Waterford TARA T25 Direct Vent Freestanding Gas Stove 5

IMPORTANT:

SAVE THESE

INSTRUCTIONS

TheTARADirectVentFreestandingGasStove

must be installed in accordance with these

instructions.Carefully readall theinstructions

inthismanualfirst.Consultthebuildingauthor-

ityhavingjurisdictiontodeterminetheneedfor

a permit prior to starting the installation.

Note: Failure to follow the instructions

could cause a malfunction of the

heaterwhichcouldresultindeath,

seriousbodilyinjury,and/orprop-

erty damage. Failure to follow

these instructions may also void

your fire insurance and/or war-

ranty.

Note: These instructions take prece-

dence over Simpson Dura-Vent

instructions.

SPECIFICATIONS

Fuels: The TARA is factory equipped for

use with natural gas. A Propane

ConversionKit(#290-969)isavaila-

bletoconverttheTARAforusewith

liquefiedpetroleumgases(propane).

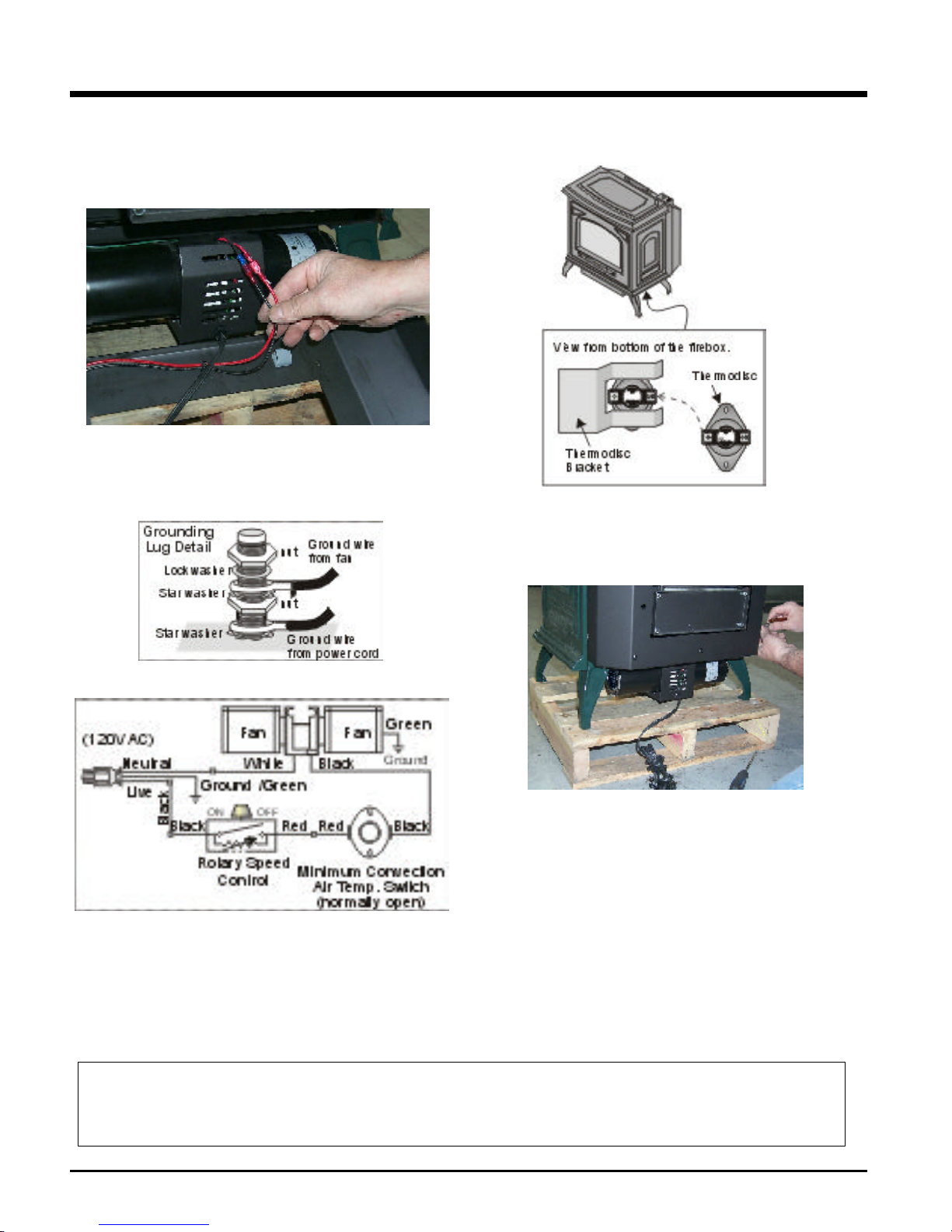

Electrical: 120V A.C. system.

Circulation Fan: Variable speed, 125/75

(Optional)

Log Sets: Ceramic fibre, 5 per set.

Vent System: Coaxial (6-5/8" outer / 4"

inner liner) rigid flue and

termination cap.

The efficiency rating of the appliance is a

product thermal efficiency rating determined

under continuous operating conditions and

was determined independent of any installed

system.

INFORMATION FOR

MOBILE/

MANUFACTURED

HOMES AFTER

FIRST SALE

This Waterford product has been tested and

listedbyWarnockHerseyasaDirectVentWall

Furnace to thefollowing standards: UL 307B-

1995,CAN/CGA-2.17-M91and ANSIZ21.88b-

2003/CSA 2.33b-2003.

INSTALLATION

This Direct Vent System Appliance must be

installed in accordance with the manufactur-

er's installation instructions and the Manufac-

turedHomeConstructionandSafetyStandard,

Title24CFR,Part3280,orthecurrentStandard

of Fire Safety Criteria for Manufactured Home

Installations,Sites,andCommunitiesANSI/NFPA

501A, and with CAN/CSA Z240-MH Mobile

Home Standard in Canada.

Thisapplianceinstallationmustcomplywiththe

manufacturer'sinstallationinstructionsandlocal

codes, if any. In the absence of local codes

follow the current National Fuel Gas Code,

ANSIZ223.1andthecurrentNationalElectrical

Code ANSI/NFPA 70 in the U.S.A., and the

current CAN/CGA B149 Gas Installation Code

and the current Canadian Electrical Code CSA

C22.1 in Canada.

INSTALLATION AND REPAIRS

SHOULDBEDONEBYAQUALIFIED

SERVICE PERSON. THIS APPLI-

ANCE SHOULD BE INSTALLED,

REPAIRED, INSPECTED BEFORE

USE AND AT LEAST ANNUALLY BY

A QUALIFIED SERVICE PERSON.

MORE FREQUENT CLEANING MAY

BE REQUIRED DUE TO EXCESSIVE

LINTFROMCARPETING,ETC. ITIS

IMPERATIVE THAT THE CONTROL

COMPARTMENT, BURNERS AND

CIRCULATINGAIRPASSAGEWAYS

BEFORE YOU START

Safeinstallationandoperationofthisappliance

requires common sense, however, we are

requiredbytheCanadianSafetyStandardsand

ANSI Standards to make you aware of the

following:

1) Provideadequateclearancesforservicing,

proper operation and around the air open-

ings into the combustion chamber.

2) The appliance must be installed on a flat,

solid,continuoussurface(e.g.wood,metal,

concrete).Thismaybethefloor,oritcanbe

raiseduponaplatformtoenhanceitsvisual

impact. The appliance may be installed on

carpeting, tile, wood flooring or other com-

bustible material. The TARA Direct Vent

Freestanding Gas Stove can be installed in

awidevarietyofwaysandwillfitnearlyany

roomlayout.Itmaybeinstalledinarecessed

position,framedoutintotheroom,oracross

a corner.

3) The TARA Direct Vent Freestanding Gas

Stove is approved for alcove installations,

whichmeettheclearanceslistedonpage6.

Thisunitisapprovedformanufacturedhome

installations, see page 6 and pages 9 to 17

for the required vent arrangements. If in-

stalled into a manufactured home the unit

must be bolted down to the floor.

4) Thisappliance isListedforbedroom instal-

lations when used with a Listed Millivolt

This Waterford Mobile/Manufactured

Home Listed appliance comes factory

equipped with a means to secure the

unit.

This Waterford Mobile/Manufactured

Homelistedappliancecomesequipped

withadedicated#8groundlugtowhich

an18gaugecopperwirefromthesteel

chassis ground must be attached.

This appliance may only be installed in

an aftermarket permanently located,

manufactured (mobile) home, where

not prohibited by local codes.

This appliance is only to be used with

the type of gas indicated on the rating

plate. This appliance is not convertible

forusewith other gases,unless acer-

tified kit is used.

OF THE APPLIANCE BE KEPT

CLEAN.

DUE TO HIGH TEMPERATURES,

THE APPLIANCE SHOULD BE LO-

CATED OUT OF TRAFFIC AND

AWAY FROM FURNITURE AND

DRAPERIES.

WARNING: FAILURE TO INSTALL

THIS APPLIANCE CORRECTLY

WILLVOIDYOURWARRANTYAND

MAY CAUSE A SERIOUS HOUSE

FIRE.

CHILDRENANDADULTSSHOULD

BE ALERTED TO THE HAZARDS

OF HIGH SURFACE TEMPERA-

TURES, ESPECIALLY THE FIRE-

PLACE GLASS, AND SHOULD

STAY AWAY TO AVOID BURNS

OR CLOTHING IGNITION.

YOUNG CHILDREN SHOULD BE

CAREFULLY SUPERVISEDWHEN

THEYAREINTHESAMEROOMAS

THE APPLIANCE.

CLOTHING OR OTHER FLAMMA-

BLE MATERIAL SHOULD NOT BE

PLACEDONORNEAR THEAPPLI-

ANCE.