Part number 550-100-272/1021 – 3 –

ECO®Tec series 2 gas-fired water boiler – advanced manual

ECO Tec control setup

1. Set control parameters using the WIZARD option provided on ini-

tial start-up or manually enter parameters using control menus (see

Figure26,page56 and following pages for information.)

2. See Express setup instructions beginning on page10 for basic

systems and minimum settings required.

Boiler Model, Altitude and Fuel Type are critical settings.

Failure to set correctly could result in severe personal injury, death or

substantial property damage.

Temperature settings — You must ensure that the control is set for the

proper water temperatures for the system. Excessive water temperature

can cause signicant property damage in some applications.

Multi-temperature systems — If the heating system includes circuits

that require lower temperature water (radiant slab circuits, for example)

as well as higher temperature circuits (DHW, nned tube baseboard, etc.),

it is recommended to protect low-temperature circuits with limit controls

that are wired to an control external limit circuit. Failure to provide

regulation can result in substantial property damage.

Control Features

Advanced interface and troubleshooting via Bluetooth®

communication.

Color touch-screen display for ease of operation monitoring and

troubleshooting.

Easy conguration with WIZARD step-by-step setup including

on-screen help.

e ECO Tec control can communicate to existing UnityTM controls

in a multi-boiler network.

ree (3) programmable priority assignments for up to four (4)

heat inputs.

Preset operating parameters for typical heating systems, including

target temperatures, reset curves and circulator assignments.

Integral outdoor reset option, with reset curves matched to the

system type selected.

ModBus communications for external communication and

monitoring.

0-10VDC input modulation or remote target input.

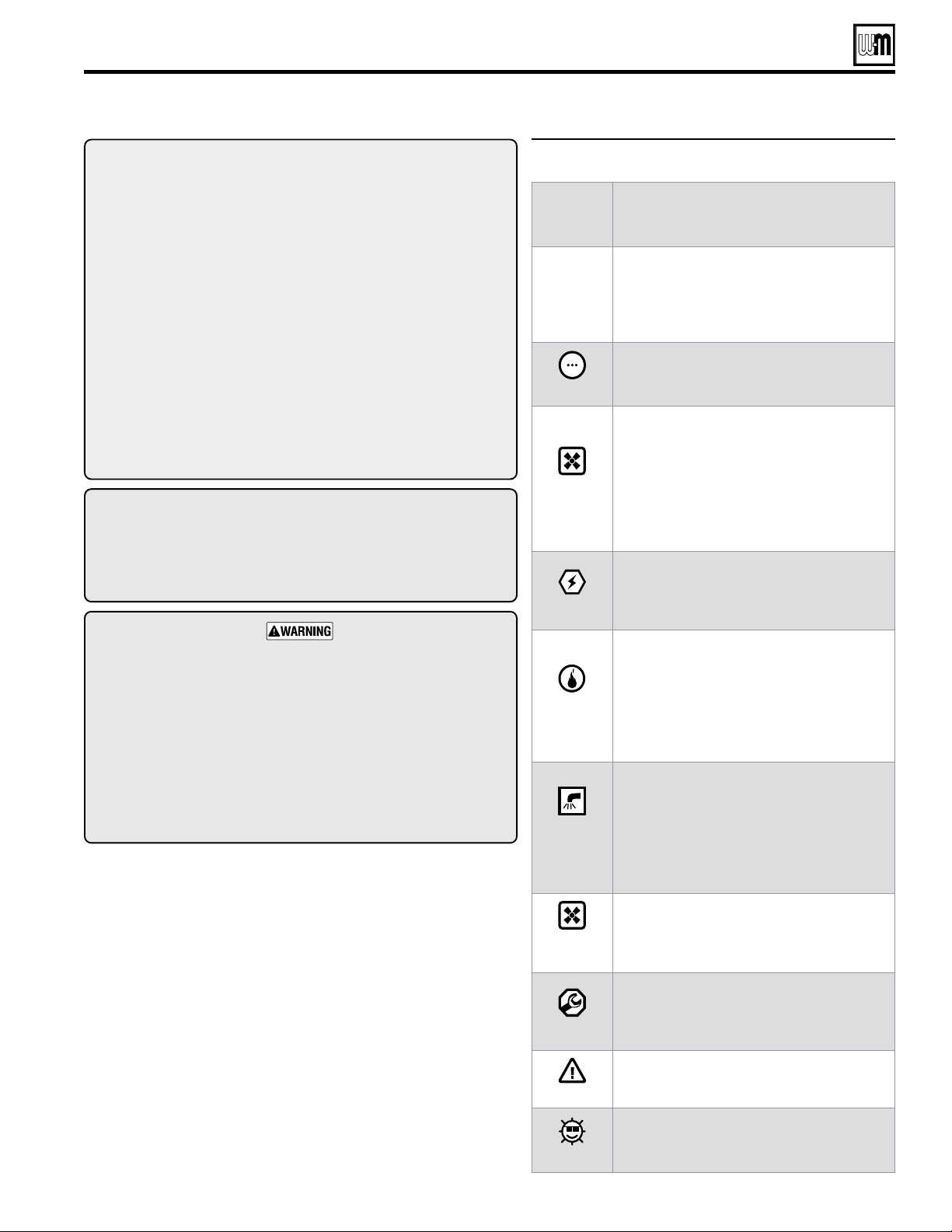

Figure 1 Control sequence of operation

Display

status

text

Control action

(Also see Figure20,page50)

POWER

UP

yCheck the boiler model listed on the power-up screen.

If it is not correct, turn o the boiler. See page 59 for

instructions to change setting.

yWhen power is turned on, the screen lists sensors that

are detected. If any sensor is not listed, make sure it is

connected correctly. Turn o power and restart.

Standby

yStandby - no calls for heat.

yToggles through no dots, 1 dot, 2 dots, then 3 dots

while in standby (wrench symbol will show instead if

maintenance is needed).

Blower

ON

yCall for heat detected.

yDisplay on with BLUE banner (space heating) or

PURPLE banner (DHW).

yStart min/max timers if more than one system is call-

ing - highest priority starts rst.

yStart circulators for this priority setup based upon

settings.

yCalculate target temp — If sensor temp is below target

temp, begin ring sequence.

yBlower to ignition speed for prepurge.

Ignition

yAer prepurge times out, begin ignition cycle.

yActivate gas valve and ignition spark.

yContinue ignition spark for ignition period.

yTurn o spark and use electrode to check for ame

signal.

Space

Heating

yFlame detected.

yRelease boiler to modulation.

yNOTE: If ame is not detected, the gas valve is turned

o, blower turns on (postpurge), and control starts

cycle again. Aer 5 failures, the control waits 60

minutes, then tries again.

yIf priority timer times out, switch to next priority and

start priority timer.

yIf demand satised, go to postpurge.

DHW

Heating

yFlame detected.

yRelease boiler to modulation.

yNOTE: If ame is not detected, the gas valve is turned

o, blower turns on (postpurge), and control starts

cycle again. Aer 5 failures, the control waits 60

minutes, then tries again.

yIf priority timer times out, switch to next priority and

start priority timer.

yIf demand satised, go to postpurge.

Blower

OFF

yDemand satised (temperature reaches target tempera-

ture or limit setting).

yGas valve o.

yBlower to ignition speed for postpurge.

yReturn to standby aer purge.

Maintenance

yDisplay banner turns BLUE, toggling between graphic

screen and maintenance screen (occurs if maintenance

schedule timer times out).

yWill show during standby only.

yBoiler operates as normal.

Error/fault

yDisplay banner turns RED due to error or limit event.

WWSD

yWarm weather shut down - the boiler will not be

allowed to re on space heating if the outdoor tem-

perature is greater than the WWSD setting.

yDHW operation is not aected by WWSD.

ECO Tec control overview

yControl inputs and outputs allow operation of multiple heating circuits

(space heating and DHW, for example).

yUp to three priority levels can be set, providing automatic switch-over

on demand.

yis manual provides quick set-up information for boiler installations.

ECO Tec control operation

ye control responds to signals from the room thermostats, DHW

aquastats (if used), boiler sensors (Boiler Out, Boiler In, ue temperature),

outdoor temperature and system sensors, if used. Combi models will also

respond to signals from DHW ow sensor and DHW temperature sensor.

ye control automatically adjusts blower speed to match boiler output to

space heating and/or DHW heating demand.

ye default control settings provides up to four (4) space heating zones.

e control can be easily set up for operation with a DHW zone, with or

without domestic priority.

ECO Tec control WIZARD

ye Wizard leads through a step-by-step setup procedure designed for

the application chosen.

yContext-sensitive help is available to explain the purpose of key setup Items.

ECO Tec Control — Overview