Wavetek 1395 User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

OPLKATION

AND

MAIN

I

ENANCL

MANUAL

Model

l395/1395

Mate

50

MHz

VXIbus Arbitrary

Waveform

Synthesizer

O

1996Wavetek

Ltd

This document contains information proprietary

to Wavetek and is provided solely

for

instrument

operation and maintenance. The information in

this document may not be duplicated in any

manner without the prior approval inwriting

from Wavetek.

Wavetek

Ltd.

Hurricane

W'q,

Norwich Airp~)rtIndustrial

Estatc

Nurwch

Nl~rfolkNllh hJ13

I1K

Manual Revision

C,

6195

Manual Part Number 1006-00-0699

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

WARRANTY

Wavetek warrants that all products manufactured by Wavetek conform to published Wavetek

specifications and are free from defects in materials and workmanship for a period of one

(1)

year from the date of delivery when used under normal conditions and within the service condi-

tions for which they were furnished.

The obligation of Wavetek arising from a Warranty claim shall be limited to repairing, or at its

option, replacing without charge, any product which in Wavetek's sole opinion proves to be

defective within the scope of the Warranty. In the event Wavetek is not able to modify, repair or

replace non-conforming defective parts or components to a condition as warrantied within a

reasonable time after receipt thereof, Buyers shall be credited for their value at the original

purchase price.

Wavetek must be notified in writing of the defect or nonconformity within the Warranty period

and the affected product returned to Wavetek's factory or to an authorized service center within

(30)

days after discovery of such defect or nonconformity.

For product warranties requiring return to Wavetek, products must be returned to a service

facility designated by Wavetek. Buyer shall prepay shipping charges, taxes, duties and insurance

for products returned to Wavetek for warranty service. Except for products returned to Buyer

from another country, Wavetek shall pay for return of products to Buyer.

Wavetek shall have no responsibility hereunder for any defect or damage caused by improper

storage, improper installation, unauthorized modification, misuse, neglect, inadequate mainte-

nance, accident or for any product which has been repaired or altered by anyone other than

Wavetek or its authorized representative and not in accordance with instructions furnished by

Wavetek.

Exclusion of Other Warranties

The Warranty described above is Buyer's sole and exclusive remedy and no other warranty,

whether written or oral, is expressed or implied. Wavetek specifically disclaims the implied

warranties of merchantability and fitness for a particular purpose. No statement, representation,

agreement, or understanding, oral or written, made by an agent, distributor, representative, or

employee of Wavetek, which is not contained in the foregoing Warranty will be binding upon

Wavetek, unless made in writing and executed by an authorized Wavetek employee. Under no

circumstances shall Wavetek be liable for any direct, indirect, special, incidental, or consequen-

tial damages, expenses, losses or delays (including loss of profits) based on contract, tort, or any

other legal theory.

This productcomplieswith the requirementsof the following EuropeanCommunity Directives:

Cf

89/33B/EEC

(Electromagnaic

Compatiblllty)

and

731231EEC

(Low

Voltage)

as amended

by

93/68/EEC (CE

Marking).

However,noisy or intense electromagneticfields in the vicinity of the equipmentcandisturb the measurement

circuit. Users should exercise caution and use appropriate connection and cabling configurationsto avoid

misleadingresults when makingprecisionmeasurementsin the presenceof electromagnetic interference.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

SAFETY

FIRST

PROTECTYOURSELF.

Follow these precautions:

Don't touch the outputs of the instrument or any exposed test wiring

carrying the output signals. This instrument can generate hazardous voltages and

currents.

.

Don't bypass the

VXI

chassis' power cord's ground lead with two-wire

extension cords or plug adaptors.

.

Don't disconnect the green and yellow safety-earth-ground wire that

connects the ground lug of the

VXI

chassis power receptacle to the chassis

ground terminal (marked with

@

or

a

).

Don't hold your eyes extremely close to an rf output for a long time. The

normally nonhazardous low-power rf energy generated by the instrument could

possibly cause eye

injury.

Don't energize the

VXI

chassis until directed to by the installation

instructions.

.

Don't repair the instrument unless you are a qualified electronics techni-

cian and know how to work with hazardous voltages.

.

Pay attention to the

WARNING

statements. They point out situations

that can cause injury or death.

.

Pay attention to the

CAUTION

statements. They point out situations that

can cause equipment damage.

CONTENTS

iii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CONTENTS

SECTION

1

GENERAL

1.1 THE MODEL 1395

...................................................................................

1-1

1.2 SPECIFICATIONS

....................................................................................

1-1

.......................................................................

1.2.1 Waveforms(Functions) 1-1

..................................................

1.2.2 ARB WaveformCreation and Editing 1-1

.............................................................................

.

1 2.3 Operational Modes 1-2

..........................................................

1.2.4 Input and Output Specifications 1-2

...............................................................................................

1.2.4.1 Outputs 1-2

1.2.4.2 Inputs

..................................................................................................

1-4

1.2.5 WaveformCharacteristics

...................................................................

1-5

1.2.6 Frequency

...........................................................................................

1-6

.......................................................

1.2.6.1 Arb Clock and Waveform Timing: 1-6

...........................................................................................

1.2.7 Amplitude 1-6

1.2.8 Offset

..................................................................................................

1-6

1.2.9 Filtering

..............................................................................................

1-6

1.2.1

0

Linked SEQuenceOperation

..............................................................

1-7

1.2.11 Sweep

.................................................................................................

1-7

1.2.12 Triggering

......................................................................................

1-7

1.2.13 Modulation

........................................................................................

1-8

1.2.14 IntermoduleOperation

........................................................................

1-8

1.2.15 Frequency List

....................................................................................

1-9

1.2.16 Option

...............................................................................................

1-9

...........................................................................

1.2.1

7

AutoCal/Diagnostics 1-9

1

.

3 GENERAL

.................................................................................................

1-9

.............................................................................

1.3.1 SCPl Programming 1-9

1.3.2 VXI Interface

......................................................................................

1-10

1.3.3 Environmental-

....................................................................................

1-11

1.3.4 Size

.....................................................................................................

1-11

1.3.5 Power

.................................................................................................

1-11

1.3.6 Reliability

............................................................................................

1-11

..........................................................................

1.3.7 Cooling Requirement 1-11

1.3.8 Safety

.................................................................................................

1-11

1.3.9 EMC

....................................................................................................

1-11

SECTION

2

PREPARATION

2.1 RECEIVINGINSPECTION

.......................................................................

2-1

2.1.1 Unpacking Instructions

.......................................................................

2-1

2.1.2 Returning Equipment

..........................................................................

2-1

2.2 PREPARATIONFOR STORAGE OR SHIPMENT

....................................

2-1

2.2.1 Packaging

...........................................................................................

2-1

2.2.2 Storage

...............................................................................................

2-1

2.3 PREPARATIONFOR USE

.......................................................................

2-1

..................................................................

2.3.1 LogicalAddress Selection 2-2

.............................................................

2.3.2 DataTransferBusArbitration 2-2

2.4 INSTALLATION

.........................................................................................

2-4

......................

2.5 INITIAL CHECKOUT AND OPERATIONVERIFICATION

2-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CONTENTS (Continued)

SECTION

3

OPERATION

.......................................................................................

3.1 INTRODUCTION 3-1

.................................................

3.2 CONNECTORS AND LED INDICATORS 3-1

................................................................

3.3 MODEL 1395PROGRAMMING 3-1

........................................................................

SCPl CommandTable 3-1

Long and Short Form Keywords

.........................................................

3-4

Command MessageFormat

...............................................................

3-4

ProgramMessage Unit

.......................................................................

3-4

Program Message

..............................................................................

3-4

ProgramMessage Delimiters

.............................................................

3-4

Parameter Forms

................................................................................

3-4

..........................................................

ProgramMessageTerminators 3-8

...............................................................................................

Queries 3-8

Model 1395SCPl Commands

...........................................................

3-9

CALibrationSubsystem

..................................................................

3-9

............................................................................

INlTiateSubsystem 3-11

............................................................................

OUTPut Subsystem 3-11

...............................................................................

RESet Subsystem 3-13

SOURce Subsystem

..........................................................................

3-13

............................................................................

STATUSSubsystem 3-18

SYSTem Subsystem

.....................................................................

3-19

TEST Subsystem

...........................................................................

3-19

Trace Subsystem

................................................................................

3-20

TRlGger Subsystem

.........................................................................

3-22

High Speed Binary WaveformTransfer

.............................................

3-22

IEEE-488.2 Common Commands

.......................................................

3-25

3.4 MODEL 1395OPERATION

.....................................................................

3-25

...........................................................................

OutputTerminations 3-25

.......................................................................

Input/OutputProtection 3-26

...................................................................

PowerOnIReset Defaults 3-26

...................................................................

StandardFunctions(CW) 3-29

..................................

Trace Operationsand USER Function(RAST) 3-29

Trace Definition

.................................................................................

3-29

Trace Data

..........................................................................................

3-31

.........................................

Trace Copy. Resize. Rename. and Delete 3-32

Trace Limits

......................................................................................

3-32

Trace Queries

...................................................................................

3-33

Waveform DownloadOperations

........................................................

3-34

.............................................

DefiniteLengthArbitrary BlockTransfer 3-34

.............................................................

WaveForm DSPTMDownload 3-35

....................................................................

Shared MemoryTransfer 3-37

Non-continuousModes

.......................................................................

3-38

TriggeredOperation

..........................................................................

3-39

.................................................................................

GatedOperation 3-42

...........................................................................

Sequence Operation 3-42

...................................................................

CONTinuous Sequencing 3-42

TRlGgered Mode Sequencing

............................................................

3-45

AMISCM Operation

...........................................................................

3-45

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CONTENTS (Continued)

SyncIPositionMarkers

........................................................................

3-46

FrequencySweep

...............................................................................

3-47

Sweep Generator

...............................................................................

3-48

Frequency List

....................................................................................

3-49

SUMBUS Operation

............................................................................

3-49

Clock InpuWOutput Operation

.............................................................

3-51

IntermoduleOperations

.....................................................................

3-54

lntermoduleTriggering

.......................................................................

3-54

IntermodulePhase Lock

.....................................................................

3-58

SECTION

4

CALIBRATION

...................................................................................

4.1 FACTORY REPAIR 4-1

..........................................................................................

4.2 CALIBRATION 4-1

4.3 REQUIREDTEST EQUIPMENT

...............................................................

4-1

....................................

4.4 PERFORMANCEVERIFICATIONPROCEDURE 4-1

StandardTest Equipment

...................................................................

4-2

StandardTest Conditions

..................................................................

4-2

Test Specifications

..............................................................................

4-2

.................................................................................

VXlbus Interface 4-2

Self Test

.............................................................................................

4-2

FunctionOutputOnIOff

......................................................................

4-2

Trigger Count

.....................................................................................

4-2

....................................................................................

Trigger Source 4-3

....................................................................

Sine Amplitude Accuracy 4-3

...............................................................

Square Amplitude Accuracy 4-4

...........................................................................

AttenuatorAccuracy 4-4

DC OffsetAccuracy

............................................................................

4-4

..........................................................................

FrequencyResponse 4-5

...................................................................

SquareWaveformQuality 4-5

.....................................................................

SquarewaveDuty Cycle 4-5

Sync Marker Output

...........................................................................

4-6

PositionMarker Output

.......................................................................

4-6

Clock Output

.......................................................................................

4-6

Clock Input

..........................................................................................

4-6

Frequency Sweep

..............................................................................

4-6

.....................................................................

4.5 ALIGNMENT PROCEDURE 4-7

...................................................................................

4.5.1 Self Calibration 4-7

...............................................................

4.5.2 Semi-AutomatedProcedure 4-7

.........................................................................................

4.5.3 Preparation 4-7

4.5.4 ConnectorTermination

.......................................................................

4-8

4.5.5 Alignment Procedure

..........................................................................

4-8

4.5.5.1 Square Wave Symmetry

...................................................................

4-8

4.5.5.2 Square Wave Quality

..........................................................................

4-8

.........................................................................

4.5.5.3 SUMBUS DriverZero 4-9

...................................................................................

4.5.5.4 Self Calibration 4-9

............................................................................................

4.5.5.5 SCM Null 4-9

4.5.5.6 Elliptic Filter Amplitude FlatnessCorrection

.......................................

4-10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CONTENTS (Continued)

SECTION

5

PARTS AND SCHEMATICS

5.1 DRAWINGS

..............................................................................................

5-1

5.2 ERRATA

...................................................................................................

5-1

5.3 ORDERING PARTS

..................................................................................

5-1

APPENDIX

A

SELF CALIBRATION

A.l INTRODUCTION

.......................................................................................

A-1

A.2 CALIBRATION QUERY RESPONSE

...................................................

A-1

APPENDIX

B

SELF TEST

.......................................................................................

B.l INTRODUCTION B-1

B.2 TEST QUERY RESPONSE

....................................................................

B-1

APPENDIX C SCPI CONFORMANCE INFORMATION

C.l INTRODUCTION.......................................................................................C-1

C.2 REFERENCE INFORMATION

..................................................................

C-1

C.3 SCPl CONFORMANCE INFORMATION

...............................................

C-2

(2.3.1 Model 1395 SCPl version

...................................................................

C-2

C.4 MODEL 1395 SCPl COMMAND SYNTAX

..............................................

C-2

C.4.1 SCPl Confirmed Commands

............................................................

C-2

C.4.2 SCPl Approved Commands

.........................................................

C-2

C.4.3 Commands not part of the SCPI Specification

....................................

C-2

C.4.4 Incomplete Command lnplementation

................................................

C-2

APPENDIX D SCPl COMMANDTREE

D.l COMMAND TREES

.................................................................................

D-1

APPENDIX E SAMPLE PROGRAMS

E.l INTRODUCTION

.......................................................................................

E-1

E.l.l Example 1.......................................................................................E-1

E.1.2 Example 2

......................................................................................

E-2

E.1.3 Example

3

...........................................................................................

E-3

E.1.4 Example 4...........................................................................................E-4

E.1.5 Example 5

...........................................................................................

E-5

APPENDIX F MATE INTERFACESYNTAX

.......................................................................................

F.l INTRODUCTION F-1

F.2 GAL COMMAND .......................................................................................F-1

..................................................

F.3 ARB GENERATOR DOCUMENTATION F-1

................................................

F.4

ARB GENERATOR ERROR MESSAGES F-2

.........................................

F.5 MlSC ARB GENERATOR DOCUMENTATION F-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table 2-1

Table 3-1

Table 3-2

Table 3-4

Table

3-5

Table 3-6

Table

4-1

Table C-2

Test Equipmentand Tools

.....................................................

2-4

Model

1395

Front Panel

.........................................................

3-3

Model 1395CommandSummary

..........................................

3-5

.......................................................................

Error Messages

3-24

IEEE

488.2 CommonCommands

........................................

3-25

................................................

Inputand Output Impedances 3-26

List of Test Equipment

...........................................................

4-1

Model 1395CommandSummary

........................................

C-3

viii

CONTENTS

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ILLUSTRATIONS

Figure 1-1

Figure 2-1

Figure 2-2

Figure 3-1

Figure 3-3

Figure 3-4

Figure

3-5

Figure 3-6

Figure 3-7

Figure 3-8

Figure 3-3

Figure

3-10

Figure 3-11

Figure 3-1

2

Figure 3-13

Figure 3-14

Figure D-1

Figure D-2

Figure D-3

Figure D-4

Figure D-5

Figure D-6

Figure D-7

Figure D-8

Figure F-1

Figure F-2

Figure F-3

Figure F-4

Figure F-5

Model 1395 50 MHz Arbitrary Waveform Synthesizer

......,....

1-0

.........................................................

Set the Logical Address

2-2

BusArbitration Level Jumpers

...............................................

2-3

.........................................................

Model 1395 Front Panel 3-2

.................................................................

Output Termination 3-26

.......................................

Model 1395 Basic Operating Setup 3-27

...................................

Continuous Waveform Characteristics 3-28

Definite Length Arbitrary Block Data Format

..........................

3-33

VXlbus System Using "External Host" GPlB Controller

.........

3-36

Triggered Waveform Characteristics. Count

=

1

....................

3-38

GateIBurst Waveform Characteristics

....................................

3-40

CONTinuous Sequence State Diagram

.................................

3-41

TRlGgered Sequence State Diagram

....................................

3-44

Sweep Mode Characteristics

................................................

3-47

IntermoduleTriggering Backplane Connections

....................

3-51

IntermoduleTriggering Command References

......................

3-52

Subsystems (Root Node)

.......................................................

D-1

INITiate. STATUS.TEST. and RESet Subsystems

.................

D-2

SOURce Subsystem

............................................................

D-3

TRACe Subsystem

...........................................................

D-4

TRlGger Subsystem

..............................................................

D-5

OUTPut System

......................................................................

D-6

SYSTem Subsystem

..............................................................

D-7

CALibrator Subsystem

..........................................................

D-8

..................................................

Common Command Format F-4

......................................................

Sine and Triangle Format F-5

.....................................................

Square and Ramp Format F-6

............................................

User Defined Waveform Format F-7

DC Function Format

...............................................................

F-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

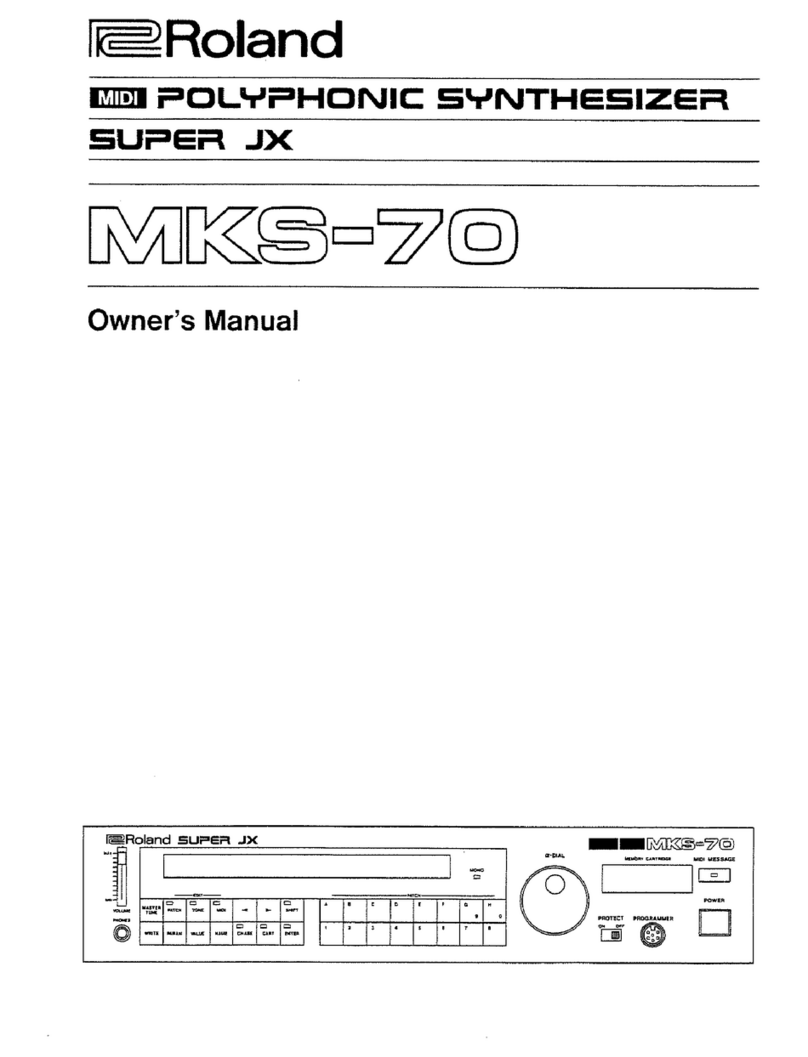

-

50

MHz

Arbitrar)

Waveform Synthesiz

model

1395

RUN

0

FAIL

@

CLK

INIOUT

TRIG IN

MAINOUT

model

1395

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Specificalions

Section

1

1.1

THE

MODEL

1395

The MODEL 1395is a high performance Synthe-

sized Arbitrary Waveform Generator (ARB)with

the following main features:

Up to 50 MHz Sampling Frequency

12 Bit Vertical Resolution

32K points (128K optional) Horizontal Reso-

lution

Intermodule Triggering, Summing and

Phase Control

Waveform Linking and Looping

64K bytes Shared Memory for fast data

transfer

SCPI Compatible Command Language

Single Slot, C-Size VXIbus Module

The waveform synthesizer can be programmed to

produce standard waveforms in the frequency

range of 1 pHz to 25 MHz; or arbitrary waveforms

from 5 points minimum to 32K (128K)maximum

sampled at frequencies from 125mHz to 50 MHz.

Additionally, a Clock Output is provided from 125

mHz to 100 MHz.

Waveforms can be created by selection of the stan-

dard waveforms, drawing waveforms by defining

straight line segments, or downloading of binary

images. The A24 Shared Memory may be used for

significantly faster downloads than by using the

word-serial protocol.

The main waveform output provides up to 15Vp-

p into 50R (30 Vp-p, open circuit). Waveform dc

offset or dc output

is

also provided up to k7.5 V

into 50R (k15V into open circuit).

The control language adheres to the SCPI (Stan-

dard Commands for Programmable Instruments)

format Version 1992.0,February 1992 (refer to the

SCPI manual for further information). SCPI is an

industry standard language for remote instrument

programming. The Wavetek Model 1395wave-

form synthesizer is a single-slot "C" size VXIbus

module. Using any manufacturer's VXIbus chas-

sis, the Model 1395can be controlled using the

SCPI language and the appropriate controller.

Multiple ARBSmay be linked and operated togeth-

er inside one VXIbus chassis. Series operation is

provided by full support of the VXIbus SUMBUS

protocol. A signal programmed at the output may

be sent to the SUMBUS, or signal present at the

SUMBUSmay be summed into the model 1395out-

put. In parallel operation, model 1395's may be

slaved to a master clock/trigger bus on the VXIbus

backplane to create a multichannel waveform syn-

thesizer with phase control between channels.

The model 1395has extensive self-adjustment util-

ities built in. Calibration constants are maintained

in non-volatile memory (containsno battery).

1.2

SPECIFICATIONS

1.2.1

Waveforms

(Functions)

Programmable standard functions include sine, tri-

angle, square, positive ramp, negative ramp, posi-

tive haversine, negative haversine, random

(noise),sinc (sin x/x) and dc. (The function

"WTST"

is a reserved function name used for fac-

tory maintenance, and it should not be selected as

a

function or used to name an arbitrary wave-

form.) One to fifty arbitrary waveforms (traces)

may be stored by name in volatile 32,768 point

(optionally 131,072 point) RAM memory. Each

trace has 12bits vertical resolution, and from

5

points to the maximum number of points in the

waveform memory horizontal resolution.

1.2.2

ARB

Waveform Craatlon

and

Edltlng

The Arb has a variety of ways to create a wave-

form. Binary data may be down-loaded from a

computer. Internal "standard waveform" algo-

rithms will create exactly one cycle of the wave-

form requiring nothing more than a name and a

space set aside for it (random, sinc and dc, obvi-

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ously, are not cyclical). Previously created wave-

shapes residing in memory may be copied to a

new trace. Waveforms can be built using line seg-

ments.

The Model

1395

Arb has several editing features.

After filling memory with data defining the wave-

form, the user may select only a portion to be

"played back" using the

TRACe

:

LIMi

t

com-

mand. The selected portion may be used for cre-

ating a new waveshape using the

TRAC

e

:

DATA

command. A trace may also be overwritten with

new datawith the

TRACe

:

DATA

command. Any

waveform may be stretched or shrunk by copying

it into a different size memory space; waveform

points are automatically added or removed to re-

tain the integrity of the shape using the

TRACe

:

DATA

command.

By

copying waveshape

segments end to end, new waveshapes can be cre-

ated with the

TRACe

:

DATA

command.

A

wave-

formmay be resized using the

TRACe

:

POINt

s

command. A line segment of any size between

5

points and the maximum memory size can be cre-

ated using the

TRACe

:

LINE

command. Any

waveform in the directory can be selected for

"play back" with the

FUNCt

i

on

:

USER

<trace-name> and

FUNC

t

i

on

:

SHAPe USER

commands. Individualwaveshapes may be delet-

ed by name or the entire memory can be erased

using the

TRAC

e

:

DELe

t

e

command.

1.2.8

Oparatlonal

Modes

CONTinuous:

The selected trace is output continuously at the

selected frequency, amplitude and offset. The

sync marker is output once per waveform (select-

able as a pulse at the start of the waveform or as a

zero-crossing output of the waveform) and the

position marker is output at any selected points of

the waveform. Frequency is determined by the

TRACe

:

MODE (CW

or

RAST~~),

programmed

FREQuency

value

(CW

waveform frequency or

RASTer

sample clock frequency), and

ROSC

i

1

-

lator

:

SOURce (IN~ernal

125mHz to

10

MHz, VXIbus

CLOCk,

or

EXTernal

clock

source). For details, see paragraph 1.2.6,Fre-

quency.

TRIGgered:

Waveform output is quiescent at first data point

of selected trace until a triggering event (select-

able by

TRIG^^^:

SOURce

as

INTernal,

EX-

Ternal,

VXIbus

TTLTrg

or VXIbus Local Bus

CHAin),

after which waveform cycle(s)

at

the

programmed frequency, amplitude andoffset is

initiated. The waveform completes the number of

cycles set by the

Trigger

Count

and returns to its

quiescent baseline value for another triggering cy-

cle. The triggering baseline is the level of the first

waveform address.

For details, see paragraph 1.2.12, Triggering.

GATE:

Same as Triggered except output is continuous for

duration of gate signal. Last waveform cycle is al-

ways completed when gate signal is removed.

AMISCM:

Operates as in ContinuousMade above, except

that the output can be Amplitude Modulated or

Suppressed Carrier Modulated by external sig-

nals. For details, see paragraph 1.2.13, Modula-

tion.

SWEep:

Operates as in Continuous Mode above, except

that the output frequency can be swept by an in-

ternal sweep generator between programmed

start and stop frequencies.

Sweep capability is provided for standard wave-

.

forms and Arbitrary waveformswith a length that

is a multiple of

4096

points. A horizontal sweep

output voltage is also provided. For details, see

paragraph 1.2.11, Sweep.

Linked Sequencemode provides sophisticated

linking, looping and advancing of multiple wave-

form segments. This allows the creation of long

and very complex waveform sequences. For de-

tails, see paragraph 1.2.10, Linked Sequence

Op-

eration.

1

.2.4

Input

and

Output

8pedflcatlolu

1.2.4.1

Outputs

The Model 1395Arb has fouroutput signals on

the front panel: the function output, the position

marker, the sync marker, and the sample clock.

The Arb also provides a clock to the selected

VXIbus backplane ECLTRG line, and a trigger

output to the VXIbus Local Bus or to the selected

VXIbus TTLTRG line. The

ECL

Trigger lines can

be used to sharewaveform sampleclocks. The

TTL Trigger lines can be used for intermodule

triggering.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MAIN

OUT:

Front panel mounted female BNC, source of pro-

grammed function at selected frequency, ampli-

tude and offset. Source impedance is

50

Q.

Protected against short circuit to ground.

SYNC MARKER/H-SWEEP OUTPUT:

Front panel mounted female BNC. The SYNC

MARKER is a TTL compatible pulse into

50R

at

the waveform frequency. Sync generation tech-

nique is selectable as

"ZCRO

ss"

or as

"BBI

TS

".

If

ZCROSS

is selected, the sync is generated from

zero-cross detecting the waveform. The sync

marker is a TTL high whenever the waveform is

positive. This is the preferred selection when

TRACe

:

MODE

is set to

cw

(phaseaccumulation).

This is because in

CW

a particular point may not

be used in every scan through the trace.

When

BBITS

is selected, the SYNC MARKER is a

TTL high for a variable number of samples (see

POSITION MARKER description for explanation)

starting at the first waveform memory location

used. When

TRACe :MODE

is

RASTer,

either

sync technique is applicable. Protected against

short circuit to ground.

Levels:

Low level

<

0.4V

into

>

508

High level

>

2.OV

into

>

508

Rise and Fall time:

<

5

ns into

50R

Configuration as a H-Sweep (HorizontalSweep)

is made when the Frequency Mode is set to Sweep

or to List. A linear output ramp from

0

to

+10

volts

(f500

mV, open circuit) proportional to

sweep position between selected start and stop

limits is provided to drive the horizontal axis of a

display device. The output impedance is

600 R

f

5%.

POSITION MARKER OUTPUT:

Front panel mounted female BNC. TTL compati-

ble pulse into

50 51.

User can clear the markers

low at all points or set the marker high at any

point in a trace. Protected against short circuit to

ground.

Amarker set at address zero will be true during

the trigger quiescent baseline. If address

1

is set

(and zero is not), the POSITION MARKER output

follows the trigger event plus the pipeline delay.

The Position Marker is one trace point (not neces-

sarily

1

clock) wide for each location selected. In

Raster mode, the trace point correspondsto a

clock cycle. In CW mode, for high frequency

waveforms, a trace point may not be accessed in

each pass through the waveform. For very low

frequencies, and in CW mode, each trace point

may be sampled for a number of clock cycles.

Levels:

Low level

<

0.4V

into

>

5052

High level

>

2.OV

into

>

50R

Rise and Fall time:

<8

ns into

50R

CLOCK INIOUT:

Front panel mounted BNC, selectable as either

TTL level clock input or TTL level clock output.

TTL Clock output is

0.1251

Hz to

50

MHz wave-

form sample clock in normal operation and

0.1251

Hz to

100

MHz in Clock mode. The output is pro-

tected against short circuits to ground.

Configured as an output:

Range:

0.1251

Hz to

100

MHz

Resolution/Accuracy:

Same as the frequency synthesizer.

Levels:

Low level

<

0.5V

into

5062

High level

>

2.1V

into

50R

Rise and Fall time:

<3

ns into

50R

TRIGGER OUTPUT (to

VXI

Backplane):

One of the eight VXIbus TTLTrigger lines can be

programmed as trigger output. The source of the

output trigger signal can be selected as "BIT",

"Loop COMplete", or "Burst COMplete". The

BIT

signal is set to be output during a specified

Trace or segment within a SEQuence, either at the

end (Trigger Marker) of the Trace or at selected

point(s)within the Trace (Position Marker).

LCOMP

1

e

t

e

indicates that a SEQuence segment

has completed its loop count.

BCOMp

1

e

t

e

indi-

cates a Trace or a SEQuence has completed its

burst count.

When these sources are selected, the minimum

pulse width is

30

ns and maximum frequency

that can be applied to a VXIbus TTLTrigger line is

12.5

MHz (per VXIbus specification). Exceeding

these limits should be avoided by setting wave-

form sample frequency below

33

MHz or by pro-

gramming

2

consecutive BITS when using the TTL

Trigger lines for a trigger output.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CLOCK OUTPUT

(to

VXI

Backplane):

Either of the ECL Trigger lines can be pro-

grammed

as

a

clock output for intermodule tim-

ing. The "master" module supplies its internal

clock to this output to be used by "slave" mod-

ules as a clock reference for Phase Lock or for

tightly controlled trigger timing. When in

TRACe: MODE

CW

and internal clock is selected,

the internal clock is a fixed 50

MHz.

In

TRACe:MODE RASTer the internal clock's mantis-

sa can range from 25 MHz to 50 MHz with 5 dig-

its or 0.1 mHz of resolution under user control.

To set Phase Lock ON, the module selected as the

"master" drives the selected ECL Trigger line

(ECLTrg<n>ON)with its frequency synthesizer

clock signal. All modules, includingthe "mas-

ter", get their Reference Oscillator (clock) from

the ECLTrg line (R0SC:SOUR ECLT<n>)for opti-

mum timing accuracy. When ECLTrg<n>is select-

ed as an output by the "master":

Clock Frequency Range:

25 MHz to 50 MHz (Raster);

50 MHz

(CW).

Resolution/Accuracy:

Same as frequency synthesizer.

SUMBUS OUTPUT

(to

VXI Backplane):

Analog signals at the 1395's MAIN OUT may also

be summed into the VXIbus SUMBUSline with a

fixedscale factor (see Intermodule Analog Sum-

ming, paragraph 1.2.14). A full amplitude 15Vpp

signal at the MAIN OUT results in a

75

mApp sig-

nal drivingthe 25R SUMBUSline. SUMBUS driv-

er specifications are:

ScaleFactor:

Accuracy:

Load Impedance:

Output Impedance:

Compliance:

Bandwidth:

5 mAN(5 mApp signal at the SUMBUS

line for each Vpp MAIN OUT).

*

(6%

+

2.5mA)

25Q

+_

2% (VXlbus specification)

>

10 kRin parallel with

<

20 pF

f

1.2 V minimum

>

50

MHz

(limited by the backplane)

1.2.4.2

Inputs

The Model 1395has two TTL signal inputs on the

front panel, clock and trigger. The external clock

frequencymay range from dc to 50 MHz, the ex-

ternal trigger may range from dc to 5MHz. Addi-

tionally, clock inputscan be accessed from the

selected VXIbus ECL Trigger line, and trigger in-

puts can be accessed through VXIbus Local Bus

or the selected TTL Trigger line. The clock and

trigger input lines from the backplane are limited

by the VXIbus specifications to a maximum of

62.5 MHz for clock and 12.5MHz for trigger. See

VXIbus System Specification for usage.

TRIG IN:

Front panel mounted female BNC, accepts exter-

nal TTL triggering signal. Input impedance is >1

kR. Protected to

f

15Vdc.

Trigger Slope:

Positive or Negativeselectable

Amplitude Range:

TTL levels, VinHmin

=

2.1 V, VinLmax

=

0.8V

Minpulse width:

20 ns

Frequency:

dc to 5 MHz

AM IN:

Front panel mounted female BNC. Signal present

at this input amplitude modulates the Main Out-

put signal. AM (amplitude modulation) and SCM

(suppressed carrier modulation) are supported.

Protected to k 20 Vdc. For details, see paragraph

1.2.13, Modulation.

Frequency Range:

dc to 500 kHz

Amplitude Range:

~t

15 V maximum

Input Impedance:

10 kR

CLOCK INIOUT:

Front panel mounted female BNC, selectable as

either TTL level clock input or TTL level clock

output. Clock input used as waveform sample

clock. Input impedance is

1

kR. Protected to k20

Vdc.

Configured

as an input:

Frequency:

dc to 50 MHz

Amplitude Range:

TTL levels, VinHrnin

=

2.0 V, VinLmax

=

0.4V

Min Pulse Width:

10

ns

TRIGGER INPUT

(from

VXlbus Backplane):

One of the eight VXIbus TTL Trigger lines (TTL-

TrgO-7) can be programmed as trigger input from

the VXIbus to the model 1395. The TTL Trigger

line has a VXI specification limit of 12.5MHz

maximum and 30 ns minimum pulse width. Ad-

ditionally, the 1395module has a practical limit of

5

MHz maximum for a trigger input signal.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

If

another

1395

module is driving the TTL Trigger

line, the above limits must not be exceeded. See

"Trigger

Output (to

VXI

Backplane)"

in para-

graph 1.2.4.1.

See paragraph 1.2.12, Triggering, for examples of

VXIbus Backplane triggering.

CLOCK

INPUT (from VXI Backplane):

The ECL Trigger lines can be programmed as a

clock input from the VXIbus to the model 1395.

The "master" module supplies its internal clock to

this output to be used by "slave" channels as a

clock source for waveform generation. This al-

lows tightly coupled intermodule operation in

Phase Lock or triggered modes.

The "slave" module(s)will receive the clock sig-

nal on the selected ECLTrigger line when the Ref-

erence Oscillator Source(R0SC:SOUR) is ECLTrgO

or ECLTrgl:

Clock Frequency Range:

25 MHz

to

50 MHz

(Raster);

50 MHz

(CW).

Note

For Standard functions, Trace Mode is

CW,

and the waveform sample frequency (and thus

the Clock outputfrom the Master) is

50

MHz

fixed. For the USERfunction, Trace Mode

is

Raster, samplefrequency is selectable, and the

Master's clock output will vary between

25

MHz and

50

MHz with the mantissa of the

1SOURce:I FREQuency:RASTer parameter.

SUMBUS INPUT (from VXI Backplane):

Analog inputs on the VXIbus SUMBUS line may

be summed into a model 1395MAIN OUT with a

selection of scale factors (see Intermodule Analog

Summing, paragraph 1.2.14). With no SUMBUS

attenuation selected, a 1.875Vpp (75mA driving

25R) signal on the SUMBUS line will drive the

MAIN out to its full-scale amplitude of

15

Vpp.

SUMBUS receiver specifications are:

Scale Factor (1:1 atten):

8 VIV (8 Vpp out at

MAIN OUT

for each

Vpp input at the

SUMBUS).

Accuracy:

+(6%

t

200rnV

t

2.5rnA)

Input Impedance:

>

10

kR

in parallel with

<

20

pF

Bandwidth:

>

50 MHz

Local Bus lnputslOutputs (VXlbus Backplane)

The VXIbus Local Bus is used for triggering and

phase locking.

LBUSAOO, LBUSBOO

These pins are internally connected to as the

Phase Reset Bus. The Phase Reset signal is moni-

tored by all phase locked modules. When this

signal is asserted all modules are reset andheld at

the start address of the active trace. This signal

can be driven by any phase locked module. If is

driven whenever phase lock is enabled and a pro-

grammingchange is made.

LBUSAOP

This pin is used to receive the Chain Trigger sig-

nal from the module to the left. The Chain Trig-

ger signal is one of the trigger sources.

LBUSB02

This pin is used to drive the Chain Trigger signal

to the module to the right. The Chain Trigger sig-

nal is always enabled and its source is the same as

that for the TTL Trigger Lines.

LBUSAO3, LBUSBO3

These pins are internally connected to form the

End Trigger Bus. The End Trigger Bus is used to

carry the End Trigger signal from the right-most

module back to the left-most module. Any mod-

ule may be programmed to drive the End Trigger

signal. The End Trigger signal is one of the trig-

ger sources.

1.2.5

Waveform Characterlstlcs

Square Transition Time:

For slOVp-p:

~9.0

ns

For

>

10 Vp-p:

~9.5

ns

Square Aberrations:

~(5%

t

20

mV)

Square Symmetry:

(0

"C

to

+50

"C)

r

10MHz:

50%*2%

Sine Distortion: (Maximum Harmonic level, Elliptic filter

selected)

<I00 kHz,

s

10 Vp-p:

-60

dBc

c100 kHz,

I

15 Vp-p:

-55

dBc

<5

MHz, >10Vp-p:

-40

dBc

d0MHz,

51

OVp-p:

-35

dBc

40MHz,

>1

OVp-p:

-28 dBc

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Intermodulation Products: (Maximum Spur level, Elliptic

filter selected)

<5 MHz:

-

60 dBc

<I0 MHz:

-

50dBc

120MHz:

-

35 dBc

1.2.6

Frequency

Range:

Sine

-

1pHz to 20 MHz.

Square

-

1pHz to 25 MHz

Haversines

-

1pHz to 20 MHz.

Other Standard Waveforms

-

lpHz to

2 MHz.

Resolution

-8 digits limited by 1 pHz, 5 digits when >20 MHz; 5

digits when inTriggered or Gated modes, or when the selected

function is

USER

vs. a Standard function.

FrequencyAccuracy-

Determined by the selected clock source. When

internal source, frequency reference is provided by the VXlbus

ICLKIOI. Frequencyaccuracy is equal to the selected source

accuracy specification t200 nHz.

1.2.6.1

Arb Clock and Waveform Timing:

CW (Phase Accumulate) Mode:

The waveform is generated by a phase accumula-

tor. "Standard" waveforms occupy a fixed 4k

block of points and are output in CW playback

mode. When standard waveforms are selected in

a triggered or gated mode of operation, the clock

frequency resolution is reduced from eight to five

digits.

Raster Mode:

User defined (arbitrary) waveforms are generated

by scanning through each point in the trace, one

clock cycle per point. User waveforms can have

horizontal resolution ranging from

5

points to

32K

(128K

optional) points. The internal raster

clock frequency is programmable from

125

mHz

to

50

MHz with

5

digits resolution, limited by

0.1

mHz. Waveform frequency is calculated by divid-

ing the clock frequency by the number of points

in the trace.

12.7

Arplltude

Range:

0.015 to 15Vp-p into 50R

0.03 to 30Vp-p into

>

10

kR

Resolution:

3.5 digits

Monotonicity:

0.2

90

Sinewave Flatness:

(

relative to

1

kHz amplitude, Elliptic

filter selected, non-sweep modes)

c

5 MHz,

T,,,

f

10°C

:

*2

96

<

5 MHz,

0

to 50°C:

*5

4b

<

20 MHz,

T,,,

_+

10°C:

+_

5

Oh

c

20 MHz, 0 to 50°C:

+lo

%

Accuracy: The greater of

+1%

of setting or the following

Limit:

Ampl(Vp)

+

ABS(0ffset)

>

2.500

&

17.500V

>

1.250

&

12.500V

>

0.625

&

1

1.250 V

>

312.5

&

1625mV

>

156.3

&

5

312.5 mV

>

78.13

&

1

156.3 mV

>

39.06

&

178.13 mV

1

39.06 mV

1.2.8

Otlset

Range:

Resolution:

Accuracy:

Limit

*

7.5Vdc into 50R

k

l5Vdc into 210 kR

3.5 digits

The same as for Amplitude Accuracy.

1.2.9

FlIterlne

(user selectable):

20

MHZ-4pole Bessel

20

MHz

7

pole,

6

zero Elliptic

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1.2.1

0

Unked

SEQuence

Opemvtlon

Number of Waveform Segments:

2

to

4

Segment Loop Count

Start Conditions:

Advance Conditions:

Advance Trigger Types.

Advance Types:

Sequence Modes.

1 to

65,535

or continuous.

Requires a trigger to Start a SEQuence.

Uses the Word Serial command or any

selected start trigger event.

Segment Loop Count complete;

Loop continuously until selected

advance trigger event true;

Loop done and advance trigger true

Event -Trigger must transition to the

true state to qualify as an event Tr~gger

event is latched

Level

-

Trigger must be in the true state

to initiate an advance. Trigger isnot

latched

Synchronous

-

Current segment is

completed before next segment starts

Asynchronous

-

When advance

conditions

are met, next segrnent is

slarted Immediately Current segment

1s

not completed.

Continuous

or Triggered; Trigger Count

selectable (1 to 524,287).

Notes

Ifadvance conditionfrom last segment tofirst

segment is "advance trigger true" or "Loop

done and advance trigger true", the sequence

must be run in continuous mode.

The trace limits of each trace takenfrom each

block in the sequence are determined by the

trace selected by the TRACe:SELect command

previous to selecting the SEQuence Mode.

1.2.11

Sweep

Sweep Time:

30 ms to 1000s (15 frequency points at

30 ms) with (11512) s resolution and an

accuracy of 0.1%+(1/512) s.

Sweep Modes:

Continuous up

or

down

-

Output frequency sweeps from start

frequency to stop frequency, or stop to start if direction is

down, with selected characteristic (linear or log).

Continuous up/down

-

Output frequency sweeps from start frequency

to stop frequency, then back to start frequency with selected

characteristic.

Triggered

up

or down

-

Same as Continuous except output holds at

start frequency (or stop

if

down selected) until receipt of

trigger. Programmed number of sweeps, set by Sweep Count,

are completed for each trigger signal.

Triggered up/down

-

Same as Continuous upldown except output

holds at start frequency until receipt

of

trigger. Programmed

number of sweeps are completed for each trigger signal.

Triggered Sweep

&

Hold

-

Same as Triggered upor down except

frequency is held at end of each sweep. An additional trigger

is required to return to beginning of sweep.

Triggered Sweep

&

Hold with Reverse

-

Same as Triggered upldown

except frequency

IS

heldat stop frequency. An additional

trigger is required to initiate a sweep back to start frequency.

Sweep Spacing.

Linear or Log

Sweep Count:

1

to 1,000,000

Minimumsweep trfgger pulse width:

>

500

p

1.2.1

2

Wiggering

Trigger Sources:

BUS Trlgger ('TRG or GET; TR1Gger:IMMEOiate)

VXlbus Word Serlal Tr~ggerCommand

Trlgger Input Connector(s)

Internal Trigger Generator(s)

VXI TTL Trigger line driven by another module

Chained Trigger, receive trigger signal on the VXlbus Local Bus driven

from adjacent module.

Linked Sequence Advance Condition:

derived from:

Trigger Count Complete

Loop Complete from any or all segments

of a linkedsequence.

Waveform Complete from an arbitrary

waveform or any or all segments of a

linked sequence.

Trigger Destinations:

Start Trigger:

Initiates gated or trigger modes and

starts sequences.

Advance Trigger:

Conditions advances between segments

of

a

linked sequence.

Internal Trigger Generator(s):

Period:

200 ns to 1000 s

Resolution:

200 ns

Accuracy:

Same as VXlbus ICLKI01

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Trigger Delays and Jitter: (Specified for Trigger lnput

connectors with

TTL

input signal)

Delay: With Standard Functions:

<250

ns

With User Waveforms:

~400

ns

Jitter: With Standard Functions:

<20

ns

With User Waveforms:

<40

ns

Note

Trigger delays and jitter specified with inter-

nal sample clock only.

If

external clock is

used:

Delay:

Jitter:

Trigger Count:

7

clock periods

+

400

ns

+

1

clock period

For waveforms:

1

to

1,048,575

For sequences:

1

to

524,287

Note

Triggered modes

of

operation are limited to

10

MHz waveformfrequency with

5

digits of

frequency resolution.

1.2.1

8

Modulation

Types:

AM

(Doublesideband

with

carrier)

SCM (Doublesideband suppressed carrier)

B3ndwidth:

>

500

kHz

Carrier Suppression (SCM):

>

-40

dB

Modulation Distortion:

Modulation Freq

I

100

kHz:No

harmonic

>

-50

d8c

Modulation Freq

I

I

MHz: No harmonic

>

-30

dBc

SCMScale Factor:

5

VN

AM

Scale Factor: Proportionalto programmed amplitude, as

follows:

Scale Factor Accuracy: Carrier

2

5

MHz:

t5

%;

Carrier

>

5

MHz:

+20

Oh

Ampl(Vp)

+

ABS(0ffset)

>

2.500

&

5

7.500 V

>1.250& 12.500V

>

0.625

&

11.250

V

>

312.5

&

1625

mV

>

156.3

&

2

312.5

mV

>

78.13

&

5

156.3

mV

>

39.06

&

5

78.13

mV

5

39.06

mV

Note

Ratio of Vout to

Vin

re-

quired for

I00

%

AM

1O:l

5:l

2.5:l

1.25:l

0.625:l

0.3125:l

0.1563:l

0.07813:l

All scalefactors assume Main Output termi-

nated into

500

load.

Intermodule Analog Summing:

The waveform from the

1395

module can be driv-

en onto the VXIbus Backplane SUMBUS. The

1395

can also receive the VXI backplane SUMBUS

signal, and sum it with the MAIN OUT output

signal. To extend the dynamic range of the SUM-

BUS signal, the

1395

provides eight input attenua-

tors selectable from the following:

Attenuation,

dB:

I

Division, ratio:

-42

I

111

28

Note

For SUMBUS Driver/Receiver specifications (Scale Factor,

bandwidth, etc.) refer to paragraph

1.2.4.1,

SUMBUS

Output (driver) and Paragraph

1.2.4.2,

SUMBUS lnput

(receiver).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

IntermodulePhase Control

Two

adjacent modules can be assigned a fixed

phase relationship. The "Slave" module must be

driven by the "Master's" clock generator and the

waveforms must

be

of the same length and fre-

quency. Any change in phase angle between

channels will require one waveform

cycle

to re-ac-

quire phase lock. Phase control signals use the

VXIbus Local Bus.

Note

Phase lock operates with adjacent model

1395's

using the VXlhusLocal

Bus.

Frequency Range.

1

pHz

to

SO

MHz

Phase

Resolution

360°14096 points, standard

functior;~,

360°/polnts, User def~ne~i

~aveforms

Phase

Accuracy

+

(tfl

x

360")

where

t

=

1

cloc~

perwd

t

10

ns

and

T

--

waveform

oeriod

Intermodule

Triggering

Adjacent modules can also use the

VXI

Lo;

<i!

Bus

to "daisy chain"

a

trlgger signal from the "<tartf'

module, through a number of adjacent

rr:~~ci:iles

~r,

the "Chain"

to

the "End"module. Each

module

receives the triggering signal on the Local Bus

CHAin line from the module to its left, and dr~ves

the CHAin line with its selected Trigger Source

to

the module on its right. The "End" module can

be set up to drive a selected TTL Trigger line with

its selected Trigger Source back to the "Start"

module, ciosing the loop.

In this fashion, complex and versatile intermod-

ule triggering schemes may be set up. Each mod-

ule can have its Trigger Source (the signal that it

uses to drive the CHAin line) and its output

waveform set up independently. Trigger Sources

include BIT (pulseoccurring at the end of or in a

selected position within a trace), Burst COMplete,

or Loop COMplete.

1.2.1

5

Frequency

List

Fast frequency changes are possible using

[Source:] Frequency:Mode List. In this mode of

operation the output frequency is determined by

the contents of the Frequency List. The Frequency

List is a user programmable list of up to

1024

fre-

quency values.

A

trigger event causes a transition to the next fre-

quency in the list. When the last frequency in the

list

is

reached the next trigger returns

to

the

first

frequency in the list. The effective size of the list

is programmable from

1

to 1024using the

[Source:)List:Pointscommand.

The maximum effective trigger rate in this mode

is approximately

2

kHz.

1.2.1

6

Option

Expanded Waveform

RAM

Quadruples waveformdata storage volatile RAM

from

32

I(

to

128

K

points.

1.2.1

7

AutoCallDlagnostics

Each

1395

AKB Module contains time and

DC

voltage measurement capability. This feature pro-

vides the ability to conduct a limited AutoCal and

self

didgnostic.

Some

parts of the calibration

(e.g.,amplifierflatness) require the use of exter-

nal measurement equipment. The calibration data

is stored in

EEPROhl.

The

Processor accesses the

data and uses

it

to

correct the output as required

to maintain the specified performance.

Performancr specifications apply within the

specified environmental conditions after a

20

minute warm up prriod. Specifications are

subject to change without notice.

The

"T,,,"

nomenclature used in this specifi-

cation refers to the ambient temperature at

which the lastfull Calibration was performed.

This temperature musf be within the range of

10

to

40

"C.

1.3

GENERAL

1.8.1

8CPI

Programming

The Model

1395

Arb adheres to the Standard

Commands forProgrammable Instruments (SCPI)

remote programming format Version 1992.0, Feb-

ruary 1992(refer to the SCPI manual for further

information). SCPI is an industry standard lan-

guage forremote instrument programming. It ad-

dresses a variety of test and measurement

instrument requirements.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

1

Table of contents

Other Wavetek Synthesizer manuals