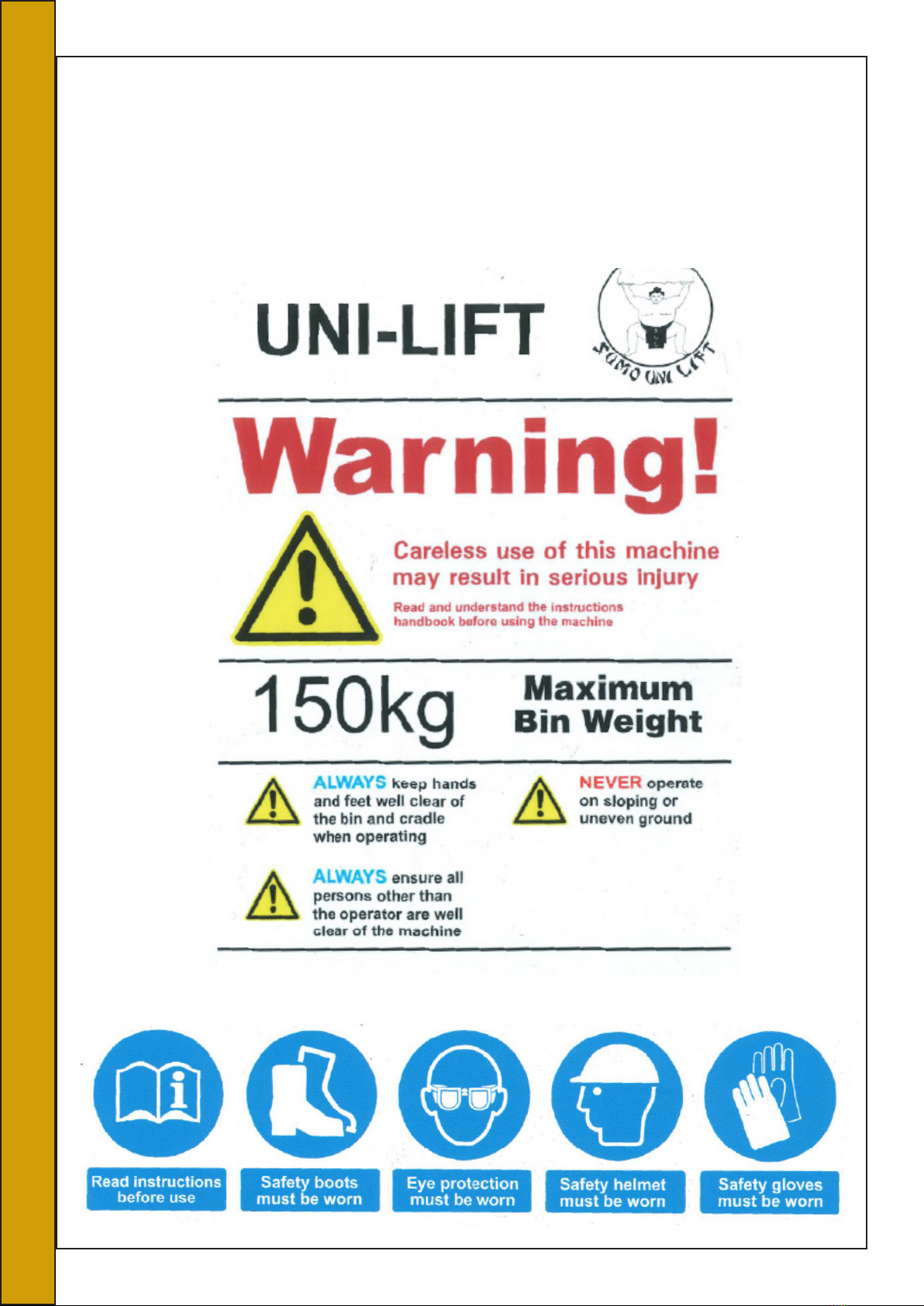

Uni Lift Safety

The Sumo Uni Lift has been designed with user safety as priority, without reducing

its capability or ease of use.

We recommend that a comprehensive hazard and risk assessment is carried out

prior to the Uni Lift being used for the first time.

This machine should not be operated by anyone who has had no training or has

not read the user manual thoroughly.

This machine should not be used to carry fully laden bins, this machine is

designed to be positioned in an appropriate place with the foot brake applied

safely and the wheelie bin should be brought to it.

The Uni Lift has a number of safety features listed below:

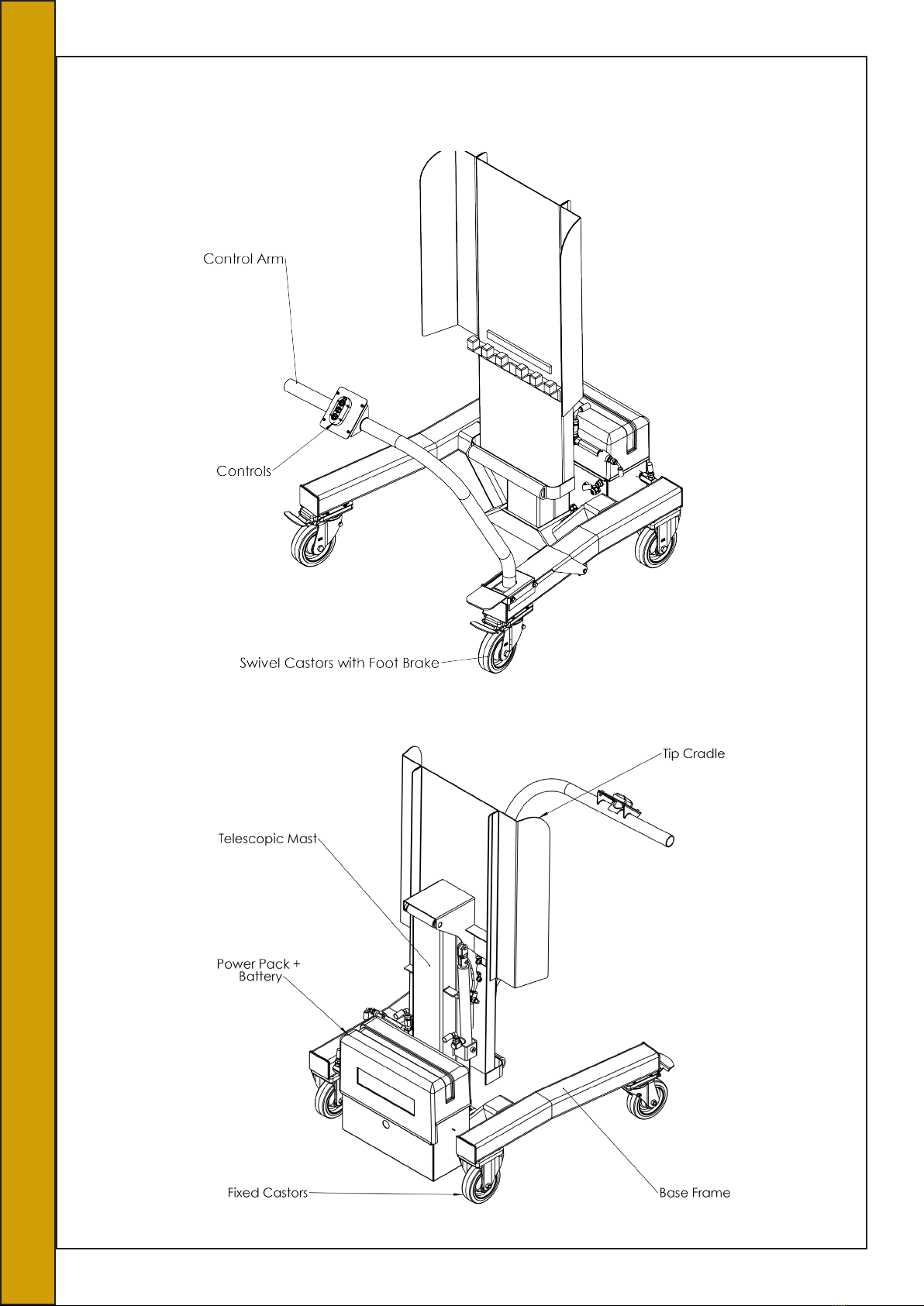

1- The control arm has 2 positions, the first is to allow the machine to be moved

around allowing the operator to have good control, with the arm in this position

the controls will not operate so the hydraulic system will not function. To rotate the

control arm the operator must physically lift the latching plate this will then allow

the control arm to rotate thru 90 degrees. Once in position the latching plate drops

back into place locking the control arm in position the controls can now be

activated. The rotation of the control arm removes the operator from harm whilst

the bin is being tipped.

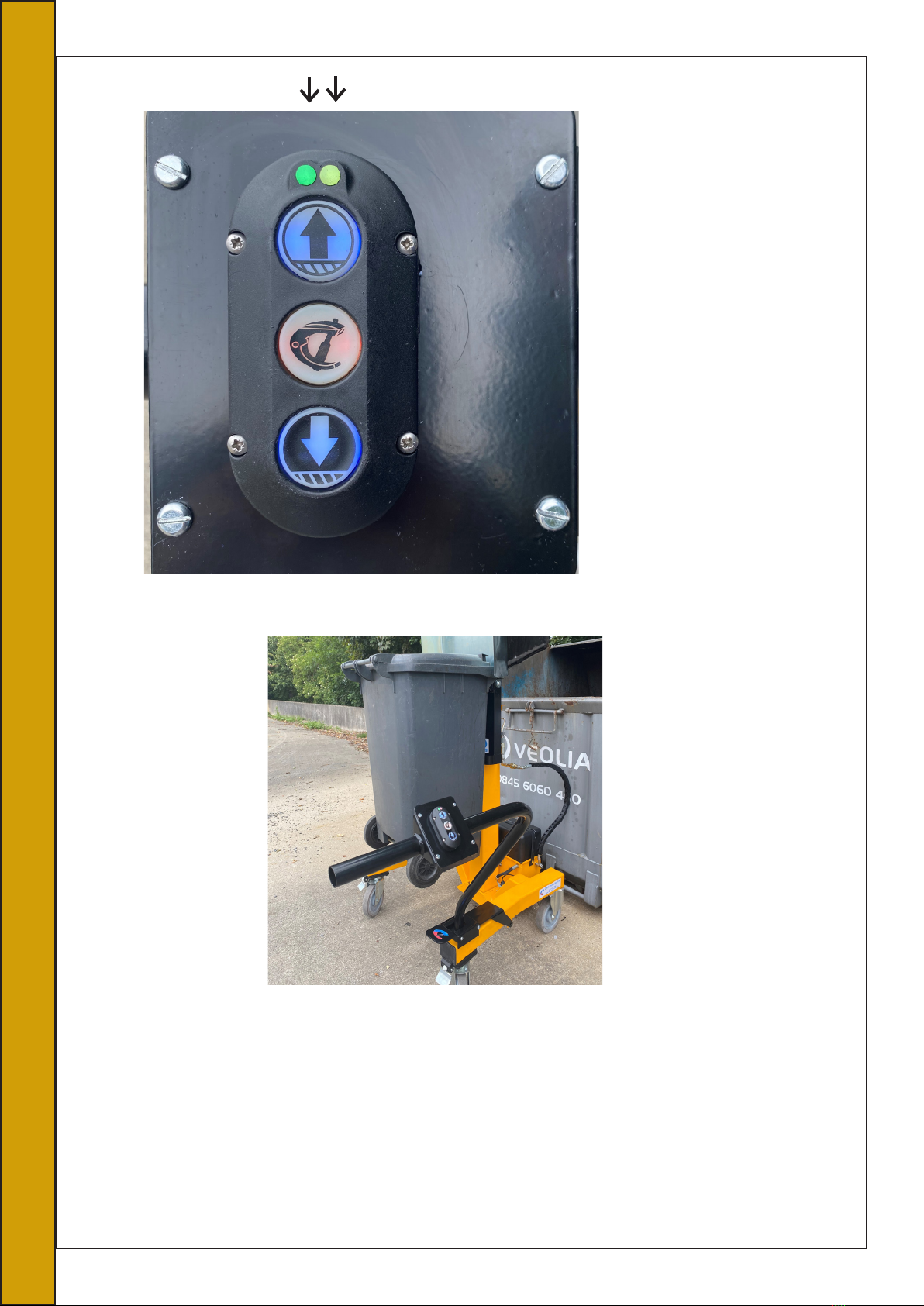

2- To activate the electronic controls the centre button must be pressed 3 times in

quick succession this will bring the control pad to life. To operate the system

follow the operating instructions on page 8. If the machine is left unattended for

more than 10 seconds the electronic controls will automatically switch off. All the

buttons on the control pad are momentary so when released the machine will

automatically stop.

3- When the hydraulic system is in operation an audible beeper is also activated

simultaneously to warn anyone nearby that the machine is in operation.

4- The footprint of the machine combined with the low centre of gravity ensure

that the machine remain stable throughout the tipping cycle.

5- Pressure compensated flow control cartridges ensure that during the lowering

cycle the machine is always under control even when handling a fully laden bin.

5