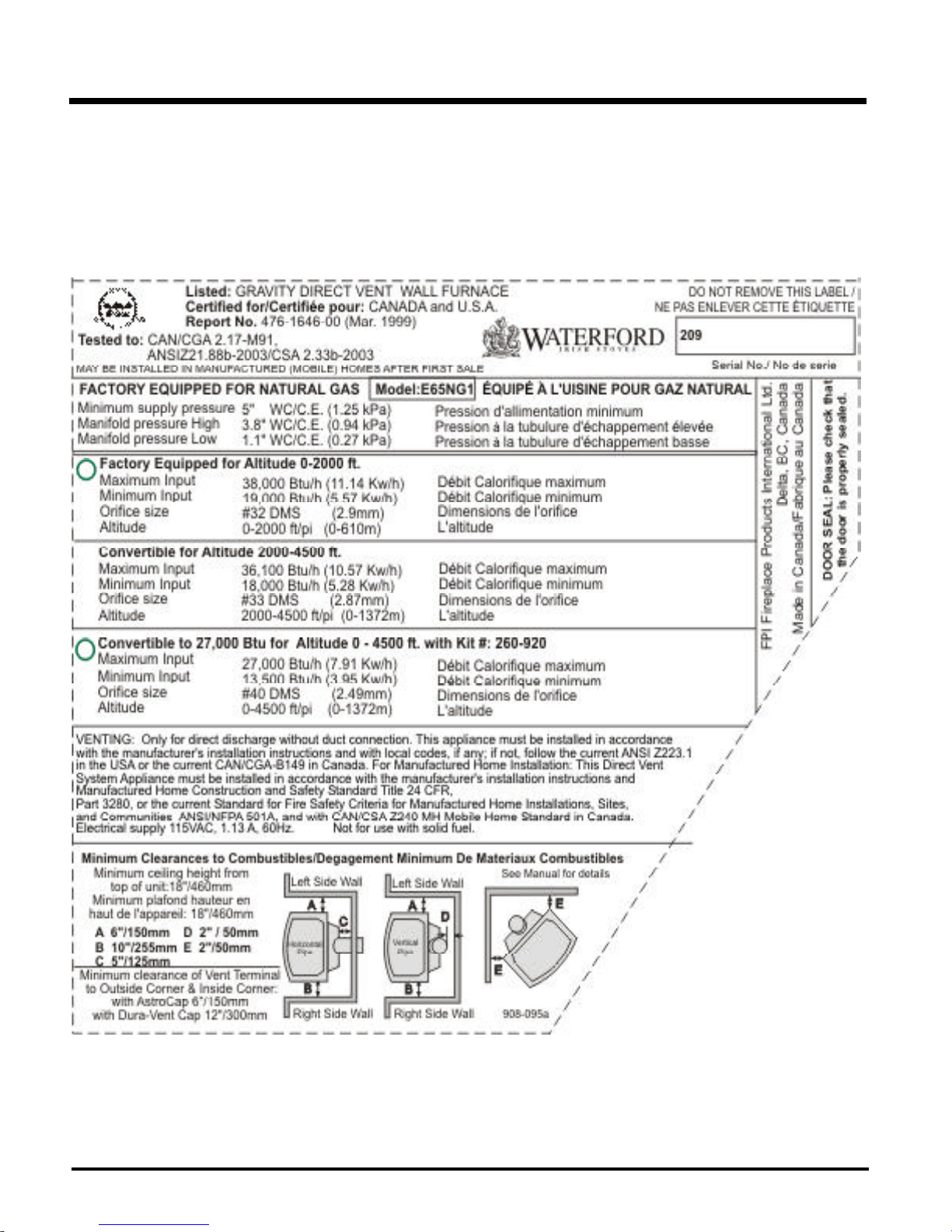

Fuels: E65-NG1 is approved for use with

natural gas.

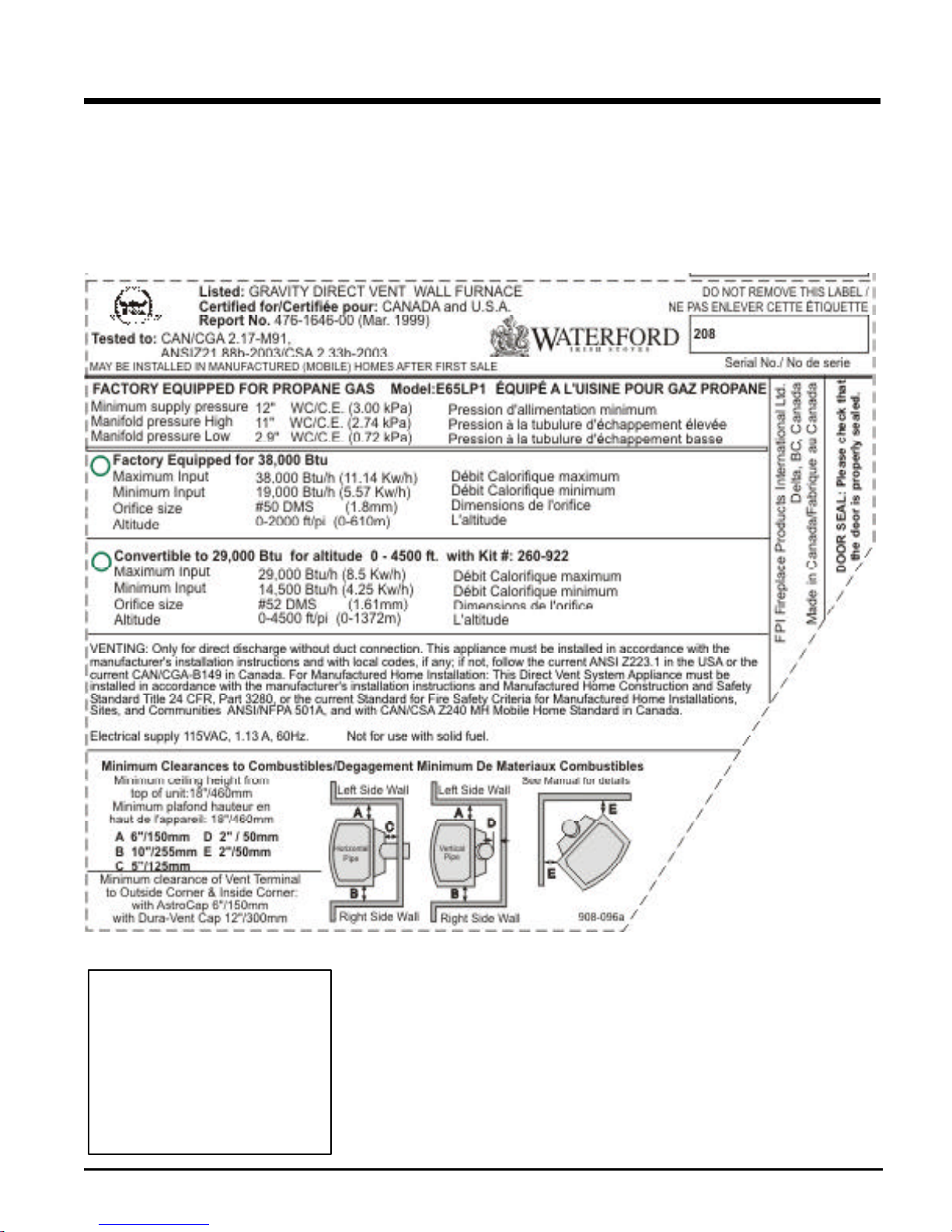

E65-LP1 is approved for use with

liquefiedpetroleumgases(propane).

Electrical: 120V A.C. system.

Circulation Fan: Variable speed, 125/75.

Log Sets: Ceramic fibre, 3 per set.

Vent System:Coaxial(6-5/8"outer/4"inner

liner) rigid flue and termination cap.

The efficiency rating of the appliance is a

product thermal efficiency rating determined

under continuous operating conditions and

was determined independent of any installed

system.

INFORMATION FOR

MOBILE/

MANUFACTURED

HOMES AFTER

FIRST SALE

This Waterford product has been tested and

listed by Warnock Hersey as a Direct Vent

RoomHeatertothefollowingstandards:CAN/

CGA 2.17-M91and ANSIZ21.88b-2003/CSA

2.33b-2003.

INSTALLATION

This Direct Vent System Appliance must be

installedinaccordancewiththemanufacturer's

installation instructions and the Manufactured

Home Construction and Safety Standard, Title

24 CFR, Part 3280, or thecurrent Standard of

Fire Safety Criteria for Manufactured Home

Installations, Sites, and Communities ANSI/

NFPA 501A, and with CAN/CSA Z240-MH Mo-

bile Home Standard in Canada.

Thisapplianceinstallationmustcomplywiththe

manufacturer's installation instructions and lo-

calcodes,ifany. Intheabsenceoflocalcodes

followthecurrentNationalFuelGasCode,ANSI

Z223.1andthecurrentNationalElectricalCode

ANSI/NFPA 70 in the U.S.A., and the current

CAN/CGA B149 Gas Installation Code and the

currentCanadian ElectricalCodeCSA C22.1in

Canada.

BEFORE YOU START

Safeinstallationandoperationofthisappliance

requires common sense, however, we are

required by the Canadian Safety Standards

andANSIStandardsto makeyouawareofthe

following:

1) Provide adequate clearances for servic-

ing, proper operation and around the air

openings into the combustion chamber.

2) The appliance must be installed on a flat,

solid,continuoussurface(e.g.wood,met-

al,concrete).Thismaybethefloor,oritcan

be raised up on a platform to enhance its

visual impact. The appliance may be in-

stalled on carpeting, tile, wood flooring or

other combustible material, because the

appliance's metal pedestal base extends

the full width and depth of the appliance.

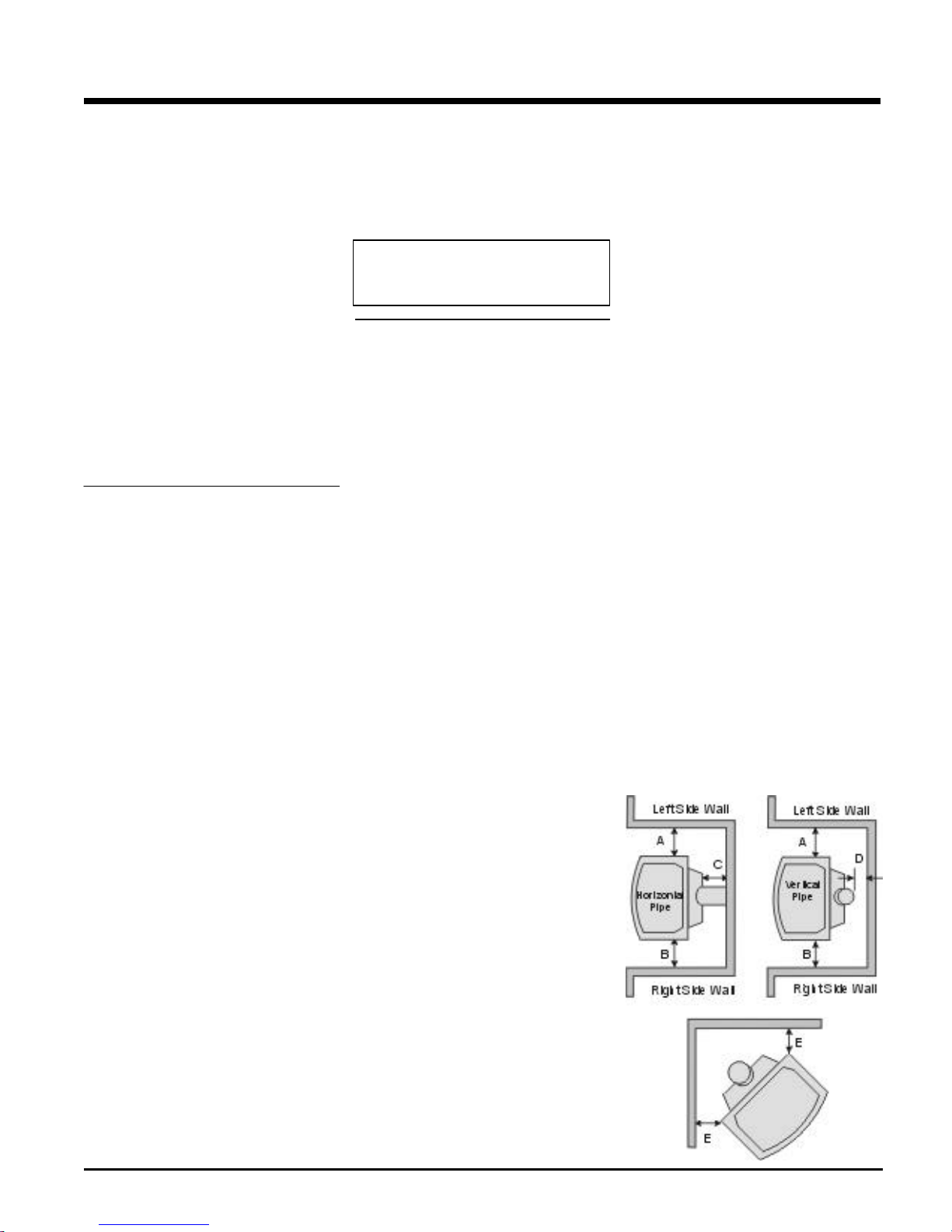

The EMERALD Direct Vent Freestanding

GasStovecanbeinstalledinawidevariety

ofwaysandwillfitnearlyanyroomlayout.

It may be installed in a recessed position,

framed out into the room, or across a

corner.

3) The EMERALD Direct Vent Freestanding

GasStove isapprovedfor alcoveinstalla-

tions, which meet the clearances listed on

page7. Thisunitisapprovedformanufac-

tured home installations, see page 8 and

THE CONTROL COMPARTMENT,

BURNERSANDCIRCULATINGAIR

PASSAGEWAYS OF THE APPLI-

ANCE BE KEPT CLEAN.

DUE TO HIGH TEMPERATURES,

THE APPLIANCE SHOULD BE LO-

CATED OUT OF TRAFFIC AND

AWAY FROM FURNITURE AND

DRAPERIES.

WARNING: FAILURE TO INSTALL

THIS APPLIANCE CORRECTLY

WILLVOIDYOURWARRANTYAND

MAY CAUSE A SERIOUS HOUSE

FIRE.

CHILDRENANDADULTSSHOULD

BE ALERTED TO THE HAZARDS

OF HIGH SURFACE TEMPERA-

TURES, ESPECIALLY THE FIRE-

PLACE GLASS, AND SHOULD

STAY AWAY TO AVOID BURNS

OR CLOTHING IGNITION.

YOUNG CHILDREN SHOULD BE

CAREFULLY SUPERVISEDWHEN

THEYAREINTHESAMEROOMAS

THE APPLIANCE.

CLOTHING OR OTHER FLAMMA-

BLE MATERIAL SHOULD NOT BE

PLACEDONORNEARTHEAPPLI-

ANCE.

This Waterford Mobile/Manufactured

Home Listed appliance comes factory

equipped with a means to secure the

unit.

This Waterford Mobile/Manufactured

Home listed appliance comes

equipped with a dedicated #8 ground

lug to which an 18 gauge copper wire

fromthesteelchassisgroundmustbe

attached.

Thisappliancemayonlybeinstalledin

an aftermarket permanently located,

manufactured (mobile) home, where

not prohibited by local codes.

This appliance is only use with the

type of gas indicated on the rating

plate. This appliance is not converti-

blefor usewith othergases,unlessa

certified kit is used.

INSTALLATION AND REPAIRS

SHOULD BE DONE BY A QUALI-

FIED SERVICE PERSON. THIS AP-

PLIANCESHOULDBEINSTALLED,

REPAIRED, INSPECTED BEFORE

USE AND AT LEAST ANNUALLY

BY A QUALIFIED SERVICE PER-

SON. MORE FREQUENT CLEAN-

ING MAY BE REQUIRED DUE TO

EXCESSIVE LINT FROM CARPET-

ING,ETC. ITISIMPERATIVETHAT