An ISO 9001:2008

Certified company

MFR.OF INDUSTRIAL CENTRIFUGAL PUMPS

Regd .Office & works : Plot No : 57/9 , Phase-1 , Nr.Kiran Industries ,G.I.D.C ,Vatva , Ahmedabad-382445, Gujarat , India

Phone : 079-32917873 Email : jramolia@sify.com , marketing@weltechpumps.com

Web : www.weltechpumps.com

_________________________________________________________________________________

Page 4 of 25

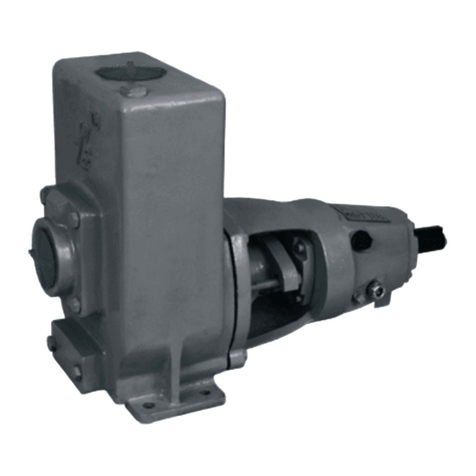

CP Series

Introduction

Preface

This manual provides the information for proper functioning and maintenance

of the pump and contains instructions to prevent possible accidents and damages

and to ensure the safe and smooth functioning of the pump.

Before commissioning of the pump, read the manual carefully and strictly follow the

instructions.

General information and safety instruction

The product supplied by WELTECH has been designed with safety in mind.

Pump installation area must be kept clean and free of obstructions that may

restrict safe access to the controls and maintenance access point

The pump nameplate is fitted to each unit must not be removed. Loss of it

could make identification impossible which in turn could cause difficulty in

obtaining spare parts. If accidental loss occurs, contact WTE immediately.

Access to the equipment should be restricted to the personnel responsible for

installation, operation and maintenance and they must be trained adequately

qualified and supplied with appropriate tools for their respective tasks.

All personnel that are responsible for installation-operation-maintenance of

the pump must study the product instruction manual before any work is done

and that they will comply with all local and industry based safety instructions

and regulations.

Safety glasses or goggles should be worn where working with pressurized

systems and hazardous substances. Other personal protection equipments

must be worn where local rules apply.

Do not wear loose clothing or jewelry which could catch on the controls or

become trapped in the equipments.

Read the instruction manual prior to installation and confirm that the manual is

relevant copy by comparing pump type on the nameplate and with that on the

manual.

Note the ‘limits of product application and permissible use’ specified in the

manual. Operation of the equipment beyond those limits will increase the risk

from hazardous and may lead to premature hazardous pump failure.

Clear and easy access to all controls, gauges, and dials etc. must be

maintained at all the times.

Hazardous or flammable material must not be stored in pump rooms unless

safe area or racking and suitable containers have been provided.