Watkiss Automation Automatic SpineMaster User manual

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Watkiss

AutomaticSpineMaster

Service Manual

Issue Date : 17 June 2004

Issue Number : 1a

Part Number : 969-235

Watkiss Automation Ltd

1 Blaydon Road,

Middlefield Industrial Estate,

Sandy, Beds SG19 1RZ

United Kingdom

tel: +44 (0)1767 682177

fax: +44 (0)1767 691769

email: [email protected]

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Conventions

The following conventions are used in this manual:

WARNING Warning messages alert you to a specific procedure or practice which, if

not followed correctly, could cause serious personal injury.

CAUTION Caution messages appear before procedures which, if not observed, could re-

sult in damage to equipment.

© Watkiss Automation Limited 2004

All Rights Reserved.

Reproduction, adaptation, or translation without prior written permission is prohibited, except as allowed

under the copyright laws.

Warranty

The information contained in this document is subject to change without notice.

Watkiss Automation Limited makes no warranty of any kind with regard to this material, including, but not

limited to, the implied warranties of merchantability and fitness for a particular purpose.

Watkiss Automation Limited shall not be liable for errors contained herein or for incidental or consequential

damage in connection with the furnishing, performance or use of this material.

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Introduction •

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04 1 - 1

Chapter 1 Introduction

SECTION PAGE

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warning Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Basic Operating Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Book Thickness Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Error Indicator / Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 - 2 Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Introduction • Introduction

1.1 Introduction

The Watkiss SpineMaster post-processes stitched or stapled booklets to give

them the professional flat appearance of a perfect bound book, but with the se-

curity of a stitched spine. The resulting SquareBack books are flat, making

them easy to stack, handle and pack.

1.1.1 Product Variants

The Automatic SpineMaster is available as a standard machine, suitable for

use online to Watkiss booklet-makers or off-line.

Product variants are also available for Duplo, Bourg and Nagel booklet-mak-

ers. The function of the unit is unchanged. Only the infeed assembly and base

assembly are different.

1.1.2 Terminology

In this manual the Watkiss Automatic SpineMaster is referred to by its product

code ‘ASM’.

Where instructions refer to particular product variants, they are referred to by

the product code, suffixed with ‘B’ (Bourg), ‘D’ (Duplo) or ‘N’ (Nagel).

i.e. ASMB, ASMD, ASMN.

Introduction • Safety

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04 1 - 3

1.2 Safety

Please observe good Health and Safety practices when lifting or moving ma-

chinery. When it is necessary to have power connected to the machine whilst

covers are removed, always ensure that extreme caution is taken to avoid per-

sonal injury.

Note: The disconnect device is the appliance inlet.

1.3 Warnings

The following warnings are used in this manual:

Warning Warning messages alert you to a specific procedure or practice which, if not

followed correctly, could cause serious personal injury.

Caution Caution messages appear before procedures which, if not observed, could re-

sult in damage to equipment.

1.4 Warning Labels

The following warning labels are used in the Watkiss Automatic SpineMaster.

Indicates high voltages are present.

Label is sometimes accompanied with voltage indication.

Black figure on Yellow background.

Indicates danger of crush or cut injuries if fingers or other

body parts are inserted into this part of the machine.

Black figure on Yellow background

Indicates the Safety Earth

White figure on green background

Indicates a Functional Earth

White figure on green background

Table 1:1 Warning Labels

1 - 4 Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Introduction • Orientation

1.5 Orientation

Where procedures or descriptions refer to the RH (right hand) or LH (left

hand) side of the machine, this is always as viewed from the delivery (outfeed)

end of the machine.

1.6 Product Overview

1.6.1 Paper Path

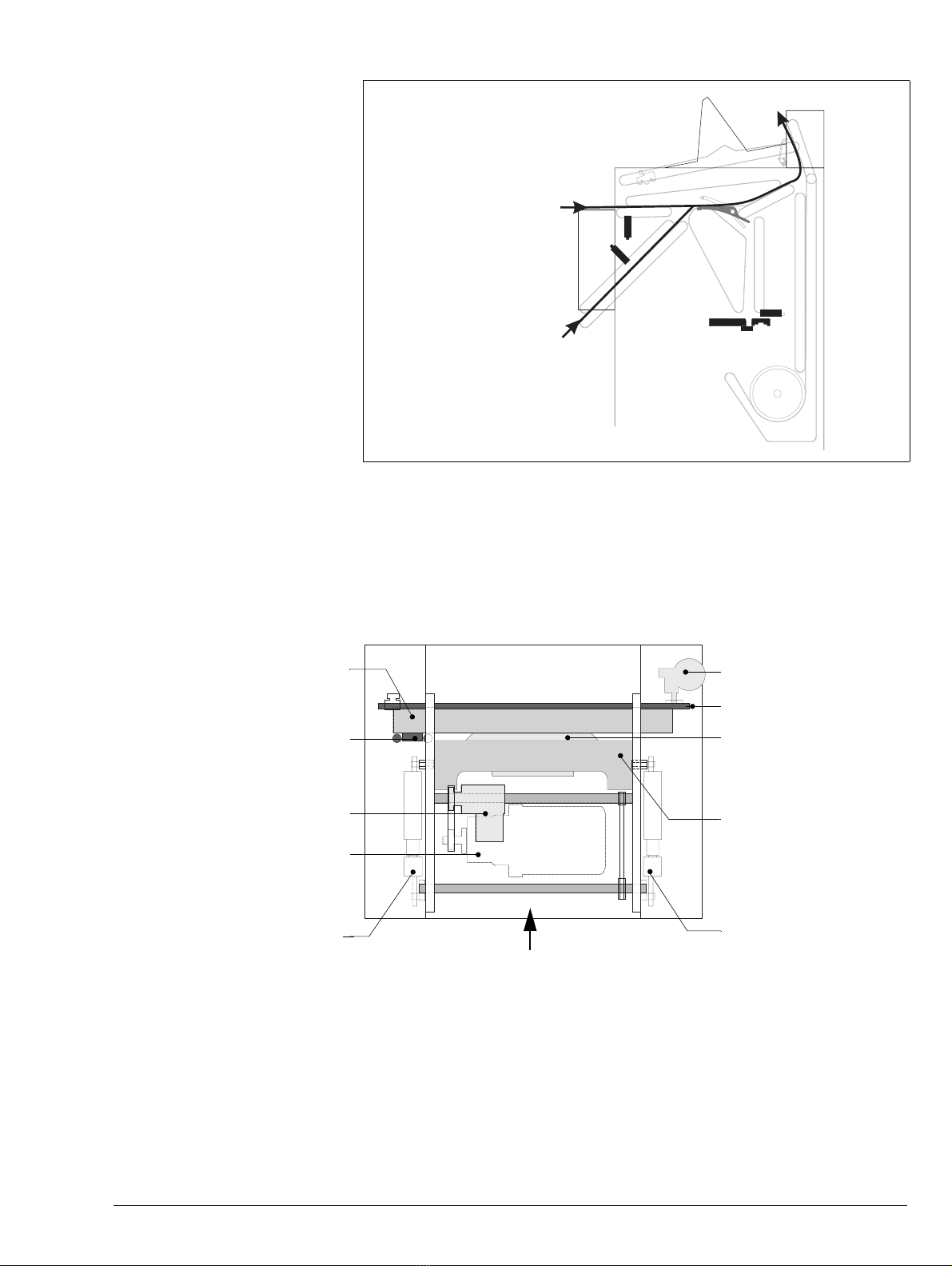

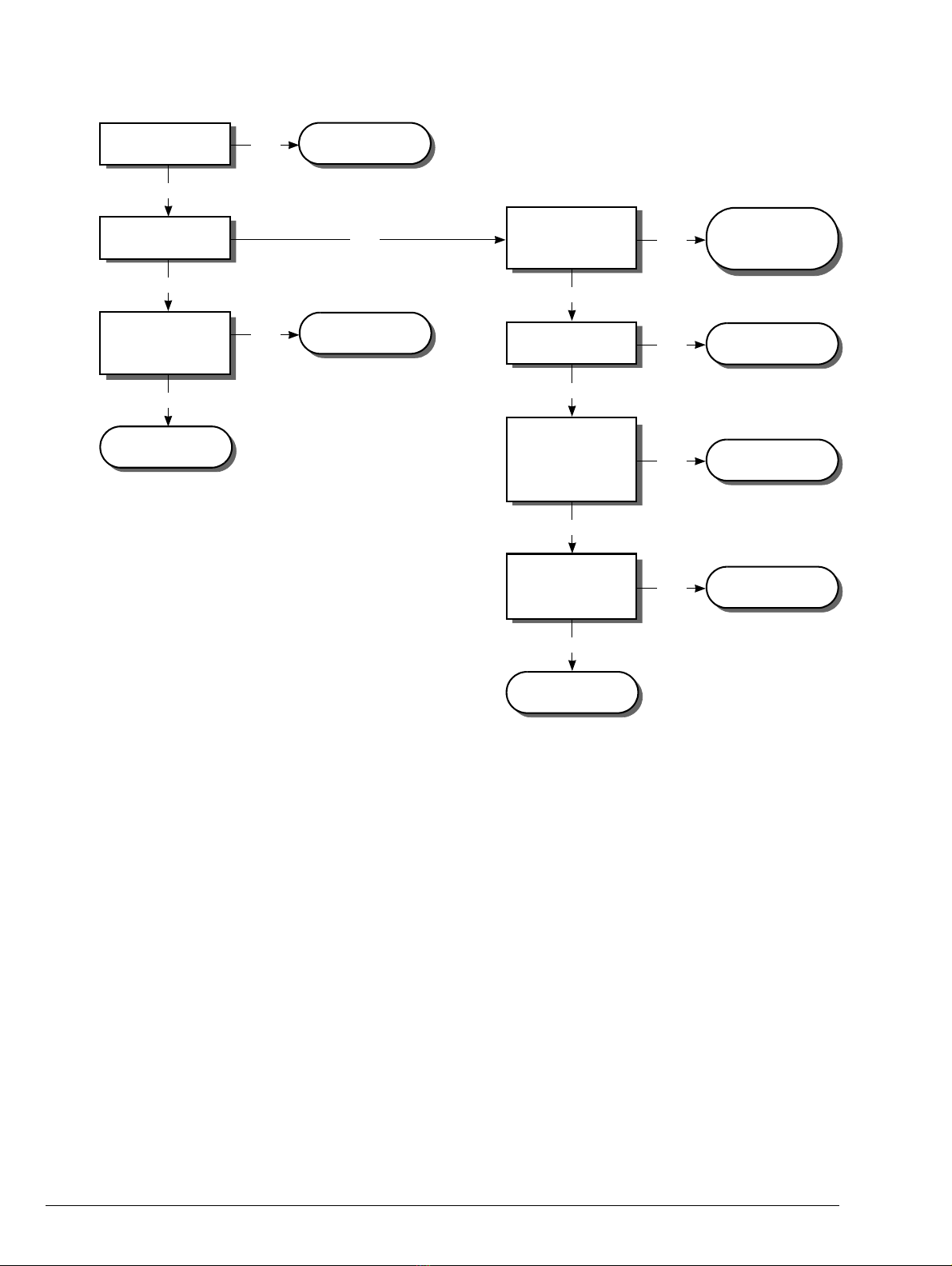

Figure 1:2 Paper Path - SquareBack Mode

Figure 1:1 Top view (ASM version shown)

Infeed

RH sideLH side

Delivery (outfeed) end

Upper Infeed

Lower Infeed

Introduction • Product Overview

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04 1 - 5

Figure 1:3 Paper Path - Bypass Mode

1.6.2 Basic Operating Principles

Booklets are inserted at either the Upper Infeed or the Lower Infeed. The In-

feed Sensors activate the Drive Motor and the booklets are transported from

the infeed, to the top of the machine and into the Booklet Loading Slot, where

they drop squarely onto the Stop (see Figure 1:5)

Upper Infeed

Lower Infeed

Figure 1:4 Automatic SpineMaster Component Diagram (top View)

Anvil

Carriage

Clutch

Drive Motor

RH Cam Link

Carriage Motor

Stop

Bolster

LH Cam Link

Transverse Chain

Infeed

1 - 6 Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Introduction • Product Overview

The Clamp Optical Sensor detects the presence of the booklet, and activates

the Carriage Motor.

After a preset pause, the Clutch on the Drive Motor is activated, which allows

the Drive Shaft to make one complete revolution. This drives the Bolster to-

wards the Anvil (the rotary motion of the Motor is converted to this lateral

movement via two Cam Links on the chain-driven Drive Shaft). The Bolster

and Anvil clamp the booklet in place, just above the spine (see Figure 1:6).

Collectively the Bolster and Anvil are known as the ‘Clamp’.

The spine is formed by the Roller Follower which is transported on the Car-

riage (see Figure 1:6). This Carriage is driven by the Transverse Chain, pow-

ered by the 24V Motor. With the booklet firmly clamped, the Carriage travels

the length of the spine, and the Roller Follower presses the spine into the re-

quired square profile. For this to happen, the Stop must first be moved out of

the way, so the Carriage is fitted with vertical Cam Rollers that push the Stop

rearwards.

When the Carriage reaches the end of the Carriage Guide, it activates either

the LH or RH Limit Sensor. There is one of these sensors at either end of the

Guide, because the Carriage can travel in both directions. For more informa-

tion on this see Section 1.6.4.

WARNING If for any reason the Carriage is stopped before it reaches one of the Limit

Sensors, it will move towards either the RH or LH Limit Sensor once power is

Bolster

Anvil

Stop

Booklet

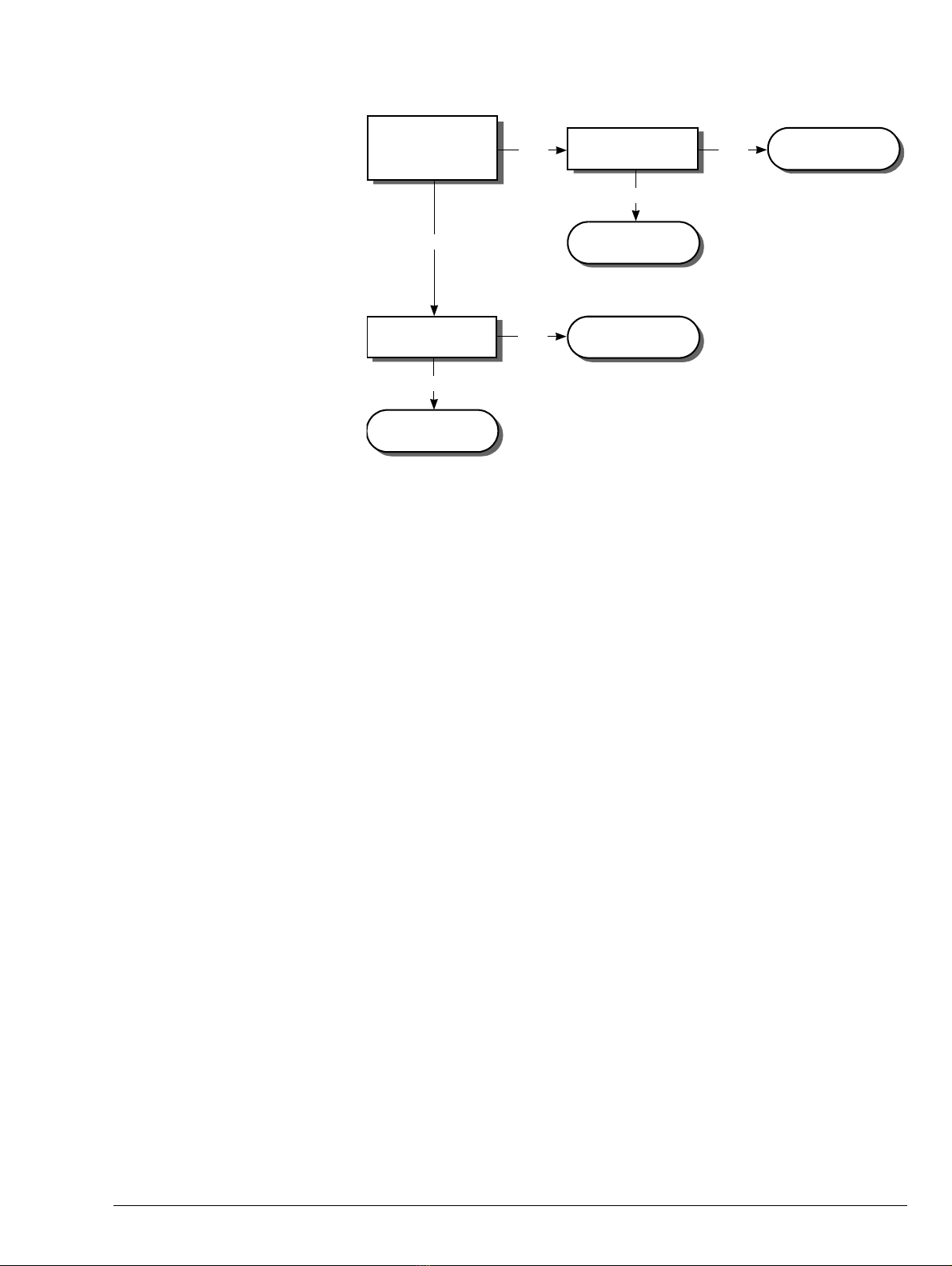

Figure 1:5 Booklet is dropped onto the Stop

Figure 1:6 Clamp Closes.

Figure 1:7 Carriage Triggered.

Introduction • Product Overview

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04 1 - 7

restored Therefore, always disconnect the ASM from the mains power supply

before putting hands or tools inside the machine..

Once the Carriage reaches either sensor, the Carriage stops and the Clutch is

engaged so that the Drive Motor releases the Clamp. The Drive Motor will

continue to run for about 15 seconds after the last book has been removed.

1.6.3 Book Thickness Adjustment

This control alters the height of the Stop. The control is turned by hand, which

operates a worm drive via a toothed belt. If the control is set to a thicker book-

let size, the Stop will be lowered, leaving more of the spine exposed to the Car-

riage. This is necessary to form the wider spine a thicker booklet requires.

1.6.4 Operating Modes

Single Pass: The ASM will process the booklet a single time. This is the de-

fault setting, and is suitable for the vast majority of booklets. Each subsequent

booklet is formed by the Carriage travelling in the opposite direction, i.e if the

first booklet is formed by the Carriage travelling from left to right, the second

booklet will be formed by the Carriage travelling from right to left.

Double Pass: The ASM will process the booklet twice. This can be useful for

thick, inflexible covers which are more resistant to re-forming. In this mode,

the Carriage passes along the booklet’s spine twice (once in either direction)

SquareBack Mode: The booklets will be processed and receive a squared

spine (SquareBack).

Figure 1:8 Clamp Opens.

Figure 1:9 Book Thickness Adjustment

Max.

Min.

1 - 8 Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Introduction • Routine Maintenance

Bypass Mode: The booklets will bypass the SquareBacking process and will

be delivered straight to the stacker. The Book Diverter, activated by a sole-

noid, diverts the booklets directly to the stacker.

1.6.5 Error Indicator / Reset Button

This indicator/button performs several functions -

• A green light indicates an error. Correct the error and then press the

button to reset the ASM.

• The button can be used to start the machine if it is not automatically

started by hand-feeding or by connected equipment.

• When hand-feeding, the green light flashes as each booklet is proc-

essed. Another booklet can be inserted when the light goes out.

1.7 Routine Maintenance

Effective rountine maintenance helps prevent machine breakdowns and en-

sures that the SpineMaster delivers optimum performance.

Routine maintenance should only be conducted by technicians who have re-

ceived product-specific training.

The routine maintenance schedule sheet in this section may be photocopied for

this purpose and we recommend that a copy is kept for your records.

The normal service interval for the ASM is 12 months. This interval should be

reduced if the ASM is subject to heavy use.

Double Pass

Single Pass

SquareBack Mode

Bypass Mode

Error Indicator / Reset Button

Figure 1:10 Operating Modes

Introduction • Routine Maintenance

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04 1 - 9

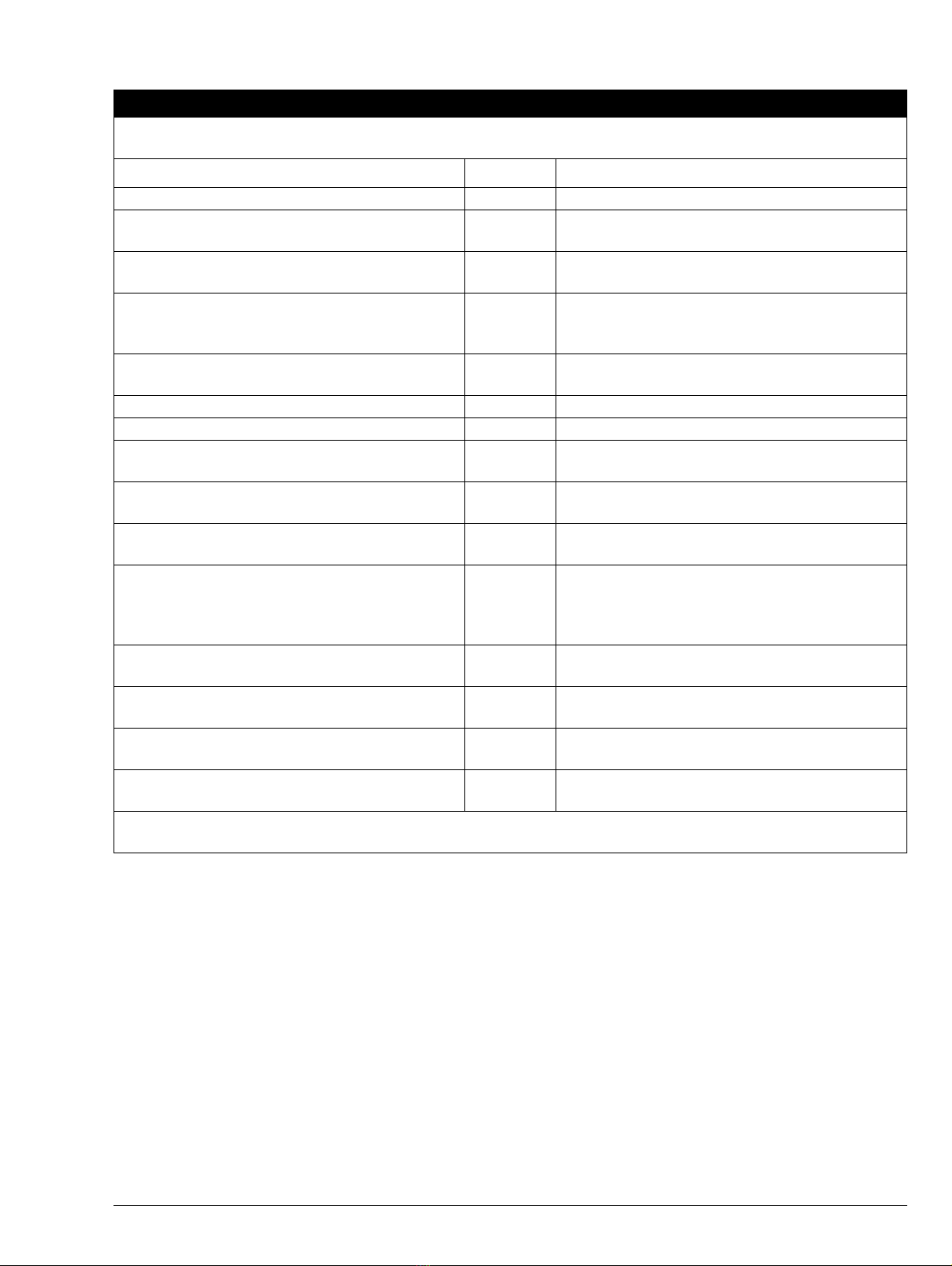

ASM Routine Maintenance Schedule

ASM Serial Number : F/W Version :

CHECK LIST CHECKED COMMENTS / NOTES

1. Check all fixing screws are tightened

2. Check drive chains and transverse chain for ten-

sion and wear

3. Lubricate drive chains using chain lubricant. DO

NOT lubricate the transverse chain.

4. Check/clean belts. Use cloth dampened with

soapy water or alcohol (iso-propanol). DO NOT

use blanket wash.

5. Check that the bolster is firmly held by all six cam

bearings

6. Clean out any paper debris

7. Clean the carriage roller and stop (see 4.3)

8. Check the stop is damped correctly and adjust if

necessary (see 4.7.8)

9. Check that the carriage runs square and tight to

the anvil and bolster

10. Check that the bolster is not burred by badly sta-

pled booklets. Deburr if required (see 4.7.9).

11. Check that the carriage parks beyond the booklet

feed slot, but does not hit either end stop. Adjust

the tension in the transverse chain and then reset

the limit sensors if necessary (see 4.7.2)

12. Check holding magnet is secure and correctly set.

(see 4.8.1)

13. Check condition of outfeed leaf springs (257-

511). Replace if necessary.

14. Check the condition of all electrical cables.

Ensure all connectors are seated correctly

15. Check condition of the interface cable between

ASM and trimmer.

Checks completed by : Date :

Table 1:2 ASM Routine Maintenance Schedule

1 - 10 Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Introduction • Routine Maintenance

Status Indicator RAPs •

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04 2 - 1

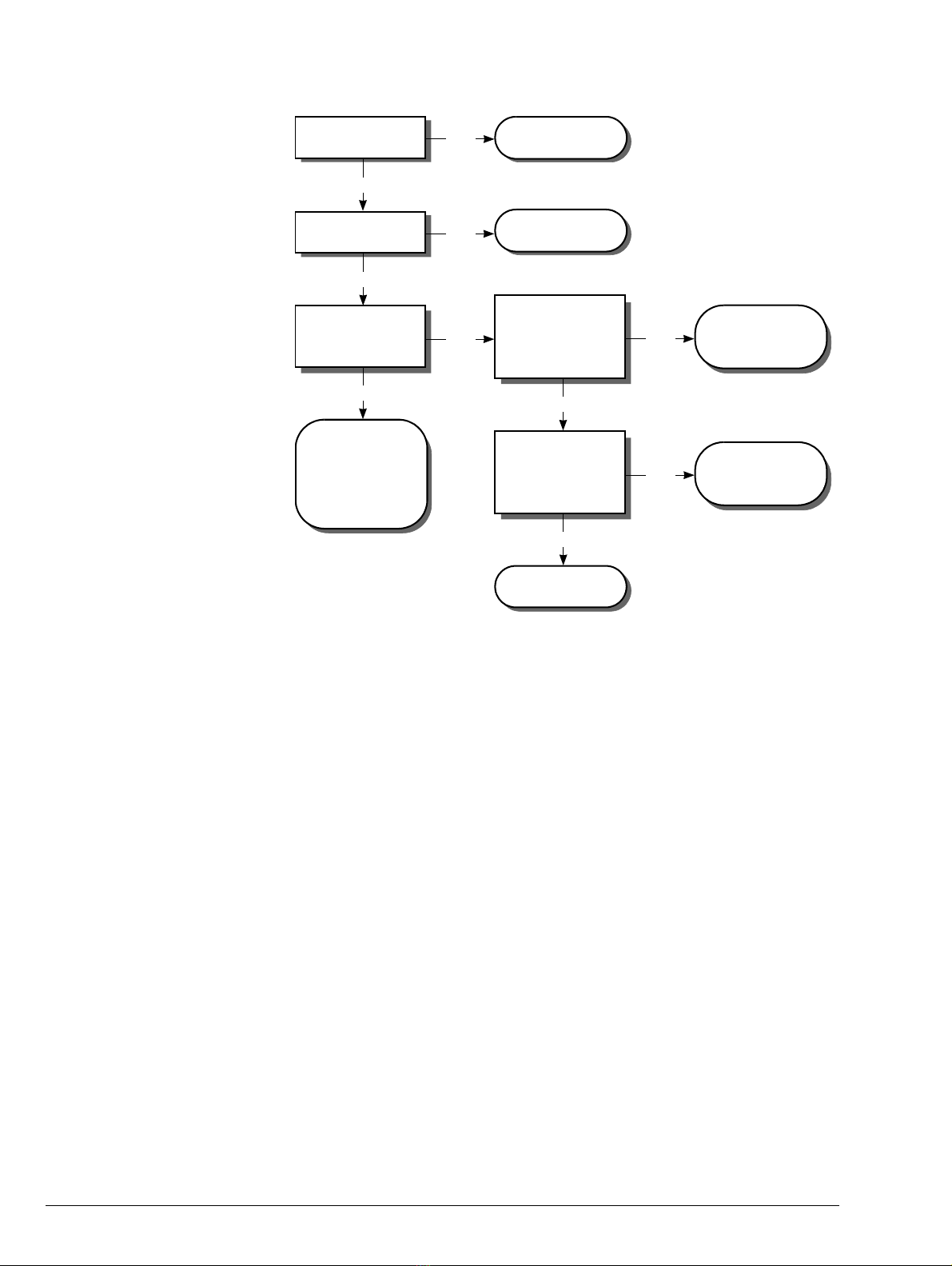

Chapter 2 Status Indicator RAPs

Entry RAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

AC Mains RAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Error Indicator RAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Jammed Booklet RAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Carriage Motor and Transverse Chain RAP . . . . . . . . . . . . . . . . . . . . . . . 6

2 - 2 Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Status Indicator RAPs • Entry RAP

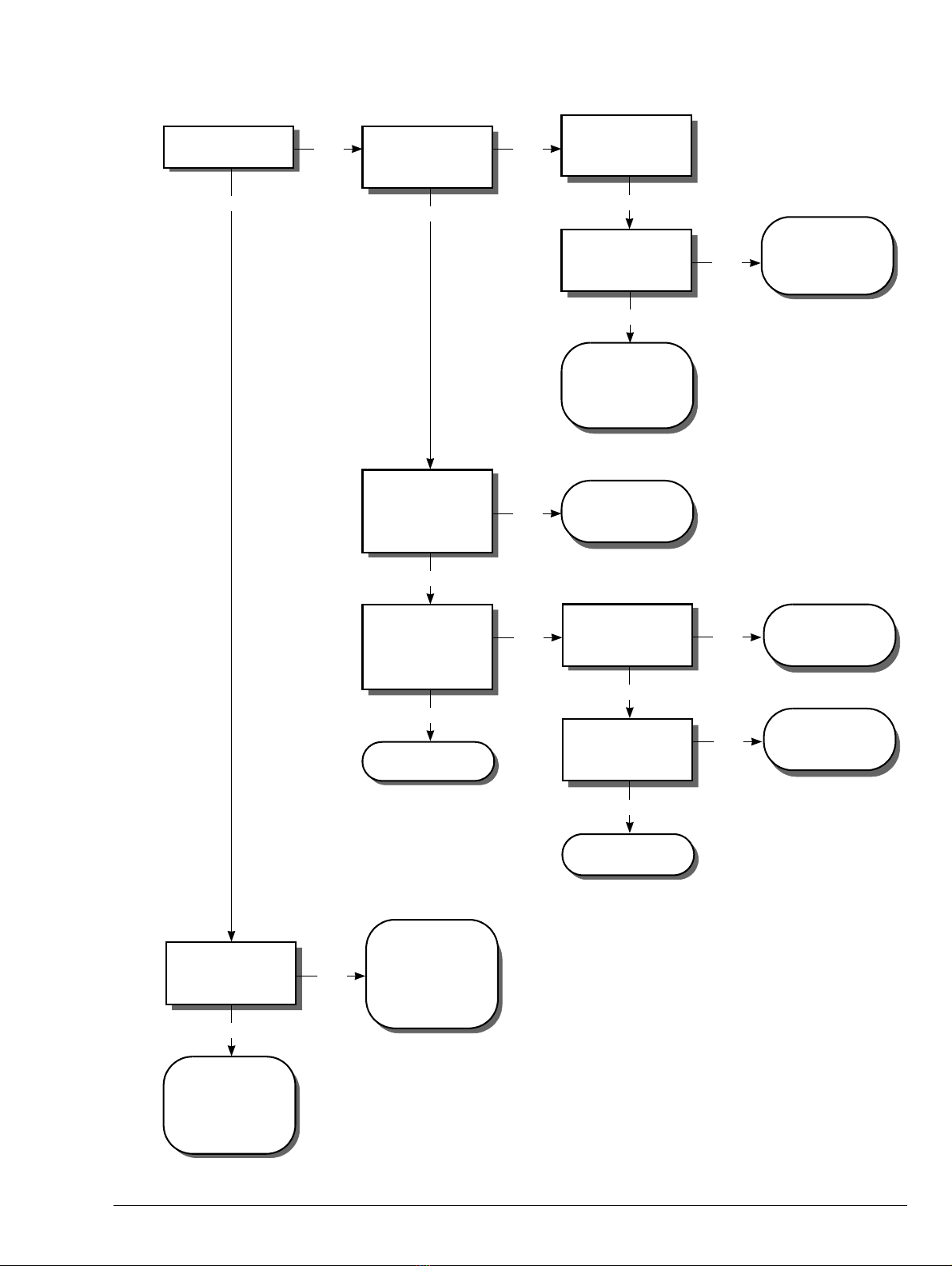

2.1 Entry RAP

Go to Error Indicator

RAP (see 2.3).

Check the

Transformer Fuse

(see 7.1).

Check the F3 fuse

on PCB 900-141.

Does the Main Motor

rotate when a start

signal is present?

Check Wiring/

Motor.

Check Drive

Chains (see 4.8.7).

Is the Main Power

Switch illuminated?

Go to AC Mains

RAP (see 2.2).

Is the Error Indicator

Light illuminated?

Is the Stacker Sup-

port triggering the

Stacker Full Sensor?

Reset Stacker

Support.

Is LED1 on the Trans-

former Input PCB illu-

minated?

Does LED1 on PCB

900-141 illuminate

when a start signal

is present?

Is LED13 on PCB

900-197 flashing?

Yes

No

Yes

No

Yes

No

Yes

Replace PCB

900-197.

No

Yes

Yes

Yes

No

No

No

Status Indicator RAPs • AC Mains RAP

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04 2 - 3

2.2 AC Mains RAP

The mains switch is not illuminated.

Is there mains

power to the Mains

Lead end?

Check mains

supply.

Is the fuse* in the

Input Socket OK? Replace fuse*.

Replace complete

Input Socket.

No

Yes

Is the fuse* in the

plug OK?

Yes

No Replace the fuse*.

No

Yes

*Fuses (see 7.1).

2 - 4 Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Status Indicator RAPs • Error Indicator RAP

2.3 Error Indicator RAP

The machine will not run and the Error Indicator Light is illuminated.

Is there a booklet

jammed inside the

ASM?

Is LED9* (Guard)

illuminated?

Check/Replace

PCB 900-197.

Close the Guards.

Are the Guards

properly closed? No

Check the Guard

Switch and wiring.

Remove the

jammed booklet. If

the problem per-

sists go to the

Jammed Booklet

RAP (see 2.4)..

Does LED10/11*†

illuminate when a

booklet is pushed

into the Infeed?

Check/replace

Infeed Sensor (see

4.8.19)./(see

4.8.20).

Does LED15* illu-

minate when a

booklet is on the

Clamp Stop?

Check/replace

Clamp Optical

Sensor (see 4.7.4).

Yes

No

Yes

No

Yes Ye s

No

Yes

No

*on PCB 900-197

† LED10 for ASM & ASMN

LED11 for ASMB & ASMD

Status Indicator RAPs • Jammed Booklet RAP

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04 2 - 5

2.4 Jammed Booklet RAP

Is the booklet

jammed in the

Clamp?

Clean the conveyor

belts, ensure the

booklet feeds in

square and that it

is folded as tightly

as possible.

Is the booklet jammed

before the Clamp?

Is the booklet thin,

with only a few

sheets?

Clean the conveyor

belts, ensure the

booklet feeds in

square and it is not

folded too tightly.

Refer to Clearing a

Paper Jam proce-

dure (see 4.4).

Switch the power off

then on. Does the

Clamp open and

release the booklet?

Remove jammed

booklet and con-

tinue operation.

Is all OK?

No fault found.

Clear jam again. Has

the jammed booklet

spine been formed?

Check Carriage

Motor and Transverse

Chain (see 2.5).

Is the booklet thin,

with only a few

pages?

Check Paper Stop

Holding Magnet

(see 4.8.1).

Is the booklet

jammed in the

Upfeed Conveyor?

Is the booklet thin,

with only a few

pages?

Clean the Conveyor

Belts and check that

the spine is not

being over crushed.

No

Yes

Check Conveyor

Belts are correctly

positioned and not

worn.

No

No

Yes

Yes

Ye s

Ye s

Yes

Yes

Yes

Yes

No

No

No

No

No

Go to Thin Books

RAP (see 3.2).

2 - 6 Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Status Indicator RAPs • Carriage Motor and Transverse Chain RAP

2.5 Carriage Motor and Transverse Chain RAP

Tension Chain (see

4.7.1).

Check/replace

Clamp Optical Sen-

sor (see 4.8.21).

Replace PCB

900-197.

Replace Drive

Motor (see 4.8.16).

Is the Transverse

Chain in place?

Does the Carriage

Motor run?

Is the Chain correctly

tensioned (see

4.7.1).

Does LED15 on

PCB 900-197 illumi-

nate when booklet is

on Stop?

Is the resistance

across the Motor

Balast Resistor

correct (68 Ohms

+/-5%)?

Yes

Yes

No

No

Yes

Replace Resis-

tor (see 4.8.4).

No

Yes

No

Re-fit Chain to

Sprockets and ten-

sion (see 4.7.1).

Is the Chain Broken?

Replace/repair

Chain (see 4.8.6).

Yes

No

Yes

Is there drive from

the Motor to the

Carriage?

Is the Roller

Assembly jammed?

Yes

Free Roller Assem-

bly (see 4.5).

Yes

No

Tighten Trantorque

Bush on Drive

Sprocket (see Fig-

ure 4:36).

Is the Drive Motor

faulty?

No

No

Yes

Table of contents

Other Watkiss Automation Booklet Maker manuals