Document P/N: 2P42520

Release Date: 07/11/2016

Revision: D

10 of 22

Installation Equipment, Accessories & Specifications

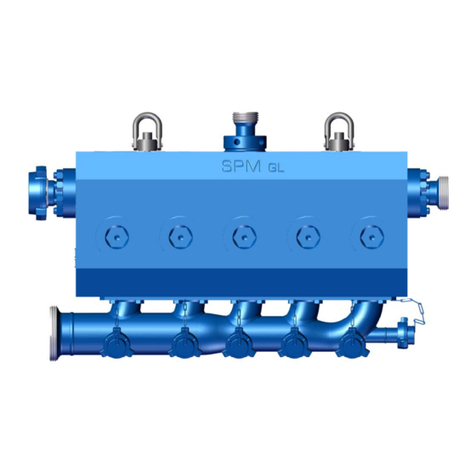

Installation of individual Safety Iron

®

components and systems should be done by persons qualified by Weir to

do so. WEIR

recommends training for all personal involved with installation and assembly of SPM

®

Safety Iron

®

.

Prior to installation, all SPM

®

Safety Iron

®

components should be inspected for improper or excessive wear,

insufficient lubrication, and general damage. Any damaged part should be immediately withdrawn from use.

In general, Weir suggests that customers adhere to the following principles:

a) Provided bolts should be clean and lubricated with an approved grease or lubricant. Stripped or worn

bolts should be immediately replaced with other SPM

®

-manufactured Safety Iron

®

bolts. These bolts are

specifically engineered for this application and are not to be replaced with unapproved bolts. Replacement

bolts must also have a SPM

®

-manufactured retainer ring installed (once bolt is inserted into a clamp) prior to

use in the field. Failure to install the retainer ring or replacing it (or the bolt) with non- SPM

®

parts can lead

to serious injury or death.

b) Provided clamps should be kept clean and lubricated on contact surfaces with an approved grease or

lubricant. Bent or worn clamps should be immediately replaced.

c) All bolted SPM

®

Safety Iron

®

connections should be initially made up with an approved power wrench.

d) All SPM

®

Safety Iron

®

connections except 4”15K should be torqued using a SPM

®

Torque Regulating

Bar. 4”15K Safety Iron

®

does not require regulating bar for assembly. This device should be verified by an

approved calibrated, manual torque wrench once during each job. This manual torque wrench should be

periodically calibrated to verify accuracy in the field.

Failure to follow Weir Oil & Gas suggestions for equipment, methodology, and verification may result in

improper installation of SPM

®

Safety Iron

®

components, possibly resulting in injury and even death.

Through product research and testing, Weir Oil & Gas has developed recommendations for the equipment and

products that should be used in the assembly and maintenance of SPM

®

Safety Iron

®

.

A) Bolt lubricant - To extend service life and ease of installation, SPM

®

recommends that all bolts be properly

lubricated. Using a general purpose anti-seize such as Loctite

®

C5-A is recommended.

B) Impact wrench – SPM

®

recommends the use of a pneumatic impact wrench for primary assembly of all

Safety Iron

®

connections. This wrench must be chosen to suit the torque requirements listed below and should

have a minimum drive of 1/2". However, a 3/4" drive impact wrench is recommended for larger sizes. If

required, an adaptor can be incorporated to allow the use of larger size impact sockets.

C) Seal pocket lubricant - SPM

®

recommends the use of Super Lube

®

41050 Synthetic Grease or approved

equivalent on all seals and Safety Iron

®

pockets.

SECTION

II:

Installation

and

O

eration