GENERAL SAFETY RULES

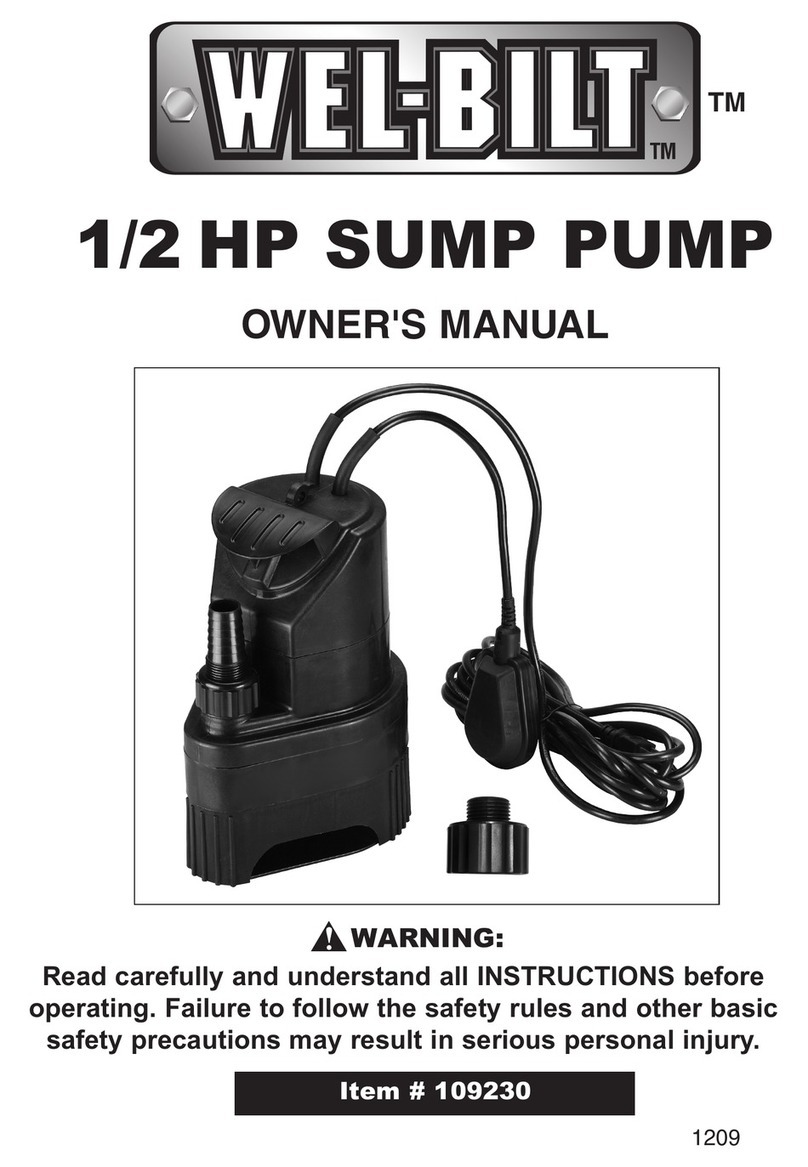

This pump has been evaluated for use with water only.

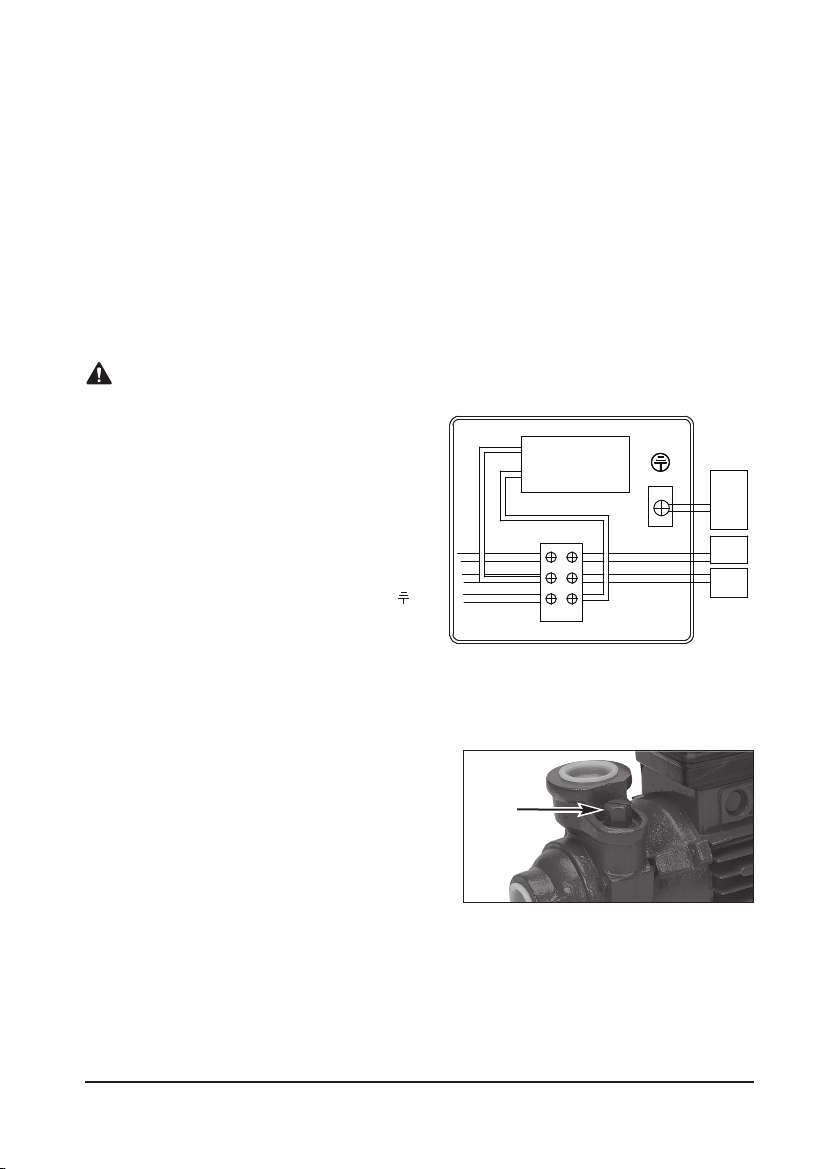

NOTE: This pump is supplied with a grounding conductor and grounding-

type attachment plug.

To reduce the risk of electric shock, be certain that it is connected only to a properly

grounded, grounding type receptacle.

WARNING!Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious injury.

WARNING! The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors which cannot be built

into this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

Every pump is carefully tested and packed during its assembly. On receiving the

pump, check that pump has not been damaged during transportation. If the pump is

damaged, immediately inform the dealer within 8 days from the date of purchase.

WORK AREA

• Keep work area clean, free of clutter and well lit. Cluttered and dark work areas can

cause accidents.

• Do not use where there is a risk of causing a fire or an explosion;e.g. in the presence

of flammable liquids, gases, or dust.Some tools create sparks, which may ignite the dust

or fumes.

• Keep children and bystanders away while operating this water pump. Distractions can

cause you to lose control, so visitors should remain at a safe distance from the work area.

• Be aware of all power lines, electrical circuits,water pipes and other mechanical hazards

in your work area, particularly those hazards below the work surface hidden from the

operator's view that may be unintentionally contacted and may cause personal harm or

property damage.

• Be alert of your surroundings. Using a water pump in confined work areas may put you

dangerously close to cutting tools and rotating parts.

ELECTRICALSAFETY

WARNING! Always check to ensure the power supply corresponds to the voltage on the

rating plate.

• Do not abuse the cord. Never carry this water pump by its power cord, or yank power

cord or extension cords from the receptacle. Keep power and extension cords away from

heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged

cords may cause a fire and increase the risk of electric shock.

• Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or modify

the plug in any way. Do not use any adapter plugs. Check with a qualified electrician if you

are in doubt as to whether the outlet is properly grounded.

2