1

WEILER E1250

1-2

General Information

1

MACHINE DESCRIPTION

The Weiler E1250 is a self-propelled elevator used for

transfering hot-mix asphalt from transport vehicles to an

asphalt paver. The E1250 is used in non-contact,

continuous paving and helps to eliminate truck end

segregation, and add a surge capacity to the paving train.

Optional Weiler hopper inserts for the paver will add

more capacity as well.

The E1250 is equipped with a CAT C7, 250 HP, 6-

cylinder turbocharged diesel engine. Power is

transmitted to all four wheels on the E1250, through two

variable speed hydrostatic pumps, driving four two-

speed hydrostatic motors and planetaries. The two

speed hydraulic motors allow smooth on-the-go shifting

at any speeds.

High-flotation 20 ply 17.5” x 25” tires and differential

lock allow the Weiler E1250 to operate in numerous

paving conditions from first to final lifts. The short

wheel base with set forward axle and wide stance, along

with low center of gravity, allow the E1250 to be very

stable and have a very tight turning radius of 17’.

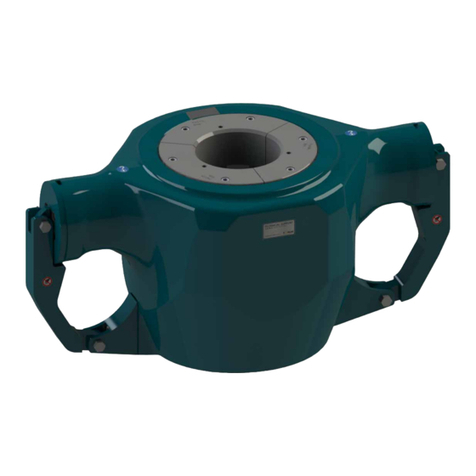

Material is dumped into the wide, high capacity dump

hopper, where it is picked up by 28” diameter, wear

resistant augers. The augers move the material to the

drag slats in the center of the machine where it is

conveyed up the 60” wide elevator and discharges into

either the conveyor or the optional remix hopper. In the

remix hopper, two 16” diameter interlaced augers mix

the material and move it to the center of the machine to

transfer to the conveyor. The conveyor transfers the

material into either the paver hopper or the optional

hopper insert. The conveyor swings 55 degrees from

center in each direction and raises up to 12 feet off of the

ground. This allows the machine to be very versatile

and be used for paving over string lines, barrier walls,

and other obstacles encountered in the paving operation.

The elevator and conveyor on the Weiler E1250 are

powered by variable speed hydrostatic pumps and high-

torque direct drive motors. The elevator is rated at 1000

tons per hour and the conveyor is rated at 600 tons per

hour.

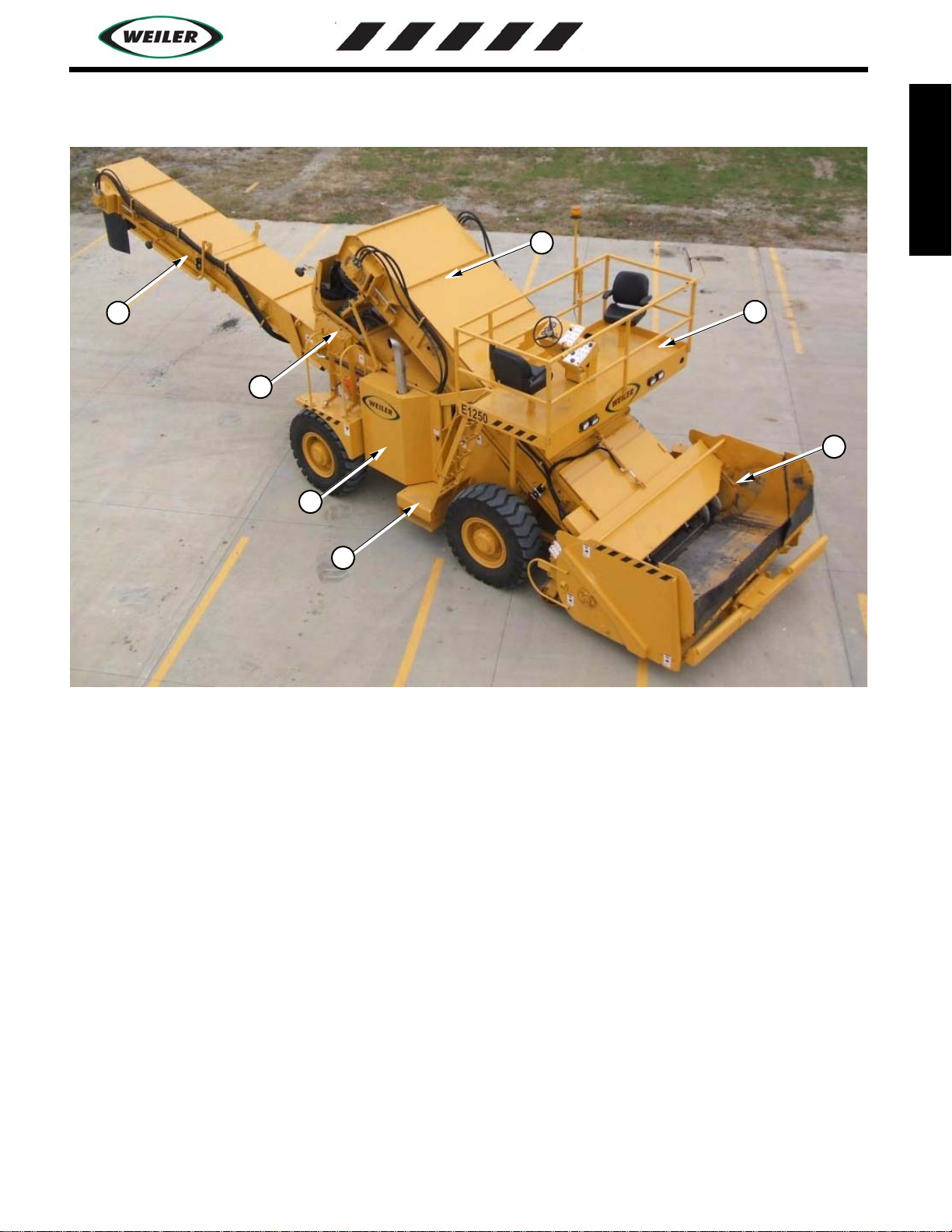

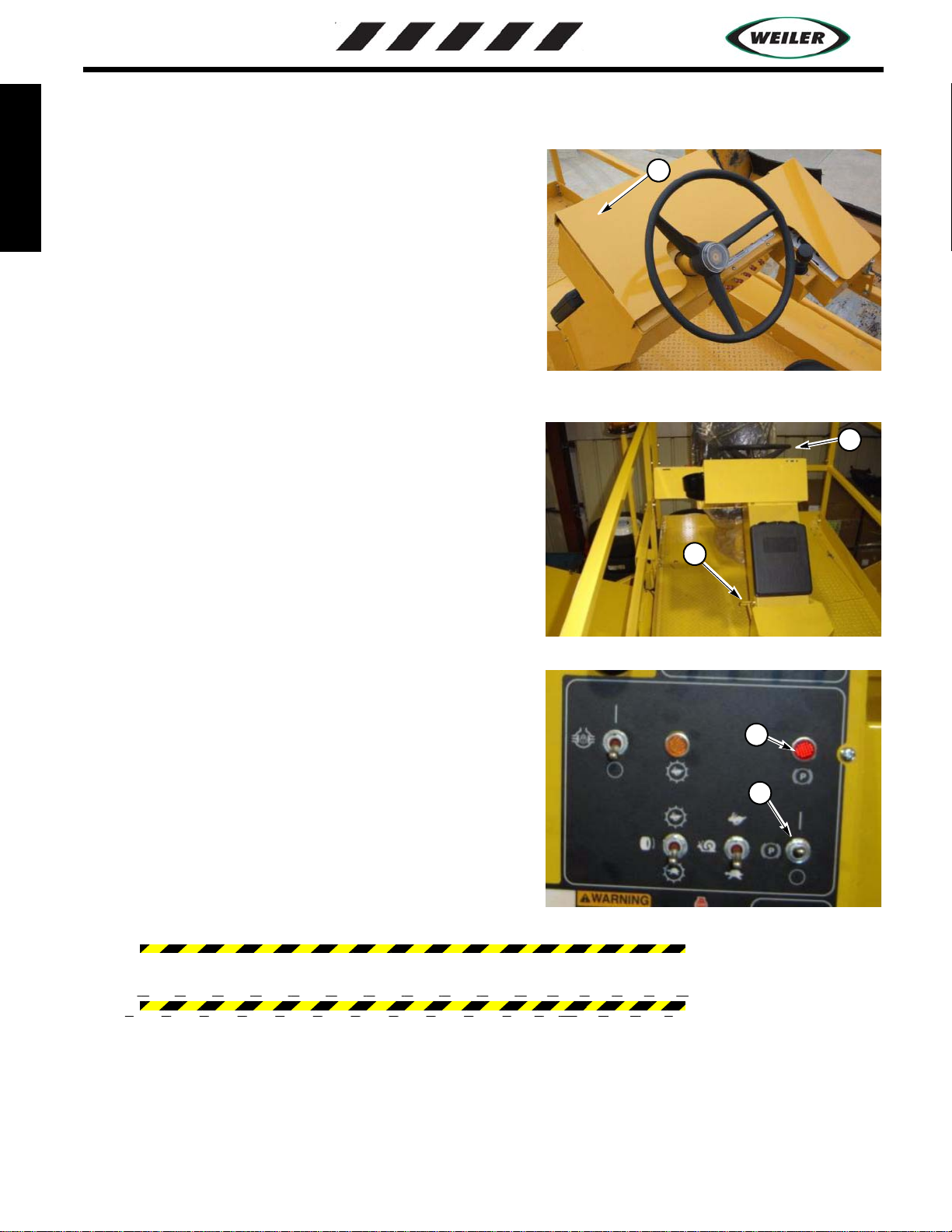

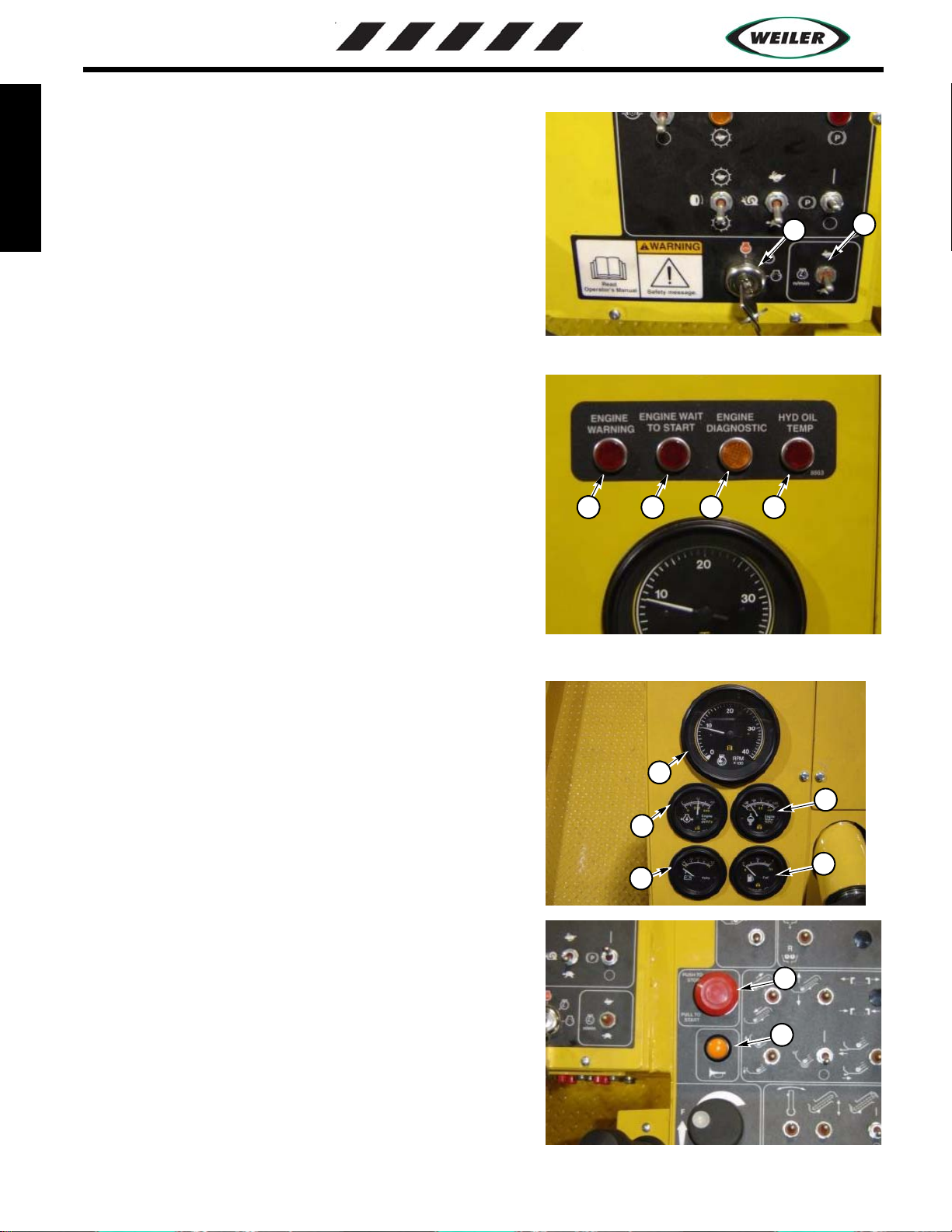

A dual position, rotating operator’s station is provided

along with two operator’s seats to allow for the operator

to move from left to ride side of the machine. All

operation functions are controlled from the operators

platform. Two control panels are located on the ground

near dump hopper on either side of the machine for the

truck dump operator to control the hopper functions, as

well as clean out functions. An additional service

control panel is located near the rear of the machine to

aid in conveyor and mix hopper clean up.

A washdown system with electrical pump is provided

with each machine along with a separate tank for wash

down solvents. The wash down system includes a 50ft

hose reel and quick attach wand for reducing asphalt

build up on the contacted components and lubricating

them before use.

Options avaliable are rotating beacon light, 9KW

generator, additional working lights, hopper insert, truck

hitch, windrow pickup unit, and cold start kit.