5

Wavin AS+ Technical Manual

1.2. Field of application

Areas of application

Wavin AS+ is resistant to hot water and fulfills or exceeds all

the requirements of DIN EN 12056 and the associated norms

given in DIN 1986-100, i.e. short-term exposure to tempe-

ratures of 95°C and long-term exposure to temperatures of

90°C.

The chemical resistance of Wavin AS+ makes it suitable for

transporting waste water in the range pH 2 - 12.

Wavin AS+ is suitable for building, roof and below ground

drainage purposes.

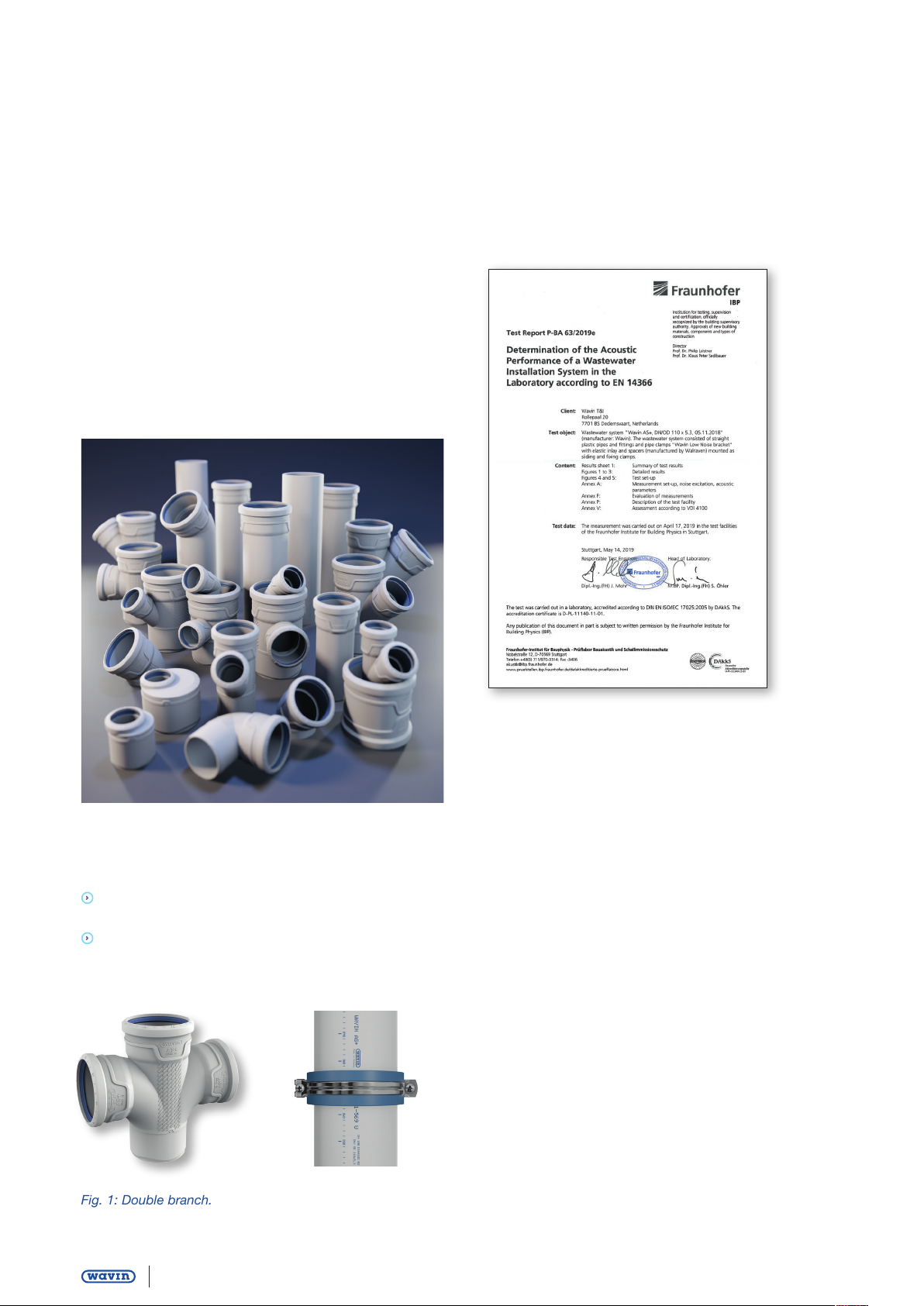

The outstanding acoustic performance of WAVIN AS+ makes

it ideal for wherever DIN 4109-compliant sound insula tion

might be required, such as in hospitals, hotels, nursing

homes, office buildings, or single/multi-occupancy residential

properties.

Noise pollution affects both health and behavior.

Exposure to noise can effect both health and behavior.

Unwanted sound (noise) can damage physiological health. It

can cause hypertension, high stress levels, tinnitus, hearing

loss, sleep disturbances, and other harmful effects. It is for

this reason that modern buildings are equipped with a range

of sound-insulation measures designed to favour comfortable

living, such as thick exterior walls and soundproofed win-

dows. But we often forget that noise is not just external; it

can also be generated from inside the building. Wavin wants

to create better buildings. Wavin AS+ is a premium-quality,

sound-insulating pipe system designed to minimise noise

from plumbing systems and maximise living comfort.

Commercial kitchens and abattoirs

Wavin AS+ is ideal draining fat-containing waste water from

e.g. commercial kitchens and abat toirs. Long-term functional

reliability and temperature resistance (continuous exposure

up to 90°C / short-term up to 95°C in accordance with DIN

EN 12056 / DIN 1986-100) are funda mental requirements

here. The smooth internal surface of the pipe prevents incru-

stations. When installing Wavin AS+ in commercial kitchen

and abattoirs with high fat-containing waste water, the use of

NBR sealing rings is advised. If fat-containing waste waters

need to cover a long distance before reaching the grease-trap

facilities, the premises have to be equipped with an auxiliary

electric heating system designed to keep the waste water in

a liquid state, while main taining a temperature of no more

than 70°C.

Photographic laboratories

Wavin AS+ pipes and fittings – made of mineral-reinforced

PP and supplied with factory-fitted sealing rings – are resi-

stant to the developing and fixing media used in photographic

laboratories over long-term exposures at 60°C. They are also

approved for short-term temperature loads of up to 95°C.

(Please refer to the Chemical Resistance List in the annex for

further details).

It is recom mended that piping is installed with sufficient fall

to reduce the contact time between fluid and guiding surface

to a minimum.

Dental practices

Wavin AS+ can be used unreservedly in dental practices,

provided the piping downstream of the dentist’s chair is fitted

with an integrated amalgam separator. Wavin AS+ (including

the sealing rings) is resistant to dental amalgam. In addition,

cleaning agents and disinfectants normally used in dental

practices, if present in the usual concentrations, are harmless

to the pipe system.

Food-processing and chemical industries

Usage with waste water containing lactic acid from the food

sector and chemical industry, Wavin AS+ pipes and fittings

are resistant to media containing lactic acid (at concentrati-

ons up to 90%) at liquid temperatures up to 60°C. This also

applies to the factory-fitted EPDM sealing ring that form part

of the push-fit connecting system, especially as contact is

marginal. It is recommended that piping is installed with suf-

ficient fall to reduce contact time to a minimum.