1

Congratulations!

You have purchased the finest hydroponic water system

available for your home garden. It will provide you years of

reliable service if properly installed, operated and maintained.

Please read this entire manual before attempting installation

and operation.

Section 1. Frequently Asked Questions

Before getting started, take the time to familiarize yourself with your new Waterite

Excelgro+™ system by reading some FAQs listed below. Call us or ask your dealer if you

have any other questions about your system’s operation.

Q: How does your Excelgro+™ Hydroponic Water System differ from an ordinary water filter?

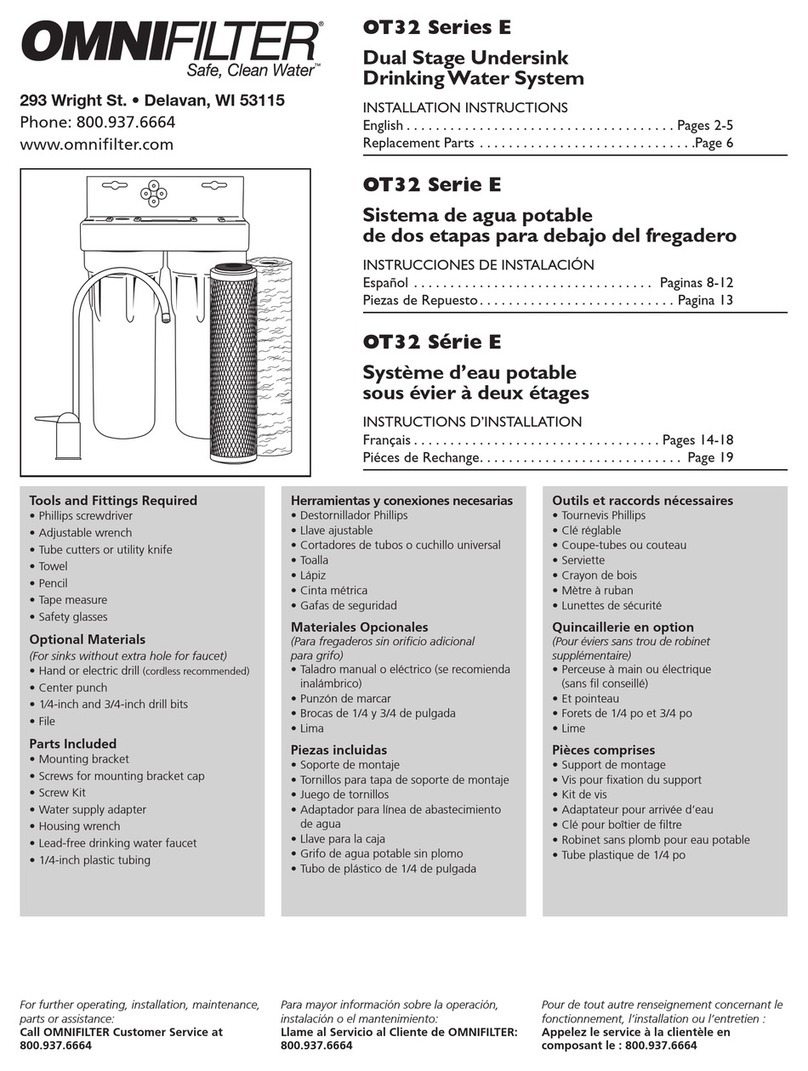

Ordinary water filters use a cartridge or membrane contained in a sump or housing to filter your

drinking water. Cartridge or membrane changes require housing wrenches and manual insertion of

the cartridges into the housings. Excelgro+TM systems use a convenient quarter-turn bayonet style

cartridge that may be easily changed without any system disassembly. Your system will deliver pure

water for an optimal crop yield.

Q: What is a membrane and how does it work?

A reverse osmosis (RO) membrane is a semi-permanent synthetic film that is spiral wound and

separates raw water from product water (permeate). Water containing dissolved contaminants and

salts is forced though the membrane by water pressure, with pure water being collected in the

storage tank and rejected contaminants flushed to waste.

Q: What processes does the Excelgro+TM systems use?

Excelgro+™ systems use combinations of 4 types of treatment to produce your drinking water. 5-

micron polypropylene (PP) particle filters remove dirt, rust and other sediment. Activated carbon

cartridges (granular carbon in GAC and moulded briquettes in CBC) remove chlorine, colour, taste,

odours and other contaminants. RO membranes will reduce concentrations of dissolved mineral

and salt ions in the water by up to 99.9%.

Q: Where is the system installed?

The Excelgro+™ systems are compact and take up very little space, they can be installed in virtually

any indoor or sheltered outdoor location. Should an outdoor location be chosen the system must be

protected from freezing. Keep in mind that filter cartridges will need periodic replacement and that

easy access must be maintained. Do not install in a location with high humidity, heat or direct sun.

Q: How much water does the Excelgro+™ system produce?

A Excelgro+TM RO system will nominally produce 300-350 US gallons (1130-1325 litres) of product

water per day. This output will be affected by system pressure, concentration of Total Dissolved

Solids in the raw water, raw water temperature and other localized factors. Normally, you can expect

the system to produce 45 to 55 litres of water per hour. You may wish to install a pressure water

storage tank on the permeate line if peak usage exceeds system output. Your dealer can help select

a tank and provide the fittings necessary.