3

Table of contents

Safe Servicing Practices .......................................... 2

Grounding Instructions ............................................ 2

Features ..................................................................... 4

Section A – Installation ............................................ 5

Free-Standing ............................................................. 5

Built-In Installation ...................................................... 5

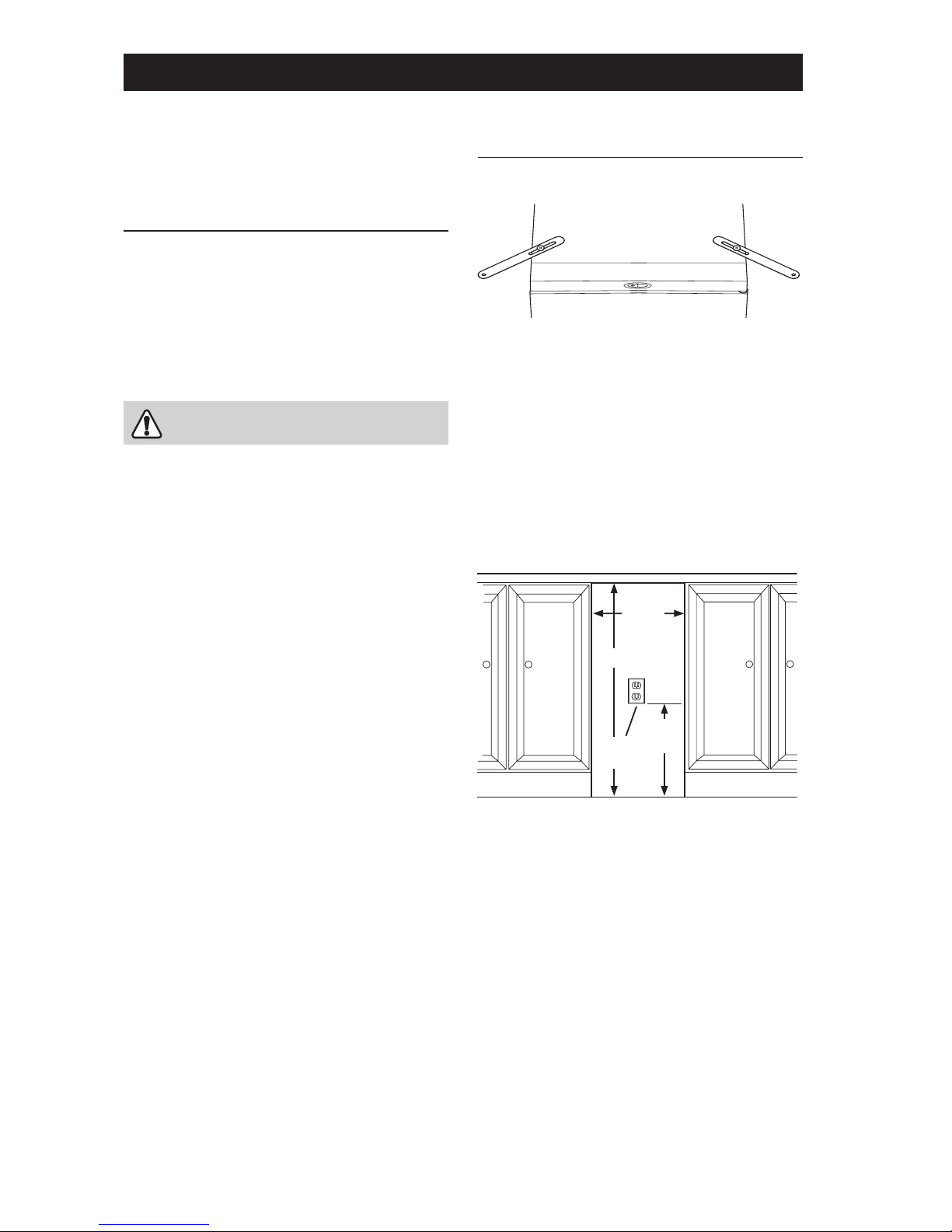

Mounting Straps .................................................... 5

Under-Counter Opening ........................................ 5

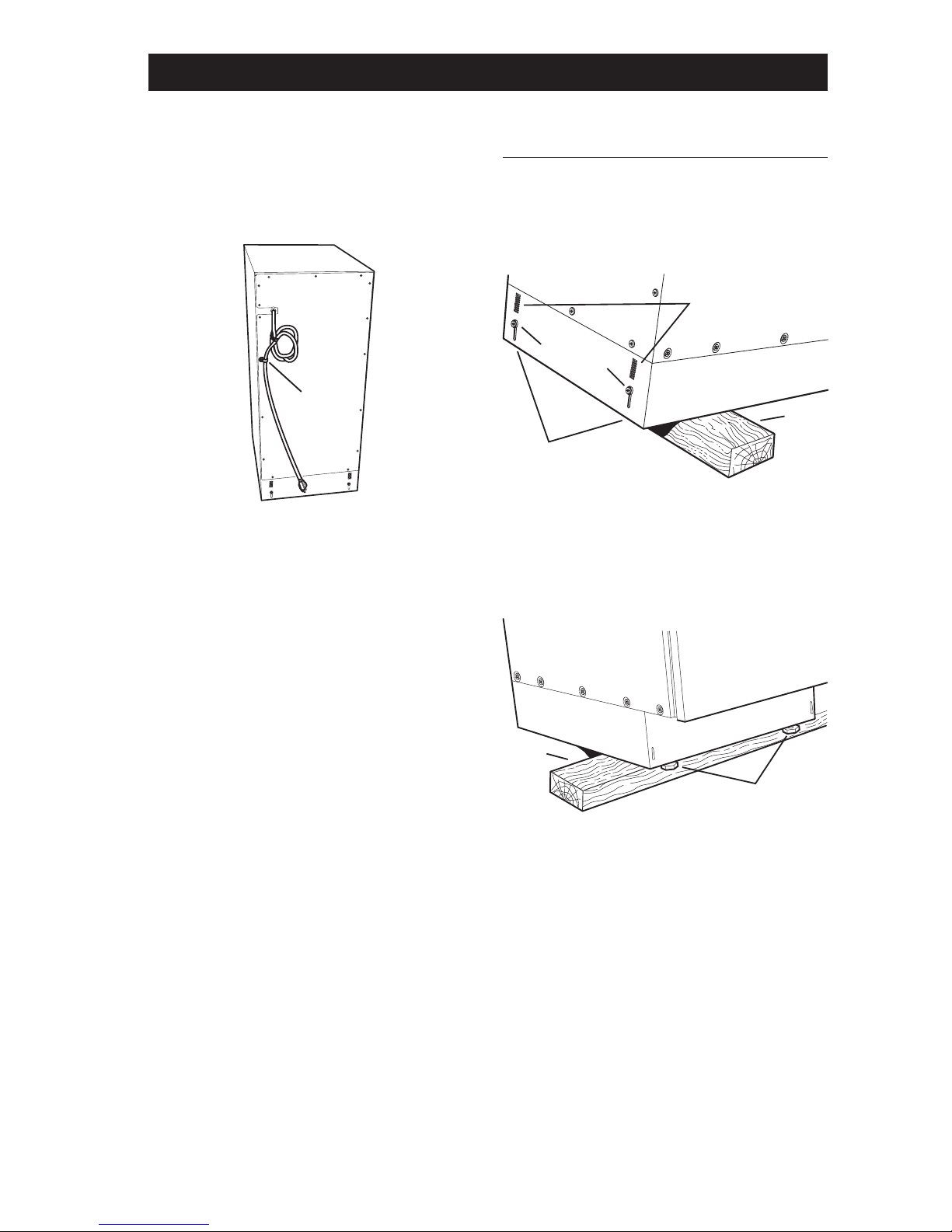

Cord Clamp ............................................................ 6

Leveling the Compactor ............................................. 6

Section B – Cabinet .................................................. 7

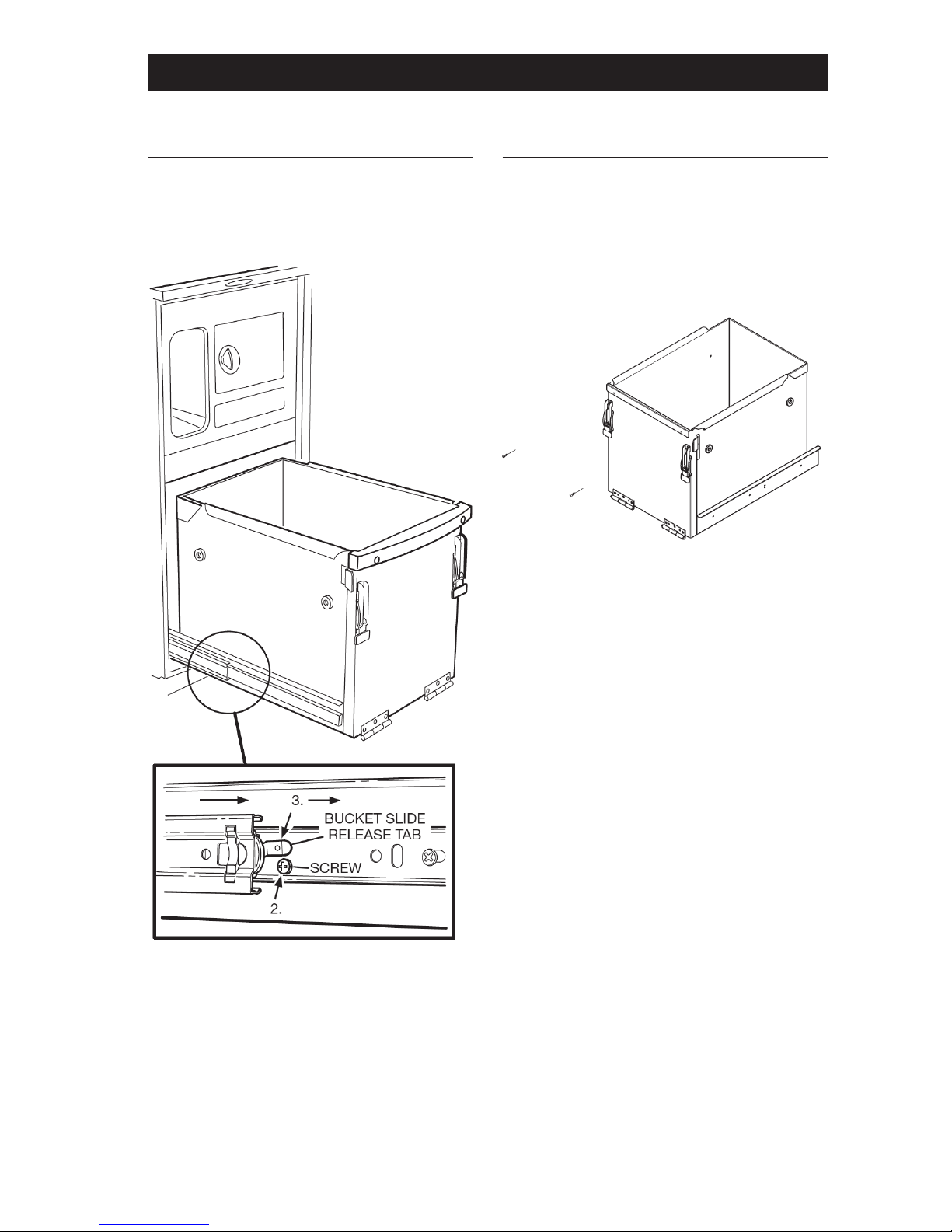

Trash Bucket ............................................................... 8

Remove .................................................................. 8

Bucket Handle . ........................................................... 8

Remove and Replace . ............................................ 8

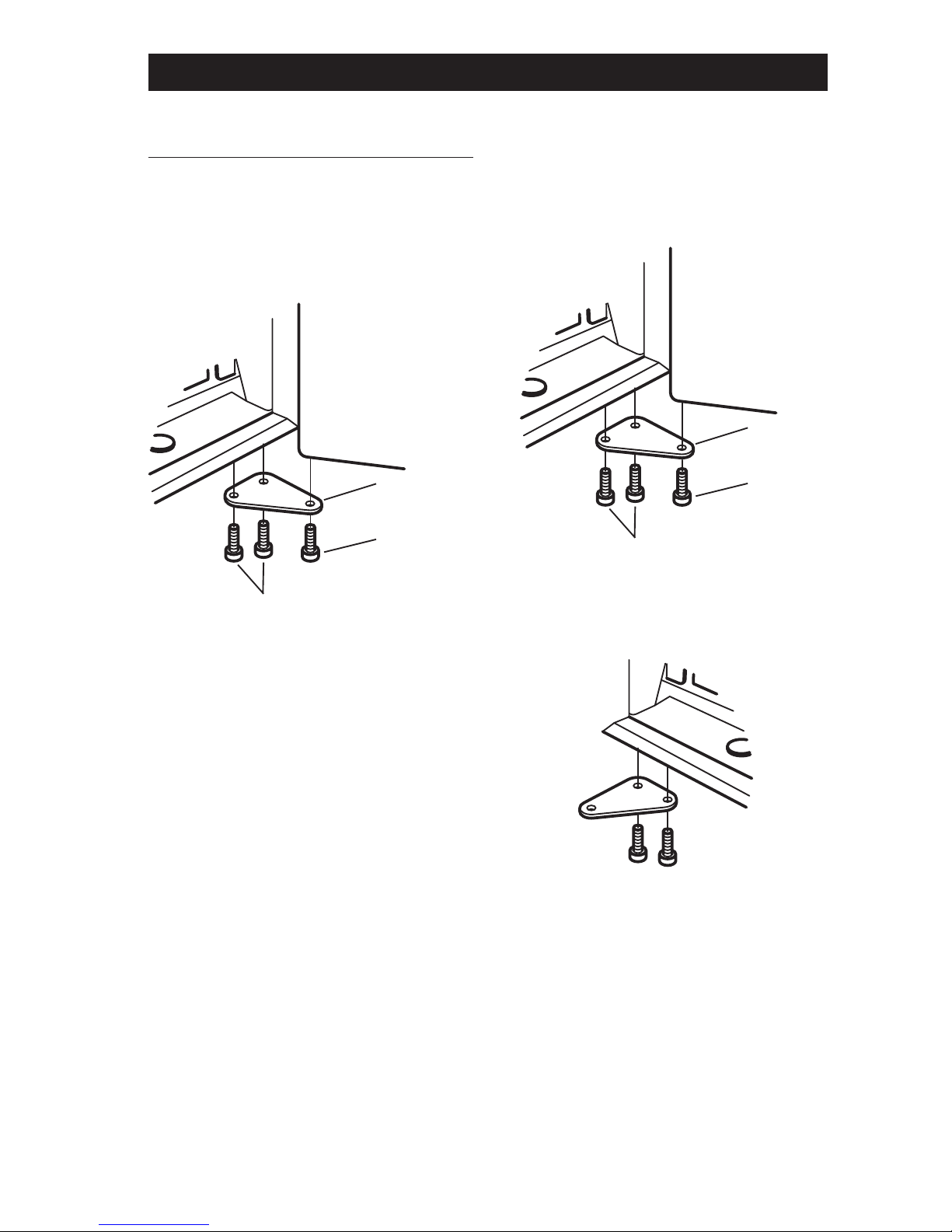

Slide Rails (Cabinet) .................................................... 9

Remove and Re-install . .......................................... 9

Slide Rails (Bucket) . .................................................... 9

Remove and Re-install . .......................................... 9

Door Assembly ......................................................... 10

Remove and Re-install . ........................................ 10

Reverse Door Hinge Position . .............................. 10

Safety Interlock Actuator .......................................... 11

Remove and Re-install . ........................................ 11

Gasket Assembly ...................................................... 12

Remove and Re-install . ........................................ 12

Top Trim Cover Assembly ......................................... 13

Remove and Re-install . ........................................ 13

Section C – Power Unit Mechanism ..................... 14

Drive Belt .................................................................. 15

Remove and Re-install ......................................... 15

Main Motor ............................................................... 16

Remove and Replace ........................................... 16

Complete Power Unit Mechanism ............................ 17

Remove and Re-install ......................................... 17

Drive Wheels ............................................................. 17

Remove and Replace ........................................... 17

Ram Screw Assembly .............................................. 18

Remove and Replace . .......................................... 18

Section D – Electrical Components ...................... 21

Start Switch .............................................................. 22

Remove and Replace ........................................... 22

Access to Components ............................................ 22

Remove Cabinet Cover ........................................ 22

Re-install Cabinet Cover ...................................... 24

Control Panel Assembly ........................................... 25

Remove and Re-install ......................................... 25

Display Module Assembly ........................................ 26

Remove and Re-install ......................................... 26

Key Switch ................................................................ 26

Remove and Replace . .......................................... 26

Interlock Switch Assembly ........................................ 27

Remove and Re-install ........................................ 27

Upper Limit Switch Assembly ................................... 27

Remove and Replace ........................................... 27

Lower Limit Switch ................................................... 28

Remove and Replace ........................................... 28

Motor Centrifugal Switch Assem .............................. 28

Remove and Replace ........................................... 28

Motor Capacitor ....................................................... 29

Test, Remove and Replace .................................. 29

Section E – Troubleshooting

Troubleshooting Table ............................................... 31

Section F – Specifications

Specifications Table .................................................. 34

Section G – Diagrams and Parts Lists

Wiring Schematic ..................................................... 34

Drawing and Parts List – Cabinet ............................. 35

Drawing and Parts List – Mechanism ....................... 36

Table of Contents