Waterite Fusion 2 Installation and operating instructions

By Waterite, Inc.

Advanced Water Conditioners

Addendum for the F2TC Time Clock Valve

OWNER’S MANUAL ADDENDUM

FOR ALL FUSION² F SERIES AND FCA SERIES WATER CONDITIONERS

EQUIPPED WITH THE F2TC TIME CLOCK VALVE

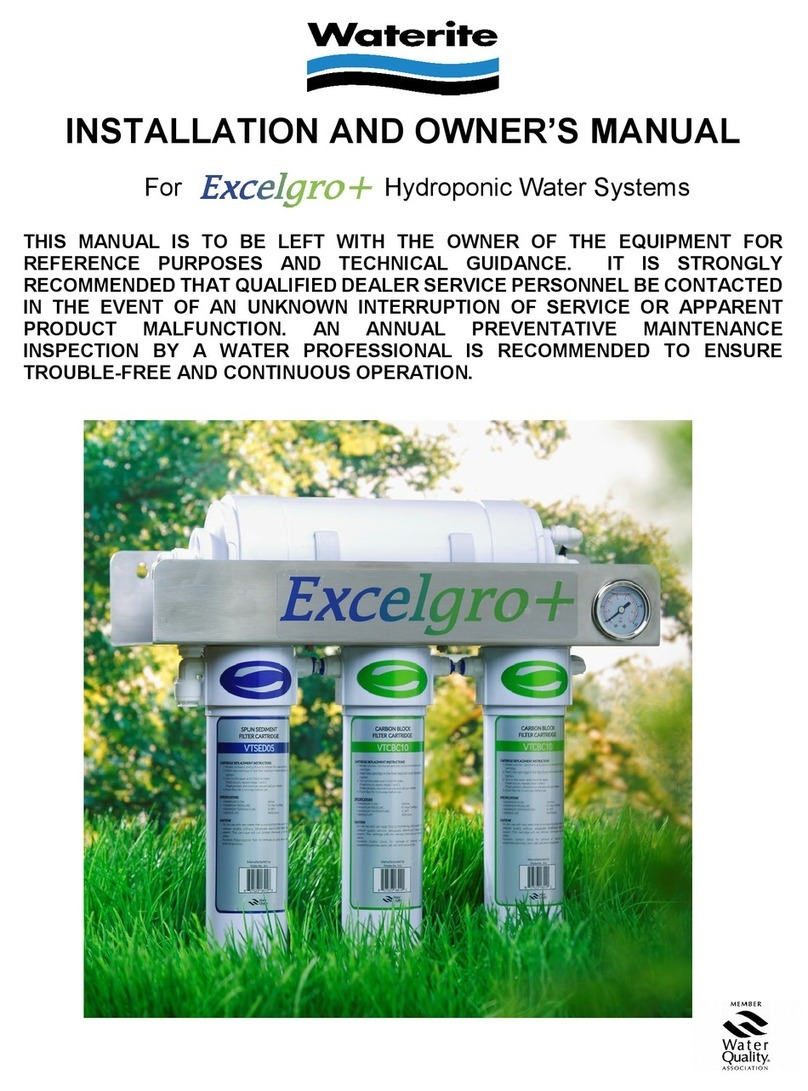

THIS MANUAL IS TO BE LEFT WITH THE OWNER OF THE EQUIPMENT FOR

REFERENCE PURPOSES AND TECHNICAL GUIDANCE. IT IS STRONGLY

RECOMMENDED THAT QUALIFIED DEALER SERVICE PERSONNEL BE

CONTACTED IN THE EVENT OF AN UNKNOWN INTERRUPTION OF SERVICE OR

APPARENT PRODUCT MALFUNCTION. AN ANNUAL PREVENTATIVE

MAINTENANCE INSPECTION BY A WATER PROFESSIONAL IS RECOMMENDED

TO ENSURE TROUBLE-FREE AND CONTINUOUS OPERATION.

www.waterite.com

Waterite, Inc. ■ Winnipeg, MB Canada

R2

1

QUICK REFERENCE INFORMATION

GENERAL OPERATION

When the system is operating one of

two displays will be shown: time of

day or days until the next regenera-

tion. Pressing UP or DOWN will

toggle between the two choices.

TO SET TIME OF DAY

In the event of a power outage, time of day

needs to be reset. All other information will

be stored in memory no matter how long

the power outage. Please complete the

steps as shown to the right. To access this

mode, press SET HOUR.

TO SET TIME OF

REGENERATION

For initial set-up or to make adjustments,

please complete the steps as shown to

the right. Access this mode by pressing

SET HOUR and UP simultaneously for 3

seconds.

Arrow will point to Regen if a

regeneration is expected

“Tonight.”

1. Accessed by pressing SET

HOUR.

2. Adjust to the nearest hour using

UP or DOWN. An arrow points to

PM during p.m. hours.

3. Press SET HOUR to complete

and return to normal operation.

1. Accessed by pressing SET HOUR and

UP simultaneously for 3 seconds.

2. Adjust time of regeneration hour using

the UP or DOWN. An arrow points to

PM during p.m. hours. Simultaneously

press SET HOUR and DOWN to return

tonormal operation.

MANUAL REGENERATION

NOTE: For softeners, if brine tank does not contain salt, fill

with salt and wait at least 2 hours before regeneration.

If you need to initiate a manual regeneration, either

immediately, or tonight at the preprogrammed time (typically

2 a.m.), complete the following steps.

For Immediate Regeneration:

Press and hold UP and DOWN simultaneously until valve

motor starts (typically 3 seconds).

For Regeneration Tonight:

Press and release UP and DOWN simultaneously (notice that

arrow points to Regen).

Arrow will point to Regen if a

regeneration is expected “Tonight.”

ERROR CODES: If the display shows “E1,” “E2” or “E3” (for error),

call a service technician.

To shut off water to the system, please position arrow handles as shown in the bypass operation diagram below.

If your valve doesn’t look like the diagram below, contact your dealer.

NORMAL OPERATION BYPASS OPERATION

Treated

Water

Supply Water Supply Water Supply Water

_______

or

2

Addendum to Main

Manual for timeclock

softeners and filters

HOW TO USE THIS ADDENDUM

THE DEALER...

Before Installation:

1. Read GENERAL INSTRUCTIONS, QUICK REFERENCE INFORMANCE page,

INSTALLER SETTINGS, and NORMAL OPERATING DISPLAYS.

2. Complete the SYSTEM SETUP section.

a. Decide if unit is to be a softener or a filter.

b. Choose a program number, P0-P9.

c. Set refill time

d. Select 1-99 or 1-7 for days between regenerations.

e. Choose 60 or 50 Hertz option.

f. Note that an external signaling device like a pressure differential switch can be

used to trigger the backwashing of a filter. An explanation of this is at the end

of SYSTEM SETUP.

g. Use the main manual for specs, installation, parts, and service.

THE INSTALLER...

1. Read BYPASS VALVE in main manual.

2. Read GENERAL INSTRUCTIONS, NORMAL OPERATING DISPLAYS, and QUICK

REFERENCE INFORMATION in this addendum.

3. Be sure SYSTEM SETUP is done before you leave for your installation.

4. Follow INSTALLATION instructions found in main manual.

5. Perform INSTALLER SETTINGS & TIME OF DAY from this addendum.

6. Follow the START UP INSTRUCTIONS in this addendum.

3

GENERAL INSTRUCTIONS

The control valve offers multiple procedures that allow the valve to be modified to suit the needs of the

installation. These procedures are:

• SYSTEM SETUP

• INSTALLER SETTINGS

These procedures can be accessed in any order. Details on each of the procedures are provided on the

following pages.

When in operation, NORMAL OPERATING DISPLAYS show the time of day or days remaining before

regeneration. When stepping through a procedure if no buttons are pressed within five minutes the display

returns to a normal user display. Any changes made prior to the five minute time out are incorporated.

To quickly exit SYSTEM SETUP or INSTALLER SETTINGS simultaneously press SET HOUR + DOWN. Any

changes made prior to the exit are incorporated.

To reinitialize the control valve (usually needed after disassembly), check to be sure the valve is in the NORMAL

OPERATING DISPLAYS. Then simultaneously press SET HOUR + DOWN or unplug power source plug (black

wire) on the circuit board, and plug back in. When stepping through the displays, if no buttons are pressed within

five minutes, the display returns to a normal user display. Any changes made prior to the five minute time out

are incorporated. To quickly exit SOFTENER SETUP or INSTALLER SETTINGS, press SET HOUR and

DOWN.

Any changes made prior to the exit are incorporated.

SYSTEM SETUP

STEP 1SS

STEP 2SS

STEP 3SS

STEP 1SS – From normal mode, press SET HOUR + UP buttons simultaneously for

3 seconds and release.

Then press SET HOUR + UP buttons simultaneously for 3 seconds and release.

STEP 2SS – Choose the desired program by pressing the UP or DOWN buttons.

Press SET HOUR button to go to Step 3SS.

REGENERATION CYCLES & TIMES (minutes) FOR PROGRAMS PO-P9

Program

Number

C1

1st Backwash

C2

Regenerate

C3

2nd Backwash

C4

Fast Rinse

C5

Refill

P0

3

50

3

3

1-99

P1

8

50

8

4

1-99

P2

8

70

10

6

1-99

P3

12

70

12

8

1-99

P4

10

50

skipped

8

1-99

P5

4

50

4

1-99

P6

12

6

12

1-99

P7

6

skipped

4

skipped

P8

10

6

P9

14

8

Note: Cycle numbers that are skipped will not be displayed during regeneration

STEP 3SS – If program P0 through P6 was selected, enter in the minutes of fill

using the UP or DOWN buttons. The allowable values vary from 1 to 99.

If program P7, P8 or P9 was selected, dashes will appear for minutes of fill.

Press SET HOUR button to go to Step 4SS. Note: For each minute of fill ½ gallon of

water is added to the solution tank. With salt (sodium or potassium chloride) this

equates to approximately 11/2 pounds of salt per minute of fill.

Press SET HOUR button to go to Step 4SS.

4

STEP 4SS — Use UP or DOWN buttons to switch

between:

• 1-99 Days, or

• 7-Days Between Regenerations

Press SET HOUR button to go to Step 5SS.

STEP 5SS — Use UP or DOWN buttons to switch

between 60 Hz or 50 Hz option. Supply your own

transformer if using 50 Hz option.

Press SET HOUR button to go to Step 6SS.

STEP 6SS — If a differential pressure switch is

installed and actuated:

• a regeneration will occur immediately if no arrow

points at Regen Hour; or

• a regeneration will occur at the delayed

regeneration hour if an arrow points at Regen Hour.

Use UP or DOWN buttons to switch between the

two choices. If a differential switch is not installed

the settings in this display are ignored. Press SET

HOUR to exit SYSTEM SETUP.

NOTE: The two terminals at “A”, if connected to an external pressure differential switch or other “dry” contact

switch which closes for five minutes, can be used to initiate an immediate backwash or a backwash scheduled for

the next regeneration time. The choice is determined in Step 6SS above. If no connection is made at “A” it

doesn’t matter what setting is made in 6SS. The backwash will occur according to the days between

regenerations and the time of regeneration settings.

A. Differential pressure switch or other external “dry” switch connection

B. Motor wire connection shown for reference only

C. Transformer wire connection shown for reference only

A

BC

5

INSTALLER SETTINGS

STEP 1ID

STEP 2ID

STEP 3ID

REGENERATION TIME & DAYS BETWEEN (1-99 day option)

STEP 1ID – From normal mode, press SET HOUR + UP buttons simultaneously for 3

seconds and release.

Set Regeneration Time

STEP 2ID – Regeneration Time: Set the clock to the hour the regeneration should occur

by using the UP or DOWN buttons. An arrow points to PM after 12.

Press SET HOUR to go to STEP 3ID.

Set Days between Regenerations (1-99)

(The choice of 1-99 days or 1-7 days is set in Step 4SS)

STEP 3ID – Days To Regen: Set the number of days between regenerations.

The allowable range is 1 to 99.

Press SET HOUR to exit.

STEP 1I7

REGENERATION TIME & DAYS BETWEEN (1-7 day option)

(The choice of 1-99 days or 1-7 days is set in Step 4SS)

STEP 1I7 – From normal mode, press SET HOUR + UP buttons simultaneously for

3 seconds and release.

Set Regeneration Time

STEP 2I7

STEP 3I7

STEP 4I7

STEP 2I7 – Regeneration Time: Set the clock to the hour the regeneration should occur

by using the UP or DOWN buttons. An arrow points to PM after 12.

Press SET HOUR to go to STEP 3I7.

Choose Days for Regeneration (1-7 day option)

STEP 3I7 – ACCESS DAY OF THE WEEK CODES by

using the UP or DOWN buttons.

Press SET HOUR to go to STEP 4I7.

STEP 4I7 – d1, Sunday, will be

displayed. (See chart at right for day

codes).

To regenerate on Sunday use the UP or DOWN

button until the arrow points to Regen.

To SKIP Sunday, use UP or DOWN to remove arrow from Regen.

Press SET HOUR to go to d2, Monday.

Repeat procedure of using UP or DOWN to select or skip REGEN and using SET HOUR

to advance to next day.

After d7 the display will return to the normal operating display.

DISPLAY

DAY OF WEEK

d1

Sunday

d2

Monday

d3

Tuesday

d4

Wednesday

d5

Thursday

d6

Friday

d7

Saturday

6

SETTING THE TIME OF DAY

STEP1U

STEP 1U – Press SET HOUR

STEP 2U – Current time: Set the clock to the closest hour by using the UP and

DOWN button. An arrow points to PM after 12. After a power outage, the time of

day will need to be reset. Press SET HOUR to exit.

NORMAL OPERATING DISPLAYS

When the system is operating one of two displays will be shown. Pressing UP or

DOWN buttons will alternate between the displays. One of the displays is always the

current time of day (to the nearest hour). The second display is the days remaining

until the next regeneration. If the days remaining is equal to one, a regeneration will

occur at the next preset regeneration time. The user can scroll between displays as

desired. If the system has called for a regeneration that will occur at the preset time

of regeneration, the arrow will point to Regen.

Regeneration Mode

Typically a system is set to regenerate at a time of low water usage...usually

overnight. If there is a demand for water when the system is regenerating, untreated

water will be used.

When the system begins to regenerate, the display will change to indicate the cycle

of the regeneration that is occurring and an arrow will also point to Regen. The

system will run through the steps automatically and will reset itself to provide treated

water when the regeneration is completed.

Manual Regeneration

Sometimes there is a need to regenerate the system sooner than when the system

calls for it.... usually referred to as a manual regeneration.

To initiate a manual regeneration at the preset delayed regeneration time,

simultaneously press the UP + DOWN buttons together and release. The arrow will

point to the word Regen if a regeneration is expected “tonight.” To cancel the

regeneration simultaneously press the UP + DOWN buttons and release.

To initiate a manual regeneration immediately, simultaneously press the UP +

DOWN buttons together for three seconds. The system will begin to regenerate

immediately. This cannot be cancelled. Note: For softeners, if brine tank does not

contain salt, fill with salt and wait at least two hours before regenerating.

Power Loss & Error Messages

If the power goes out current time of day will need to be reset. If the power goes out

while the system is regenerating, the cycle picks up where it was interrupted when

the power returns.

Note: The display will flash if a power outage has occurred.

If “E1,” “E2” or “E3” appears on the display contact a technical service person for

help. These indicate that the valve did not function properly.

7

START UP INSTRUCTIONS

• After installation is completed and checked for leaks, rotate the bypass handles to the bypass position

(see Figure 2, Bypass Valve diagram page in main manual).

• Fully open a cold water faucet.

• Allow water to run until clear to rid pipes of debris, which may have occurred during installation.

• The system is now ready for testing:

1. For all units...With the bypass valve still in the bypass mode.

If starting up a softener or a regenerating filter, manually pour enough water into the regenerant

tank to reach the top of the air check valve.

2. Press and hold the UP and DOWN buttons simultaneously for three seconds until the drive

motor starts. Wait until the motor stops and the display reads “C1”, 1st backwash position.

3. Open the inlet handle of the bypass valve very slightly allowing water to fill the tank slowly in

order to expel air. Go to 4a or 4b.

CAUTION: If water flows too rapidly, there will be a loss of media to the drain.

4a. For softeners and regenerating filters only, Programs PO-P6...

• When the water is flowing steadily to the drain without the presence of air, press the UP

button. This will advance the valve to the regenerant draw position, C2.

• Fully open the inlet bypass valve handle (the diagnostic mode, Figure 3.)

Check to verify that regenerant solution is being drawn from the regenerant tank with no air

bubbles.

There should be a slow flow to the drain.

Allow three minutes for the media bed to settle. Go to 4b.

4b. For all units including backwashing filters and acid neutralizers, Programs P7-P9...

• Press the UP button again until the control valve displays cycle C4, final rinse. Depending on

the program used C3, 2nd backwash, may appear before C4 is displayed. Allow water to run to

the drain for 2-3 minutes or until clear. At this point the control may be allowed to automatically

time out and return to service or SET HOUR + DOWN can be pressed to exit program.

5. For softeners and regenerating filters only, Programs PO-P6...

• Press the UP button to advance the control to where the display reads C5. This will allow

water to refill the regenerant tank and prepare it for the next regeneration. Allow this to time out

automatically and return to service.

• While the regenerant tank is filling, load it with salt or regenerant chemical, if appropriate.

8

TROUBLESHOOTING PROCEDURES, TIMECLOCK UNITS

Problem

Cause

Solution

1. Timer does not display time of day

a. Transformer unplugged

a. Reconnect

b. No power at outlet

b. Restore power

c. Defective transformer

c. Replace transformer

d. Defective PC board

d. Replace PC board

2. Timer does not display correct time of day

a. A "switched" outlet may be in use

a. Use uninterrupted outlet

b. Power outage occurred

b. Reset time of day

c. Defective PC board

c. Replace PC board

3. Unit regenerates at wrong time of day

a. Power outage occurred

a. Reset time of day

b. Time of day not set correctly

b. Reset time of day

c. Regeneration time set incorrectly

c. Reset time of regeneration

4. E1, E2 or E3 Error Codes displayed.

E1 - Unable to recognize start of regeneration

E2 - Unexpected stall

E3 - Motor ran too long. It timed out while

trying to reach the next cycle position or

trying to reach home position.

a. Valve has just been serviced

a. Press SET HOUR and DOWN for 3 seconds

or momentarily unplug power from PC board

b. Piston is obstructed

b. Check piston and spacer stack for

obstruction

c. High drive forces on piston

c. Replace piston(s) and spacer stack assembly

d. Piston not in home position

d. Press SET HOUR and DOWN for 3 seconds

or momentarily unplug power from PC board

e. Motor not fully inserted and not engaging

pinion gear. Motor wires loose or broken.

Motor failure.

e. Check motor and wiring. Replace motor if

necessary.

f. Center drive gear reflector dirty or damaged.

Missing or or broken gear.

f. Swap drive gears to have good reflector on

center gear. Clean drive gear. Replace gear.

g. Drive bracket incorrectly aligned on

backplate

g. Reset drive bracket. Be sure wires are clear.

h. PC board is damaged or defective

h. Replace PC board

i. PC board not seated correctly on drive

bracket

i. Reinstall PC board

5. Valve stalled in regeneration

a. Motor not operating

a. Replace motor

b. No power at outlet

b. Restore power

c. Defective transformer

c. Replace transformer

d. Defective PC board

d. Replace PC board

e. Broken drive gear or drive cap assembly

e. Replace gear or drive cap assembly

f. Broken piston retainer

f. Replace drive cap assembly

g. Broken main or regenerant piston

g. Replace broken piston

6. Unit does not regenerate automatically when

UP and DOWN buttons are pressed and held

a. Transformer unplugged

a. Check connection at outlet and at PC board

b. Broken drive gear or drive cap assembly

b. Replace gear or drive cap assembly

c. Defective PC board

c. Replace PC board

7. Unit does not regenerate automatically but

does when UP and DOWN are depressed

a. Defective PC board

a. Replace PC board

b. Programming error

b. Check days between regen setting

PAGE LEFT BLANK INTENTIONALLY

WATERITE, INC.

Winnipeg, Manitoba

Canada

www.waterite.com

Table of contents

Other Waterite Water System manuals

Popular Water System manuals by other brands

Charger

Charger WS1-CD Quick start manual

Monitor

Monitor MFH-5398 instructions

Kenmore

Kenmore 625.347051 owner's manual

EcoWater

EcoWater ERO-375 Installation, operation and maintenance guide

STIEBEL ELTRON

STIEBEL ELTRON SBB 300 PLUS Operating and installation

SolarShine

SolarShine SR981 Installation and operation manual

felisa

felisa FE-371 owner's manual

ChlorKing

ChlorKing ChlorSM Series Installation, operation and maintenance manual

AmeriWater

AmeriWater SILEX 00M20821 Operation & maintenance manual

intermountain

intermountain watermaster owner's manual

evenes

evenes EV-ZUP-T 15 PLUS Installation and operating instructions

Watts

Watts TD-300 Instructions for installing